Comparative characteristics of the floor covering scored from carpet and rolling carpet coating squares, practical recommendations for choosing and care.

Apparently, the main characteristic of modern interior fashion must be recognized mobility. We increasingly appreciate the opportunity to easily and quickly change the appearance of your home, while it has not yet had time to bother or out. Hence this popularity of modular designs - modular furniture, modular suspended ceilings, modular parquet. It has reached the modular floor covering, which for a number of indicators is superior to the usual rolled carpet.

Carpet rolled and carpet modular

The side of the square carpet module is usually 50cm, although it is possible to meet 60cm, and among American products- and47cm. Like a rolled carpet, this coating consists of the base and the top layer. The front side is formed from a woven, tuffing or flocked pile, and can also be a needle-free or wicker. The pile or is connected to the primary basis and fastens with the base of the secondary, non-woven, through the latex layer (as in the roll carpet), or is fixed in the upper layer of a single multilayer base. Anyway, the reverse side of the foundation module is placed on the floor.

A bit of history

The development of machine carving at the turn of the XIX-XX centuries made it possible to reduce the maintenance and speed up the process of making carpets, and at the same time expand their circle of their buyers. Summary of consumer experience contributed to the appearance at the beginning of XXV. Floor carpets. Creation in 1947. Dupont synthetic yarn, and in 1950. In the USA-tuffing method of making a pile made these covers available to all. B1954 HEUGA has mastered the production of modular coatings, which implemented all the advantages of carpet in front of carpets. Starting with 80-hgg. XXV., Microprocessor equipment management helps to equalize the products of mass production and handmade on a variety of pile shape and pattern. This led to the conversion of carpet into one of the most practical and elegant species of flooring.

The mud-repellent properties of the coating are improving by applying a thin layer of Teflon on Dupont technology. Other options for such protection are also known: for example, Bayergard of the German company Bayer, until recently used the ScotchGard of the American company 3m. The result is mud just does not stick to the fiber and easily removed with a vacuum cleaner. In the manufacture of modules, their antibacterial and antifungal processing is performed.

Differences of the modular carpet from a roll

But from individual modules, you can collect any intricate outline, material waste will always be less than when using a roll coating. Some collections include a set of 3-4 elements with different fragments of a single pattern, by difficulty not inferior to the drawing of carpet or roll carpet. The evaporator surface of individual modules is not necessarily brushing directly on the floor, they can, for example, to give in dry cleaning. If, in places of the most intensive exploitation of the floor, the surface was noticeably watched, nothing prevents you from changing modules with places with those that are used in more "calm" zones, or just replace new. If necessary, repair the main floor (let's say, in the case of a raspiece of parquet), it is sufficient to raise only one or two fragment of the coating, and not to learn a significant part of the roll. Some collections allow you to slightly change the drawing of the carpet, on their own "pulling" its parts. Aesley you fear for the roadside parquet floor, you can literally an hour before the arrival of a large number of guests to the coating on it (the apot is also easy to remove). Finally, when changing the apartment, the modules can be captured with them, equally simply by removing them in an old place and putting in a new one.

Modular carpets are sold in specialized salons. On the Russian market there are products of manufacturers such as the American company Interface and its Dutch department Heuga, Belgian Desso and its Dutch Esco Branch and German DLW, French Tarkettsommer, English Brintons, Graduc and Bonarfloors, Belgian Lano, Dscarpets and Tasibel, German Fulda, Dura and Domo.

Module base: Material and structure

The reverse side of the base is performed with a small ripgy - to increase the friction force when laying on the floor. The base thickness is usually 2.5-5mm, the total thickness of the module is 5-9mm. But you can find elements and with a higher vors - up to 7-9mm. The maximum density characteristic of a flocked pile, by convincing the managers of the company "Kontraftstroy", increases the resistance of the facial surface of the coating to pollution. Some firms make modules with a dirt-waving surface, which is inserted into the pile of a mixture of wool (80%) with polyamide fiber (20%), more rigid threads, such as a thin line or metal wire.

Options coloring surfaces

The modular coating with the fasteners of the company Gradus on the staircase surface of the coating can be a monophonic, melange or have a drawing. Waterproof option is achieved the most durable staining - Massage (solutiondyed), before pulling the thread. Melange coloring (small drawing with a chaotic combination of colors) is achieved either by twisting several threads of different color, or as a result of repeated staining of individual sections of one thread with different colors even before the manufacture of the coating. The plot pattern is obtained either by combining the threads of different colors, or apply the paint screen or inkjet to the surface of the ready-made module.

The relative position of the sides of the adjacent modules, even with a monochon or melange color, usually matters. The laying direction is indicated by the arrows on the reverse side of the base. If the elements are different, in different ways, a deforming pile will eventually emphasize the composition of the surface. Proper laying will make gaps between modules invisible, and high-quality pile will exclude the appearance on the coating of the trotted paths.

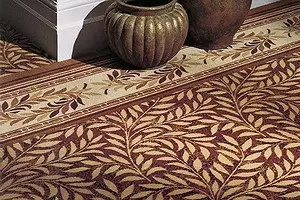

Depending on the degree of complexity of the figure, the coating can be formed from 1-4 modules. Sometimes the composite surface nature is specifically emphasized (for example, a chess cell in the Tisseynattey collection and a strip in the PremiumDesigh collection of the company TARKETTSOMMER, as well as in the coatings of Montana and Taupe Multi from Bonarfloors). And, let's say, the various elements of the Galleria collection from the company Interface allow the surface with such a complex single pattern that at first glance, the coating is difficult to distinguish from the carpet (even the curb is provided). Modularity makes it easy to adjust the drawing along the indoor contour, since the length and width of the coating are created in almost the process of laying.

Moldings, layouts and framing steps

To interfacitate the dysfype, modular coating with rolled or for framing the steps, you can use the fasteners of the company Gradus. They simplify the laying and protect the edges of the modules from squeezing. So, for each step and for the inner staircase, in general, there are sets of layouts and framents performed in several color variations. The carpet is attached to the floor rigidly, after which the edges are covered with fasteners, giving the connection to the connection a kind and elegant look. Light bulbs and wires of hidden wiring can be embedded for highlighting when using the staircase. Extras are provided with grooves and folds, corresponding to the altitude of the coating. So it is allowed to floor modules without attaching.On the surface of the modular coating, you can create any original drawing. It is only necessary to record it on a floppy disk and wait for about four weeks, while in the factory it will be applied to the white surface of carpet modules using inkjet printing. It will be more expensive to cost such a coating. But you can order modules with your logo, and in several combinations of colors of the inscription and the background.

Free flight fantasy

Single-type modular coatings with bright patterns or multi-colored inserts in two or three places are quite widespread. However, with this solution, it sometimes has to make additional patterns that are missing in the package of the company. According to the company's specialists of EscapService, the only restriction in the implementation of the customer's fantasy becomes the ripples from the varnish color and a large number of surface elements.

Modular coating care features

It is necessary to monitor the modular coating in the same way as for the roller. Experts warned by carpet owners from abundant use of fluid to remove cleaning products, as well as from excessive hobbies with a cleaning vacuum cleaner. Excessive moisture stalk through the gaps between modules to the floor. Of course, the restriction can be not considered when cleaning modules outside the floor.Fighting with static electricity

DuPont has developed another mechanism for electrostatic protection of modules. It produced by the fiber with the name Antron is supplied with a conductive filler. According to such a thread, the accumulating charge flows first into latex, and then a broken bitumen layer of the base. Moreover, both the other layer has a reduced electrical resistance (volumetric and surface). The overall coating resistance should be at least 5105 and not more than 21010, which limits the size of the charge and the risk of sparking. All layers of the basis for reliability are "flashing" through special conductors. Several collections of modular coatings with similar properties on a bitumen basis and with ATRON fiber produce Interface, Desso and Gradus (for example, Tatami from Interface, Pallas-XL from Desso and Cascata from Gradus). On the wrong side of the module, there is an inscription indicating the presence of antistatic protection that meets the IBM / ICL methods test requirements (Interface Company ComputerGuard system, Polyscan Computer system from Desso). To completely eliminate the accumulation in such a coating of the electrostatic charge, it is enough when laying ground the base. It is very convenient when creating a home theater, with active use of a personal computer and a variety of electrical appliances.

Module mounting methods to the floor

Free laying ("dry") is effective with a clean and smooth floor surface, for example, if it is a lacquered parquet. Also permissible in the case of a thoroughly aligned plane covered with organice stoves.

With the help of two-way skotch, the module is attached by analogy with a roll coating: a mesh is glued to the surface of the floor from the arrangement of the cross-closer stripes (there must be less than the side of the module). This method is sometimes combined with the first, fixing the coating only around the perimeter, and the central part laying freely.

The glue is most often used acrylic, polyurethane or epoxy, high quality. It will provide a solid coating with floor, but the reuse of the modules will be quite problematic. At the same time, the specialists of the Bamard company distinguish the preliminary preparation of the surface of the floor with conventional moisture (on a cement screed or wooden) and with high humidity.

Requirements for the floor surface

Storage modules

Practical recommendations

one. Some manufacturers firms indicate two directions of possible laying of monophonic modules: the promotional and "chess" position of the pile of adjacent modules. Note that in the second case, the original texture of the smooth surface is created, especially noticeable at a look at an angle.2. So that the gaps are invisible, it is not necessary to get involved in frequent permutation of modules: the waging of some time in a new location will be visible. For the same reason, it is better to numbered all the elements of the coating on the reverse side if its transfer is envisaged to another place.

3. You can make an original pattern of coating from multicolored modules laid by the "cross" or on the principle of a patchwork blanket. Do not limit yourself with one collection. Outdoor panels are especially advantageous when the room is over 30m2.

four. A very tempting laying of modular and roll covers is not always realized due to different requirements for their basis. The unsatisfactory result is sometimes manifested immediately, but after some time. Separating thresholds on the border of heterogeneous materials will help solve the problem.

five. When using modules with a mud-making surface, it is worth pre-picking them in the tone of the main collection. Stop these modules in the hallway with the use of thresholds, ranging from the entrance door and 4-5m to the depth of the room. By the way, such a coating with a rather rigid pile can be used to massage feet feet.

6. The highest quality protection against electrostatic electricity will provide a metal foil mesh, laid between the carpet and the floor and grounded in the usual way. It can be made and lay an assembly company with coverage flooring.

Warranty obligations

Examples of modular carpets

| Manufacturer | Model | Outer layer | Picture | The foundation | Price 1m2, $ | |||

|---|---|---|---|---|---|---|---|---|

| Preparation method | Material | Character | The number of frag- cops | Material | Number of layers | |||

| Interface (USA) | Galleria. | Tafting, looting | Polyamide Antron. | Multicolor | 2. | PVC | five | 63. |

| Galleria. | Tafting, cut | Polyamide Antron. | Multicolor | 3. | PVC | five | 63. | |

| Galleria. | Tafting, cut | Polyamide Antron. | Multicolor | four | PVC | five | 63. | |

| Tatami. | Tafting, combined | Polyamide Antron. | Monophonic | one | Bp | five | 43. | |

| Desso (Belgium) | Vitae. | Tafting, looping, multi-level | Polyamide Antron. | Melange, multicolored | one | Bp | five | 38. |

| Pallas-XL. | Tafting, looting | Polyamide Antron. | Melange, multicolored | one | Bp | five | 33. | |

| Mila. | Tafting, looting | Polyamide Antron. | Melange, multicolored | one | Bp | five | 28. | |

| Tarkett Sommer (France) | PREMIUM DESIGN. | Tafting, looting | Polyamide | Multicolor | one | PVC | five | 28. |

| Tissey Nattey. | Tafting, looting | Polyamide | Multicolor | one | PVC | five | 38. | |

| Brintons (United Kingdom) | Cornerstone. | Woven, Wilton. | Wool - 80%, polyamide - 15%, polyester- 5% | Single, Melange | one | PVC | 3. | From 80. |

| Gradus (United Kingdom) | Cascata0. | Tafting, looting | Polyamide Antron. | Melange | one | Bp | five | 24. |

| Tahoe. | Tafting, cut | Polyamide Antron. | Monophonic | one | Bp | five | 51. | |

| Bonnar Floors (United Kingdom) | Santiago. | Flocated | Polyamide | Monophonic | one | PVC | * | 35. |

| Montana. | Flocated | Polyamide | Monophonic | one | PVC | * | 35. | |

| LANO (Belgium) | Matrix 500. | Tafting, looting | Polyamide Antron. | Melange | one | Bp | five | 34. |

| Matrix 900. | Tafting, looting | Polyamide Antron. | Melange | one | Bp | five | 42. | |

| DS Carpets (Belgium) | Tonga. | Tafting, looting | Polypropylene | Melange | one | Bp | * | nineteen |

| Tasibel (Belgium) | Tasicocos. | Wicker | Coconut - 53%, sisal- 47% | Single, Melange | one | Bp | five | 62. |

| Domo (Germany) | Firenze | Tafting, looting | Polyamide | Single, Melange | one | Bp | five | 29. |

| Rallye. | Tafting, cut | Polyamide | Single, Melange | one | Bp | five | 29. | |

| FULDA (Germany) | Ment. | Medalmobive | Polyamide | Melange | one | PVC | five | 26. |

| Star | Medalmobive | Polypropylene | Melange | one | PVC | five | 24. | |

| Dura (Germany) | Prestige | Tafting, cut | Polyamide | Single, Melange | one | PVC | * | 23. |

| Derby | Tafting, looting | Polyamide | Single, Melange | one | PVC | * | twenty |

* - The number of layers does not provide.

The editorial board thanks the company "EscapService", "Bamard", "Bobrovcompani", "Kontraftstroy", Carpet House stores, Interface, Desso, DuPont and Tarkettsomer representative offices for help preparing material.