So what kind of product is this - a massive floorboard? Features of the design and laying, manufacturers, prices.

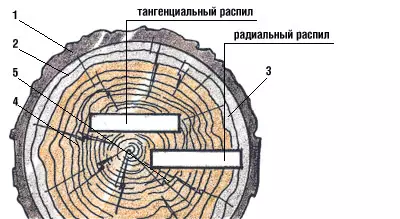

2. Cambium

3. Collot

4. Nucleus

5. Core

Photo M.Stepanov

Photo by A. Babaev

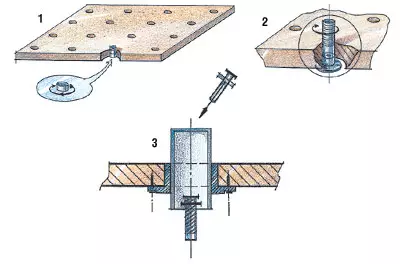

1-drill holes in plywood and the installation of plastic sleeves;

2-installation of bolts-racks in the sleeve;

3-mount bolts-racks with metal dowel-nails to the base

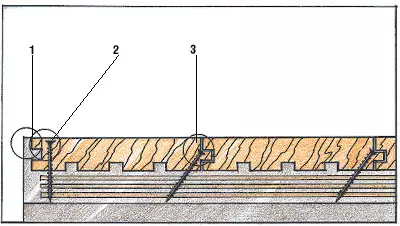

1 - between the woven coating and the walls leave the gap of 7-10 mm;

2 - fastening through the front surface of the first row;

3 - The hole is deplorable from the side of the ridge at an angle of 50

For our compatriots, the massive board of the floor simultaneously new and old. Old, because wooden board floors existed in Russia from time immemorial. New, because at certain times they were practically ousted by other floor coverings and somehow forgotten by the consumer.

Especially recently, the board as floor coatings was used in the construction of the cheapest wooden structures, such as barrarians. Many times repainted, boarding floors from coniferous "Sockeys" or "Fifty-toy" became the lot of uncomplicated country houses, wooden summer turbases, sports halls. The inadanist apartments of the old building were widely shown by parquet, linoleum, and even removed and thrown away. Anchina from the 60s in typical high-rise buildings floor board was not used at all.

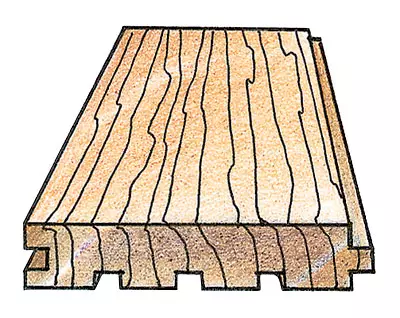

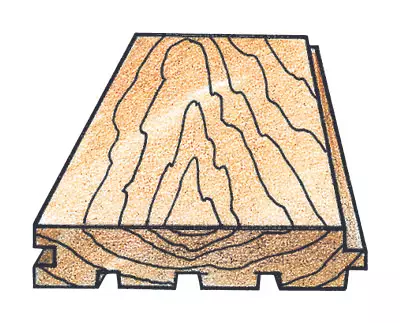

So what kind of product is such a massive floorboard? How happened that fashion came to her again from the West? Profiled large-format planks are manufactured and processed on high-precision equipment on modern technologies, achieving parquet standards. A high-quality massive board has a comb-groove on all four parties, which allows the flooring tightly. Its width ranges from 80 to 150mm, length is from 600 to 3000mm. The proposed thickness of the finished board can be 20-22mm. Domestic firms are placed on request and thicker, 30-35mm. Products are sorted by wood texture, that is, on cutting, by the presence of bitch, according to the absence of crucible and wood vices. Cooked, as you know, is tangential and radial. However, we approached the most difficult and confusing issue facing both manufacturers and sellers, and buyers. And collided, alas, the author of these lines.

Sorting

Advertising editions are trying by ads of the type: "We offer hit sales: the floor and euro-rope", as well as "Europol", "Paul ELITE board. Kach. "," Aeridarized drying ", etc. Many firms and firms, along with other lumber," chase "to the market and floors for floors. We do not undertake to say that these products are bad, but to check their quality and determine the variety by a non-specialist is quite problematic. Not to focus on epithets like "Euro" or "Elite".The premises that the implementers use under warehouses are not called dry. Very often the board lies on the wet floor, unpacked. The brisk girl, the seller-a storekeeper, pointing to one big stack of three-meter boards, says: "This is the" Select "grade. Then it shows on the other:" And this is the oak of the Robust variety. The names of varieties, of course, are beautiful, only that's what they mean? And in general, is it? Maybe in a large solid store we will explain everything? But in a large solid store, the seller could not clearly answer than the product of the premier's oak differs from a very similar, but the variety "Extra", and did not hear anything about the "robust". Although, of course, the differences are clearly traced on the price tags. One word-auction.

But, if you calm down a little and reflect, you have to admit that the trees are still a living material and, probably, is not amenable to tough standardization. Achto GOST? It turns out that there is no GOST for a massive board as such. Some clarity made employees of the company "Parquet Hall", providing us with the regulatory document to which they oriented in their work. Of course, they are guided not only by him, on the company there is a laboratory and qualified specialists work. But in a simple consumer, it will definitely be interesting, as it contains a brief and useful refusal from GOST 2695-83 "Lumber of hardwood. Technical conditions. " For comparison, we give regulatory requirements for a piece parquet and board (see table below).

In addition, in addition to sorting by cutting, the Russian selection of wood for parquet occurs in two categories - A and B. Category A (higher grade) - Assume one healthy, fragile with a tree of the bitch, on the front surface - diameter up to 15 mm, by off-diameter up to 20mm. Category B (first grade) - admissible healthy, struck with a tree of swirls (no more than 3 pieces), on the front surface-diameter to 15mm, by involve- any. Bordee categories are unacceptable unhealthy bitch, cracks, swamp.

As experts were told, for a massive board, these categories of fortiness are also in principle acceptable. But not everything is so simple. It is clear that, having such significant differences in size, parquet bar and, for example, a three-meter board cannot be sorted equally. Let us turn again to the aforementioned GOST. We will indicate only three varieties of sawn timber - 1, 2, 3rd. Details are listed in wood patterns, the norms of limiting defects in lumber are given by varieties, depending on the size of the product. At the same time, the tolerances are sufficiently large, and they increase with increasing product size.

Modern requirements for the quality of the massive board became somewhat different, much tougher. That is why large manufacturers exercise sorting according to their own criteria, often more stringent and numerous (we will negate that our own "enterprise standards" existed before). For example, the domestic company Woodroom created a system that includes 8 sorting stages from the moment of selecting a round forest to the packaging of the finished product. Three varieties are offered: "Premium", "Select" and "Natur", inside which there are two subgroups that determine the type of sawdial and tangential (mixed). "Premium" (first grade) is selected wood without any vices and defects. "Select" allows single minor ingrown knots, unacceptable falsewood wood. "Nators" solves multiple strong not drop-down swirls. Some breeds are not represented by a variety of "natures", for example, birch, beech, larch. The characteristic feature of coniferous rocks is the so-called resin pockets of wood, richly impregnated with resin (dark dashes). Based on the company standards, a larch board containing small resin pockets or a small bitch accidentally opened during processing refers to the "Select" variety.

Determination of wood moisture

To determine humidity there is a special device - an electroalloger. Its action is based on changing the electrical conductivity of wood, depending on its humidity. The needles of the device with the wires connected to them are injected into the tree and passes through them the electric current. The scale of the device shows the moisture of wood in the place where needles are introduced.

Only experienced crawler masters can determine the moisture content of the tree on the eyes. A very wet material is easy to cut, an wet trail is noticeable at the point of passage. If, when processing a planer, a thin wood chip, compressed by hand, is easily frozen, it means that the material is wet. If the chips break and crumble - the material is sufficiently dry. Identify the moisture content of wood by weight, the presence of cracks on the end or along the fibers, warming, the color of the crust and its size can only be good for the wood, their density and other physical properties. This can only specialists.

Often firms enjoy the same name, but the products are hidden in the quality of the quality. The same applies to the imported goods. Therefore, we advise you to buy material from well-proven in the market of large sellers and manufacturers. Holding a brand, they carry out strict selection. A certain criterion when choosing is the price of the product - the higher it is higher, the higher the quality. Bribing low cost here will be a bad adviser. If you decide to go on another way and plunge into the endless waves of a practically wild market, you can use the following recommendations when choosing a massive board. They do not in all correspond to the guests - in something strictly of them, in something more consolidating, but they give at least some idea of quality standards.

Grade "Higher." The front side is allowed:

- Longitudinal vanity of plastic and edge of no more than 0.5% fixed length;

- Content of healthy thorough bitch with a diameter of 3-5mm in an amount of 1 pc. on 1 p m;

- Resin pockets in quantity 1 pc. At a fixed length.

- The presence of non-current alternating cracks up to 200mm long;

- the presence of blue, not leaving on the front side;

- Non-profresing from the side of the ridge without limitation in length, provided that the crest width is at least 3mm.

Grade "First." The front side is allowed:

- Longitudinal vanity of plastic and edge of no more than 1% fixed length;

- The content of healthy inacted bitch diameter up to 20mm in the amount of 2 pcs. on 1 p m;

- The content of partially contrived and unreleased bitch with a diameter of up to 20mm in an amount of 1 pc. on 1 p m;

- Cracks are plastic and edging non-separation alternating depth and a length of 1/6 fixed thickness and lumber length;

- Cracks for non-current no longer than 200mm;

- blue and colored sampling surface stains in the form of individual spots and strips;

- Smithful pockets in the amount of 2 pcs. on 1 p m;

- Celebrations, chips, cuts depth no more than 2mm;

- Non-profresant on a length of no more than 50mm.

- the presence of non-cocked cracks in unlimited quantity;

- Non-profresing from the side of the ridge without limitation in length, provided that the crest width is at least 3mm.

Timber whose grade is defined as lower compared to the "higher" and "first", are not suitable for finishing residential premises. They are suitable for the device of draft floors, finishing of non-residential and technical premises.

Some wood flavors

Cracks. Their formation as natural factors and internal stresses affect the trunk. Throw through frosty cracks, directed radially - they appear as a result of the freezing of internal moisture in severe frosts; Rubber cracks are separated from each other of the annual layers and meticulous cracks, go along the barrel from Colely to the top. All of them arise as a result of internal stresses in the trunk. In addition, cracks can appear as a result of the height of the solid tree.

Bitch Significantly reduce the value of wood. Inside the branches, the strength decreases, since after drying, the bitch often loses communication with the base and falls. Increasing healthy bitch has a bright color, almost the same as near the nearby fabrics, and is organically connected to the texture. An unreleased falling bitch circled with a clear dark circuit in the form of a ring. The rotten bitch is usually small in size, much darker of main wood, does not fall, but worsens the appearance of the texture.

Kososala - This is the slope of the fibers, various deviations of the direction from the longitudinal axis of the tree. Wood with such a vice poorly perceives the transverse load. The claroves of the cosovation include the fiber-waveness and curl curvature of the annual layers.

Proportion - Defect that arose as a result of local mechanical damage to the fiber of a tree. Often, in this place there are mushroom spots and "squeezing". This vice spoils the appearance of the wood and makes it difficult to finish.

Mushroom lesions Arise as a result of the impact on the wood of concrete processes, it changes its mechanical properties and color.

| Product | Limit deviations from nominal values, mm | Deviation from perpendicularity of adjacent edges, mm | Deviation from the plane | Wood moisture,% | Regulations | |||

|---|---|---|---|---|---|---|---|---|

| by lenght | By width | Thick | Longitian | transverse | ||||

| Massive board | + 50 ...- 25 | 2 for boards width up to 100mm; 3 Over 100mm | 1 for boards thick up to 32mm | Not installed | 0.5% of all lengths | 1% of the whole width | twenty* | GOST 2695-83 |

| Piece parquet | 0,3. | 0,2 | 0,2 | 0,2 | 0,6mm at a length of 1 m | 0.2mm | 9 3. | GOST 862.1-85 ** |

| * - In "Parquet Hall" there is its own internal standard of wood moisture content of a massive board, which corresponds to a parquet rate and is 93%; ** - GOST 862.1-85 "Parquet products. Parquet piece. Technical conditions » |

Wood

In its microstructure, wood is a natural composite. Its fiber cells have a tubular shape and directed along the barrel. Nature provided this material as a number of advantages. Wooden thermal insulator has a small weight, has high strength, elasticity. Due to the density, the material is capable of holding metal fasteners. The greater the density of the tree of the tree, the higher the resistance to pulling the screw or nail. The hardness determines the ability of wood to resist the penetration of solids. The greater the density and hardness of the material, the smaller its wear, that is, the ability to resist the destruction.

But, along with advantages, wood has disadvantages. The properties of the tree are significantly different in the direction along or across the fibers, this phenomenon is called "anisotropy". If the tree had a hard fate and he was not lucky with the "place of registration", his barrel would certainly have vices of the structure. And the most controversial property of the tree is hygroscopicity. Single side, changing its humidity, depending on the state of the environment, wood is capable of regulating the humidity of this medium in a limited limit for man, absorbing water pairs from air (sorption) through the cell walls (sorption) or highlighting them (desorption). Solid Party, the ability to swell leads to humidity deformations, and even to reinforcement. Woven rooms with low wedge wood dries and breed. Too dry, it is easily lit, so fire hazardous.

The listed properties are different not only from different wood species. Physical features can differ significantly within the framework of the same breed and even one tree. Truly, as there are no two identical people, there are no two identical trees. For example, in the middle strip, thanks to a short vegetative period, the tree will have a higher density and small-layerness of the structure than its breed, growing south, in a more favorable climate. Even within one climatic zone of oak, grown in a swampy terrain, differs in color, a picture of an annual rings from an oak, grown on dry soil.

The idea of the structure of the trunk gives a cross section. It is possible to distinguish the following main parts: 1-cortex, 2-cambiumes, 3-cloth, 4-core, 5-core. The height of the growth of the wall of wood cells adjacent to the core, gradually change its composition, the movement of juices in this part of the barrel is terminated, the structure becomes more solid and less susceptible to loading. This part of the trunk in some breeds is called the core, in other ripe wood. Zabolov is called a young part located closer to the crust and having live cells. It is more wet, relatively easily rotates, has a smaller strength. The boards of it, unfortunately, are prone to warping and significant drying. The core is a thin "tube" in the very center of the trunk - it has low strength and easily loads.

Breeds in which the core differs from the chloride with a darker color and smaller moisture, is called "sound". The books include pine, larch, cedar, oak and others. Wasy, fir, beech, linden, the central part of the trunk differs from the chloride only with smaller humidity. This is a "peelless" breed. There are also "sabot" rocks that cannot be noticed a significant difference between the central and outer parts of the trunk. The books include birch, maple, alder, aspen, etc. Such a detailed description of the tree structure will help to understand why it is customary to distinguish products from it. So, in most breeds, radial cuts have significant advantages over the tangential, higher geometry stability and there is practically no warping by plastic. Accordingly, the price is different.

Since we started talking about woody rocks, let us dwell on those of them that are most commonly used to make a massive board.

Pine. Since ancient times, it is widely used for construction in northern and medium latitudes, as it is distinguished by a long, smooth, straight, resinous trunk. In Russia, it was decided by decisively and sheds, and exhibition pavilions. The tree is not particularly solid, but easy to work, stroke, resistant and durable in various products. Along the pine is placed easy, but across it is difficult and stupid. Sleeping well and keeps glue. The best qualities are distinguished by pine, growing on dry sandy hills (radiant, drilling). It is tight and compressed, the autumn part of each layering is relatively wide. Much worse pine, growing on swampy places (ore, Mendova). It has a pale wood and wide loose one-year layers. Pine is popular due to low prices and widespread and quite suitable for floor coverings. However, its color and structure are not very decorative, moreover, dents and scratches (for example, from heels) are easily on it.

Larch. One of the best tree breeds. Indispensable in construction. Despite the ease, her wood is distinguished by remarkable strength, surpassing in this oak and only slightly inferior to him in hardness. Equally endured both in air and in water. Due to the special composition of the resin (zhivitsa) is resistant to rotting, insect-affected by insects, does not need antiseptation. Moreover, over time, the larch wood is only gaining strength. With ordinary drying almost no harmony. With vacuum drying, he dries significantly, and when the modes non-compliance, the modes are strongly cracking. Smoothly and is well processed by a hand tool. This wood is diverse in drawing, rich in color transitions and is very expressive.

Oak. This is a solid and durable tree. On the spire, one-year layers are strongly expressed, in the spring part of which there are many pores. Special characteristic of the dub - the presence of frequent and thick core rays. Young wood is characterized by grayish brown, hardness and flexibility. Old wood yellow and fragile. A lot of oak varieties are known, but they can be divided into two groups. Cruiser includes trees growing in the south and characterized by the fact that their leaves are yellowing in the fall, but falling only in winter or even in the spring when "will" scratch "young. This kind is called winter oak, and his wood is more valuable. Another group of oaks is characterized by the fact that their acorns are sitting on long stiffs. These are the so-called spring oaks. Their wood is somewhat viscous, suchcotte and gray, it is lower in terms of its qualities. The best wood gives 80-150-year-old oak, grown in dense forests (Chernolesie). Purely oak forests are not distinguished by good trees, as the trunks of them are, as a rule, squat, thick and bitch. Specialists take oak for the standard, comparing other wood species with its wood.

Ash. It has light wood with an elegant "overflow" texture. Under favorable conditions, it can achieve a giant growth and thickness. The hardness is superior to oak. This tree is dense, heavy, but elastic. The ash is sensitive to atmospheric changes, in dry form is quite stronger, but, being raw, is easily affected by insects-anchors.

Maple. Wood is bright, almost white, with a variety of small silky splashes. It is dense, characterized by the average hardness and almost does not have a costelor. Maple is little susceptible to the charge and resist dizogt well, it's beautifully plastered and ourselves, for which he has always been loved by masters-in-masts (remember at least "Songy new, maples ..."). Klennodniquia maple include maple plain, maple white, yavor, plane. The latter is characterized by more dense wood beautiful pinkish yellow color with brown specks.

Beech. A rather capricious breed with pinkish-brown wood and many large-in-dark brilliant enclosures. Little inferior on the strength of the oak, but when drying is very much breeding. Previously, the tree is less brewing, he was cut down in the middle of summer, and then, after the year, they saw on the boards, which put into the water and kept in it during the apex. The beech the beech is easily strung and after drying, it retains the attached shape for a long time. This quality was used in the production of the famous bent of Vienna furniture. Well suitable for the manufacture of veneer.

Birch. It is characterized by very light, almost white wood with barely noticeable texture. Valid dreams from other breeds, birch does not have significant differences in the properties of radial and tangential saws, its swamp is almost no different from the sound wood. It turns out perfectly, sills, sawing and plane. Slowly and hardly enhances, and he is very cracking and rushing. In general, birch caprit, as it is sensitive to humidity. The best wood gives aged 40-50 years, and then its good qualities progressively decrease. Old wood is darker.

Rosewood. Grows in the hot climate of South America and East India. Beautiful, valuable, but very expensive material with a pleasant smell, for which he used to be called "violet tree." Wood is very solid, dense, thin-fiber and porous, although in terms of strength is inferior to the red tree. Dark brown with purple bodies alternate with yellowish-ocher, forming a beautiful drawing. Over time, the rosewood darkens to black.

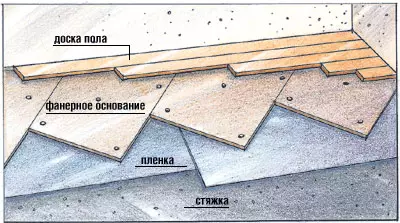

Laying a massive board

The massive board should be laid in rooms that meet the technical requirements for flooring of natural wood coatings. Mandatory is compliance with the following conditions:

- All materials applied must pass acclimatization in the room where it will be mounted, for at least three days (better than a week).

- Wood moisture should be 8-10% (the maximum permissible is considered to be 12%).

- Floor coatings are stacked at the final repair stage.

- The windows and door boxes should be installed in the premises, aligned and how the ceilings, walls and, of course, the screed should be sucked.

- A ceramic tile laying should be completed, as it is a "wet process", especially if there is an interconnection in one room of two floor coatings (for example, when combining the kitchen and living room).

- Well, if the relative humidity indoor air humidity is at 40-60%.

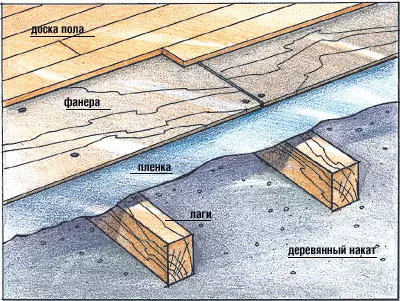

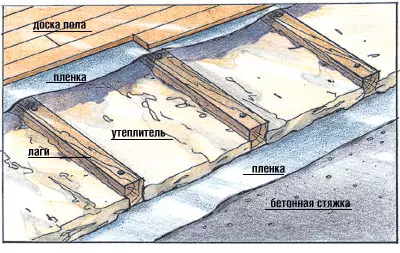

Naturally, afterwards with a beautiful expensive outdoor coating, there were no problems, it is necessary to correctly prepare the basis for it. The methods of the base device are several. The appropriate option should be chosen depending on the type of overlap in the house, as well as your desires and material opportunities. The massive board can be placed on reinforced concrete floors: on the screed and lags; on the screed and fane; on lags and paneur without pouring a screed; on adjustable faeer. On wooden and mixed overlaps, it is placed on lags and faera; on lags and plates (OSP, chipboard, fiberboard); on lags and wooden flooring. We will tell you in more detail on the preparation of the grounds for the installation of chisty floor coverings in our following publications.

Before laying the board, a coarse grinding of a slab or a dumping base with a ribbon grinding machine with an abrasive ribbon graininess of 40 or 63 (P30 or P40) is carried out. The ground base is cleaned of dust. The massive board is attached to it with a samples of 335-14mm samples with a pitch of 20-30 cm. Pre-board is climbed by the spike side at an angle of 50. The first row is mounted as a groove to the wall. If the coating is placed on a flat base (plywood, osp, wooden flooring), it is recommended to use parquet glue, which is applied with a spatula on the base surface. However, it is impossible to lay the board only for glue. It only improves the quality of laying, but is not a mandatory component when installing, the mounting self-draws is necessary in any case.

The laid floorboards are snugged in transverse and longitudinal directions. If necessary, they are tightened with wedges. Between the waters and walls around the perimeter necessarily makes a gap of 7-10mm width. The first and the last rows of boards are fixed with self-proofs and through the facial surface, but so that in the future the fasteners turned out to be hidden plinth. When laying a boards, more than 150 cm wide is also recommended additional mounting through the front surface. Facial self-tapping screws are interpreted to a depth of 9-10mm and closed with impudent (preferably of the wood of the same breed).

If an array in the factory conditions, in the production, no coating is not applied, the board is grinning and covered at the request of tinting, oil, wax, or (more often) varnish. It should be noted that grinding makes sense to spend to eliminate all the lights of the installation so that the surface becomes perfectly smooth.

For the most part of the area, it is recommended to use tape and disk grinders, in hard-to-reach places, along the walls, in the corners are small hand and special angular. Abrasive tape is taken, sequentially reducing the graininess: first 100, then 80 and 60. The finish treatment is made by a disk machine using abrasive circles with a grain of 120 or 160 μm. Grinding is always carried out in the direction of laying the floor. If all the technical conditions are observed on the installation of the coating, to reach the surface of the perfect quality is removed in the amount of not more than 1mm wood.

After the end of grinding and careful removal from the surface of the dust immediately proceed to the coating of the board with varnish. If it is supposed to tint the tree, first apply a toning composition, and then varnish. Since grinding reveals the structure of the wood, during the first applix, the varnish penetrates deeply into the pores. It is recommended to apply at least three layers of varnish, producing intermediate grinding with a disk machine. Varnish, wax and oil compositions are designed not only to give the flooring more attractive form, but also protect wood from mechanical damage and moisture penetration.

| Manufacturer | Wood breed | Variety | The size | Price, $ for 1m2 |

|---|---|---|---|---|

| Royal Woodkraft, United Kingdom | Beech | "Natur" | 120012022. | 72. |

| "Select" | 120012022. | 111. | ||

| Oak | Country | 120012022. | 59. | |

| "Natur" | 120012022. | 77. | ||

| "Select" | 120012022. | 119. | ||

| Maple | Country | 120012022. | 75. | |

| "Natur" | 120012022. | 95. | ||

| "Select" | 120012022. | 149. | ||

| Leonardo, Italy | Dossia | - | 120012022. | 93. |

| Iroko | - | 120012022. | 96. | |

| Maple | "Natur" | 120012022. | 103. | |

| Ash | "Natur" | 120012022. | 87. | |

| Nolte, Germany | Oak | "Natur Antik" | From 100013221. | 120. |

| "Rustic Antique" | From 100013221. | 111. | ||

| "Natur" bleached | From 100012521 | 149. | ||

| "Natur" | From 100012521. | 97. | ||

| "Rustic" | From 100013221. | 85. | ||

| Flounder | - | From 100013221. | 121. | |

| Maple | MARKANT | From 100012521 | 137. | |

| "Natur" | From 100012521. | 177. | ||

| Macoera | - | From 100013221. | 143. | |

| Mahagon | - | From 100013221. | 141. | |

| Merbau | - | From 100013221. | 111. | |

| Woodroom, Russia | Oak, ash | "Premium", radial cut | 600-150080-90 | 55. |

| 600-1500127-135 | 75. | |||

| "Select", radial cut | 600-150080-90 | 45. | ||

| 600-1500127-135 | 60. | |||

| "Premium", tangential cut | 600-1500127-135 | 55. | ||

| Larch | "Premium", radial cut | 600-150080-90 | 36. | |

| 600-1500127-135 | 46. | |||

| "Select", radial cut | 600-150080-90 | thirty | ||

| 600-1500127-135 | 40. | |||

| "Premium", tangential cut | 600-1500105-110 | 32. | ||

| Beech | "Premium", radial cut | 600-150080-90 | 55. | |

| 600-1500127-135 | 65. | |||

| "Select", radial cut | 600-150080-90 | 45. | ||

| 600-1500127-135 | 55. | |||

| Matimex, Russia | Oak | "Natur" | 600-180012520. | 62. |

| Beech | "Natur" | 600-180012520. | 62. | |

| Ash Russian | "Natur" | 600-180012520. | 62. | |

| Clean Canadian | "Select" | 600-180012520. | 90. | |

| Maple Canadian | "Select" | 600-180012520. | 110. | |

| American American | "Natur" | 600-180012520. | 155. | |

| Wenge Zair. | "Natur" | 600-180012520. | 228. | |

| "Obninsky Parquet Plant", Russia | Oak | "Extra" | 120012020. | 49. |

| "Natur" | 120012020. | 34. | ||

| "Radial" | 120012020. | 59. | ||

| "Option" | 100014022. | 42. | ||

| Ash | "Premier" | 140014022. | 67. | |

| "Option" | 140014022. | 57. | ||

| Beech | "Premier" | 160012022. | 62. | |

| "Option" | 100014022. | 42. | ||

| Junckers, Denmark | Oil-treated oak | "Classic" | 240012920.5 | 126. |

| "Harmoy" | 240012920.5 | 116. | ||

| "Variation" | 240012920.5 | 109. | ||

| Merbau | - | 220012920.5 | 100-109 S. | |

| "Siberian Master", Russia | Oak | "Extra" | 200012522. | 54. |

| "Class A" | 200012522. | 47. | ||

| Larch | "Elite", radial cut | 1000-250013022. | 39. | |

| "Sort A", radial cut | 1000-250013022. | 32. |

The editors are grateful to Woodroom companies, Parquet Hall, Parquet Center for the materials provided.