Autonomous gas supply of cottages with a liquefied gas: the advantages and disadvantages of this method of heating, safety and installation of the installation.

The liquefied gases were successfully used for heating even dacha houses up to 70-kgg.

Capacities are allowed to warm up using Speed Cables

Design of vessels from WTS:

1- Foundation;

2-flask;

3- casing;

4- lock;

5 - Cap;

6- Cover

Russian tanks are made in the form of horizontal barrels with elliptic bottoms with a diameter of 1100-1600mm and necessarily supply the neck with a diameter of at least 450mm, in which control-adjusting devices and locking valves are mounted. 5m3 capacity ("Kuzpoli-Mermash")

Gas reservoir fenced and equipped with lightning protection, as required rules

WTS tanks are made according to the principle of thermos: a durable metal flask is inserted into a polyethylene casing that protects the vessel from chemical and electrochemical corrosion

Capacities AMICO from WTS can be put in any soil. The heavy balancer foundation protects them from the float (included)

The gas phase is assigned to the gas pipe complimentary from the metal gas pipe. It stacked on the bottom of the ditches with a bias of the basement or condensate collection

Capacity ("Eastern Czech Plant GO") Metal ribbons (503mm) attracts to a heavy (2t) reinforced concrete plate to eliminate the vessel movement during the seasonal deformation of the soil

The vessel steel cable is connected to the grounding circuit

In imported tanks nozzles for gas reinforcement welded in the wall of the vessel: A-AMICO (WTS); B-TUBERO EPOX (Antonio Merloni)

Algas-SDI evaporator (Zimmer) can evaporate 40kg of liquefied gas per hour. It can be put on the wall of a remote greenhouse or a greenhouse

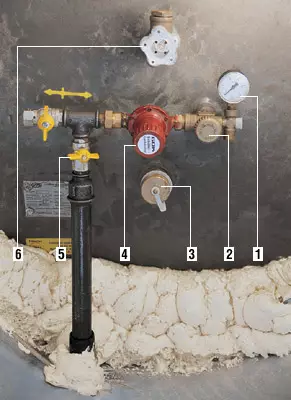

1- pressure gauge;

2- consumable valve;

3- pouring nest;

4-gear;

5 - gas supply unit;

6- Pumping nozzle Sug

Electropoiler for SUG is performed by two-line, with full duplication of equipment to ensure gas supply in any situation. When one line was faced or examined, the second operates

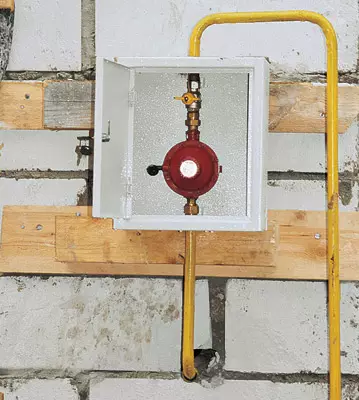

For autonomous supply of a group of houses or the village use cabinet gas regulatory points. Such a cabinet from Cotraco with a capacity of up to 1000kg / h is able to serve the village of 50-100 houses

With a higher need for gas, several tanks can be combined into a group (in liquid and gas phases). Usually the group connects to the electrical assistant.

When planning the construction of a country house, we, first of all, consider the possibility of its heating gas. At the same time, the default is meant that the gas will be a trunk. However, abroad for these purposes has long and in a constantly growing scale, liquefied gases are used. Akak with us?

The structure of fuel types is changing continuously on the eyes - the market will not ceremony with traditions. Literally 2-3 years ago, only boilers operating on solid fuel, diesel fuel and gas appeared in our articles. Today interest is news about non-traditional energy sources. There is a revision of established views on the comfort and ways to achieve it.

One of the "old" new products is autonomous gas supply (AGS) cottages with a liquefied gas. It develops obviously not from scratch. Judge for yourself: for the first year of the current century, the world consumption of gasoline amounted to 800 million tons, and liquefied gases - 200 MBNT! But if we have to face gasoline at every step, then did we all hear about the "liquid" gas? And between that, it is widely used in industry (there are many types of its varieties) and to some extent - in everyday life. Here such gas is burned in gas stoves and radiators, in the fireboxes of boilers and fireplaces, supplies heat for absorption refrigerators and air conditioners, and also works in heat pumps and cogenerator drives.

For Russia, liquefied gas (SG) in everyday life is also not a wonder. Small gas cylinders at 5, 27 and 50l became an indispensable attribute not only most of the country's houses, but also got to many remote villages. But here to make a house "liquid" gas, it makes millions of families abroad for decades, "this Russians do not think seriously about this. The reasons for this probably two. The first: we are spoiled by the cheap natural gas and all alternatives are assessed by it, using the inertia of the scale of the spent decades. Second: a subconscious feeling of fear of the hidden relics of liquefied fuel, born myths, rumors and horrors of television pictures from fires and bursts of gas cylinders. There is an explicit deficit of reliable information.

Meanwhile, the successful experience of heating with the help of the SG in Russia is also considerable. In the current years of the SG "worked" for the benefit of thousands of remote settlements and state farms. Later, gasification of settlements, "Perestroika" and the collapse of the USSR destroyed the SG supply system. Today it is ready to work again, but on new, market conditions. Ipriri little to the consistent analysis finds out that the idea of dumping a house with the help of SG is clearly competitive, and often the only reasonable.

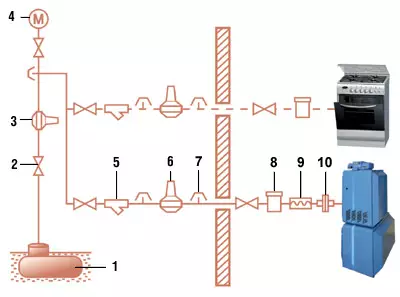

Diagram of installation of autonomous gasification at home (example):

1-reservoir for liquefied gas;

2 crane;

3-gear of the first stage for pressure 1bar;

4- pressure gauge;

5-filter (type of steam);

6-reduction of the second stage for pressure of 30MBAR;

7- jack for pressure measurement;

8 - filter;

9- anti-vibration spacer;

10- coupling connective

There is no words, where the main gas pipeline passes near the main gas pipeline, gas heating is out of competition. But with each kilometer of distance from the "pipe", its cheapness is becoming increasingly relative. Through 5 km about it (in the suburbs, at least), perhaps, you can forget. Consider themselves: 5-15 thousand. For 1km of the local gas pipeline (and the highway so and in general "pulls" at 250-500 thousand) plus the construction of the gas distribution point (GPP) to reduce the pressure, and even "modest" 5-15 thousand. Only for permission to connect gas. True, these data were obtained privately and not officially confirmed, but their order is already talking about one. Connecting to a highway is set only to a group of houses or villages, but not to the owner of a remote home. He remains an autonomous system. The choice, I must say, are: these are traditional hard or diesel fuel boilers or new solutions - thermal pumps or AGS system.

Make the dignity of autonomous gas supply? It combined some of the advantages of their rivals. First, it is the comfort and environmental friendliness of gas heating. The gas is also provided with a stove and boiler. There is neither ash with problems of its removal (as in the case of coal), no soot, no sulfur oxides (like diesel fuel). The SG fell on the soil does not destroy her like a diend one. Secondly, it is autonomy, like liquid-fuel boilers, and, consequently, independence from gas pressure drops in a pipe, which are simply scorched gas heating systems. Therefore, turning off the gas and defrost to your radiators does not threaten. Third, efficiency. According to the cost of the energy carrier, the SG system is inferior to gas boilers and thermal pumps, but won in liquid fuel boilers. For the year, saving on fuel from the SG compared with the diesel engine is about 40-60 rubles. On 1m2 area of the house. And finally, the equipment on such a gas works better and serves longer.

Well, is there any deficiencies? Of course, not comic. SG are related to fire and explosive substances and require careful compliance with security measures. But that is why all the settings that use SG are under the non-grade approach of Rostechnadzor (former Gosgorthek-Supervision), ranging from buying a reservoir for SG and ending its service life. Each building at "birth" receives his passport, which is registered in the supervisory authority and further reflects the full history of its life. All installations have a variety of protection systems. Only licensed specialists are allowed for installation and maintenance, and the home owner has the right only to visually remove the instrument readings (by the way, do not forget to look at the level gauge and clean the hatch of the tank from snow). In general, the whole technique is reliable and has a service life of 20-30 years. Aeina ignition or an explosion may occur only as a result of malicious actions. To make sure that there is no doubt about the safety of AGS systems, consider their design and work in more detail.

Resource reservoirs when heating at home, day (according to the company "Hamard PCT")

| Tank volume, m3 | House area, m2 | ||||||

|---|---|---|---|---|---|---|---|

| 150. | 200. | 250. | 300. | 350. | 400. | 500. | |

| 2.7 | 150. | 112. | 90. | 75. | 64. | 56. | 45. |

| 4.9 | 269. | 202. | 162. | 135. | 115. | 101. | 81. |

| 6.7 | 372. | 279. | 223. | 186. | 159. | 136. | 112. |

Concentrated energy

The principle of the device of the AGS system is simple. A roomy durable reservoir burned to the ground near the house (and in warm areas they put on the surface of the Earth). From his neck to the house, the pipeline is stretched from which taps into the boiler house and in the kitchen. The container is filled with liquefied gas (God forbid, "under the neck"!) From the special vehicles, which comes to you 1-3rd in a year. The flooded SG begins to evaporate, and the pairs (gas phase), passing through the gearboxes, under reduced pressure, 30MBAR comes along the pipe to the consumption instrument. Such is the scheme. Well, further into action, a lot of particulates come into effect, which determine the success of the case.The beginning of the whole type of SG. Today, mixtures of liquefied technical propane and butane (SPB) are used for AGS, or, as they are also called liquefied petroleum gas (given its origin), and not liquefied natural gas (methane). The latter is stored at low temperatures in special cryogenic vessels, it requires additional evaporators and is economically justified for heating a group of houses (villages).

So what is noteworthy "good" SG? First of all, it is a hydrocarbon gas (SUG), which under normal conditions is in a gaseous state. With a slight increase in pressure, it must go into a liquid state. Then it can be easily transported and stored. When the pressure decreases or a slight increase in the temperature of "liquid" gas begins to evaporate and goes into the gas phase. The process ends with the achievement of saturation state. The pressure of saturated vapors depends only on the ambient temperature and does not depend on the amount of fluid. From one liter of South, about 0.25m3 of the gas phase is obtained. In winter, the gas pressure is reduced and the productivity of the gas phase, a clear case, falls noticeably. That is why the tanks are more profitable to shower in the ground, where heat flows, maintaining stable regasification parameters.

When using Sugh, it is necessary to take into account that the process of their evaporation has the property of self-regulation. If you select pairs intensely (for example, connect several boilers), the accelerated evaporation of the fluid will lead to its cooling and, it means to reduce gas pressure over the liquid mirror. Vitog installation performance will decrease. To obtain large amounts of gases, resort to additional heating of tanks or increase their number in one installation.

With increasing temperature, the fluid in the tank is very expanding and, since it is incompressible, may even depict the vessel. Therefore, filling the reservoir with liquefied gas by more than 85% of the geometric volume is strictly prohibited. Refores this rate is strictly observed.

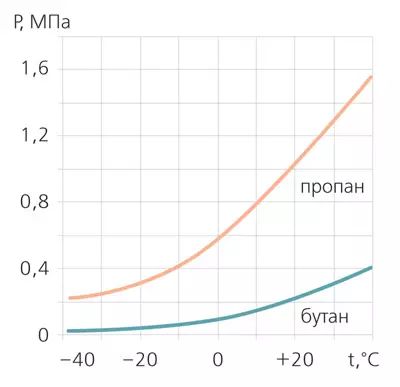

Propane has the optimal set of desired properties. It sustainably delivers the gas phase even with frosts, but relative to roads and is good only in winter. In summer, under the heat, the pressure of its vapor comes to the limit value allowed for the vessel walls (1,6 mp). Therefore, propane is diluted with cheaper and non-intensively evaporating butane. The norms provide that in the winter the mixture is composed in proportions 70:30 (percent of propane and butane, respectively), and in the summer - 60:40 or 50:50.

Suga is lighter than water in two times, so water condensate gradually accumulates at the bottom of the vessel, from where it has to be retracted (from small tanks about once a year). Gazo-like a mixture is heavier than air 1.5-2 times. So, when leaks, the gases flow into the lower points. Considering that these gases, although non-toxic, have suffocating properties, boilers when using Sug cannot be placed in basements and even the basements, if the area of windows in them are less than 1m2. Since it takes a lot of air for complete combustion of SPBT (see table), in boilers it is necessary to provide good ventilation - better forced. In addition, indoors it is necessary to organize natural lighting, as well as set the gases leak detection sensor and the automatic cutting valve with autonomous power.

But the main problems with Sug are different. By itself, liquefied gas does not burn and does not detonate. However, the mixture of the gas phase with air in the range of 1.8-10% will instantly light up if there is a heat source with a temperature of about 500 ° C (we recall that in the flame matches there are areas with a temperature of more than 1000С). With certain ratios of volume, pressure and temperature, this combustion may be accompanied by an explosion. The leakage of "liquid" gas is fraught with the spread of evaporating gases on a large distance, and in the mixture of them with an air-hazard to ignitance with a large cloud. Meanwhile, the flowing gas phase, mixing with air, can only light up with a small torch, and the flame inside the gas flow does not apply and does not lead to the explosion. To 100% eliminate fluid leaks, in the installations provide special security measures.

Right safe

The heart of the AGS system is a reservoir for storing SUG. Capacities make cylindrical, welding from thick (up to 10 mm) with durable coolant steel (for example, 09g2c). They are designed for 1,6 MP operating pressure. At the factory, each is tested for tightness and receives a license plate of quality. Nomenclature of products on the market is still small. Imported suppliers of all half a dozen - the complexity of transporting bulky barrels is affected. Domestic manufacturers occupy a significant part of the market. True, the size range of their tanks is limited (usually 5, 8 or 10m3), but most enterprises are ready to order to perform tanks of any volume. The most wide range of products in Italian producers (from 0.5 to 5m3 in about 0.5m3), so you can choose a suitable vessel even for a small cottage.

Domestic firms produce horizontal tanks, and Italian has both vertical, with a neck on the end. It is believed that such a vessel is laid more and is heated more heat as warm soil. In addition, its performance is more uniform in time. But with the same amount of horizontal devices, the area of the liquid mirror is greater than that of vertical, and therefore they are more productive.

Outside, all vessels are definitely protected from chemical corrosion, but each manufacturer does it in its own way. It is possible a bitumen or glass-beaten coating with a thickness of 3-4mm, as well as polyurethane (up to 1.5 mm), epoxy (up to 0.8 mm) or a layer of isoplast (8mm). Antonio Merloni (Italy) went further and complete with their tanks supplies a galvanic protection system from electrochemical corrosion. The presence of an electrode compare (CU / CUSO4) and 2-3 consumable magnesium anode, which are buried to the ground near the tank. Usually, the anodes are enough for 5 years.

The Italian firm Walter Tosto Serbatoi (WTS) protects its capacity to the original way. Its tanks (vertical execution) are arranged on the principle of thermos. Metal container is inserted into the outer container from HPDE polyethylene. From above it is put on it (with a seal) of the cap-neck so that a hermetic compartment for placing security and control devices was formed. There are three hermetic inputs: for refueling, grounding the metal vessel and the control system cable. Plastic casing works "for seven". It not only protects the metal from environmental impact (aggressive components of soil, wandering currents, microorganisms), that is, performs the function of chemical and electrochemical protection, but does not give a south into the soil in the event of reinforcement leaks. And, perhaps, the most witty- allows you to easily extract the metal container for the mandatory (according to Rostechnadzor's norms) of its integrity. By the way, such a check is carried out once every 10 years, and not annually, as many potential customers fear.

The aspects of the Techno-Italy Grand company used this feature of the design to wipe the vessel with special "bindings" of heating (3-5 kW) and warm up in frosty days. Due to this, the performance of gas generation can be adjusted for the need.

At all tanks, the so-called reduction heads are mounted, in which the control and control equipment is placed: safety-locking and discharge valves, pressure regulator, level gauge, pressure gauge, shock fittings. Heads protect this snap from moisture, snow and dust. For domestic reservoirs, they are purchased separately (cost about 50-70 thousand rubles), but in imported - built into the design of the vessel and the entire equipment is included in the cost of deliveries.

The most important question when buying a reservoir - the definition of its volume. This uses actually simple logic. Less volume is cheaper. However, less than the mirror of the liquid phase and, it means, below performance, that is, the gas may simply not be enough to power the boiler. But even with sufficient performance, a small volume means that the tank must be filled more often. Therefore, it will have to raise a refueling tank truck more often, and each flight, regardless of the amount of Sug, costs approximately $ 100. At the same time, the cost of the liquefied gas is paid separately. Asimes to each arrival of tank trucks need to clear the driveway, which also requires costs.

In fact, the calculation of the required size of the capacity makes the designer for a particular system depending on the power of the gas appliances installed in the house. In practice, the reservoirs with a margin by volume are often choosing. "Chassis" option is 3-5m3.

Properties of liquefied gases

| Parameter | Propane | Butane | Methane | Gasoline (for comparison) |

|---|---|---|---|---|

| Boiling point, with | -42,1 | -0.5 | -161 | 36. |

| Liquid phase density, kg / l | 0.51. | 0.58. | 0.45 | 0.73 |

| Inflammation temperature, with | 466. | 405. | 560. | 300. |

| Heat combustion (gas phase), MJ / M3 | 91.3 | 118.7 | 35.8. | 213. |

| Limits of ignition, in% of the ratio of the volume of gas phase and air | from 2.1 to 9.5 | from 1.5 to 8.5 | from 5 to 14 | 1.5 to 6 (pairs) |

| The amount of air required for complete combustion of 1m3 gas, m3 | 24. | 31. | 9.5 | 14.5 |

Annual heating costs 1M2 Square houses in different ways *

| Type of heat generator heating | Heat combustion fuel | Annual demand | Energy price | The cost of the energy system, rub. |

|---|---|---|---|---|

| Main Gaze Boiler | 10.1 kWh / m3 | 15.7M3 | 1,09 rub / m3 | 17,1 |

| Liquid fuel boiler | 10.2 kWh / l | 15.6l | 13.7 rubles / l | 213. |

| Electric boiler | - | 158.7 kWh. | 1,13 rubles / kWh | 179. |

| Copper on liquefied gas (propane-butane mix) | 28.4 kWh / m3 (gas phase) or 7.1 kWh / l (liquid phase) | 5,6m3 or 22l | 8 rubles / l | 176. |

| * - The data is obtained for baseline conditions: heat loss houses - 60W / m2; consumption for hot water - 15% of heating costs; The duration of the system of the system in the year- 2300 h; Annual energy costs - 0.0692300 = 158.7 kWh / m2 |

Test reliability

Reliability is the fact that the consumer of any goods is looking for primarily. Willingly with AGS systems have to consider its two aspects: equipment and supply of fuel.The stuffy trouble does not arise, its service is carried out by qualified personnel on the regulations. Vessels serve 25-30 years. Elements of their equipment are forcibly replaced by the expiration of the regulatory period. Such an idea of service to many familiar on the example of the system is for cars.

Avto The situation with the provision of Suga for most household owners is very foggy. After all, this is not a diesel fuel that you can buy almost any gas station, but a product of increased danger, it is not nailed in a barrel. Liquefied gases are delivered only through gas distribution stations (GDS), which are managed mainly by state structures. In addition, it is the GUP MO "Mosoblgaz". He has 6 GDS.

Oil liquefied gas is obtained on oil refinery as a by-product of gasoline production. From there, it is supplied to the Pipelines or in the tanks. Quam gas can only be brought from these stations and only officially, no "left fuel" in this business does not happen. The delivery is carried out by the firm with which you have entered into an agreement on the service maintenance of the reservoir. This is usually the same organization that you mounted a gasification system.

So, where to start if you firmly decided on the autonomous gasification of your home? First, search for a firm with a license for the right to conduct such works. There are not very many similar companies: the gas is responsible. This may be a division of Obgaz (gas trust) or a private firm. They act a little differently, but obey the unified security rules. With regard to the state firm, the order is:

one. We write an application addressed to the director of the nearest GDS with a request to issue technical conditions (TU) to gasifying the house with installation of the installation for liquefied gas. Apply copies: passports, right-layering documents for land, situational plan, heat engineering calculation of the heating system (to know the boiler power and determine the annual gas consumption).

2. After interviewing and paying an advance on the site, a specialist leaves and in place assesses the possibility of installing the tank. At the same time, the relief and hydrogeology of the site are important, as well as the norms of the safe arrangement of the capacity: to the house - 10m, to the buildings, 8m, to the fence and the hatch of the sewage - 3M IT.D. The corrosion activity of the soil and the presence of wandering currents is also determined. If the electrical resistivity of the soil is less than 50 OMM or the average cathode current density of more than 0.05a / m2, you are not lucky: the vessel will require additional protection against corrosion. It is usually galvanic or even cathode protection. The latter will require not only one-time costs (minimum of $ 1000), but also current on the operation of the tank. At the same time, it is impossible to dismiss the problem, since without protection measures the project will not be approved, and without it the division of "Mosoblgaz" will not mount the vessel.

3. Enchanting the TU received to the packet package, you order a gasification project in a licensed organization. He takes approval in the architectural management services, power supply, gas supply and environmental protection, as well as an independent examination (firefighters, ecologists and builders). It is clear that these services work "for a private owner" do not want for free, and the spending you will come true. What kind? There is no definite answer. When preparing the material, we received different answers: we did not reveal the numbers at all, called the amount of 30 thousand rubles., 120 thousand rubles. and even 12 thousand rubles. (in the regions). The project is registered in the territorial administration of Rostekhnadzor, which gives "good" to the beginning of construction. Everything takes 3-4 weeks.

four. After passing the examination of the project, you can buy a container. This usually makes an assembly company on the basis of a separate agreement on the acquisition of the tank. You can buy it yourself, but then the installation will cost more.

five. Conclude an agreement on the installation. After that, the company starts work, which ends with a summing up of the supply pipe of the gas phase to the house. The work lasts 1-3 days and costs about $ 1000. At the same time, earthworks make the customer (cost $ 10-25 / m3).

6. Upon completion of installation work, the installation is tested for tightness in the presence of an inspector of the territorial administration of Rostekhnadzor and a representative of the gas network service. Only after receiving positive results, the vessel can be bought. The act of "commissioning" of completed works is issued.

7. All accumulated papers accumulated by this time are added to the service agreement (costs about $ 300 per year), the policy of civil liability insurance and the act of delimitation of responsibility, if the installation of the internal gas pipeline for the house and the connection of the equipment performs another firm. The entire package you apply to the application for registration of the mounted installation in Rostekhnadzor, which takes the installation for accounting and gives permission to refuel the tank with liquefied gas.

See how everything is serious, with multistage control, without the lowest opportunity for accidents!

Private firms work differently - usually turnkey. The pre-project examination themselves makes themselves, carry out the project, hold it in all instances and approve. As an assembled installation, they also experience and register in supervisory authorities, as well as the State Efficiency. Options with the implementation of part of the works by other firms at the discretion of the Customer are possible. The cost of work is negotiable.

Reservoirs for storing liquefied petroleum gas

| Firm | Location Firm | Volumes of reservoirs *, m3 | Price reservoir ** by 4-5m3, thousand rubles. |

|---|---|---|---|

| "Efremovsky experimental mechanical plant" | Endremov, Tula region | five; 10 | 150. |

| "Promholding" | Gagarin, Smolensk region. | one; 1.7; 2.2; 2.7; 4.85 | 170. |

| "Himmash" | Cemerovo. | 2.5; five | 157. |

| "PROMEXPORT" | Magnov | 10 | 260 *** |

| "RED HILL" | Saint Petersburg | one; 2.5; 3.2; five | 170. |

| "Hydrodtal-design" | Thekhov, Moscow region | four; 6; eight; 10 | 156. |

| "Kuzopolymermash" | Kuznetsk, Penza region. | five; eight | 157. |

| "PROMSERVIS" | Penza | five; 10 | 145. |

| "East Czech Plant GO" | Czech Republic | 2.3; 3.2; 4.85 | 189. |

| Antonio Merloni. | Italy | 1 (B); 1.65 (B); 1 (g); 1.75 (g); 2.75 (g); 5 (g) | 248. |

| Walter Tosto Serbatoi. | Italy | 1 (B); 1.65 (B); 2.25 (B); 4.5 (c); 3 (g) | 281. |

| Chemet. | Poland | 2.7; 4.85 | 172. |

| * - Designation of execution: (B) - vertical; (d) - horizontal; ** - For domestic products, only the vessel, without a reduction head, the price depends on the order conditions; *** - for tank 10m3, other dimensions- to order |

System mounting features

The volume of installation work is small. A pit under the vessel is made with a reserve in length and a width of about 0.5m. The depth includes such that the neck of the capacity opposed the earth. The barrel necessarily anchor to the heavy concrete slab base to avoid the suspension of the vessel in the spring when the soil is thawing. Grounding, protection against electrochemical corrosion and lightning are performed according to the project. The gas pipeline is made from steel, protected from corrosion or polyethylene pipes with a diameter of 25-63mm. All connections are performed only by welded. Pipes are put in the trenches, below the drainage depth. Under the pipe and make a sand pillow over it. The output of the gas pipeline from the ground at the house is performed using a special node of the base input. It ends with a flange connection. Entering into the house is carried out only with a steel pipe. Pull with the capacitance of sifted sand, manually. Therefore, the owners of the house should be thought of where to go to the ground from the pit, and take care of the delivery of sand (2-3 cars).Question price

Today, liquefied gas is cheaper than diesel fuel - about 7-9 rubles. per liter. But on the world market its value is 0.6-0.7 Prices for gasoline. We almost achieved these proportions, therefore there should be no sharp changes. The cost of operation of the installation is still small, not higher than that of the gas boiler. Therefore, for the home area, say, 300m2 heating "liquid" gas per year will cost about $ 400 cheaper than when using a liquid fuel boiler. However, the capital costs of the construction of the AGS system are great. Today, they start from $ 10 thousand. Moreover, a large difference in the cost of the system, when using domestic or imported equipment, it is often not visible.

The fact that prices are overestimated and are conjuncturally confirmed by a very long payback period of such systems - 15-20 years. According to the specialists of the company "AZS-SNA", for more mass introduction of autonomous gasification systems in the Moscow region, their cost turnkey should be a maximum of $ 8. This amount is more responsible for both the real labor costs of all involved in the process of the parties (designers, manufacturers of reservoirs, installers and supervisory authorities) and solvency of developers. Understanding this circumstance by firms and reducing prices for services deploates a large number of doubting potential customers in favor of autonomous gasification. Vitog benefits all.

The editors thanks the company "Techno-Italy Grand", "ServiceWransgaz", "AZS-SNAB", "Entis" and "Mosgazniyproekt" for help in the preparation of material.