Anatomy of stairs, design solutions, materials, installation, care. Typical errors in designing and construction. Manufacturers and prices.

Marshamic staircase of curvilinear form. The door, according to the standards, goes to the staircase

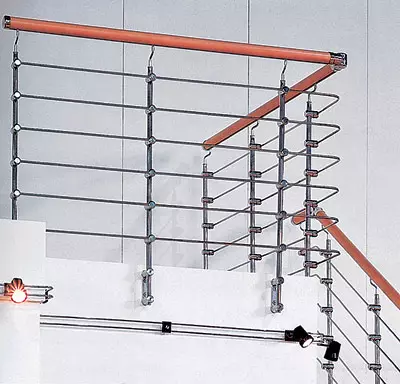

This is what the fencing of the staircase of the upper floor looks like. It will save you from falling into the mine

Staircase, furniture and the entire constructivist interior eddition of noble simplicity

Ring steps help save space

MINI ELECTRA staircase: Metallic Kosur will be covered with wood

Screw stairs are very beautiful, but not very comfortable for movement.

Solve the problems of shrinkage of the building and the most staircase is easy if the height of the support post is adjustable

Gara is a classic marching staircase. Steps are made of beech, and fence - from forged metal

Surprisingly light and elegant product. This is the Araya staircase from Rintal (France)

Small mobile lamps - fireflies on the fence

Tree and metal, most popular materials in the production of stairs. Aero Construction from Alfa Scale

In premises with a large passability, it is recommended to use strong materials, such as porcelain stonewares.

Massive staircase - SESTANS- Convenient option for large techno-style premises

Non-standard version of a porcelain staircase: steps are fixed on a metal koser. Imola Ceramiche.

Decorative ladder design is one of the main concerns of a specialist

In the ancient times, high-rise structures, one of the architectural elements of which was the staircase, were considered the privilege of "Godisbracted" - kings, pharaohs or priests. Today the stairs lead us not only in the sky, but also in the usual "earthly" bedrooms, living rooms, billiards or winter gardens. This article will discuss the designs that "settled" inside country houses and two-storey apartments.

The staircase, first of all, is functional: it serves as a link between different rooms, the movement should be moved quickly and most conveniently as possible. In addition, the ladder is decorative and participates in the formation of an interior style. Getting ready to become a caring owner of a two-story apartment or a country house, you will definitely "deal" on the stair issues. When to design the stairs? What designs and materials give preference? What firms are born in the Russian market and what do they offer? Finally, how to exploit the staircase so that it serves as long as possible? About this and some of some subtleties of the ladder will tell our article.

Design

Future owners of a country house or a two-story apartment are sooner or later asking: when to design a staircase? And, unfortunately, it is very often content with a schematic sketch in general terms, leaving a detailed development of a staircase design to the final stage of construction. This approach is ineffective, since it leads to a set of "building" errors. Error first: incorrectly planned space. The house is almost ready, yes, there is a trouble one design that you like cannot be inscribed in the existing dimensions of the opening. You scold a specialist, and he stubbornly claims that it is impossible to choose the literate ratio of the width of the sticky and the height of the riser. This is indeed one of the most important values in the staircase, it depends on it how convenient will be moving through the floors of the dwelling.Error Second: Planning the design of the staircase without taking into account the characteristics of the material of the walls to which the mount is carried out. The stairs can only be fixed to durable, as a rule, carrying walls (elevation, thick bar, bricks with a thickness of more than 25 cm) and in any case - kgpsocardon, asbestos-cement walls in the pollipichi thickness, there are "decorative" partitions.

Third error: Placement of heating devices directly under the stairs. This is especially dangerous for wooden structures. It is possible to determine the optimal distance between the tree and heating devices in a practical way: check the surfaces near the device to the touch and make sure that they do not heat up. In advance, consider the location of electrical wiring, pipelines, heating and windows relative to the staircase. If you value the space, try to use the corner under the staircase, build a wardrobe or bookcases here.

In a rainy climate (for example, in the central strip of Russia with a protracted autumn incense)) avoid the location of the stairs in the northern and northeastern corners of the house, since the walls are more wet here. Ibeton, and brick, albeit in small quantities, still absorb moisture, thereby contributing to the creation of a separate zone of the microclimate even within one dwelling. If the architectural plan does not avoid the northern corner, try to "tear up" the staircase design from the wall or provide a constant flow of dry air between the staircase and the wall (for example, install the thermal convector). Keep in mind that not every architect is a specialist in designing stairs, it is possible that you will have to invite another master.

When building a wooden house, it is also necessary to remember the shrinkage of the building, which continues for several months and even years, as well as the possible movements of the soils, such as clay and loam. The reference pillars in the staircase must have a compensation design of the type "telescope", if necessary, the height of such a staircase is adjustable. This is only one of the options, the specialists in each specific case will offer you the most correct decision. It is not recommended to build ladders in a completely "fresh" house-matage installation of a church, a year must pass at least a year.

Manufacturers

The staircase production takes quite a long time: from the beginning of the design before the delivery of finished parts passes from one to three months. Incasive firm turn to the issue, solved together with the architect. The Russian market presents a fairly large number of manufacturers, both domestic and foreign ones.

From the overseas most popular Italian firms Albinifontanot, Alfa Scala, Marretti, Cast, Interscala, Linea Scale, Nelur, Rintal, T.i.L., German Kenngott Treppen, recently appeared French Lapeyre. All of them produce stairs of various designs (marching, screw) and perform them from a wide variety of materials, metal, metal, glass, stone. The stairs of foreign firms are ordered through dealers who provide design services, the selection of a specific model for catalogs, ordering, delivery to Russia ready-made elements and, finally, the installation. Thus, they are a kind of "co-producers" ("Academy of Interior", "EurostroServis-K", "Saveks Stairs", etc.). Choosing the "Finished" model catalog, you choose, first of all, type, design and design . Dimensions are determined when designing. All this information enters the manufacturer, and it makes a staircase based on the model you have chosen and the size of you. Therefore, in some sense, each staircase is unique.

From Russian companies, the largest producers are "Dop #1", "Caracks Style", "Maple Lest", "Podroditsa", "Smkvadrat", an experienced MNPO Plant "Temp". There is also a fairly large number of firms specializing in the supply of stairs or their parts from one particular material (so, the "Caucasian forest" supplies wooden components, the "white stone" - steps from marble and granite, and the company "Bag" produces steps and fencing from Multilayer glass and stainless steel).

Design

There are several classifications of staircases. We will adhere to this article as simplest of them, according to which the stairs can be divided into marches and screws.The marching staircase consists of one or more spans interconnected by intermediate sites. The number of steps in one span ranges from 3 to 18 cells (according to the standards of SNiP 2.08.01-89 * "residential buildings"). The marching staircase is like a straight line (the simplest design is a direct staircase consisting of one span) and turning. Theoretically, marches can be located at any angle relative to each other and even be curvilinear, but in practice there are most often designs with a turn by 90 and 180. The latter at the same height of the steps occupy less space, although less convenient for furniture transfer. Another type of construction is open: the first one or two march leads to the site, from which two other march diverges in opposite sides. This is the most press staircase, it is often decorated with sculptures, and it can serve even the main element of the interior. Movement over the swing stairs is a whole ceremony.

The design of the spiral staircase includes a vertical reference rod and arranged along the spiral strokes around it. Strain of cases, the reference pillar has a complex composite design: the inner rod and the "glasses" struck on it, between which the steps are clamping with the help of special sleeves and rings. Some Russian firms offer structures in which the steps are attached to the reference pole using brackets. Such stairs are inconvenient in operation: they will rattle when walking, steps and the support pillar are deformed.

The minimum diameter of the screw staircase is 110cm, and the most convenient - 150cm and more. The angle of lifting can reach 55-60. Screw stairs are not particularly convenient to move people, for transporting furniture (it happened that the owners had to deliver furniture to the second floor through the windows or disassemble the entire design of the stairs and transport furniture through the opening). Screw structures sometimes do not have the main support pillar, some specialists allocate them into a separate group of circular stairs.

Fashion on the stairs is distinguished by an amazing variety. According to the specialists of all practitioners in this field of firms, the most popular structures - wage wooden and marching, combining wood and metal. The marching stairs are really much more convenient for the screws. Movement on the latter is particularly difficult for small children, the elderly, people with disabilities. Screw staircases are usually installed as secondary (for example, as a separate rise in the bedroom, a study or dressing room) or in case of large areas with an area.

Anatomy of stairs

Any staircase consists of a foundation (Kosur, the Agreement, the Hosts or Support Pole) and the steps (open or with a riser). Additional elements are the platforms between marches, railings and decorative elements, sculpture, as well as the built-in backlight. The customer usually chooses a staircase based on its appearance and compliance with the overall architectural style of the interior, and is not going to technical subtleties, relying on professionals. Although, luxurious directories, you will, quite possibly come across with more special terms and professional information.

Kosource - This is a sloping beam, which relies the steps of a staircase march. Depending on the design, the staircase can have one or two Kouryra.

ATTIV - Also the inclined carrier structure of the stairs, but the steps are "crashing" into the inner sides of the instrument.

Boltz - steel element connecting the steps among themselves. The staircase at the Bolts, probably the most "light" of all in its appearance. Its steps with one end are attached to the wall.

Support pipe - The central pillar, around which the screw staircase is tightened.

Come out - horizontal part of the stage.

Treaty - The vertical part of the stage, which closes the gap between adjacent compensation and the accusative staircase of additional stiffness. There are no extraction structures.

Running steps - Such, in which the normal width is observed only in the middle line of the march. The inner edge has already, and the outer wider.

Balustrade - Fencing of the staircase or balcony over the staircase. As a rule, has a round shape.

Balaasins - Decorative details of the fence, carry the railing on itself.

Material, installation, care

The base of the staircase can be concrete, reinforced concrete, metal or wooden. In addition to this, the staircase will be called concrete, metal or wooden (the exception is stone and glass structures, they received their name according to the material of the steps). Combined designs - "Metal-tree", "Metal-glass", porcelain stamprints with reinforced concrete kososur, etc. From all materials, the tree is considered the warmest, pleasant and affordable material. Stairs made of glass or pure metal are still rarity and exotic.Depending on the construction of the building, the reinforced concrete slabs of the overlap can withstand the load of 500-1000 kg / m2. This is usually enough to install a heavy staircase from stone or glass (weighing up to 500 kg). Most of the wooden and metal structures have a lot of 150 to 350kg. By the deputy house (here floors must withstand the load at least 250kg / m2) at the location of the ladder floors are strengthened with additional beams. At the planning stage, the state of overlapping in places of fixing the stairs should be taken into account: it is possible that the builders will have to create an additional supporting structure that will distribute the load on the larger area. The selection of reference points for the staircase depends on the configuration of a specific model. So, the direct marching structure is usually attached to the overlap and rests on the floor. The marching staircase with one turn will require additional mounting to the wall, with two rotation of the attachment to the floor, to the overlap, to the wall and support on the vertical pillar. Media structures with a large number of turns are also used through the end-to-end fastening of the cososov, the guards or steps to the wall. Metal boosters are attached to mortgage elements using anchor bolts, and wooden-spokes of bolts-screws. On the outer surface of the location of the anchors and bolts are masked by decorative plugs.

Screw staircases are created by the largest load: the area of their contact with the floor and the overlap is small. To avoid problems with the overload in wooden houses, specialists are trying to place the support pillar of the screw staircase over the beam or in close proximity to it.

Depending on the selected design, the installation will be made at different stages of construction. Thus, reinforced concrete Kosouris is cast at the stage of main construction work. Metal and wooden booms and mortgage elements of stairs are installed at the final stage of construction, before starting finishing works. The remaining elements (steps, balasins, etc.) are installed only after full paint drying. True, some firms prefer to install the stairs after finishing works. The advantage of this solution is to protect the stairs from the effects of residual moisture and one hundred percent protection of the expensive design from random ink or enamel. The complexity is that mortgage elements will need to be attached to high accuracy, in order not to damage the decoration of walls, ceilings and gender.

Each of the materials used in the production in its own way capricious and requires individual care.

Wood - The most common material for creating a staircase of any design. Moreover, a wide variety of breeds are used as soft (pine, spruce, cedar, fir) and semi-solid (birch, maple), and solid (oak, beech, ash). Especially popular today are pine (as the most affordable material), beech and oak. Exotic for stair structures are considered cherry, nut, cypress, iroko, tick, mogano and other breeds of mahogany. Regardless of the selected tree of the tree, all the elements (steps, the string, handrails, risers) must be glued, since the monolithic wood is very quickly cracking and deformed. The permissible moisture content of dried wood for staircases is 8-12% - to measure it will help the special device moisture meter. All components are recommended to buy in one place, where they are selected on decorative properties (tone, drawing) and passed the same processing. The incoming structures are not recommended to combine rocks with a different coefficient of thermal expansion of the fiber, after some time the staircase "swells" or "swimming".

Wooden staircases are treated with mourn and varnish. It can be both colorless varnish and various colored tinting varnishes, enamels and paints. The coloring procedure is carried out before the construction of the construction of the structure. Keep or not the natural color of the tree depends on your taste. Many prefer to tint wood, achieving its maximum matching of doors, parquet or even window frames. Lovers of uniformity should be remembered that the varnish is erased. Restore the initial appearance of the color varnish will not be easy - when re-applying it dissolves the previous layers, and you will not achieve uniform painting without interfering with restorers. If the tree was originally covered with colorless varnish, the problem of re-coating is solved by the owner itself at home.

Even the adhesive tree is inclined to cracking, especially due to temperature differences. Therefore, manufacturers guarantee the normal wooden staircase service only under certain conditions of its operation. The alert should be maintained by air temperature 20-22c and relative humidity of 60-70%. Lower dry weather is recommended to use humidifiers. Inclusive of humidifiers, not only specialized devices can be applied, but also various discharge plants (for example, "crying" lianas), as well as fountains installed directly under the staircase. The stairs must be protected from direct sunlight, be at a sufficient distance from the heating devices. It is also necessary to exclude the likelihood of entering parts of the water design in case of failure of the water supply system. These requirements, unfortunately, are not performed almost in 80% of the exploitation of wooden stairs. First of all, we are talking about the so-called "low-budget" stairs located in summer houses that are not heated in the winter. But the result is the appropriate: the staircase creaks, dissipates, the gaps appear in it.

The second minus of the wooden staircase is its high fire hazard. Therefore, in houses with a height of more than two floors, the only staircase in the house must have metallic Kosur and the metal substrates of steps covered with fire-resistant paint (for example, UNITERM).

Wooden stairs, like wooden houses, have a shrinkage period for several months, perhaps, after that you will have to adjust the fastening screws. Completing parts for wooden stairs supply Russian firms "Arbol", "Caucasian Forest", "Canadian cedar", "Practice".

A natural stone. When working with it, it is simply necessary for a good sense of measure, because the bulky stone staircase threatens to turn your home into the railway station or scenery to the film about the new Russians. It is not necessary to build a stone from a stone, it is enough to limit the steps and separate decorative elements. The framework frame is most often performed from metal, concrete or reinforced concrete, the railing is usually metallic.

It is recommended to use a stone extracted in a quarry by drilling, and not an explosive way (the inner cracks that occurred from the explosion will most likely show themselves during operation). Of all the breeds, granite and marble received the greatest distribution, and the latter is noticeably capricious. The marble is easily scratched, absorbs various acids (spilled a cup of coffee or tea will entail very unpleasant consequences). It is not necessary to use a conventional cement solution or adhesive for ceramic tile to lay marble - after a while on the surface of the stone, unreassed spots will appear. The Russian market offers special adhesive compositions and plasters of AKEMI (Germany), Bellinzoni (Italy), Lithofin (Germany). The same firms produce various mastic for the care of stones - both marble and granite.

With the arrangement of stairs, preference is better to give polished surfaces, because on a polished stone it is very easy to slip. For additional protection against drops, the central part of the steps are covered with special anti-slip rugs (for example, SUR STEP). They can be performed from various materials: sisal, natural wool, polypropylene, polyamide or rubber. Such mats on one side are usually self-adhesive, due to which they are fixed on the steps, and if necessary, it is easily replaced. The second option, allowing to protect the stone staircase and at the same time not to disguise all the beauty of the natural material - anti-slip bands that are cut or are sprayed at the outer edge of the stage. To the touch, this edge becomes a little rough.

In the Russian market, stone steps as an independent product (plates of various thickness) offer manufacturers like "Alparistk", "White Stone", "Pellets", Sardis Association. But many firms specializing in stairs supply stone steps in a set .

Ceramics. One of the possible solutions for those who wanted to arrange floors and staircases in a single style, their cladding with ceramic plates or porcelain stoneware. Votchchychi from natural stone, it is more durable materials resistant to chemical exposure and abrasion.

Most of the producers of floor tiles are both Russian and foreign, offered products in size 3030, 2020 and 1530cm. Such elements are convenient, including for the design of the staircase steps. It is better to choose anti-slip tiles. Warm lovers have the opportunity to provide a "ceramic" heated staircase.

The convenience of the staircase is determined by a set of several factors: an angle of lifting / descent; The width of the passage; the presence of rotary sites, intermediate sites; the presence of free space over the head of the rising person; Safe ladder fence; good lighting.

It is obvious that gentle stairs are more convenient than steep, the optimal option of tilt for the marching stairs is 30-40. If the design is intended to move the elderly or disabled, it is recommended to make it more common. The residency of the lift is associated with the ratio of the two-dimensional step (riser) and the width of the step (sticking). Back in the XVIIIVEK, the French architect Jean-Francois Blondez calculated the formula of the "architectural step": G + 2H = 59 64 cm, where the g-width of the stage, H is the height of the lift, and the 5964 cm average step of the person. But compared with those distant times today, not only the average human height, but also the size of his legs (so, in the XVIIIV, on average, the size of the adult man was 37-38). Therefore, now the most comfortable stairs with a riser 14-17 cm and a width of a sharpening 34-37 cm. The one, where there are small children, it is recommended to choose designs with risers - it is more secure.

The most compact is the staircase with variables ("goose") step. Its steps have a non-standard form for them "fully" the feet of only one leg can fit.

For a convenient passage along the stairs of one person, its width should be 70-80 cm, for two- 120-150cm. The distance between any step of the march and the ceiling must be at least two meters. This distance increases if the host growth is more than 180cm. Standard railings and balasins have a height of 90-100 cm. For convenient movement on the elderly stairs, the design is complemented by a wall handrail 80-85 cm. The distance between the balusters is from 12 to 25 cm.

The last three years on the Russian market there are new products - monolithic steps from porcelain stoneware. They are offered by the Italian factories IMOLA CERAMICA, PANARIA, MIRAGE CERAMICA and the Russian Firm "White Stone". The monolithic steps of aesthetic (seams do not spoil their appearance) and besides, they are not clogged with sand and mud. They can be fixed without prior equalization of the concrete base. For laying it is recommended to use special clamographic adhesive (for example, Atlas Plus by the Polish company Atlas or Keraflex Italian company Mapei, the last more expensive). The cost of one altair porrite plate (manufacturer- Imola Ceramica) is from $ 34. Ito is the lowest price for monolithic plates, achieved due to the flow of production steps of 330125022mm and their subsequent trimming under the individual dimensions of the stairs. The cost of steps of other firms is 2-3 times more expensive. Plates will need exactly as many steps your staircase has. Manufacturers also offer auxiliary elements - risers, plinths, angular steps, eaves. Ceramic steps slippery, like stone, - recommendations for creating safe operating conditions the same.

Metal - The most durable material for stairs. Steps exposed to the faster operation are made of steel (profiled rental) and cast iron (shaped casting). Metal fences are often used as an element of a tree staircase, stone, ceramics or glass. The main options for fences are a forging of ferrous metal, a bent polished profile or a pipe made of stainless steel or brass. More rare and expensive variations of non-ferrous metals, as well as combinations of "metal glass", "metal-ceramics". The cheapest fencing is the reinforcement, rod, grid. Metal artistic processing firms, most of them offer and fences for stairs ("Paravoz", "Welgart", "Factory of German Art Forging", "Russian forging", "Crystalsk").

Glass. This is the unconventional, avant-garde material for the design of the stairs. For the manufacture of staircases, glass, manufactured using multi-layer gluing technology ("triplex"), is used. Two or more layers of glass are combined with a polymer material (this may be a liquid polymer, followed by ultraviolet or polymer film, laid between the layers, followed by heating in special furnaces). The intermediate layer of the polymer is a reinforcing element and gives the design a special strength, and also does not allow glass fragments to crumble from the blow. For the production of non-ferrous glass in the liquid polymer, core additives are introduced. The mass of one step is 15kg and more (with a size of 100035028mm). For the safety of movement on glass steps, it is recommended to put anti-slip carpets, mount inserts from rubber or any other non-slip materials. In addition, protective rugs will be removed glass from scratches. The cost of the staircase is very high and practically does not depend on the design chosen by you- so expensive are the glass steps themselves (from $ 500 per piece). Russian firms "San Master" and "Bag" are engaged in the production of glass steps.

Style

Design, material, color - all this forms the style of the stairs, which ideally must match the stylistry of the interior or even dominate the house. There are no hard division of structures on various styles, but still historically there are some priorities. So, the classic interior is associated with massive wooden stairs. They are decorated with difficult in configuration by balasines, volitions, carved fittings. The carrier of the string has a complex configuration. At the same time, the staircase should be elegant and in no case is not rude. The classic-style room can be decorated with stucco and decorated with wooden panels with the same decor elements as the stairs. Country-style warm and homely cozy. It is welcome here rudely dyed stone, ceramic steps with effect effect, dark wood surface with small cracks or rough logs. On the sides of the stairs hang copper buckets, bouquets of dried colors or knitting onions. The stylistics of polished metal, as well as metal in combination with glass is close to the interiors of "techno" and High Tech. Forged metal fences are a traditional element of Modern and Gothic styles.

Prices

The cost of the staircase includes the cost of design project, materials, the manufacture of parts, taking into account the complexity of the selected design (handmade wooden bales are more expensive than serial), delivery and installation. A simple single-hour pine staircase When the distance between floors, three meters will cost a customer about $ 2,000, from a beech - $ 4,000, from an ash or oak - at $ 6,000. It is also accepted to calculate the cost of one meter of lifting vertical. For wooden structures, it averages $ 1500-2000 per meter, for metal-dressing- $ 1000-1, 1700, for fully metallic- $ 800-1500, for stone- $ 2500-5000, for glass- $ 7000. The upper threshold of prices does not exist. Most designs sold in the market are laid in a period of $ 5-6 thousand $ 12-15 thousand.Attic stairs

Specific and mansard stairs are presented with specific requirements. These designs are used quite rarely, should be invisible and compact integrity of saving residential space. Enchanting in a small drawer and conveniently decompose when you need. These are the most "cool" products (angle of inclination reaches 63-74). On the Russian market are presented by Alfa Scale (Italy), Century (USA), Henke (Germany), Oman (Poland), Rintal (Italy), Roto (Germany).

Depending on the design, the attic stairs are telescopic (sliding) and folding (folding as a harmonica), and according to the method of fastening, built-in and attached (removable). In order to access the roof, attic stairs are made with a blocking device that protects your home from unauthorized access. Factory stairs have a height of 250-350 cm, you can order the design of other sizes. The cheapest staircase from the tree will cost $ 100-200, most of the models offered in the market are worth $ 300-400.

| Firm | Country | Model | Design | Elements | Materials | Fastening | Product price *, $ |

|---|---|---|---|---|---|---|---|

| Albini Fontanot. | Italy | Scenik Sport | Screw | Running post, running steps, fencing type "Pouthene" | Beech (bleached), aluminum | To the floor and overlapping | - |

| Alfa Scala. | Italy | Vania. | Screw | Support, steps, fencing in the form of spiral-shaped tents | The Red tree | To the floor and overlapping | 15000. |

| Cast. | Italy | Mini Electra. | Marching, curvilinear | Kosur, Steps, Railings, Balasins | Frame, Perilan, metal, Tree | To the floor and overlapping | 7500. |

| Lapeyre | France | Prima. | Marsh, M-shaped | Two tents, steps (13-14), risers, railing, balusters | Tarari (Brazilian Oak) | To the floor and overlapping | 2500. |

| Nelur. | Italy | Nautilus. | Marching, curvilinear | Two testers, grooves, fencing type "Pouthene" | ATTA, "POTINE" -METAL, STEPS, RAYLEN | To the floor and overlapping | - |

| Rintal | Italy | Gara. | Marsh and turn 180 | Two tents (one attached to the wall), steps, risers, railing, reference pillars, balusters | Beech, wrought metal (fence) | To the floor, walls and overlapping | 6000. |

| "See Square" | Russia | Classic | Marsh and turn 180 | Two tents, steps, risers, reference pillars, balusters | Pine / oak | To the floor, walls and overlaps | 1600/4700. |

* - The product is a conditional staircase with a width of 1m, 3m height.

The editorial board thanks the company "Academy of the Interior", "EUROSTROYSERVIS-K", "Carex Style", "Saveks stairs", "Skvirel", "see Square" for help in preparing the material.