Find the optimal solution when choosing a material for a roof is sometimes very difficult. Where to begin? How to avoid mistakes? Why "crying" roof?

pee from a couple of water- phenomenon are quite unpleasant

Sexian moisture

This is a bullle of energy at home.

Anatoly Krivtsov, architect

Three term issued in the title are often perceived as different names of the same. WHAT is the concepts different from each other, but very closely related. Help readers understand the essence of the question and avoid mistakes when choosing materials for creating roofing errors that can lead to a violation of its normal functioning, the task of our publication.

Part I.

Roofing materials

With the arrival of the summer season, everyone who builds or repairs a country house, necessarily faces the question: how to make a roof more durable and at the same time beautiful, so that the architecture does not spoil, and the neighbors of Akhali. There is no problem in Russia now in Russia. Order any- will bring and mounted. That's just finding the optimal solution sometimes it is very difficult. Some of the roofing materials in each store are up to a dozen species. Here let's talk about similarities and differences between them.If you take the floor to the classification of roofs according to the type of waterproofing layer, you can select roll, leaf and type (from small-piece elements) of the coating.

Rolled roofs

Rolled roofs are made of bitumen and bitumen-polymeric materials with a reinforcing base (synthetic, cardboard, from glass cholester or elastomeric vulcanized film materials). How is it not to remember the well-known reference root-bitumen coating on a cardboard basis! But this is yesterday, so many familiar material of the shortcomings: low frost and heat resistance, exposure to rotting, deterioration of elasticity under the influence of solar radiation.

If you decide to protect against bad weather buildings (especially with flat roofs), shed, garage or update the canopy, the most reasonable to buy modern polymer materials that have replaced the rubberoid. The most widely used three of their types: bitumen-polymer, polymer and mastic roll coatings. Everyone is superior to the rubberoid both at the price and service life. For the rubberoid roll (115m) of the RPP-300 brand, you pay $ 4, and bitumen-polymer coatings will cost $ 20-40. But they serve from 15 to 20 years old, and the roof turns out again in one and a half cheaper regteroids, because you do not have to regularly reproduce the roof, pay a new rubberoid and work on its installation.

Rolled roofs from a combination of bitumen and polymers are at the heart not resolved polyester, fiberglass or glassball. The addition of polymer modifiers to the binder (bitumen) gives the defined heat and frost resistance and elasticity to the binding material, prevents the formation of cracks and, therefore, increases the durability of the coating. As for the basis, the glass christmas is the cheapest option. It, like cardboard, is fragile, so the materials based on it is better to apply as a lining layer. Polyester and fiberglass 1.5-2 times more than glass chill than significantly increase the service life of the material and reduce the risk of damage to the roofing carpet during operation. The panels are fill with the method of moving on the base of concrete, metal or glued with mastic.

Bituminous polymer roofs are divided into materials with binding from oxidized bitumen ("Locarrome", "Bikrost") and actually bitumen-polymer ("Bicroplast", "Isoplast"). It and others retain sufficient flexibility at a temperature of 15-25 ° C, have a heat resistance of 100-150s and is quite resistant to ultraviolet radiation. All modern bitumen materials have a sufficiently large thickness (from3mm), which makes it possible to significantly reduce the number of layers of roofing or waterproofing carpet compared to the rubberoid without any loss in reliability and durability.

"Locur" and "Bikrost" is quite strong materials with a thickness of at least 3mm, the coating of them serves 7-9 years. They are well suited for both the bottom layer of the roof and waterproofing (kept the water layer to 52mm). "Bikroplast" and "Isoplast" are more expensive. But this is complete bituminous polymeric materials, the coating of which will serve 15-20 years in any climatic conditions. Bitumen-polymer materials in rolls 70-100 cm wide and from 7 to 20m long, both Russian ("thermoplast", "Philestone", "TechnoNIKOL", "Gerbierit") and foreign manufacturers, such as Finnish firms Lemminkainen, Icopal (coatings LiimaultRa and PintaultRa) and KatePal (Tupla Roll Roofs).

Soft roofs

Under the concept of "soft roof" there is a flexible bitumen tile (it is also called roofing tiles or shingles). It is small flat sheets (their usual dimensions - approximately 10034cm) with figured petals or petals on one edge. Petals can have the kind of regular or elongated hexagon, pentagons and rectangles, "fish scales", etc.Flexible tile looks great on the roofs of houses of any architecture. Its main advantage is that the material can be used for the roofs of the most varying degrees of complexity, form and configuration, up to the domes and bulbous roofs, providing almost complete tightness. It is lightweight and inexpensive material ($ 7-8 per 1m2). On 1m2 roofing consumes almost 7lists, the mass of which is 18.5 to 11kg.

Bituminous tile has a multi-layer structure. The base is pre-impregnated with a modified bitumen glass cholester (prevents deformation, which is very important for a material exposed to longitudinal loads). Ddvu sides it is covered by a modified or oxidized bitumen. A color stone or mineral sprinkver is applied from above, and below the silicon sand. The sprinkles allow not only to "color" the front side of the tile in different colors, but also to extend the material in the fight against weather by eating rains, snowfall, hail, etc.

The tiles are applied to the lower plane of each tile (truncation). A variant is possible when 100% of the lower surface is covered with glue, thereby ensuring the complete tightness of the roof, and the installation procedure is significantly facilitated. But sometimes the adhesive layer occupies 60% of the surface (for example, in roofing tiles from Katepal and Tegola). At the plant, such a layer is protected by a special silicone film, which is removed immediately before gluing the tile in place. At the flooring of the brand, the sticky surface is superimposed on the roofing tile laid below, and under the influence of solar heating, the sheets are bumping among themselves, forming absolutely hermetic, almost monolithic coating, hiding joints of the strips and the hts of mounting nails. Such a coating does not force the wind!

Unlike many roll roofs, a soft bituminous tile is perfectly withstanding high temperatures on a hot sunny day (bitumen softening point is within 110-120C). Therefore, for concerns that the coating starts to fill, there is no reason. In addition, the soft roof has a low thermal conductivity, so that the lack of a snow-icy avalanche when heating the roof of the spring is guaranteed. The roof is fairly easy to repair, it is only worth cutting a damaged area and glue a new gear. And finally, the bituminous tile is very good noises arising, for example, from rain or hail.

The average (confirmed by the written guarantee of manufacturers) The service life of the soft tiles is 15 years. But when compliance with the installation technology, the roof will serve much longer than 30-50 years. TEGOLA (Italy), Icopal, Cate, Lemminkainen (Finland), IKO (Belgium), Gaf, Celotex, Certainteed (United States) are supplied to the Russian market. Bituminous tile. The soft roof is produced in Russia, Ryazan Cardboard and Ruberoid Plant and the Moscow company Tekhnonikol.

The texture and painting of the bituminous tiles of the leading manufacturers is very diverse. The number of colors and shades is calculated by tens (TEGOLA lathers are more than two hundred). The tile itself is manufactured with petals whose texture mimics the tree, slate or old burned clay. There are very original solutions. So, thanks to the mixing of black and painted granules, the putting on the upper parts of the petals is formed shadows. As a result, the laid coating creates a fancy transfusing embossed pattern on the roof, and the entire building gives an elegant and respectable look. Such tiles are manufactured by KatePal (models Katrilly and Jazzy, $ 8-10 per 1m2) and Tegola (collection Mosaik, $ 8-9 per 1m2).

However, in stores you can find more interesting options. Say, tiled with copper (purity99.7%) coating from Tegola (the prestige collection of elite, "prestige compact", "Prestige TRADISHNL"). This material will help many finally carry out a cherished dream - build a house with "copper roof". Moreover, the "imitation" over time will also cover the patina-characteristic noble flaw that gives the roof a truly exclusive appearance (by the way, Patina also protects the metal from atmospheric influences and pollution).

The plate of flexible copper tiles "Prestige elite" consists of 8Shloev of different materials: fiberglass, oxidized bitumen, actual copper plate, self-adhesive strip, plastic film. Total thickness - 5mm. Copper bent along the edge of petals to ensure complete protection of the bituminous layer from the effects of atmospheric phenomena. At 1m2, the roof is approximately 704cm in size each at a cost of 1M2 material $ 16.9.

Flexible tile is put on the roofs with a bias from 12. For installation, it is necessary to carefully prepare the bearing base. Mandatory condition for solid flooring. For it, you can use oriented chipboard (OSB-3 brand), tipped or edging boards or waterproof plywood (which is preferable) with relative humidity of no more than 20% of dry weight. When the roof is biased in 11-18 throughout its area, a lining carpet is laid with the basis of a glass cholester impregnated with bitumen with the additives of synthetic rubber. Additional waterproofing is also provided. Carpets are supplied in rolls with a length of approximately 15m and 100 cm wide. If the inclination of the roof is greater than 18, the carpet is attached only around the perimeter of the roof and in the most loaded places (by ice skate, eaves, end elements, in places of adjoints to pipes and walls). The inner ohons of the roof are enhanced and waterproof the so-called elevated carpet (it comes in rolls 100.7M).

In addition to the lining carpet, the installation of soft tiles requires the presence of challenges: skate-carnice tiles, ventilation penetrations, finally, frontal and cornice elements. There will be no roofing nails (galvanized or galvanized) and glue to attach the edges of the roofing tiles on the front alone and the adhesive of the lining carpet.

It is very important that soft tiles can be laid even alone. It is not necessary to be professional to be strictly followed by branded installation instructions. Of course, the rafter design will have to be closed with a solid crate, but the soft tile is uncomfortable: almost any trim can be used in some other place roof. It is cheaper than paying 15-25% of sheet material wastes (say, metal tile) on fairly simple roofs. Aesley Roof has a complex form, the amount of waste is rapidly increasing. The cost of laying soft tiles varies from $ 5 to $ 8 for 1m2 (depending on the complexity of the roof). I review the device of the drain system- $ 6-8 in order.

Sheetworks

Let's start with the usual and well-known asbestos-cement fibrous sheets, or, as they are often called, slate. The usual wavy slate leaf has a size of 1200700mm, the height of the corrugated-28mm. Now you can also purchase the medium slate (corrugation height 40mm) and high (51mm) profile. The size of the sheets ranges from 1750980mm to 25001150mm. Interesting produced by the company "Red Builder" (G.Voskreshensk) Slate "New", coated with polymer phosphate paints (about $ 4 per sheet 17501130mm). Externally, it is very different from traditional gray coatings and gives homes a much more picturesque appearance.

Work with slate is extremely simple. When installing the roofs, it is recommended to make a lining layer of pergamine or rubberoid. Sheets are put on the mustache and are attached to the crate of nails with an elastic gasket.

Today you can often hear the word "erectifier". As a rule, this is called relatively new for the Russian market materials - profiled wavy sheets, externally resembling the slate-familiar to the Russian consumer. True, the form of similarity and is limited. EuroSholer is relatively soft and therefore the leaf material that allows deformation with the base of cellulose or fiberglass fibers, which are impregnated with bitumen or rubber-polymer binders. Sheets can be bent along and across, which allows you to mount the coating on the surfaces with a radius of curvature from 5m. "EuroSholer" does not rot, do not corrode and withstand the most unfavorable operating conditions, including snow load up to 300kg per 1m2. It is quite easy, therefore, it does not need a powerful rafter system and a solid doom. That is, it is possible to significantly save on the cost of assembly and building materials.

Roofing system using "erector" includes skaters made of the same material as sheets; end figured strips; nails with washers or screws; endanda; skate and thorns (for decorating the roof edges) elements; Ventilation pipes.

The most popular in Russia enjoys a leaf bitumen fibrous coating of the French company Onduline. But there are other Suppliers: Gutta Werke with Aqualine Coated (Switzerland), Nuline Corporation (USA).

ONDULINE coating (lists of 2000950mm) are made by saturating cellulose fibers with distilled bitumen at high temperature and pressure indicators. In addition to these substances, the manufacture of mineral filler, thermotrancing resin and mineral pigments are used. The "combat coloring" of sheets provides for six colors. Price - from $ 9 to $ 10 per sheet. The ease of materials (orders3kg / m2) allows you to lay them on old or repaired roofs. It is enough just to mount a new crate and lay it on it. To make the roof of the roof of the tile coating, Onduline sheets can be cut into the bands with 50 cm wide and put on the crate in 30 cm between the axes.

Nuline coatings are corrugated sheet material made from the core fibers of solid trees, impregnated with bitumen at high pressure and temperature. Lists of 20001220mm in size with 35mm depth corrugations have eight colors. Nuline coating weight is approximately 8kg / leaf with a thickness of 3mm, the cost of one sheet is $ 11.5. By the way, Nuline sheets are two species, shiny, with silicone coating, and matte. Thus, you can choose options suitable for various style buildings.

The manufacturer's technology involves laying nuline sheets on a hard coating of waterproof plywood, the thickness of which should be at least 12mm. It also takes a lining carpet, one layer of vapor barrier material, laid by the bands parallel to the eaves with an overlap less than 51mm (to the helpful fixation of each nail in the nails).

The "highlight" of corrugated bitumen materials Aqualine is that their color palette is completely manifested only after some time after installation, under the influence of sunlight. This is due to the special technology of their manufacture, as a result of which the natural oxidation of the bituminous coating over time makes the surface lighter, and the color is more saturated. Aqualine sheets (size of 20001060 and 2000950mm) have a 15-year warranty for waterproof; Resistant to the effects of an aggressive industrial medium, acid rain and severe frost. The price of one sheet is $ 10.5.

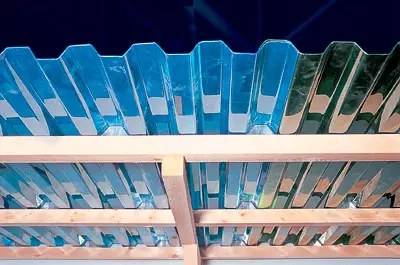

Quite often, the "euroshests" refers transparent or translucent sheets of polycarbonate, manufactured by extrusion. Such sheets are indispensable if you have conceived the translucent roof for the greenhouse, a winter garden or pool. These materials (their durability is approximately 50 years) are offered both domestic and foreign firms.

Translucent PVC sheets are produced, for example, Nuline firms (Tuftex brand, $ 8.5 per leaf size of 2000660mm), Gutta Werke ($ 16 per sheet 20001060mm) and German Salux ($ 16 per sheet 20001050mm). Light and durable (service life 10 years), they are applicable to design light lamps, roofs of arbors, canopies in front of the house, balconies and terraces. Do not miss UV radiation, racks for aggressive atmospheric influences. From domestic producers of roofing PVC sheets, the Mytishchinsky plant "Mosstroyplastmass" can be called, manufacturing the colored polymer slate in flat ($ 3 / sheet) and corrugated ($ 4 / sheet) sheets of 10542880mm.

There are materials specifically designed to arrange greenhouses, greenhouses and winter gardens. These are roofing coatings with high traffic lights (more than 80%), such as "ONDUKLER" from Onduline and Valovoima from ICOPAL. They are made of special polymeric materials or acrylic glass (cellular panels).

Metal roofs

Roofing steel , appeared in XIX. (First, the black, in need of periodic color, and then galvanized, more resistant to corrosion), one time was the main type of sheet material for roofs. Galvanized steel continues to be produced today, mainly in the form of sheets of 1.252.5m with a thickness of 0.5-1.5 mm. The mass of the coating is 4.5-7 kg / m2. The material is recommended for roofs with a bias 14-20. Despite the fact that the roofing device from sheet steel requires a qualified handmade, the decorative properties of such roofs, alas, not too large.Copper As the roofing material likes very many, over time, the copper roof is covered with a layer of patinas, which gives the whole house a noble and respectable look. Copper casing includes its high corrosion resistance, and therefore durability (more than 15 years), environmental friendliness, as well as complete lack of operating costs. Consistent disadvantages of the coating include an increased formation of condensate on the inner surface of the roof (this is due to the high thermal conductivity of copper). Copper today has become relatively affordable. You can buy it in rolls 600-700mm wide and 0.6mm thick ($ 18.4 / m2) or 0.8 mm ($ 24.6 / m2). Installation will cost even the same. Copper for roofing, as well as fasteners and challenges supplies the Russian firm Navy.

Zinc In roofing works, used in the form of a alloy with a very small amount (0.1-0.2%) titanium and copper. Therefore, in the building materials market, the roofing zinc is sometimes called "zinc-titanium". Additives give materials plastic in cold condition. It is suitable for the device of folding roofs of any configuration with a slope of at least 5%. In addition, the alloy makes the elements of water-fired systems and other accessories. The largest supplier of roofing zinc is Union Zinc, manufacturing sheets of up to 50.66m and rolls wide from0.2 to0.66 width. Cincan sheet thickness from 0.2 to 1 mm. The color can be either a natural and silver-brilliant, moving with time to a noble matte light gray (Union Zinc, $ 14 / m2) or matte-light-slapted (Quartz Zinc, $ 17.4 / m2). The most expensive option is a matte gray-coal (Antra Zinc, $ 19 / m2).

Metal tile.

Metal tile sheets are made of hot-dip galvanized steel 0.5 mm thick, less often 0.4 mm. The manufacture of production is coated with a protective layer of zinc or zinc aluminum alloy, passivated, are ground, after which they give the form of various types of traditional tiles to the form of cold stamping. The sheets are then treated with an anti-corrosion composition, coop the layer of plastic (for example, polyester, plastisol), and by reducing varnish. The mass of 1m2 metal tile-approximately 5.5kg. As for the color range of coatings, it is not difficult to choose the desired color. Prices (excluding the cost of quantities) vary from $ 8 to $ 15 / m2, regardless of the brand of the manufacturer. For laying, a solid doomle is not required, sheets are mounted with screws with seals.

Metal tile from Gasell Profil, Kami, Nola Proflab, Teras-Taive, Mera System (all-Sweden), Weckman Steel, Rannila (Finland), Coversysys (Belgium), Gerard Roofing Technologies (USA), Gerard Roofing Technologies Domstal "(Poland) and others make profiled sheets and domestic manufacturers:" metal profile "," Moscow Center for Roofing Materials "," Stalinvest "," Mos-Facade "," Stanov "," INSI ".

An important indicator of the quality of the material is the thickness of the steel sheet. It should be at least 0.5 mm. Today in stores you can meet a metal tile of 0.4 mm thick, which is only suitable for mounting on small buildings, visors and canopies.

Why is it so important to galvanized sheet? In principle, any metal tile, if not to be mechanically exposed, will serve a long time (up to50 years) even under an aggressive environment. But, as a rule, when the installation of the roof begins, the sheets lie (usually in the region of Chepetts and Unders), the holes under the self-tapping screw are drilled in them, nails are driven. This is where the quality of the material is detected. Just painted steel sheet in the location of the cut immediately starts corroded, and the protective coating can be collapsed up to the base of the sheet. The galvanized leaf will be more resistant to corrosion, because zinc performs the function of cathode protection, due to the gradual self-destruction under the influence of moisture, it will "save" the steel basis. The lack of a passivating layer or primer leads to the fact that the main polymer coating (it is decorative) serves no more than 1-3 years. During this period of time, a polymer coating is peeled from the leaf, after which the rust appears.

There are several main types of protective-decorative polymer coatings: polyester, matte polyester, poural, plastisol, PVDF. They have the operational characteristics that you can learn from the table we bring.

Profiling Metal tile determines not only the appearance of the future roof. Changes and technical requirements for installation, such as the shaft step. The most popular is a drawing that imitates natural tile, that is, in the form of scales or adjacent to each other tiles.

The profile can be both symmetrical (Weckman) and asymmetric (Rannila). Therefore, docile sheets from different manufacturers on the same root will not work. The density of the seam fit density depends on the quality of profiling - they will be visible on the roof or not. Moreover, the joints can only be visible at a certain angle. Therefore, when choosing a tile, ask Show photos to see what the material looks like on the roof. Ashche is better asked to dock 2-3 sheets with you.

High-profile sheets give the roof good stiffness, help withstand snow load at a fairly thin and inexpensive crate. But if the tile sheet has a lower profile, a more rigid doom is required.

When working with metal roofing coatings should take into account several nuances. First, the plasticity of the metal is limited, and the profiled sheet is not at all designed for bending. Secondly, such coatings are more suitable for the roofs of a simple form, with steep slopes (bias 45-60). On complex roofs up to 20% of the sheet metal can go into waste, and it is still not cheap.

A special kind of metal tiles are materials with mineral sprinkles. They were invented in New Zealand as an alternative to a traditional ceramic tile, less than the aggressive exposure to the external environment. After all, it happens that the architectural concept of the building does not allow you to apply natural tile, and you burn the desire to decorate your home the most original roof in the area. Then it makes sense to pay attention to the "elite" roof of Metrobond, Metroshake and Metroshingle from Metrotile (Belgium), Decra from Icopal, "Ondustil" from Onduline and Terraraplegel from Kami.

The basis of the majority of such roofing materials is a galvanized sheet. The estranges from the Metrotile basis are protected on both sides by a layer of aluminum (this is an alloy of 55% aluminum, 43% zinc and 2% silicon). Aluminum and silicon coating thickness is 20mkm- increase the protection of the sheet 4-6 times compared with the usual galvanized steel, which allows the roof to serve about 50 years in the aggressive environments. The 15-year written warranty is given to this material, which is rare. It can be said that according to the ratio of "anti-corrosion properties-price-quality" it is between galvanized iron and pure aluminum.

But the anti-corrosion protection of the metal is not limited to. Mineral (basalt) granulate is also applied on the front side than several goals are achieved. First, the surface acquires the characteristic texture of genuine tiles. Secondly, the sheet is not so "noisy", softening the rain blows about the roof. Losses of mineral granules as a result of weather cataclysms are 1% for 10 years. Such strength of the fastening of the sprinkling is achieved due to the use of a special acrylic adhesive (it is cured in the furnace for three hours at 400 ° C). As a result, the material is not afraid of temperature drops, "is operational" and in the bodied frost, and in the wild heat (from -120do + 120 ° C). Thirdly, mineral sprinkle protects the organic coating (acrylic adhesive) from exposure to open flame, sparks, etc. If Kami releases sheets with a sprinkler, similar to the size of conventional metal tile, then the rest of the manufacturers offer smaller products: 1330410mmm- Metrotile, 1250370- Icopal, 1395455mm- onduline. With the "panels" of such dimensions, it is possible to carry out the roofs of complex forms (grainbones, auditory windows, etc.), including curvilinear (no less than 1-2 m radius). Moreover, you can even alone. Materials are not too demanding to the crate. For example, the "panels" from Metrotile are stacked on a 4040mm bars (expensive waterproof plywood not required). Tile itself relies with a wave on the top of the bar and its lower end.

On the roof with a mound. You can move in rubber shoes, but run with scrap on the roof, frowning icicles, not worth it. This material is not intended for installation on the principle of "Make Himself" - it is better to use the services of a professional brigade of builders in order not to lose guarantees due to the violation of the laying technology. The retail price of sprinkled metal tile (when buying less than 150m2) is about $ 19 for 1m2. From the total costs, you can immediately strike out the cost of waterproof plywood, lining carpets, reduce the cost of installation work (since they are not particularly laborious). In addition to the material itself, manufacturers offer a whole range of challenges (skates, end planks, etc.), allowing to fully form a high degree of complexity in one style.

Types of protective polymer sheets of sheets of metal tile

| PVF2 (PVDF) | Polar (PU) | Polyester (PE) | Matte Polyester (PEMA) | Plaserisol (PVC) | |

|---|---|---|---|---|---|

| Coating thickness, μm | 27. | fifty | 25. | 35. | 200. |

| Maximum operating temperature, with | +110 | +100 | +90. | +90. | +60 |

| Minimum processing temperature (flexion), with | -10 | -fifteen | 0 | 0 | +10 |

| Resistance to ultraviolet radiation (on a 5-point scale) | ***** | **** | **** | **** | *** |

| Resistance to aggressive environments (on a 5-point scale) | ***** | **** | *** | *** | **** |

| Resistance to mechanical damage (on a 5-point scale) | **** | ***** | *** | **** | ***** |

| Terms of application | Suitable for operation in conditions of aggressive media (sea coast, industrial buildings, etc.) | Universal coating for operation in a wide range of climatic conditions | The most common and universal coating is suitable for any climatic belts. | Due to good corrosive and mechanical stability, it retains its properties in a wide range of climatic conditions. | It is not recommended to use in the southern regions. Optimal in conditions of polluted environment |

Natural tile

Tiled roofs made for a very long time, they are extremely widespread in Europe and Asia. The familiar ceramic tile is durable, its service life is more than 100 years, and the roof itself is very beautiful. But, thinking to build a tiled roof, it must be borne in mind that the mass of 1m2 coating is 40-70 kg and for a light wooden house such a roof is not suitable.

Now you can find a large number of different types of ceramic tile (Dutch, Pazeda, Frankfurt, etc.) from Meyer-Holsen Dachkeramik, Creaton, (Germany), Rupperkeramik (Lafarge Concern, France), Braas (This German company opened in Russia Own tile production on the basis of Moscow DSC-1). The products presented in the market differ in appearance, mass, and most importantly, according to the method of laying.

The modern type of tile is concrete, or, as it is more often called, cement-sand tile. It is mainly used by pressing technology. To give this tiled color, pigment (bulk staining) is introduced into it or produce surface treatment. This can be a spraying of color cement composition; Instrument finish, including the sprinkler of colored sand with granulate; spraying of a polymer emulsion on a freshlyformed surface, etc. The main types of tiles produced, Vienna, Alpine (flat). Preferential color - red and brown. Cement-sand tile is less durable than ceramic, and for the rest of the parameters is close to it. Weighs somewhat less ceramic, but also not recommended to create roofing light structures. To properly put cement-sand tile, we need highly qualified specialists. As for prices, the solid tile will be relatively cheaply from $ 59 / m2. Avot for good items (skate, end, snowstorming, etc.) will have to pay at least three times more.

Think and choose

As a rule, first of all evaluate the appearance of the material and only then, its physical, heat engineering and mechanical properties. Azry. The approach should be different.Pay special attention to the durability of materials - this parameter varies from five (rubberoid) to one hundred years (copper roof). If you do not build a monumental house with durable roofs, calculating it to transmit it from generation to generation by inheritance, you may well satisfy the coating designed for 25 years of service.

It is important from the very beginning to evaluate not only the quality of the material, but also the complexity of its installation. Well, if you can cover the roof yourself, clearly follow the instructions. But, as a rule, the laying of most roofing materials requires applications for the efforts of a team of qualified professionals.

It is worth taken into account that some types of roofing materials require complications (asnauding, appreciation) of the rafter system. For example, a rafter system for natural tiles, as well as walls and foundations should be calculated on the appropriate load. The result will increase the flow rate of sawn goods, and consequently, the cost of the roof (by 15-20%). The price of components and challenges can increase the cost of the finished roof by 50-100%. So indicated in the advertisement rate of 1M2 actually coating, although it matters, but does not determine the total costs of the roofing carpet. After all, you buy not scattered pieces of iron or bitumen, but a full roofing system.

Part II.

So that the roof is not "crying"

We devoted to the first part of our article with roofing materials. Their use of any problems with the "cold" roof. But when you begin to make a "warm" roof, for example, when equipped with an attic room, unexpected complications arise related to errors in the design. Moreover, it does not occur immediately, but at the stage of operation. We will tell this part of the article on how to avoid them.Why "crying" roof?

The usual roofing coating, or, as it is also called, the roofing "pie" looks like this (counting from the bottom up): finishing-insulation-roofing material. Moisture pairs from the room, where their sources are abused, through the layer of finishing material is quite easily penetrated into the insulation, which, in the case of moisturizing, dramatically loses its heat insulating properties. In addition, the moisture condensed inside the insulation or passed through it in the form of a pair, and the roofing material condensed on the back surface and then "fallen" back into the insulation, may return to the room and perform in the form of droplets on the surface of the ceiling and walls. With a high level of humidity in the building, the number of condensate shearding on the ceilings and walls is capable of creating a complete illusion that the roof flowed.

From the summer heat such a "pie" saves unimportant to the roofing coating, heated by sunlight transmits heat to the insulating material, then it moves to the supporting structure and indoors. The heating process is carried out slowly (the insulation in this case is more correctly called the "heat generator"), but steadily.

What kind of roofing "pie" does not have these flaws?

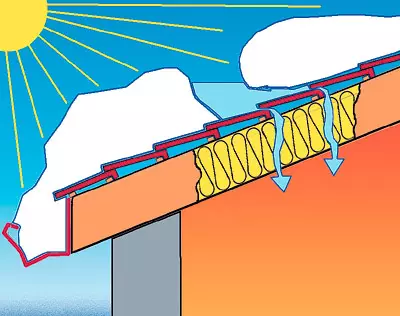

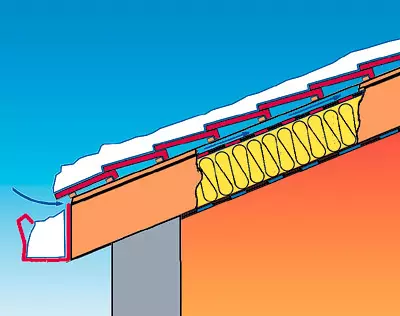

Ventilated means not "crying" roof

Contemporary roofing "Pie" is a specific design that should and maintain heat in the premises in winter, and prevent its entry into the room in the summer (heat from the hot roof), as well as to protect the insulation from the penetration of water from the room from the room and pass through its thickness And to withdraw the "Nauli" pairs of moisture, still falling into the insulation. In addition, in some cases, "Pie" has to protect the roofing material from the destructive impact of all the same vapors. To ensure this roofing should not be simply insulated, but necessarily ventilated. As a whole, this design is similar to the design of the warmed wooden wall described by us in the previous issue of the magazine, and consists (bottom-up) from: finishing-vaporizative material-insulation-moisture insulating material - one or two ventilated gaps closed on top of the roofing material.The ventilated roof has certain advantages. In winter, it does not just save heat, but- due to the fact that the roofing material does not come into contact with the insulation and therefore it does not heat up (there is a ventilated clearance between them), - prevents the formation of an ice barrier on the protrusion of the roof of the roof and prevents the phenomenon of the so-called "return" water. In summer, such a roof saves such a roof from the heat-fresh air, entering the ventilated space, heating up, rises up and comes through a hat, carrying out heat obtained from the roofing coating, and moisture taken from the insulation.

Usually, the conversations in the press of the ventilated roof end with a simple listing of these advantages. The systemic information is practically absent. There is no information on how to embody the desire to have a ventilated roof in reality. Next, we will try to fill this gap, for which we consider the main types of roofing structures "pie" and the order of their creation.

Where to begin?

Step one. First of all, it is necessary to determine which of the existing types of roofing materials will be applied. The solution is very important and responsible, since it depends on the selected material, what kind of underpants the waterproofing film will be required, and what is the number of ventilated gaps, the location of the counterrelic on the waterproofing material and the design of the crate. Change this solution without dismantling the laid underpotted carpet is unlikely to succeed.

Depending on the selected roofing material, as well as from the wind and snow load (for the middle band, in the amount of approximately 200kg / m2 of the roof), the cross section of the rafter (or the correspondence of the existing rafter system of the real load is checked), their step, and at the same time the design of the crate and the design of the crate and Her step. What for? If, for example, you have chosen a genuine (mortgage rather heavy) tile, and the rafter design on its use is not calculated, then by the spring, the roof will certainly take a rather original shape, strongly reminiscent of the saddle, if at all goes away.

Step second. We choose the waterproofing material that will be installed under the roofing coating. In order to do this, consider the existing waterproofing materials and their combination with various roofing materials.

Superdiffusion membranes. These moisture insulation materials are very important for the roofing device: a pair of water through them pass, and the water itself is not. Moreover, the vapor permeability is so high (they are called superdiffusion) that these materials can be installed close to the insulation, without the lower ventilation gap. In our market, such products are presented mainly by DuPont (Switzerland) - Membranes of the Tivek group and Juta (Czech Republic) - Utavek, which was also described in detail in the previous issue. Both membranes are quite expensive - about $ 1 / m2. Superdiffusion membranes are not recommended to be used in a pair with roofing materials, the reverse side of which is not designed for frequent or long-term contacts with moisture. That is, in this case, the metal tile will not fit in this case (by a spray with an aluminum coating, for example Metrobond) and wavy bitumen sheets ("erector"). Wpares with ceramic, cement-sand and bituminous tiles, not afraid of moisture impact on the opposite direction, superdiffusive membranes function without problems.

A superdiffusion membrane on rafters is fixed using a counterbrue, which is then mounted, the suitable roof material is mounted (the level of the counterbruce will determine the magnitude of the ventilation gap). The membrane design cover freely passes the pair overlooking the insulation into the upper air gap-ventilated space between the membrane and the roofing material, from where they are removed by the air flow.

The installation of the membrane is close to the insulation is beneficial if the rafter design is made using a bar with a cross section of 100100mm (for example, when the existing house is insulation) and it is not possible to replace it (or squeegee). Since the insulation layer cannot be less than 100mm (otherwise it is about what effective insulation speech?), It will have to lay it in full thickness of the rafted, therefore, no gap simply will not work.

The manufacture of a rafter design from a bar of 150150mm allows you to put between the rafters layer of the insulation of the required thickness. It is even better if the timing is used by a cross section of 100200mm or rafters are scored from edged boards by cross section of 50200mm. In this case, it will certainly be enough space to create a lower ventilated air gap (recommended value, 50-70mm). Its presence allows you to use cheaper moisture insulating materials than superdiffusive membranes. They are two species: diffusion and anti-condensate.

Diffusion waterproofing membranes. The task of these membranes is almost the same as superdiffusion, - as quickly as possible to release water pairs into the upper ventilated clearance. The structure of the same diffusion materials is such that they can only work in the presence of two ventilated spots - lower and upper. In fact, these materials are not that other than polyethylene films, in the canvas that very small holes are punched with needles. If the insulation is tightly pressing such a film, the holes will simply blocked and the film will stop skipping the water pairs.

Diffusion waterproofing membranes, as well as superdiffusion, can only be used in a pair with roofing materials, the reverse side of which is not afraid of the impact of moisture. This is a ceramic, cement-sand, bituminous tile and Metrobond metal tile. Producers of diffusion waterproofing membranes presented in our market - Juta (Czech Republic) and Eltete (Finland).

Anti-condensate waterproofing films. They are countertilers and are designed to work in a pair with those roofing materials with which the superdiffusion and diffusion membranes do not get along, that is, with metal tile and "erectifier". The reverse side of the films (the side facing the insulation) has an unusual "darous" surface. The prerequisite for the action of these films is also the presence of two ventilated air spots - lower and upper. Under adverse conditions, the moisture extinguishing from the insulation is condensed on the lower surface and is held on it at the expense of a "pile" (to keep water such a film can be 4-8 times more than its own weight). Upon the occurrence of favorable moisture conditions, air is carried away by the lower air gap. The reverse side of the roofing material is completely protected from the impact of moisture and is constantly ventilated due to the upper air gap. Anti-condensate moisture insulation materials are offered in our market such firms as Juta (Czech Republic) - Jutakon and Eltete (Finland) - ELKATEK EXTRA and ELKATEK EXTRA L.

When creating a structure using anti-condensate and diffusion waterproofing materials, pay special attention to which side of the film is addressed to the insulation, and what to roofing material. This moment is extremely important, it is worth confusing, and we can assume that ordinary polyethylene as a guide membrane.

The use of anti-condensate films is advantageous and from one point of view, they help extend the life of inexpensive metal tile, which is usually no longer exceeded 10-12 years. The anti-condensate film and constant ventilation of the lower surface will significantly extend the life of the lower protective layer. After the end of the warranty period of operation, the metal tile constantly monitor the state of the upper protective layer (remove the peeling coating and every year to twist with special "repair makeup"), then the total service life can be extended by 1.5-2 times. True, it should be borne in mind that "maintainable" only such coatings as polyester and poural. Plastisol "Premise" will not succeed.

Step Three. We carry out the resulting height of the rafted (see step first) with the thickness of the insulation layer laid into the project. If there is no such, we carry out the preliminary calculation of the required thickness of this layer, as it was, we also told in the previous issue.

This step is necessary in order to check again if the height of the selected rafters is sufficient. For example, in the case of using a basalt insulation, it may well be that its effective thickness should be 12-13 cm (it can be, and15). The arutor means that for its laying a rafter system, made with the use of a bar of 100mm (it is precisely from it that the rafter systems of most small country houses are performed), it will not fit the thickness of the rafter. The result will have to consciously reduce to an acceptable (100mm) thickness of the layer of the insulation, and this is undesirable. In addition, the small thickness of the rafters can "pull" the application in the design of a more expensive superdiffusion membrane, as well as introduce significant restrictions in the choice of roofing material. With the required thickness of the insulation layer (15cm), it may not be enough and the bar of 150150mmm is not enough to organize the lower ventilation gap. True, this problem can be solved by packing a 5050mm bar (or 50100mm board rafters), but it should be borne in mind that it increases the cost of the design and reduces its reliability (a counterbuster that holds the moisture insulation membrane will be packed over the bar, and is already a doom.

What insulation should be used? According to the majority of specialists, - possessing high vapor permeability, that is, freely passing a pair of water through their strata. This ability to maximize the mineral wool materials. The wooden rafter design, thanks to the ability of the insulation to skip pairs, will be able to "breathe" through it, as a result of which it will retain its integrity and carrier properties. The range of mineral wool insulation in today's Russian market is quite wide, there is something that is called, for every taste and wallet.

Step fourth. After installation (we think that it is not necessary to describe this process in detail) the insulation is closed from the bottom with a parobaric film, the purpose of which is to exclude the hit in its thickness of water vapor from the room. The parobaric layer, in turn, is closed with a finishing material.

About materials for the creation of the Parobarmer offered by such manufacturers like Tegola (Italy), Juta (Czech Republic), Eltete (Finland), Monarflex (Denmark), and methods of their installation, we also told in detail in the previous issue, so we will now make only small additions to Already said.

The cost of the parobac was to reduce if used instead of special vapor insulation materials well-known pergamine. True, he is impregnated by bitumen, the light smell of which will be felt in the room. But this is the cheapest material (P-300- 114 rubles. For roll 20m2). There is another inexpensive option-reinforced polyethylene, widely used for the greenhouse device. But keep in mind that it is not designed at negative temperatures. If you live in the house constantly and it never remains nonet, it is possible to apply the reinforced film. If the house is used periodically, it is not worth doing this, it is better to choose special vapor insulation materials or pergamine that the cold is not afraid.

The use of fillers with a "mirror" layer of metal spraying (for example, Alubar from TEGOLA and the like) helps to additionally hold heat in the room. But between the insulation layer and the film, it is necessary to leave the air clearance about 2 cm, which complicates somewhat and increases the design.

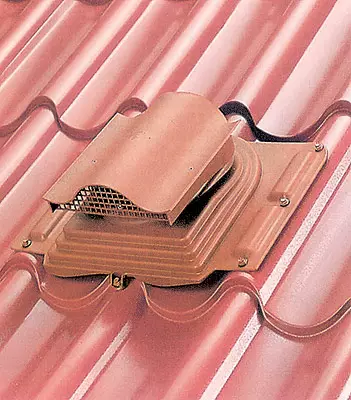

Organization of air flow in ventilated gaps

Of course, correctly collected roofing "pie" is not all. To create the necessary air flows, you need to give air the ability to act in both Ventkanal. To do this, special holes are left in the lower part of the eaves, which are protected from penetration of insects and birds with a small grid of stainless steel. Skates are also made by special design - ventilated. If there is no such possibility for any reason, special roofing fans are used to communicate the upper and lower ventilated gaps with the atmosphere.When a wavy sheet (metallic or non-metallic) is used as a roofing material, the question of communication with the upper air gap is solved quite simply holes for air intake and the ski fan is formed by themselves, even if the wavy sheet is "flat" skate. In this case, it remains to ensure the air fence and its release only for the lower air gap. This is done in the method described above.

Anti-condensate films

| Mark (firm, country) | ELKATEK EXTRA (Eltete, Finland) | ELKATEK EXTRA L (Eltete, Finland) | Jutakon (Juta, Czech Republic) |

|---|---|---|---|

| Description | 80% -Polymer fabric and 20% -anticondensate absorbing material from viscose fiber | 80% -Polymer fabric and 20% -anticondensate absorbing material from viscose fiber | Four-layer ultravioletosoy-brow (12 months) Polypropylene fabric, laminated on both sides by a polypropylene film, to one side of which the moisture absorbing nonwoven material is attached (viscose) |

| The ability to hold water,% on units. Details. Eve | 680. | 680. | 400. |

| Tensile strength, kgf / cm2, not less | 860/780 | 553/423. | 800/600 |

| Weight, g / m2 | 140. | 135. | 130-140 |

| Thickness, mm. | 0.20 | 0.19. | * |

| Roll size (shd), m | 1,346. | 1,540 | 1,350 |

| Roll price, $ | 46. | 40. | 56. |

* -temo does not specify

The editorial board thanks the company "Gasell Profil", "Ranilla", "Metrotil-RS", "Jetta Stroy", the Navy, the "Western Roof Center" for help in the preparation of the material.