Fixed internal partitions: materials for the device, practical recommendations for installation.

Photo by D.Minkina

Photo V. Vasilyeva, A. Babaeva

Photo V.Nepledov

Photo M.Stepanov

If you burn the desire to divide the space of your apartment, limited by capital walls, on separate functional zones or isolated rooms, you can not do without the construction of partitions. Studdered redevelopment, it is important to imagine what method and from which materials they will be built.

Unfortunately, no wall of your dwelling can be transferred and put in any place, where you want. This is because the wrapping structure of the enclosure design, which is based on inter-storey and attic floors and other structural elements of the building. The walls are elevated in the construction process and perform the support function for carrier overlaps. So it is impossible to demolish them yourself or to do in them without a special permission of a project organization, and not safe. Partitions are designed specifically for the zonal member of the room and at the same time, for the heat and sound insulation of the separated zones. Such structures can be put in an already ready-made home almost anywhere, and their coordination with the MVK, as a rule, does not cause problems.

In principle, partitions must provide reliable sound insulation, be durable, if possible, easy to have a small thickness and withstand certain console loads (that is, serve as a support for hanging items: shelves, cabinets, plumbing equipment, etc.). In addition, they are obliged to meet sanitary and hygienic and fire protection requirements. For example, it is built from environmentally friendly materials (suitable for use in residential premises) and be able to resist open fire. The latter circumstance is very important because in the event of a fire, the fire-resistant partition will be able to "hold" the flame, without letting it spread across the apartment. This time is not less than 15 minutes, it should be enough just to arrive a fire calculation.

For the construction of partitions, used mainly cellular gas and foam concrete blocks, clay or silicate brick, glass blocks, plasterboard and dry-fiber sheets. According to the method of construction, which, in fact, is determined by the type of material used, the partitions are divided into fine-grade (from panels), from small-piece materials (slab and block-of bricks, stone or glass blocks) and frame. In addition to how mobile, these structures make it possible to change the inner space of the premises, they are divided into stationary, team-collapsible and transforming. Inpatient (fixed) partitions are used as interiorly used apartments. About them and will be discussed.

As small-list materials for the non-bearing walls, it is usually used, as a rule, blocks of cellular concrete or brick. The partitions from glass blocks are very popular, this is a great way to zoning premises and at the same time decorating the interior.

But do not rush to bring those or other materials on the "building site", where you gathered to put the partition. Keep in mind that it is impossible to infinitely load overlapping in your apartment: the permissible load on the reinforced concrete slabs, of which the overlaps are arranged in a standard residential building, is about 3 kPa (300 kg / m2), in the extreme case, 6 kPa (600 kg / m2 ). Avteda, in addition to partitions, will still be laid out the finish flooring, placed furniture and, possibly household equipment. So when discussing the redevelopment of the apartment, do not be lazy to ask for the developers of your project, whether they spent the calculation of loads on the bearing overlaps and, taking into account this, the construction materials are correctly selected. If over time the ceiling is crack down at the bottom of the neighbors, the "joy" of emotional communication with them will have to experience you, and not to the authors of planning drawings.

Cellular concrete partitions

Mesh concrete is practically universal material. It is obtained as a result of the intake of the cement dough with special puff-forming additives. It is not a fuel and effectively prevents the spread of fire. KRYMERA, the limit of fire resistance of the self-supporting wall made of 75mm thick blocks is 150 minutes. The air prisoners in the pores of a cellular concrete gives the blocks good thermal insulation characteristics. In addition, closed pores reduce the water absorption of the material, making it more resistant to moisture.The porous structure gives ease of cellular concrete. Judge for yourself: the standard small block made of foam concrete (GOST 21520-89) The size of 20025060mm of the D600 brand has a mass of 18 kg and is able to replace in the enclosing wall 15-20 bricks (and these are as many as 80 kg). From here it is necessary to lower the complexity of masonry, since instead of a tent of the bricks, just one stone is enough. Using blocks, you can speed up the pace of repair or construction for several days. And it's not only more quickly, gas-silicate partitions and dry a much faster brick.

The partitions from the blocks of grades D400 and D500 have good sound insulation: the design of 100mm thick has a sound insulation index (RW) equal to 35-37 dB, a thickness of 125mm- 44-46 dB, and the partition is another 25mm thicker and at all 55-57 dB.

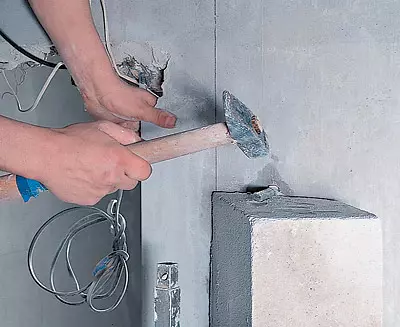

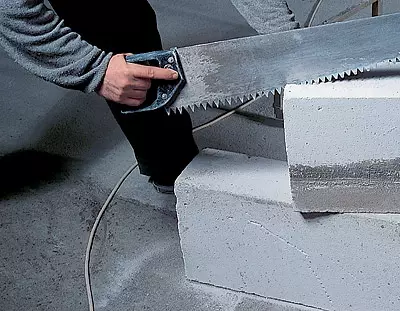

Blocks from cellular autoclave concrete allow you to create a very smooth surface. The height means that expensive materials for the finishing finish of such partitions, unlike brick, is required relatively a bit. Blocks themselves are easy enough to be cut, they cut and worn. The simplicity of the processing of cellular concrete allows you to make the designs of any configuration, including arched and curvilinear, and also processing the surface almost any way: to divide into small-sized blocks, cutting channels and holes for electrical wiring, sockets, pipelines, etc.

For the device of interior partitions, there are enough blocks with a thickness of 10 cm (add the thickness of the finishing layers, and this is not less than 1-2 cm). Then there will be no problems with the installation of doors, because the standard width of the door frame does not exceed 13 cm. Therefore, partitions from foam blocks (and, by the way, from other materials too), it is reasonable to make a thickness of 80 to 120mm. This size provides optimal indicators for fire resistance, cantilever loads and sound insulation. It makes no sense to make partitions and because the thickness required for the installation of the door block will have to be taken from the increased layer of plaster or the device of composite platbands. ATO is already overruning materials and an increase in the estimate.

The strength of the finished block structure makes it possible to build partitions of almost any height. When laying, you can use both a sandy-cement mixture and ordinary polymer cement tile glue. The partitions themselves are not only block, but also brick-emit to the device of the screed and are attached to the carrying structures by installing in the drilled holes of the metal reinforcement: one end of the rod is driven into the carrier structure, the other is placed in a horizontal seam of masonry. The basis of the future partition is equalized by cement-sandy solution. Then the thin layer of the solution is stacked, to which, setting up the level, the first row of the partition blocks are assembled.

Mounting to the floor can be carried out with the help of metal profiles (which, in turn, mounted on dowels). The surfaces of the block elements, joined each other, are pre-coated with glue. That is, each subsequent row of plates is installed with the pre-labeling of the shy surfaces with glue and with the lining plate of the previous row. Ksthenam partitions are fixed with glue (solution) and reinforcement (every 2 row of blocks). The doorway is overlapped with two-three rods of steel reinforcement (with a diameter of 6mm) to which the blocks are stacked by "rotary".

Finally, another consideration. When working with foam concrete blocks, it is necessary to consider an important nuance. Because they have a smooth, but strongly dusty surface, high qualityly stunning them difficult. A good result can be achieved, but not regretting the primer: it will be necessary to put it, at least 2-3 layers before applying the plaster.

Foam concrete products MAROK D500 and D600 different sizes produce many domestic enterprises, such as "Lipetsk House Building Products", "Sverdlovsky Plantic Product Plant", "Madis" (Chelyabinsk), "Konk" (Saratov), "Vector" ( Moscow Oblast), "Factory of Largeannel House Building" (Penza), "Savik" (Moscow region), etc. Minimal sizes of one block - 20025060mm. Products 500500100, 600400100, 600300100 and 600300100 and 600300100 and 600300100 and 600300100 and 600300100 and 600300100 and 600300100. The maximum mass of such elements, as a rule, does not exceed 14-23 kg, and the geometrical dimensions are such that it is convenient to work with them to work one installer.

In the floors of the doorways, it is possible to use products 2390250125mm. Manufacturers of gas-silicate blocks (with a density of 600 kg / m3 and dimensions of 600300100mm) there are up to several tens. Among them can be called "Lyubertsy Building Construction Blocks" (blocks 600300100mm), "Silicate Wall Materials Plant" (Stary Oskol), "Lipetsk Factory of Housekeeping Products" and others. Special attention deserves products from Lipetsk, where the production of products from cellular Concrete on the technology of the German company Hebel. Valid dreams from foam concrete blocks, in which geometric size tolerances reach 1 cm, Lipetsk gas silicate blocks are very accurate, and the tolerances are 1mm, it means that it is possible to put such elements on glue.

Prices for block elements from cellular concrete on average in Russia range ranging from $ 1 to $ 1.3 per piece. It is very important when buying pay attention to the brand of products. For example, the designations of D500 and D600 are a brand on the density of cellular concrete (500 and 600 kg / m3, respectively). But the fact is that our plants produce more heat-insulating products - with the same dimensions, but less density (350 kg / m3, Mark D350). These foam concrete blocks are not suitable for partitions, since they do not provide sufficient structural strength, and are intended for insulation of flat horizontal and vertical surfaces of buildings.

Puzzle plates

If the repair period is pressed, and you do not want to deal with construction garbage and mud, you can use simple, relatively fast and, most importantly, "dry" way of erection of partitions from puzzle plaster plates (PPP). Each such plate is made of construction gypsum and is a rectangular parallelepiped, connecting and reference surfaces of which have on the respective sides of the groove and comb.

The partition from the plaster can be assembled rather quickly, and after sealing the seams and the priming, the finished surface does not need to apply a rather thick leveling plaster layer (and therefore, almost eases wait until the plaster is dry). So you can safely begin painting, finishing with polymer coatings or tile facing. By the way, it is permissible to grind the partition immediately after drying the mounting composition, that is, after 30-40 minutes. Gypsum plates are resistant to rot and insects, minor fluctuations in temperature and humidity do not cause deformations in them. The PGP is easy to saw and process, and the electrical wiring and pipes are taken into the shoes performed by a simple hand tool. Pictures, mirrors and other lightweight objects weighing up to 4 kg are attached to the partition that are resistant to corrosion screws with dowels, heavy items (cabinets, shelves, etc.) - with anchors. However, in the opinion of many builders, the puzzle-breakele compound does not provide sufficient strength (compared to brick structures), if, for example, it is required to hang heavy sanitary equipment.

In the Russian market, the plaster represented by the products of the domestic firm "Knauff Gypsum", and 2 of their types are offered and moisture-resistant. The first are suitable for partitions in any rooms with normal (up to 60%) humidity. Moisture-resistant plates (it is possible to distinguish them from ordinary in color, it is not light gray, but green) are also called hydrophobized, since additives that reduce water absorption are introduced into the gypsum. From moisture-resistant materials you can build partitions in the bathroom, toilet and in the kitchen. In this case, cladding PSP ceramic tiles or natural stone is required. Do not forget about waterproofing. When installing partitions in rooms with high humidity rates, the slab surface is mandatory coated with waterproofing mastic "Knahf Flekendicht", and in places of conjugates, a sealing water repellent tape is used, such as "Knauf Flekendichtband".

Varieties of cellular concrete

Foam concrete is a lightweight cellular concrete obtained by hardening a solution consisting of cement, sand and water, as well as foam. Moisture from foam concrete comes naturally when it is in forms.

The cellular autoclave concrete consists of quartz sand, cement, lime and water mixed and entering the autoclave, where their foaming and subsequent curing occurs. Products from cellular concrete are produced only in factory conditions and go to sale in the form of ready-to-use blocks.

Aerated concrete is made from water and cement-sandy mixture, which gas inverters are added.

Gasilicate is a mixture of lime, cement, quartz sand, water and gypsum, stripped with additives and hardening in an autoclave or vaporumerized.

The partitions from the PGP are not on the concrete base of the overlap, but on the finished tie of the floor before applying the finish coatings. Punching the mounting glue When working with conventional plates, a fugenfuller putty is used, and with hydrophobized-"fogenfuller-hydro". In order for the design to be sufficiently rigid, the plates are laid "rotary", and the groove both up and down. As a groove is preferable, since the putty in the puzzle connection is distributed more evenly. In the case, the case of the first row slabs must be cut off the comb.

Door boxes are attached screws with special dowels. Be prepared for the fact that for a single partition from the plates 66750080mm, the standard door frame is not suitable for 12, it will be necessary to look for a narrow, 8-centimeter. Therefore, the design with the doorway is appropriate to erect from the plates with a thickness of 100mm (20mm, then it is easy to "peck" with platbands). Vertical stove seams, located next to the doorway, should not be closer than 20 cm from the edge edge. Inside the intersection and corners, the plates are stacked with alternate overlapping of the joints of the lower rows. The seams are sealed with a putty "Knauf Fougaurfuller", and so that, upon subsequent finish, improve the adhesion of the surface, use the priming with such compositions as "KNAUF TIFENGRAND".

Usually, the PGP partitions are attached to the carrying overlaps rigidly, with the help of a dowel, and the gap between the ceiling and the upper beds are closed with putty. To improve the sound insulation properties of the partition, the so-called elastic connection can be used. In this case, with a putty sticks the gasket (3-5 mm thick) from the tube, bituminous felt or Low density. Such a gasket extinguishes sound oscillations passing through the bearing building structures.

Both ordinary and moisture-resistant puzzle plates are produced two sizes: 667500 and 900300mm, thickness - 80 or 100mm. From plates laid in one row, it is possible to assemble the single partition - it meets the regulatory requirements for sound insulation (41 dB). The double design of the septum-thickness from 180mm is required if you need to enhance sound insulation (to level 60 dB) or place inside the design of plumbing communications, for example, a large diameter tap pipes that cannot be positioned in the strokes. Wing partition can be chopped by pipelines with a diameter of up to half of the stove thickness, that is, no more than 40mm. Double design is erected as follows. First one side is mounted (one row of plates) and all communications are attached to it, then the other. Empties are filled with insulating materials.

True, the variant of the double design of the partition (with a sound insulation layer between the stoves) may be too expensive. After all, the cost of one plate of 66750080mm is approximately $ 2. Nevertheless, if it is necessary to build an easy fixed interior partition in a record time, and at the same time consume the minimum of finishing materials, it is difficult to choose the alternative to the puzzle plates.

Brick partitions

This is perhaps the most classical option. Brick partitions are characterized by high strength and withstand quite large loads from items hanging on them (plumbing equipment, bookshelves, cabinets, etc., mainly that the fastening itself turned out to be quite reliable). As a rule, such partitions are laying with a thickness in the Pollipich (this is approximately 140 mm) or on the edge (80mm), and even before the device of the floor screed, directly on the bearing overlap. If necessary, the base under construction is leveled with cement-sandy solution. Next, lay a layer of solution and in terms of the level of bricks. For greater strength, the partition is advisable to reinforce. Make it by laying along the entire length of the design (every 4-5 rows of bricks) of metal reinforcement with a diameter of 4-6mm or a strip of finelyete plaster grid. The partitions are not more than 150 cm long, laid out of the brick, put on the edge, reinforced every 3-5 rows with a wire with a diameter of 3-6mm.When erecting partitions from the brick, put on the edge, the masonry lead either with the help of the guides or in several stages. This is explained by the fact that such a laying in the raw form is very unstable. So that the design is not deformed, it increases for one stage by no more than 1-1.5 m. Next, the day should be waited until the solution is grabbed, and only then lay out the entire design to the end.

If a partition in a quarter of a brick seems to you not enough hard, and it is unacceptable to build a thicker construction (in the Pollipich) for any reason, you can rein the masonry with a soft steel annealed wire with a diameter of 1.5-2mm. It is passed into laying seams from below up. For greater reliability, the wire is recommended to put in horizontal seams of masonry every 40-60 cm.

When preparing under painting or pasting, wallpaper brick structures are usually shuffled on both sides and thoroughly rub. Inside rooms with high humidity, the partition is desirable to be arranged for the entire height (or at least at least 180 cm from the floor) moisture-resistant materials, such as ceramic tiles or waterproof acrylic paints. The woven room, by the way, the partition can be shuffled only on one side, and on the other hand, put the tile directly on the brick wall, would be a good master.

When planning the construction of a brick partition, be careful: such structures are quite severe (1m2 1/2 thick bricks weigh 230-250 kg) and create an increased load on carrier overlaps. To reduce the mass of such a design, it is advisable to apply hollow or porous brick. However, only full-length red is suitable for work in premises with high humidity (in bathrooms, toilets and kitchens), since others (for example, white silicate brick) are too sensitive to moisture. Even in new monolithic houses, it is better to install brick partitions as minimal length, for example, only in bathrooms, bathrooms or near vertical bearing elements (walls and columns). If the partition length is obtained more than 5 m, it makes sense to abandon the brick and find it a replacement in the form of gas-silicate or foam concrete blocks.

Of course, you can build a partition from seven-piece or multi-profile red bricks. But the sound insulation properties of structures with internal voids are low. To reduce the transmission of noise, it is advisable to fall asleep internal cavities with sand bricks, but weighing, alas, will increase.

When preparing for overhaul or discussion with an apartment planning designer, we should not forget that brick partitions have a number of shortcomings. Forward the queue, their surface has to be thoroughly aligned, and this implies additional consumption of materials (plasters and putty compounds) and the need for a large technological pause between the "wet" processes and subsequent works. In addition to the considerable mass, brick structures have another negative side, a fairly high price. And, we note, it affects it not so much the price of materials, how many high cost of work (masonry and plaster). Work on 1m2 laying partitions with a thickness of the edge with reinforcement costs about $ 10, and a quarter of a brick is about $ 8.

As for the choice of materials, now it is unusually wide and there is no shortage of good products. In addition to domestic producers ("Golitsyn Ceramic Plant", "Victory Knauf", "Novomoskovsky Plant of Ceramic Materials", "Mster Plant of Ceramic Wall Materials", "Kerma", "Tver Plant of Building Materials N 3", etc.), foreign markets are represented in the market Firms, such as Terca and Optiroc (Finland). A good full brick of various brands (M-100, M-125, M-150) is offered at a price of $ 0.1-0.2 (1 pc.). Slital brick brands M-75, M-125, M-150 can be purchased at a price of $ 0.1 to $ 0.5. White silicate brick costs from $ 0.1. Apacks to buy materials is not a problem, the main thing that goes behind them is not to forget the dosimeter. The fact is that the main component of the brick is the clay-natural source of radiation background. It happens that products from different Russian regions strongly "fountains", and bring such materials to the apartment, of course, not worth it. So before buying a batch of bricks, check the level of the radiation background is simply necessary.

Glass blocks

Glass blocks are "bricks" with a hermetically closed cavity formed by two glass plates connected between themselves, are perhaps the most aesthetic materials for partitions. The emphasis with foam concrete blocks and bricks they look most elegant. Active- have sufficient strength, fire resistance, heat and sound insulation qualities, durability and, of course, a light-resistant ability. In addition, the glass blocks are heat-resistant material, withsting temperature differences from -40 to + 50c.

Each element-half-terminal glass "brick" is made of thick (6-7mm) glass. Standard size of glass blocks - 190190 80mm (in stores you can find products and more important - 240240 80 cm). The mass varies from 2.2 to 4 kg. Also available angular (or half-hearted) elements of a rectangular shape (their dimensions 1909080 cm) are available. The surface of the modern glass block can be smooth, corrugated, transparent, matte and even color. In this case, products with different surfaces are missing in different ways. There are completely transparent (with smooth facial walls), light-scattering and light-director (these effects usually have glass blocks with corrugated surfaces). In addition to conventional models, many manufacturers manufacturers also produce shaped triangular, angular (for trimming angles, columns, etc.) and even round. Of these, of course, the partition is not built, because their function is clean decorative.

For fastening glass blocks, any mounting formulations that do not contain large grasses or other inclusions capable of scratching the surface. These can be cement solutions, and "liquid nails", and much more. If the solution got on the glass surface during operation, try to immediately wash it off with water. In contrast, the dried mass will have to consider a metal scraper, which is very easy to damage the block.

To facilitate the installation of the partition, a modular wooden grille is usually applied. But it is best to use special plastic gaskets-inserts ($ 0.25-0.5 per piece), thanks to which you can achieve a strictly fixed distance between the stacked elements. The joints and seams are better to close the tone of the grout for the tile - so the partition will look more aesthetic. So that the glass blocks are well "closed" with cement, it is recommended to put no more than three rows of blocks in height per day. This is due to the fact that for good bonding with the cement they need more time than, for example, bricks. As in the case of the PGP, the partition from the glass blocks will need to look for a 80mm width door. The output from the position can be a universal door block with a sliding box. When installing such a design, it is enough to put forward the vertical strips in the width of the partition and consolidate.

In fact, with the help of multi-colored "glass cubes" you can solve the design of your housing in the most unexpected and original key. Very often, the glass blocks are arranged in the bathrooms, in the kitchen and even in the living room, separating one functional area of the apartment from another. The curvilinear partitions can be built, while the minimum radius is 5 m. No one bothers you to insert glass blocks into the walls and partitions for the sake of interior revival. Perhaps the only drawback of these materials is a relatively high price. Glass blocks are an average of $ 1.5 to $ 50 per piece. Now in the Russian market is presented inexpensive and quite high-quality models of domestic production (1 pcs - from $ 0.8), for example, from the company "Star Glass". The optimal ratio of price and quality can boast the products of Vitrablok (Czech Republic), Saint-Gobain (France), Weck, Solaris (Germany), Vetroarredo (Italy) and others. Pretty expensive may be the work of masters: the construction of partitions vary from $ 14 up to $ 25 (1m2).

Frame partitions

For the device partitions of this type, plasterboard sheets, fiberboard and chipboard are used. The most widespread frame partitions with plasterboard sheets (GLC) from the companies "Knauf Gypsum" (Russia) and Gyproc (England).Frame partitions with GLCs are relatively simple and quickly mounted, thereby significantly reducing the timing of work. Another indisputable advantage of GLC lies in the fact that it can be made of walls with broken or curvilinear forms, and the designs themselves only slightly reduce the useful area of the room.

The permissible height of the plasterboard septal septum (12.5 mm thick) depends on the size of the cross section of the rack profiles used and the distance between them in the frame, as well as from the constructive solution. The height of such a product can reach 5-6.5 m, and the mass of 1m2-25-49 kg. For comparison: the septum on a wooden frame (bars section 6080mm) is capable of having a height of up to 4.1 m (mass 1m2- from 30 to 50.5 kg). At the same time, the most subtle partition (95mm thick) on a single frame, sheathed with a 12.5-mm sheet on each side, is characterized by the level of sound insulation RW 37 dB and fire resistance of 0.2 hours. A similar design, but already covered with two plasterboard sheets on each side, provides sound insulation at 45 dB and can withstand an open flame for an integer hour.

If you are going to hang on a drywall partition any heavy items (for example, bookshelves), keep in mind that the load on the design should not be greater than 70 kg for each temporal meter length. Comparatively light items, the mass of which does not exceed 15 kg (for example, pictures or shelves), are suspended directly on plasterboard trim using dowels and screws. GlKl partitions allow you to carry out hidden wiring. On the finished walls, wallpapers usually stick or apply decorative plaster, and you can leave the surface and without finishing.

The price of 1m2 of the plasterboard partition is $ 20-50 (excluding installation) and depends on its configuration, the design of the frame, the number of layers, heights and other parameters. For installation work will have to supplement 10-20% of the value of materials. Read more about frame partitions in the article "Roman with Plasterton" published in this room.

Is complete silence possible?

This is one of the main questions asked by those who are going to separate the office from the nursery, and the bedroom, from the room, where in the evenings, the kinoman's relatives are seated in front of the home theater screen. It is unlikely that you can imagine a comfortable and quiet life if at the end of a busy working day you trying to fall asleep, you will be forced to listen to conversations in the next room, the rumble of speakers or something like that. Yes, and homemade video with surround sound is strange not to include at least the middle power. Noise protection is needed. But from which materials should the partitions should be erected so that they helped in this?

Soundproofing of the enclosing structures (overlaps, walls and partitions) is the ability to prevent sound proliferation and weaken the sound pressure (or sound energy) of noise penetrating the quiet room. At the same time, the noise of the air (occurs in the air and, thanks to the air sound waves, it spreads through the enchanted structures) and the drum (appears directly in the structures from the strike on them and, turning inside, is emitted to the room in the form of aerial sound waves).

Construction rates introduce the concept of soundproofing ability (sound insulation index - RW), which is measured in decibels. This value does not depend on the area of the room, nor from sound absorption in it and applies only to the most enclosing structure. MHNSN 2.04-97 "Permissible noise levels, vibrations and soundproofing requirements in residential and public buildings" RW is specified for dwellings divided into categories: 54 dB- for category A homes (luxury housing), 52 dB- for category B homes ( Comfortable new buildings), 50 dB- for houses category in (old houses).

As information for reflection, such examples can be given. Brick partitions from full-length red brick, plastered on both sides, have the following soundproofing index values: wall in the Pollipich (thickness with 150mm plaster) - 47 dB; wall in 1 brick (thickness with 280mm plaster) - 54 dB; Wall in 2 bricks (thickness with plaster 530mm) - 60 dB.

The soundproofing of the air noise of the frame-solid partition from two sheets of GVL thick 12mm on each of the two independent frames with a thickness of 50mm (frame space is filled with a mineral wool 50mm thick) with an airbap between 10mm frames is about 53 dB. In this case, the total thickness of the structure is 160mm.

If you are going to install a home theater in the room, brick septa or foam concrete blocks are preferable than designs from drywall, passing low and high-frequency sounds (and what is the cinema?). Now, plasterboard walls are well protected from household noise (for example, human voices, as high as possible on average frequencies).

While the main way is the sound insulation of the room - an increase in the thickness of partitions. If the standard design with a 50mm profile and two sheets of GLC has a thickness of approximately 100mm, the partition on separate frames is 160mm. In this case, the sound insulation level will be comparable to the same indicator for a more massive wall thickness in one brick (280mm). And if your desire to get high sound insulation is great, you will have to put up with some loss of useful area. In the early time in private construction, special sound insulation structures and combined materials are becoming increasingly used. But this topic is so wide that it is necessary to consider it within a separate article.

Materials for the device of interroom partitions

| Material | Dimensions, mm. | Fire resistance, Ch | Mass 1m2, kg | Sound insulation index, dB | Price, $ | Cost 1m2 works, $ |

|---|---|---|---|---|---|---|

| Red full-length brick | 12025065. | 2.5 (with a septum thickness 120mm) | About 260 (in 1/2 brick) | 45. | 1-1,5 / pcs. | 9-25 |

| Gasilicate blocks | 600250150 | 1.5-3 (with a septum thickness 120mm) | 7-8 | 37-40 | 25 / m3. | 6-8 |

| Foam concrete blocks | 600300100 (200) | 2.5-4 (with the thickness of the partition 140mm) | 210. | 37-40 | 46 / m3. | 6-8 |

| Glass blocks | 19019080. | Not less than 1. | 70 (with a mass of one block of 2.5 kg) | 40-45 | 2-10 / PC. | 20-25 |

| Slagoblocks | 39018890. | About 1. | About 180. | 43-46 | 0.4-0.8 / PC. | 6-8 |

| Plasterboard partitions | - | 0.75-1.9 | 25-50 | 43-55 | 15-22 / m2 | 6-12. |

| Puzzle plates | 66750080 (100) | 2. | About 90. | 41 (for plates thick 80mm); 45 (for plates thick 100mm) | 10-11 / m2. | 2-3. |

Rates for the construction of an intercommercial septum measuring 42.70 m (thickness in 1/2 brick)

| Material | number | Cost per unit, $ | Total value of material, $ | Total cost of work, $ |

|---|---|---|---|---|

| Slital brick | 650 pcs. | 0.20 / PC. | 130. | 141. |

| Armature | 16 m / p M. | 0.50 / Pog. M. | eight | Included in the price |

| Solution | 0.5m3 | 20m3 | 10 | Masonch |

| Plaster | 500 kg | 0.10 / kg | fifty | 113. |

| Putty | 90 kg | 0.50 / kg | 45. | 84. |

| Cutting materials (to choose): | ||||

| paint | 11 kg | 7 / kg | 77. | 5 / m2. |

| Panels | 21,6m2. | 20 / m2. | 432. | 15 / m2. |

| wallpaper | 4.5 Rulona | 10 / Roll | 120. | From 4 / m2 |