Laminated floor covering: market overview. Manufacturing, drawings and textures, installation methods. Manufacturers and prices.

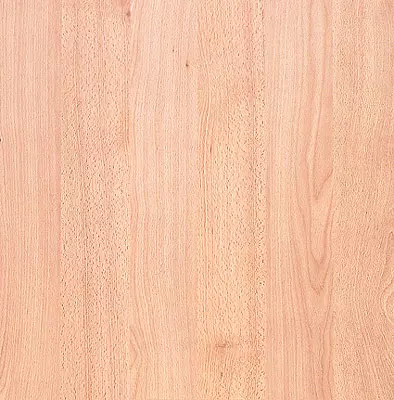

The surface of the laminated panels Living Surface from Unilin Decor is as close as possible to the texture of a living tree.

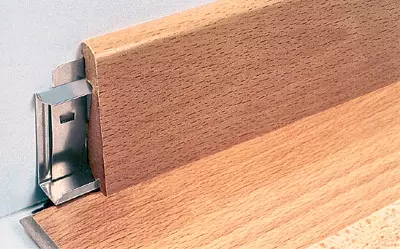

To simplify work and install plinths without screws and glue, you can use removable clamps

Laminated coatings are suitable for mounting on warm floors. Mention of this should be on the package with panels

How to be if you want to have a wooden floor, but without the shortcomings inherent in a natural parquet board? The solution to the problem may become a laminated floor covering, a relatively new class of materials developed in the early 80s of the last century.

What is laminate?

Let us immediately argue: we will create laminated flooring for brevity with laminates. In fact, the laminate (from English Laminate) is just a film layered material. But in everyday life, many use this word just to designate laminated flooring, although in fact it is not entirely true.Have you ever watched how the documents roll in plastic? The spokest of the special apparatus-laminator-sheet of paper under low pressure is pulled through the rollers between two layers of a thick plastic film. The resulting plastic coating gives the paper stiffness, protects it from abrasion. Approximately the same principle manufactures laminated parquet. Only instead of paper is processed by the bearing base HDF base, and synthetic resins and various coatings are used as a kind of "film". In other words, the lamination process involves the scrupping of each other of various materials, as a result of which a qualitatively new product is formed.

The form of laminated coatings are practically no different from the natural parquet. Plus, they possess a lot of their own advantages, among which the most significant: lower price and higher wear resistance. There are such floors from the size of about 1200200mm in size. The panel itself has a multi-layered structure, with each layer made of a certain material and performs its special function. And although the number of layers and materials from different manufacturers may differ, fundamentally multi-layered design remains unchanged. Lovely laminated parquet, at least four main layers.

The carrier base of the laminate is the average layer - water-resistant wood-fiber plate (HDF). From above, it is covered with a decorative layer with an infused pattern that imitates the natural parquet of the tree of wood. To increase the impact resistance and give the additional rigidity of the entire surface of the panel (including its edges), several layers of craft-paper with impregnation from synthetic resins are administered between the decorative coating and the bearing base. On the decorative layer, in turn, apply the upper protective coating of transparent melamine or acrylate resins. It is it that gives the laminated semi wear, light and heat resistance, as well as mechanical strength, making it insensitive to impact heels, pressure legs of severe furniture, burning cigarettes. But that's not all. You are practically not limited to the choice of detergents when you need to remove non-dangling paint stains from the floor of the floor or, say, traces from the marker, it is possible to use even acetone!

In the highest-quality brands of laminate for the sake of increasing wear resistance in the resin, particles of corundum are added (the mineral is so solid that diamonds are treated) or aluminum dioxide crystalline (synthetic analog of corundum).

Finally, on the bottomside, the laminated panel is coated with a stabilizing layer of paraffinated or impregnated paper resin (thickness from0.1 to0.8 mm), or a layer of plastic (thickness from0.4 to0.8). It performs two functions: first, does not give moisture to penetrate the plate; Secondly, balancing bending stresses at the base (they occur when the upper layers of resin and glue are cured), which does not allow the entire panel.

But this case does not end. One of the latest trends in the class of laminated flooring was the appearance of an additional lower layer-absorbing. It milds not only blows from drops or knock heels, but also a general background noise indoors. Moreover, different manufacturers here have their own, original, solutions that we will talk later.

It may seem that such a multilayer "cake" is obtained quite thick, but this is not so. The total thickness of the panel is from 6.2 to 11mm. Most manufacturers produce laminates with a thickness of 6.5-12mm (for comparison: a natural parquet plate has a thickness of 15mm.).

HIGH PRESSURE AND DIRECT PRESSURE

There are two technologies for obtaining laminates, each of which directly affects the most important characteristics of the product, the resistance of abrasion and the blastiness.

The layers are manufactured separately and glued. All operations are carried out under high pressure. Let's start with the HPL labeling, which means High Pressure Laminate, or high pressure laminate. The process is quite complex and expensive, and parquet with such a coating refers to the upper price level ($ 27-40 per 1m2). I will not be in vain. First, the HPL-laminate strength is the same at each point of the panel, secondly, the protective layer can be made thicker, up to 0.9mm, and this is the pledge of the durability of the floor covering, its strength and resistance to intensive loads. The coating turns out to be so strong that some firms give on their collections a fifty year warranty for household premises from abrasion, the formation of spots and loss of color. The guarantee of the Original and Kitchen families from Pergo and the Commercial and Original collections from Alloc has a similar warranty.

In the accompanying documentation, you can often find the HDF abbreviation. By structure, this is an analogue of domestic fiberboard. HDF labeling (high density fibreboard) means that the bearing base of the panel is made of high density plates (more than 800 kg / m3). All modern laminated floors are made precisely from HDF, because the density of the base is a very significant factor, directly affecting the technical characteristics of the coating. The higher the density, theme, respectively, above and the mechanical strength of the slab on the break, impact resistance, pressure resistance and long-term loads. The most importantly, the resistance of moisture is also improved.

Another laminate-dpl manufacturing technology (Direct Pressure Laminate, or direct pressing) is that all layers of which future laminate panel will be consisting under the press and glued at the same time. As a result, the starting materials change their physicochemical properties, sparking in a single integer panel. The use of DPL technology has significantly reduced production, which means that massively produce laminated high-quality coatings available to consumers with any level of income.

Parquet with direct pressing laminate is offered by most manufacturers, and this product enters the optimal average price niche ($ 12-21 per 1M2). The quality of the coating does not suffer: the company Jurgi (Austria), for example, releases several collections designed for floors with high, middle and small loads (respectively, Floor 31 Click, Floorlevel 32 Click and Floorline 33 click), precisely from multi-layer direct pressing plates.

Wear resistance of the coating, of course, lower than that of HPL laminate. However, the floor is guaranteed to serve in your apartment for 5-7 years.

Its special technology for the manufacture of laminate, the name of EleSGO, patented the HDM concern. The method is that the decorative surface on the basis of an acrylate resin is curated using an electron beam, without the use of high temperatures and pressure. Due to this, the surface of the laminate becomes not only strong, but also antistatic. The result is the surface of the parquet does not accumulate static electricity, so the dust does not attract to the floor and it is enough to use dry or slightly damp cloth.

Are you azure stone or antique pine?

Modern laminated floor will provide you with a sea of opportunities for elegant and extraordinary interior design. Since the laminate manufacturing technology is such that in the diversity of drawings and textures, manufacturers are not limited to anything, pick up the necessary tone of the floor covering for a room with aged in any style will not be difficult. The most popular coatings, copying natural parquet and massive boards, and a classic "Christmas tree". Vggazines can be found laminate, imitating almost all the woods of the tree: oak, maple, beech, nut, rosewood, elm, birch, etc. It does not come out of fashion and design under ancient, natural, natural and cream oak always in price. Standard neutral shades (let's say, beech or maple), as well as a cherry tree.Among the latest developments, the laminated country-style floors can be noted, imitating the appearance of the rustic houses. The panels of such floors have a rounded V-shaped cant with a continuous cladding, which increases the strength of the flooring and gives them a natural look. Such products are released, for example, HDM (Collection of Country Floor) and Unilin Decor (Perspective).

In the kitchen and in the corridor, a coating under ceramic tile or natural stone can be used. At the same time, the panels themselves quite often have a type of tiles of approximately 400400mm, 1200400mm. Series of floors under the tile can be found among the products of Berry Floor (Tiles Collection) or Witex (CASA). An interesting development was the laminated Parquet Superglanz Floor from HDM with an absolutely mirrored surface of the surface. As a result of a combination of unusual decors (as a cube-blue stone on the floor?) And a special brilliant effect, the surface has acquired a deep and at the same way, even a refined view.

Click - and ready: Paul on the castle

Mount the laminated floors can be easily and fast. The panels are glued, they are tightened with each other brackets or are connected using different grooves and protruding ridges (tongs) forming a dense lock connection. Vitoga will decorate your apartment smooth, without gaps and noticeable seams, a coating that does not need to be kniting or glued to the rough floor, since the laying "floating". Inet dust, chips, knocks and squealing machines, which is always in the oppression when working with natural parquet.

When assembling floor panels, they are bonded with each other with the help of a lock based on the "Spool-PAZ" system. It happens that the panels located in the horizontal plane are connected alone on the other with the long end side (such a system of HARO floors).

The unique castle called Quick Step Uniclic patented the Belgian company UniLin Decor. Thanks to the original design of the tongue compound, you can dock the panels in two ways: by inserting the crest in the groove or the groove nozzle to the crest. Depending on the specific situation, the panel fit can be made by placing the mounted panel at an angle of 20-30 to the already installed (rotation method) or connecting the panel in the horizontal plane (sliding method). The most common is the rotation method. The second method is used in cases where, for example, you need to connect the panels along the short edge, while their long sides are already fitted or when the panels are rotated (when laying flooring under the door boxes or radiators). Thanks to the small thickness of the panels (8-9.5mm), the Quick Step floor system can be installed on the existing old coating, without "configuring" thresholds and without changing doors.

Quick Step Uniclic Castle provides tight fit of the panels to each other, and the docking seams become almost invisible. By the way, their strength is such that after the docking panel is able to withstand the tearing force of 450kg / mb, both along and across the edges.

The Quick Step Uniclic Castle Design from Unilin Decor was so successful that other manufacturers, in particular, HDM, Witex, Kronotex, Pergo acquired a license for its application.

Alloc, whose laminated panels have a mansion, whose laminated panels have an aluminum castle system that holds laid boards with higher strength than fibrous locks. On floors with aluminum locks you can safely put heavy furniture, without fear of separation of boards. In addition, the floor can be repeatedly disassembled and laid in another place - the compound will preserve the initial strength.

An important question that will definitely stand in front of you when you come to the store to buy a laminate: what is the connection of the panels prefer - adhesive or inflamped? At present, almost all firms produce laminate with a locking compound that do not require bonding. Adhesive options are gradually removed from production. The introduction of new technologies allowed firms to guarantee the density and strength of the connection of panels without any gaps.

And yet a number of companies continue to produce adhesive laminated floors (by the way, they are now 9-11% cheaper than blissful). Kslov, from the company HDM each collection has a glue, and a glossless connection. Wet have its own sharms. Some builders believe that glued laminated parquet is more durable and durable than Besleva. However, the implose method of assembly has more advantages.

Start at least with the speed of installation. To put a laminate with locks, it is necessary in 2 times less time than for styling without them. Higher coating price is compensated by a relatively low cost of work with it.

The floors on the adhesive compound can be operated only after 10 hours (the best in total, after a day). Sometimes this happens unacceptable, for example, if you finish the room one after another and there is no time to wait, when you can rearrange the furniture. The locking method of installation in general will relieve you from the need to release the whole room to unlax. Parquet coating is ready to use immediately after the end of the work. As for prices for services for laying a laminate, the installation of the adhesive coating costs $ 8-10 per 1m2, the Besleless is more than $ 5. The difference in price (about $ 4) between the floors of the two types is compensated on the assembly: work with adhesive compound it is advisable to entrust professionals.

When laying outdoor coating with adhesive method, you should consider several features of working with laminates. Forward turn, this is due to the basis of the HDF-slabs panel. Soda side, laminate with such a basis well perceives the load and is distinguished by moisture resistance. But on the other, the gluing of the panels can be quite complicated by each other. The fact is that the higher the density of the material, the less deep and slowly penetrates the glue, and therefore the connection becomes less durable. In this case, securely docile panels with each other only manually is quite difficult. Manufacturers firms recommend using special devices - wedges, brackets, screed or clamps.

Be prepared for the fact that the finishers, absolutely not familiar with the right system of laying laminated parquet and accustomed to do everything in their own way, will express discontent when you will require them to comply with the subtleties of the installation technology. Meanwhile, the docking seam is the weakest place of laminated floors, which are not attached to the rough base, and hold in the desired position in their own weight. Such floors are called "floating". The mobility of poorly glued together panels can lead to a violation of the tightness of the coating - the vitoch of its elements will be dispelled and curved.

Manufacturers

The largest suppliers of laminated parquet floors to Russia are Pergoab (Trademark Pergo, Sweden), Unilin Decor (QUICK STEP), Berry Floor (Belgium), E.P.I. (France), Classen, Hamberger IndustRiewerke (Brand Haro), HDM, Kronotex, Tarkett Sommer, Witex (all Germany), Alloc (Norway), Jurgi (Austria), etc. However, 90% of all production of laminated flooring provides a dozen major firms. World leaders in the production of laminated floors - Kronotex, Witex, Unilin Decor, Pergo AB.| Firm (country) | Collection | Dimensions, mm. | Abrasion class | Load class | The presence of waterproof impregnation | Application area | Guarantee, | Price 1m2, $ |

|---|---|---|---|---|---|---|---|---|

| Haro (Germany) | Tritty75 | 12821957. | AC3 | 23, 31. | +. | For laying on already existing flooring | 10 | 17,25 |

| Tritty100. | 12821957. | AC4. | 23, 33. | +. | Massive floor for heavy loads | 12 | 23,1 | |

| Tritty 250. | 12821957. | AC3, AC3. | 23, 33. | +. | For highly loaded floors; for commercial and residential purposes | fifteen | 29. | |

| Alloc (Norway) | Universal | 119518610.8 | AC3, AC4. | 23, 32. | +. | For floors with any load in the residential premises | Life | 32. |

| Original. | 12071939.5 | AC3, AC4 | 23, 32. | +. | For floors with a moderate load in residential premises | Life | 33. | |

| Kronoflooring (Germany) | Kronostep. | 12081918. | AC4. | 23, 32. | - | For highly loaded floors in residential premises | 12 | 13 |

| Kronotex (Germany) | Dynamic | 13801958. | AC3 | 31. | +. | For premises with high load | 10 | 13 |

| Lambada Click-2-Click | 13761918. | AC3 | 31. | +. | For floors with high load: in the hallway, living room, children's, etc. | 10 | fourteen | |

| Unilin Decor (Belgium) | QUICK STEP800. | 12001908. | AC5 | 33. | +. | For floors with intense load in residential premises | 10 | 32. |

| QUIK STEP800 MAJESTIC | 12001908. | AC5 | 33. | +. | For highly loaded floors in residential premises | twenty | 32. | |

| Tarkett Sommer (Sweden) | Loggia SLS. | 12881907. | AC3 | 23. | +. | For highly loaded floors in residential premises | 7. | 17. |

| Villa SLS. | 12881908. | AC4. | 32. | - | For floors with a large load in residential premises | 10 | nineteen | |

| BERRY FLOOR (Belgium) | REGENCY. | 12851208. | AC3 | 23, 31. | - | For floors with intense load in residential premises | 10 | 26. |

| Tiles. | 11902948. | AC3 | 23, 31. | +. | For floors with a large load in residential premises | 12 | 28. | |

| HDM (Germany) | Premium. | 11861906,2 | AC3. | 23. | - | For floors with a large load in residential premises | 10 | 7.6 |

| Imperial | 11861908. | AC3. | 31. | +. | For floors with intense load in any rooms | 10 | 9.5 | |

| Superglanz. | 11841857. | AC3 | 23. | +. | For floors with intense load in any rooms | 10 | 14.8. | |

| Wellness | 11841857.7 | AC3. | 31. | +. | For floors with intense load in any rooms | fourteen | 11.5. | |

| PERGO (Sweden) | Kitchen. | 11981988. | AC5 | 33. | +. | For intensively exploited floors in residential premises | Life | 32. |

| Comfort. | 11981987. | AC5 | 33. | +. | For floors with high load in residential premises | fifteen | 24. | |

| Original. | 11941948. | AC5 | 33. | +. | For floors with high load in residential premises | Life | 32. | |

| CLASSEN (Germany) | Allegro. | 12901948. | AC3 | 23, 31. | - | For floors with high load in residential premises | 10 | eight |

| Presto. | 12901948. | AC4. | 32. | +. | For floors with high load in residential premises | 10 | 11,2 | |

| Witex (Germany) | Casa. | 11983968. | AC3. | 23, 31. | +. | For floors with a large load in residential premises | 10 | thirty |

| Comcom | 12801928. | AC3. | 23, 31. | +. | For floors with a large load in residential premises | 10 | 28.5 |

His floor for each room

When the question arises about buying a laminate, first of all, you need to decide where you put it and what load is intense, medium or insignificant, it will be on the floor covering in each particular room. In order not to overpay, divide your dwelling on the functional areas: hallway, kitchen, bedroom, children's, living room (hall). Then evaluate where the floors are subjected to maximum and minimal abrasion loads. Let's say the hallway and the kitchen is perhaps the most rigidly exploited parts of the apartment. Here you will need wear and moisture-resistant coating. As a rule, laminates 21, 22, 23 grade class laminates are recommended for residential premises. Typically, the warranty on such floors does not exceed 10-15 years. But if you want the coating troubles and further, it is better to buy laminates 31, 32 or 33 class. True, they are created for public premises, but it is originally designed for a more serious load. The optimal option can be the use of 31st class laminates in the kitchen, in the hallway and living room. For residential rooms with low load-bedroom intensity, libraries, the cabinet is quite suitable for the 23rd class coating.

As a rule, manufacturers indicate which types of premises this or that coating is recommended. What, first of all, makes sense to pay attention?

Water resistance. Laminate serves as long as its weak part is strong. This most vulnerable place was always the pair of one boards on the other. As a rule, laminate is afraid of direct water from entering the connection between the panels. In principle, the top layer of high-quality laminate does not suffer from short-term contact with water, even if you remove it from the surface in an hour. A small amount of moisture that fell under the laminate will evaporate with time, because it, like natural parquet, breathes. But if the liquid penetrates into the pairing, and then the base of the board, the HDF-stove increases in size, swelling, and the floor is covered with seaside ripples, as a result of which it can "lead the screw". The swollen areas of the pairs are over the common plane and, when we walk on them, are subjected to the most intensive loads, wearing prematurely wear and abruptly. Therefore, manufacturers tend to protect the coating by all ways.

When do not go on tiptoe

In accordance with European standards, all outdoor laminates pass a series of tests for abrasion resistance, impact resistance, light-resistance, formaldehyde content, etc. (In total, 18Tests are provided). After each test, the coating is assigned a specific class, and then the class of the entire laminated floor is determined by the smallest indicator. The service life of each collection of laminate floors declared by manufacturers determines the type of premises in which such floors can be operated. Therefore, if you large the 21st class laminate in the hallway, do not be surprised that in one year-another floor will come into disrepair.

Load classes for laminated flooring

| Load class | Application area | Load level when used | Abrasion class on European standards EN13329 |

|---|---|---|---|

| 21. | Residential premises: Bedroom, Cabinet | Easy | AC1 |

| 22. | Residential premises: living room, children's | Average | AC2. |

| 23. | Residential premises: entrance hall, kitchen | High | AC3. |

| 31. | Public rooms and residential premises with intensive load | Easy | AC3. |

| 32. | Public and commercial premises: boutiques, offices | Average | AC4. |

| 33. | Public and commercial premises: shops, gyms, bars, restaurants | High | AC5 |

Noise isolation. Until recently, most firms offered a separate product with a special polymer film with a thickness of 2mm as a sound insulation substrate under laminate. This material was called up to muffle modulation noise (let's say, the knock of the heel). Nefirma Tarkett Sommer, for example, such a film is called SoundBlock Foam. Now many manufacturers began to fix the insulating layer directly on the reverse side of each panel, eliminating consumers from the need to buy and retain rolled materials. Acclaimed, HDM focus on the reverse side of the WELLNESS FLOOR collection panels a special layer (2mm) based on the thermosetting plastic Laminopax, having a view of the beesh cell (4600YCs per 1m2). Spatial noises, as well as shock noise arising when walking on the floor, are almost completely absorbed by such a structure due to sound reflection by opposite walls of cells. As a result, noise indoors decreases by 50%. The sound-absorbing gasket Unisound for the floors of Quick Step is offered both in the form of a roll material and in the form of an accrued substrate, which reduces the installation time and additionally gives an anti-acoustic effect by 20%. Unisound muffles the sound and creates a feeling of durable floor from a natural tree.

Guarantee

Specify from the seller, under what conditions the manufacturer will exercise its warranty obligations and what document will be a confirmation of such obligations. Pergo, together with laminate, transfers through the seller a special written warranty on its products. The document is filled directly when making a purchase, and one part it is issued to you, and the other enters the Russian representative office of the company. Reminder of other firms Warranty card is located inside the packaging with laminate.

Prices

For each improvement in the parquet panel design you have to pay. This applies to the thickness of the laminated layer and the bearing base, the reliability of the lock, the presence of additional protection against moisture and the noise absorbing layers. Of course, there are floors at a price of $ 5-7 for 1m2. But so many high-quality laminate such products are difficult to name. The cost of the inexpensive, "decent" parquet begins with a mark of $ 9-15 / m2 (among such products it is possible to name the products of the Kronotex concern). Economy floors, optimal in terms of price-quality ratio, cost $ 12-22 / m2 (Lamindes from HDM, Haro, Tarkett, Unilin Decor, etc.) are categories category. Camiy dear laminated coatings will be sold at a price of $ 26 to $ 40 / m2. Such products can be found from Pergo, Alloc and Witex firms.

The editors thanks the company "Parquet-M", HDM, "March", "Elit Parquet", "Polimpex", "Stroydecor" for help in the preparation of material.