Pros and cons of water outdoor heating in comparison with radiator, installation scheme and features of operation.

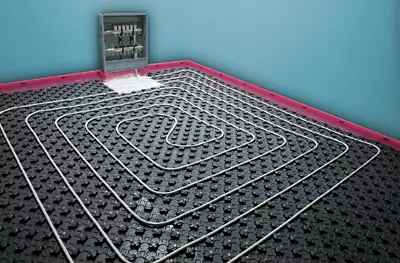

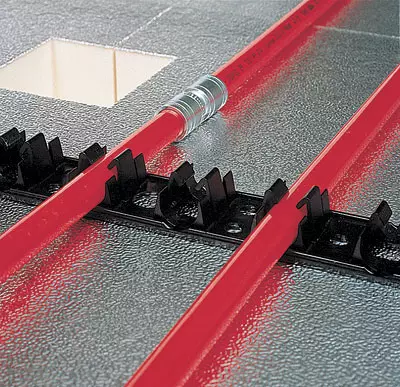

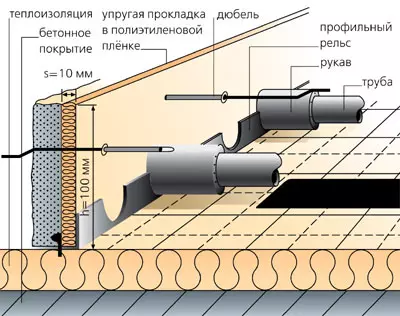

Installation on thermal insulation with bobbs allows you to reduce the installation time due to the absence of a pipe fastening operation to the heat insulating layer

Very valuable property is quite large length of the pipe supplied in the bays

Range tape to compensate for temperature extensions screed

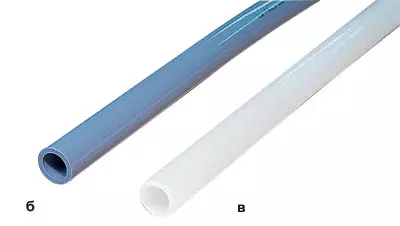

Modern pipes:

A- metal-polymer;

B- polybutene;

PE-RT heat-resistant polyethylene from Aquaterm

Inspection compound according to SNiP 2.04.05-91 * "Heating, ventilation and air conditioning" can be monitored in building structures

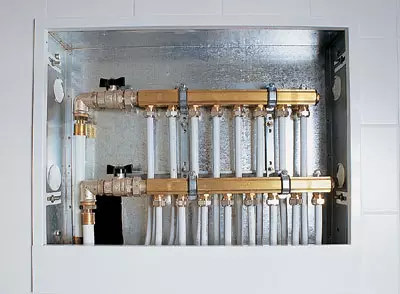

Collective cabinets organically fit into the interior

Warm floor mounting stages: Sitting Radder tape and laying a layer of heat-insulating material

"Rask" pipes are made according to the project

STEP STOCK - the value is calculated, it should not exceed 30cm. In the opposite case, the formation of a temperature zebra, manifesting alternating warm and cold stripes on the floor

Compensation seam prevents cracking due to its temperature expansion

Laying pipes on the "occupational" technology is carried out in the grooves of special polystyrene foam plates

Installation of pipes using reinforcement grid. Pipes are attached to the grid with plastic clamps or knitting wire

Laying pipes can be made on profiled planets

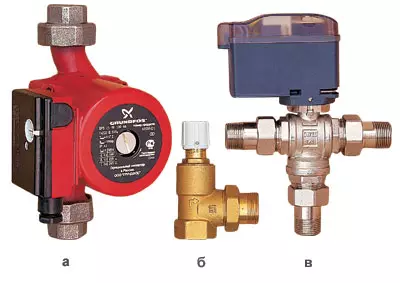

Circulation pump UPS 32-80 (A) from Grundfos (Denmark), three-way ball valve with MODULO Compact servo (b) from Emmeti and bypass valve (B)

Control panels of modern boilers allow you to control multiple heating circuits. As a rule, the temperature in these circuits is set by the control panel automatically depending on the outdoor temperature

Currently, water warm floors are becoming increasingly popular in individual construction. First of all, this is due to the desire of modern developers to improve the conditions of residence in their home and, if possible, reduce heating costs.

Advantages of warm floors

Outdoor heating, unlike radiator, is known to a wide circle of readers not so long ago, although it is a fairly ancient invention. Archaeological excavations indicate the presence of a warm floor system in antiquity, which, unlike modern technologies (systems), he was heated with an electrical cable or pipes with hot water, but by means of warm air, which passed from the furnace on the network of the channels. Interestingly, another fifteen years ago, the Russian consumer about the possibilities of warm floors was almost nothing unknown.So, the system that serves to heat the floor surface and using it as a heat accumulator and the heat powerover, is called a "warm floor" system.

The warm floor compared with radiator heating has the following advantages:

With outdoor heating, the heat distribution in the room from the point of view of physiology is close to the perfect. "Keep your head in the cold, and the legs are warm." However, this old saying does not quite correctly describes the temperature distribution schedule at the height of the room;

The main part of the heat (up to 70%) is transmitted by radiation, which is perceived more comfortably;

saving thermal energy - in residential buildings 20-30%, in rooms with high ceilings (from three meters high) to 50% and higher;

The absence of traditional heating devices allows you to more efficiently use the living area;

The absence of convective streams leads to a decrease in the amount of dust in the air of the heated room;

Due to the low temperature of the coolant, it is about 25-50C, the warm floors are a low-temperature system that excludes the occurrence of positive air ionization.

Presentation with constant finding people The maximum heating of the floor surface on European standards should be + 29C, in pools, bathrooms and rooms with short-term finding of people- to + 33c, while the average temperature of the floor surface for the heating period varies within the boundaries plus 24-26c.

Problem of choice

Warm floors are electric and water. For the first case, the warm floor is a heating cable, in which electrical energy is converted to thermal, and we were told about it in detail in our previous article "Rising warmth". In a sudden version, the source of energy is the heated coolant (most often water), which, passing along the pipes laid in the floor, gives heat. It should be noted that the technology of water heating "Warm floor" is used mainly only in contours with forced circulation, as it is necessary to organize a mixing unit to obtain a relatively low temperature of the water, and it is not capable of functioning without a pump. The mixing unit provides a reduced temperature of the coolant supplied to the system by mixing water from the boiler having a temperature of up to 90 ° C, with the already cooled, returned from the pipes with water (from the "Furning"). Mount such a system based on the heating system with natural (gravitational) circulation of the coolant is sufficiently problematic, in addition, the area of heated floors with such a system will be small.

Water warm floors are most often used in private houses. In central heating to centralized heating apartments, the arrangement of such floors is strictly prohibited - due to an increase in the hydraulic resistance of the system. Moreover, it is unacceptable and connecting to hot water pipes. After all, water from the DHW riser, passing through the circuit of warm floors, returns back already chilled, which will not like the consumers of hot water from other apartments that are riser after such a system. Despite this, many craftsmen still carry out similar connections, although their actions are definitely administratively punishable. The exception can be considered some modern new buildings, where there are already specially designed risers for connecting warm floors.

Based on the foregoing, the electric heating floor system can be considered the most acceptable. Even houses it is advisable to use water floors.

Advantages of the use of water floors, compared with electric in country construction, are indisputable. First of all, it is a decrease in the power of the electrical installation of the house and, as a result, reducing costs for the payment of astronomical accounts for electricity (for heating a small house of 150-200m2, about 45,000 kWh of electricity per year will be required, the cost of which will be more than $ 1550). Regarding the power of the electrical installation in general, the conversation is separate. Sometimes this power is just nowhere to take. Suppose if the electrical installation of the house has a highlighted power of 5 kW, and the warm floor is planned to be put on the square 100m2 and use 100-120W / m2 as the main heating, it is easy to calculate that the total power of such a system will be 10-12 kW.

Another advantage of water floors is the complete absence of electric and magnetic fields, the dangers of which are still being disputes. However, with the help of water warm floors, it is difficult to obtain a specific power exceeding 80-100W from a square meter of the surface, so the use of such heating as the main thing in the conditions of the middle strip of Russia is possible only when the building is very well insulated.

Characteristics of collector groups

| Manufacturer | Number of connected loops | Diameter, inches | Contents of delivery | Price, |

|---|---|---|---|---|

| Aquatherm. | From 2 to 12 | one | Shut-off cranes, a pair of brackets for fastening, 2-handed air vent, 2 delicious cranes | From 120 to 476 |

| Emmeti.(Italy) | From 2 to 12 | ; one; one | Cranes, pair of brackets for fastening, 2 Automatic air vent, 2-delicious cranes and direct and feed line thermometers | From 60 to 230 |

| OVENTROP. | From 2 to 12 | one | A pair of brackets for fastening, 2rd air vent, 2-grade cranes, flow meters | From 100 to 400 |

| Pexal (Italy) | From 2 to 12 | ; one | A pair of fastening brackets, flow meters, 2Automatic air vent, 2-grade cranes and crimping fittings for pipe attachment 162.25 | From 80 to 360 |

| Rehau. (Germany) | From 2 to 12 | one; one | Shut-off cranes, a pair of brackets for fastening, 2-handed air vent, 2 delicious cranes | From 100 to 430 |

| TC (Germany) | From 2 to 12 | one | Pair of brackets for fastening | From 110 to 315 |

| Tiemme. (Italy) | From 2 to 12 | ; one | Shut-off cranes, a pair of brackets for fastening, 2Automatic air vent, 2 delicious cranes | From 68 to 270 |

| Wirsbo. | From 2 to 4 | one | Gaskets, Handles and Crimp Fittings for Rech Pipe 20 | From 72 to 126 |

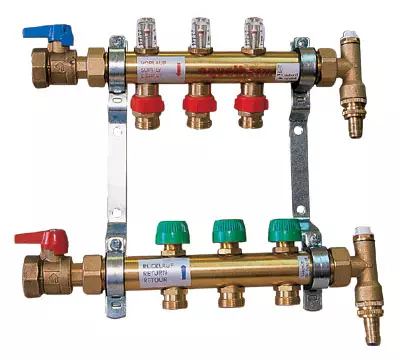

Accessories for mounting floors

Almost all manufacturers of modern pipes (AquaTherm and Oventrop, Germany; Wirsbo, Sweden; Purmo, Finland; Universa, Slovakia, IDR) offer a full range of components and auxiliary materials for mounting warm floors. These are pipes, thermal insulation (as a rule, with applied markup), compensation (rant) tape, fasteners, special elements for the compensation seams, which are plastic profile with a stuffing stacking, as well as collectors with fittings for connecting the hinges of a warm floor To the heating system. Collectors are available for a possible connection from two to twelve loops to the system. Their cost is 80-140 per collector for two hinges and comes to 400-480 per twelve-steppete.

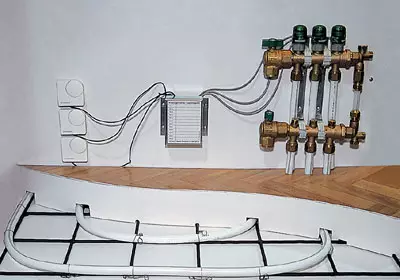

Collectors can be placed both open and in overhead or embedded collector cabinets. The rant tape is a strip of foamed polyethylene with a thickness of at least 5mm and 120-180mm width and serves to compensate for the temperature expansion of the screed. Also, many firms offer pump groups with mixing nodes that are serving to organize the circulation of the coolant in the hinges of the warm floor with a given temperature.

Pipe

Previously, before the appearance of polymer and metal-polymer pipes, in our country they tried to perform a warm floor of segments of a steel water-gas pipe, which was bent into the serpent with a pipe bender. Subsequently, these segments were welded with a gas welding, and the whole design was laid on the floor and deposited with cement mortar. Attendance does not have to talk like this system.The situation has changed radically with the advent of polymer and metal-polymer pipes. Possessing a number of advantages, they immediately gained widespread and, as for water warm floors, became almost the only material for their manufacture. In the West, outdoor heating using such pipes is known for more than twenty-five years. Fortunately, they are not subject to corrosion, their inner layer is resistant to abrasion and does not contribute to the accumulation of deposits, thereby preserving the diameter of the pipe cross section on the pipe constant during the entire service life (at least 50 years). An important property is the complete oxygen-resistance of the material, which is preventing premature corrosion of the heating equipment and the heart of the entire system of the boiler.

Of particular value is a fairly large footage of pipes that are supplied in the bays. Depending on the given diameter, the length of the pipe in the bay varies from different manufacturers in the range from 50 to 500m. This allows you to lay it in large areas in the area of uniform, without intermediate compounds, which eliminates the possibility of leakage of the system. However, how to be, if there is still a need to perform intermediate connections? Is it permissible? According to paragraph 3.34 * SNiP 2.04.05-91 * "Heating, ventilation and air conditioning" such compounds are permissible only if they are inseparable (to collapsible compounds, according to the same SNiP, it will be necessary to provide luchs). For warm floors, the following types of pipes are used: metal-plastic, polyethylene (both PEX and PE-RT) and polybutene.

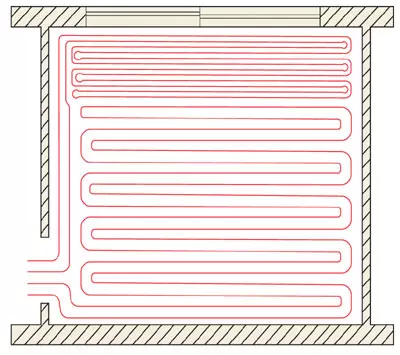

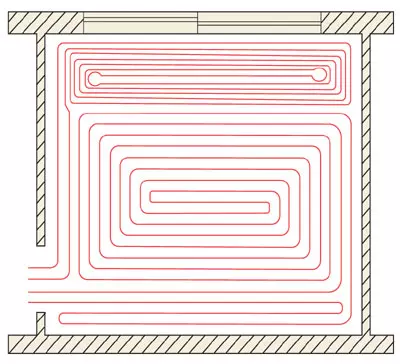

Looping schemes

There are several pipe laying schemes with the formation of a working (heating) loop. This is a snake, double snake (or "meander"), spiral and spiral with a displaced center. When installing the hinge in the shape of a serpentine, hot water supply is organized from the outer wall side, near which heat loss is higher than in the center of the room. Stroke contour uneven heat distribution. In order to fix it, you need to mount the loops in the form of a double snake or spiral. Region near the outer walls of the building is called boundary zones. It is recommended to reduce the pipe laying step in order to compensate for the heat loss. The installation step is the value of the calculated one, but in any case should not exceed 30cm - otherwise an uneven heating of the floor surface will arise with the appearance of warm and cold strips. So that the "temperature zebra" was not perceived by the foot foot, the maximum temperature difference along the length of the foot should not exceed 4C.

The flow of pipes on the 1m2 surface of the floor during step 20cm is approximately 5 pounds. m. Associated with the fact that due to hydraulic losses in the loop loop loop no longer, it is not recommended, it is easy to calculate that in a step of laying 20cm it will be possible to put the pipe on the area of 20m2. Sections of the larger area must be heated with several hinges, each of which, in turn, connects to the distribution manifold. With water warm floors, in contrast to electrical, it is not necessary to take into account the location of the furniture. The fact is that the electrical cable under furniture can overheat and fail, the pipes with the coolant of this lack are deprived.

Heating system Warm floor using as auxiliary heating in a small room can be installed without going into serious calculations. But the installation of the same system used as the main source of heat is impossible without taking into account the heat loss of the building, as well as the knowledge of the laws of hydraulics. There are no specialists without help. Many firms offer design and installation of outdoor turnkey heating systems. The calculation of such systems is usually performed using special computer programs.

| Manufacturer | vendor code | Circulation pump | Pump parameters | Note | Price, | ||

|---|---|---|---|---|---|---|---|

| Max head, m | Max Consumption, M3 / h | Connection diameter, inch | |||||

| Aquatherm. | 94008. | WILO RS 25-60 R | 6. | 3,2 | one | - | 630. |

| 94028. | WILO RS 25-70 R | 7. | 3.8. | one | With a weather-dependent controller | 1470. | |

| Buderus. (Germany) | HSM-25. | WILO RS 25-60 R | 6. | 3,2 | one | Designed for sharing with a boiler equipped with a controller | 406. |

| De Dietrich. (France) | EA 63. | Grundfos. UPS 25-60. | 6. | 3,2 | one | Designed for sharing with a boiler equipped with a controller | 634. |

| Meibes. (Germany) | MK 32. | Without pump (the pump is purchased separately) | - | - | one | Designed for sharing with a boiler equipped with a controller | 520. |

| Wirsbo. | 410080387. | Grundfos. UPS 25-60. | 6. | 3,2 | - | 570. | |

| 410803881. | Grundfos. UPS 25-60. | 6. | 3,2 | one | With a weather-dependent controller | 1560. |

Montaja technology

The technology of installation of water outdoor systems in different manufacturers is in principle, little varies for concrete floors includes the following steps. First of all, the breakdown of premises on the plots or, as they are also called, fields. The number of fields depends on the area of the room and its geometry. The maximum field area is 40m2 with the ratio of at least 1 side of the parties: 2. The need to create such sites is caused by the temperature expansions of the screed, which must be compensated - otherwise it will occur. Therefore, on the lines of space breakdown, after mounting pipes, it is necessary to provide compensation seams that perform the role of temperature compensators.Such a seam is a gap between two parts of a screed or screed and ascending structures (walls, columns) filled with elastic material. Through the compensation seams, only the feed and reducing loops can be passed, and these pipes must be protected by a corrugated tube from possible damage. Rooms having G-and P-shaped shape are divided into areas regardless of the area.

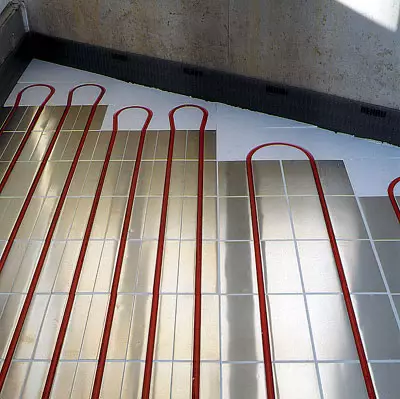

Then, the thermal insulation is also placed on a pre-purified base, and a rant tape is glued along the perimeter of the room, which serves to compensate for the thermal expansion of the screed. It should be noted that none of the manufacturers do not require waterproofing of warm floors. Pipes, in accordance with a specific project, are "rolled" over the layer of the insulation material and are attached to it or special harpudchers, which are stuck directly into the insulation or are configured to the reinforcement grid preceded over it. Wirsbo offers for fastening pipes to the grid to use a special fastening wire, spinning around the pipe when installing a special tool.

Some manufacturers, such as REHAU and AQUATHERM, produce thermal insulation with special bolsters, between which the pipe is invested. It disappears the need to fix it, the significantly reduces the installation time. The cost of this kind of isolation with a total thickness of 73mm with a soundproofing layer 10mm is at Aquatherm 8.94 per 1m2. Also, the pipe can be fixed on special profiled strips, which are plastic rack with grooves for placing and fixing pipes.

At the next stage, after mounting, the pipes produce the layout of compensation elements on the lines of space breakdown. Immediately before the fill of the screed, the heating system is pressed. Pressure pressure is made by one and a half times more than the nominal pipe pressure, which is indicated on it. The fill of the screed is produced at room temperature, while the system is under the calculated working pressure (under the conditions of the cottage it is about 2-2.5 atm).

For the device, the screeds are usually used cement-sandy solution or sandbetone M-300. Some firms, such as Purmo, are offered to add a special plasticizer to the screed (the cost of 25-liter canister from 12). This drug reduces the surface tension of water used to prepare the solution, and contributes to an increase in the volumetric mass of the coating, which increases the increase in its thermal conductivity and at the same time the strength of compression increases at the same time. The consumption of the plasticizer is usually 10% of the volumetric mass of pure cement, which is part of the mixture. Typically, the thickness of the screed layer, which is directly above the pipes, based on the thermal calculation, is at least 50mm (at a temperature of the coolant 50c and the surface of the floor 30c). The plasticizer allows you to reduce this value up to 30mm, however, it will have to lower the coolant temperature, so as not to overheat the floor. Solid side, an increase in the thermal conductivity of a screed leads to a decrease in the likelihood of "temperature zebra".

You can include the system only after complete "maturation" of the solution (for compositions based on cement, this process takes at least 28 days). Or after the solution fully gains strength, it is necessary to gradually and smoothly increase the water temperature in the system, with a gradual output to the operating mode for three days.

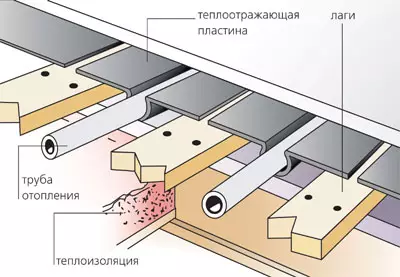

There are special cases of installation of water warm floors, when the widespread "wet" technology (sand-cement screed) is not applicable. For example, if the floors are wooden or when the construction of dry floors is made using KNAUF (Germany) technology, significantly reduced work time (it is due to the exclusion of all "wet" processes) and reduces the total weight of the system in case an unacceptable increase in the load on overlapping. Here are the so-called "occupational" technologies.

For the installation of water floors on a wooden base, a special technology has been developed. It involves the use of metal heat-reflecting plates, for example, from Wirsbo, which are mounted between the lag, after which the polymer pipe is embedded on the plates. It is further, on top of the beams, a wooden floor covering is laid. It is desirable that the thickness of such a coating does not exceed 15mm due to the low thermal conductivity of the tree.

Solid side, manufacturers of some water warm floors, such as Thermotech Scandinavia Ab (Sweden) and Rehau, offer products that are indispensable for the work on the technology of "dry" construction. Elements for dry mounting are polystyrene foam plates having grooves for pipes. Urehau on these plates in the factory conditions are applied aluminum thermal conducting profile. Thermotech Scandinavia AB offers a similar profile acquisition separately and installed during the installation process. From above, such elements are closed with plates based on plaster (GWL).

Separately, you should talk about the coatings stacked over the system of water warm floors. First of all, the material must have a heat transfer coefficient of no more than 0.15m2k / W. Already because of one of this, the currently popular cork coverage will be unacceptable. There will be no problems with a surname slab and other similar materials, but for the installation of parquet, probably not every company will take. Finally, not all kinds of elastic and carpets are suitable for such floors. Athe that are allowed to use should have special designations.

Equipment and materials for mounting systems Warm floor for a two-storey house of 250m2 (laying area 210m2)

| equipment identification | Designation | Number of | Units. change | Price, | Cost |

|---|---|---|---|---|---|

| Polystyrene thermal insulation 120060030mm | Penoplex. | 292. | PC. | four | 1168. |

| Dampfer tape | Aquatherm. | 75. | rm. M. | 0.8. | 60. |

| Element for the device of compensation seams | Aquatherm. | 2. | 10 pieces. 2pog.m. | 28. | 56. |

| Mesh reinforcement 5050mm | 210. | m2. | 1,8. | 378. | |

| Collector group on 5 loops | Emmeti. | 2. | PC. | 146. | 292. |

| Cabinet collector 744700150mm | Shrv-3. | 2. | PC. | 51. | 102. |

| The ending for attaching the pipe to the collector | Emmeti. | 12 | PC. | 1,3. | 15.6. |

| Head thermoelectric 10 pcs. | Emmeti. | 10 | PC. | 23. | 230. |

| Room thermostat | Emmeti. | five | PC. | 65. | 325. |

| Clamps plastic for fastening pipes to the grid | Fisher. | 1200. | PC. | 0.03. | 36. |

| Thermostatic fittings | OVENTROP. | 2. | set | 192. | 384. |

| Safety thermostat | OVENTROP. | 2. | PC. | 38. | 76. |

| Pipe metal-plastic 16. | Henco | 1100. | rm. M. | 1,2 | 1320. |

| Circulating pump | Grundfos. | 2. | PC. | 117. | 234. |

| The wire | ShVVP | 150. | rm. M. | 0,2 | thirty |

| Peskobeton | M-300 | 450. | Bag 50kg | 2,1 | 945. |

| Plasticizer | Aquatherm. | four | Kanistra 25L. | 24. | 96. |

| TOTAL | 5747.6 | ||||

| Mounting work | |||||

| Installation of warm floors | - | 210. | m2. | 12 | 2520. |

| Mounting collector groups | - | 2. | PC. | fifty | 100 |

| Tie device | - | 210. | m2. | 6. | 1260. |

| TOTAL | 2620. | ||||

| TOTAL | 8367.6 |

Control and rule

How is the temperature adjustment of the coolant in the entire heating circuit, "serving" several loops? To solve this problem, a special thermostatic and shut-off reinforcement has been created, which is offered by many manufacturers of polymer pipes and components for the installation of water warm floors. As a rule, it is thermostatic mixing valves that supply the coolant of the desired temperature in the collector. Separately, such reinforcement produce such cornea of the market of thermostatic and shut-off reinforcement, as Ta-Hydronics (Sweden), Oventrop (Germany), Herz (Austria), Danfoss (Denmark). This reinforcement is installed before collectors on the supplying highway. Some models of such fittings have the ability to maintain not only the temperature of the supply line of the contour, but at the same time and room temperature, for example, UNIBOX E Plus from OVENTROP worth 192.

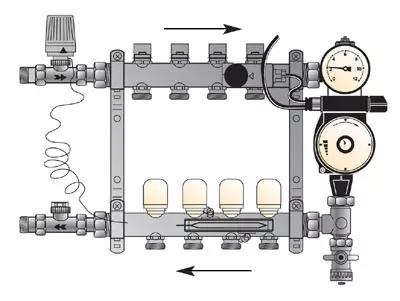

For the operation of the warm floors, as mentioned earlier, a circulation pump was needed, which can be installed both in the boiler room and mounted on the collector node. This pump in combination with thermostatic reinforcement for semon-adjustment temperature forms the so-called mixing unit, about the principle of which we told at the beginning of the article. To facilitate the installation, many serious firms produce mixing nodes of the finished factory configuration. The pump in a similar module can control both normal and electronic thermostat with the ability to select the heating program. The cost of these nodes varies within 800-1600.

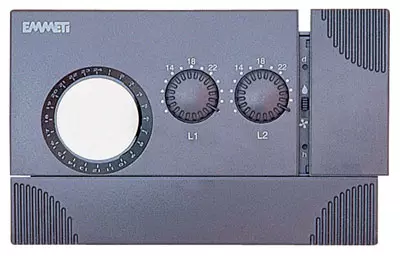

Separate attention deserve control panels of many modern boilers, such as Buderus, Viessmann, Vaillant, Wolf (all Germany), CTC (Sweden), ACV (Belgium), de Dietrich and many others. These devices allow comprehensive control over the entire heating system as a whole, including the ability to manage multiple contours. Usually complete with the control systems of modern warm floors, instead of traditional thermostatic fittings, three- or four-way mixing cranes are used, equipped with servo drives. Each such servo drives the corresponding crane, obeying commands that gives the control panel. Monitoring the temperature of the feed line is carried out using a temperature sensor. The cost of a three-way crane with a diameter of 32mm is approximately 85, and the servo will cost 150-200. Also, there are also ready-made pumping and mixing groups consisting of a three-way mixing tap with a servo drive, a circulation pump and shut-off for thermometers. Similar equipment, for example, manufactured by Meibes.

As a rule, the temperature of the coolant in these circuits is set by the boiler automatically- depending on the outdoor temperature. In other words, the contour is meteo-controlled or, as experts say, weather-dependent. Such, for example, the LogMatic 4211 control panels from Buderus, R16 Digi Comfort from Wolf or Vitotronic 200 kw2 from Viessmann. Adjusting the mixing circuit using the boiler control panel is zone, which allows you to configure the entire contour as a whole and, taking into account the fact that it can be connected to it to it, several hinges of the warm floor, heating different rooms can be connected.

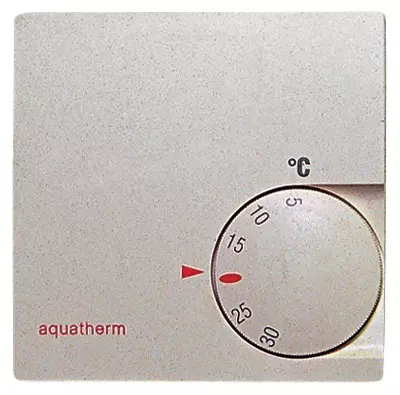

Local temperature control of the loops is carried out using thermostats installed on distribution manifolds. Thermostats are two types of thermomechanical action (conventional thermostatic heads that we used to see on heating radiators) or electronic thermostats in a pair with a thermoelectric head (servo). It is usually located on the "reverse" collector comb (for each loop a separate thermal head is needed). For the next case, the temperature setting in the hinges of the warm floor is carried out manually. For this, each time you need to approach the collector node and, rotating the thermostatic head, set the necessary mode. In the second embodiment, the heating degree depends on the electronic unit, which can be located directly in the room where the warm floor is mounted. The corresponding sensor measures the temperature of the room, not the floor, which is very convenient. At the same time, the coolant supplied to the loop of the warm floor should not be heated above 55c.

A codcan electronic thermostat can be connected to several servo drives. The need for such a connection occurs in very large rooms, which cannot be "covered" only one loop. In this case, the electronics manages servos of several loops at once, which means the floor temperature will be the same throughout its area. In addition, similar thermostats have a programming feature. For example, they allow you to choose the night heating mode with a reduced temperature or set the timer operation program to include and turn off the heating through different intervals.

The limit of perfection is radio beermostats installed in various premises and transmitting a signal to thermoelectric heads that are, as always, on the collector, by radio waves. Of course, such systems are very convenient for the user, besides, they are simply easy to mount (it disappears the need to lay wires). The only drawback of these thermostats is their high cost. For example, a set consisting of six servo drives, six radiothermostats (for each room there is one thermostat), the six-channel radio-regulating unit from Aquatherm will cost the consumer in 1550.

To exclude a random feed to the collector of the coolant with a temperature above 55s, safety thermostats are used. They disconnect the circulation pump if the liquid pumped them will be heated above the specified limit.

Including I would like to say a few words about the cost of warm floors. Water warm field is not cheap. For the house of about 200-250m2, the cost of acquiring the entire system together with its installation will be 30-60 per 1M2. Against this, the electric warm floor of 15-20 per 1m2 will look more attractive, but it should be remembered that the costs of acquiring and installing water heat floors are one-time and, according to experts, the operation of the gas boiler will pay off through some six eight years.

| Manufacturer | Commercial designation | A type | Fittings system | Outer diameter, mm | MAX working pressure, bar / temperature, with | Pipe price for 1Pog / Fitting per pcs, (for pipe 16) | Note | |

|---|---|---|---|---|---|---|---|---|

| "Altais" (Russia) | "Altais" | MP | Crimp and press fittings | From 16 to 32 | 10/95 | From 0.5 / from 1.0 | Aluminum layer thick 0.2mm, welded | |

| Co.e.s. (Italy) | Coesklima Super K. | MP | Crimp and press fittings | From 14 to 32 | 10/95 | From 1.4 / from 2.2 | Aluminum layer thick 0.4mm, welded jack | |

| Geberit. (Switzerland) | Geberit Mepla | MP | Special fitting system without crimping bushings | From 16 to 63 | 10/95 | From 2.8 / from 6.5 | Aluminum layer thick from 0.8 mm, welded jack | |

| OVENTROP. | Copipe | MP | COFIT crimp and press fittings | From 14 to 32 | 10/95 | From 2.2 / from 5.7 | Aluminum layer thick 0.4mm, welded jack | |

| Prandelli. (Italy) | Multirama. | MP | Crimp and press fittings | From 14 to 32 | 10/95 | From 1.6 / from 2.3 | Aluminum layer thick 0.4mm, welded jack | |

| TC. | Teceflex. | MP | Special fitting system with movable sleeves | From 16 to 63 | 10/95 | From 1,8. | Aluminum layer thick 0.4mm, welded jack | |

| Valsir. (Italy) | Pexal, Mixal | MP | Crimp and press fittings | From 14 to 32 | 10/95 | From 1.0 / from 2.5 | Aluminum layer thick 0.2mm, welded | |

| Uponor (Finland) | Unipipe. | MP with the inner layer of PE-RT | Crimp and press fittings | From 14 to 110 | 10/95 | From 1.6 / from 3.1 | Aluminum layer thick from 0.2mm, welded | |

| Bir Pekc (Russia) | - | Pex. | Crimp and press fittings | From 16 to 63 | 6/95 | From 0.8. | - | |

| Rehau. | RAUTITAN FLEX | Pex. | Special Raubasic Fittings System | From 16 to 32 | 6/95 | From 1.8 / from 4.2 | - | |

| Tiemme. | - | Pex. | Crimp and press fittings | From 16 to 32 | 6/95 | From 1.4 / from 2.2 | - | |

| Wirsbo. | PE Pex. | Pex. | Special Quikeasy Fittings System | From 16 to 32 | 6/95 | From 2.0 / from 5.3 | - | |

| Aquatherm. | 90300. | PB. | Crimp fittings | From 16 to 20 | 6/95 | From 1.38 / from 3 | - | |

| Gabotherm SystemTechnik. (Germany) | Gabotherm Constructa. | PB. | Thermal welding, crimp and press fittings | From 6 to 20 | 6/95 | From 1.6 / from 2.3 | - | |

| Universa. | - | MP with the inner layer of polybuthen | Thermal welding, crimp and press fittings | From 16 to 32 | 10/95 | From 3.8 / from 6.5 | - | |

| MP-metal-plastic with the inner layer of PEX; Pv- polybutene; Rehot - from stitched polyethylene |