Waterproofing the foundation and swallowed parts of the building. Types of waterproofing according to the method of applying and the principle of action. Practitioners.

The reason for the formation of stalactites in the basements of residential buildings is the same as in natural caves, the leaks are to blame.

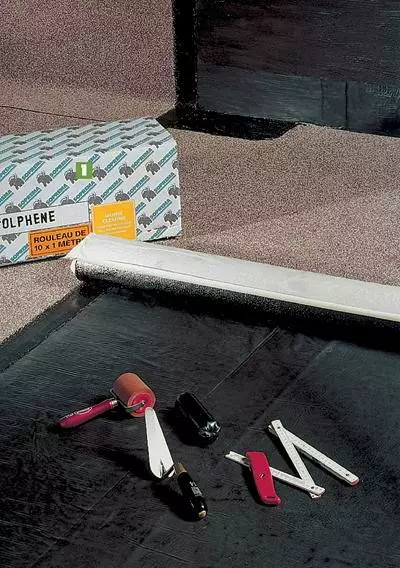

Stages of repair of waterproofing coating:

a) stripping the surface of the metal brush;

b) bringing the brush to the metal armature of the KEMA Armafix anticorrosion coating;

c) applying a layer of waterproofing FASI FM (3 mm);

d) Recovery of the protective layer of concrete using the laid dry mixture of FASI RM.

Styrodur plates not only protect the basement from the water, but also saved from the cold.

Water is the basis of life, without it, a person will not last five days. However, the appearance of moisture in the basement of the house can not only spoil the owner of the mood, but also to poison this very life.

Of the tens of thousands erected in recent years (and often very expensive) cottages, many people already require a serious repair of basement floors and basement. Moreover, this repair does not make sense without the restoration of the entire system of waterproofing the foundation and the beaten parts of the building. The reason for such a "epidemic" leaks - in errors at the design stage, in the absence of experience or intense builders, in poor quality work, and sometimes in excessive leisure of the developer.

Underground rivers, clay shores

The level of groundwater (AGB) depends primarily on the species of soil. For example, for the Moscow region is typical loam. It is distinguished by weak water permeability and uneven depth of the bombing of the aquifer. The fancy of underground landscapes is forced to prevail any construction of hydrogeological surveys. If some obstacle will be in the capillary lift zone (for example, the concrete foundation of your home), underground sources will wash it. Spring melting of snow and ice, summer shower, small autumn rain, such a cute heart of poets, - All this creates an additional threat to the flooding of the house.The characteristic of the soil "width =" Fixed

Somewhere there, in the depths, there is a water-saturated layer of soil. From it, the moisture climbs up all the soil in one degree or another is water permeable and, like any porous material, trying to absorb liquid into itself. The more denser the soil and the thinner of the pores in it, the higher the capillar climb of water. Even a dense fatty clay is very slow, but it raises moisture to a height of 12 m and more over the aquifer.

Height of the capillary lifting of moisture above the level of aquifer

| Characteristic of soil | View of soil | Height of capillary lifting, m |

|---|---|---|

| Well-permeable | Alert washed, gravel | 0 |

| Pliced | Sand coarse sand | 0.3-0.15 |

| The sand is fine-grained | 1,1-2 | |

| Weak-produced | Spring | 1,1-2 |

| Suglink easy | 2-2.5 | |

| Suglok medium, heavy | 3.5-6.5 | |

| Waterproof | Suglok fat, clay | 12 or more |

The foundations are sitting at the same time with the prohibits (joke)

The cost of the foundation is usually 15-20% of the total cost of the house, and the cost of waterproofing the foundation is 1-3%. But the miscalculations and poor-quality performance will inevitably require investment in the future of essentially.So, construction begins with the foundation bookmark. The most commonly offered block foundations have a lot of advantages, among which is a large bearing capacity and cost-effective way of laying. But from the point of view of waterproofing it is preferable to the foundation of monolithic. The lack of docking seams eliminates the need for their pavement, that is, filling with cement mortar. Slightly missed the joints on top (which is limited, as a rule, brigades of builders from the southern regions) for the middle strip with its harsh winters is not enough.

No construction is done without deformations (an example, the famous tower in the city of Piza, Italy). The heterogeneity of the soil, the receipt of seasonal moisture, temperature fluctuations cause uneven decides in the earth and, as a result, internal stresses in the basement material. The moisture that has absorbed in the pores of concrete is expanding during freezing (by 9%) and breaks it. So microcracks are formed, opening the road to the active current of water. This problem arose no today, and the paths of its permission there are many.

According to the method of application and the principle of operation, the following types of waterproofing are distinguished: coating, inlet, penetrating, mounted.

In addition, there are: fast-solid compositions for repairing emergency leakage; Sanitary plasters; hydrophobic compositions for giving concrete and brick water-repellent properties; Antisole, anti-grapple impregnation and much, much more.

Foolish waterproofing

Already 5000 years ago, residents of ancient interfluve in the construction of housing in a wetlastone used natural bitumen for waterproofing. And now, bitumen and bitumenting materials are most common, known, are familiar, inexpensive, easy to use. But it should be borne in mind a significant drawback of these materials: their service life is limited to the five or six years. The fact is that the bitumen itself loses elasticity and becomes fragile already at 0 ° C and arising at this deformation temperature inevitably lead to the appearance of cracks. The coating necessarily breaks or squeeze. In addition, working with hot bitumen (heating temperature when applied at least 120 ° C!) It is extremely unpleasant and dangerous.

The briefness of the petrochetum materials led to the emergence of their serious competitors, synthetic resins (polymers) and materials based on them. Produced as bitumen rubber bitumen-polymer and mastic cold application in an organic solvent.

Types of coating mastic domestic production

| View of mastic | Application temperature,FROM | Layer thickness MM. | Average consumption kg / m2. | Price 1 kg, rub. |

|---|---|---|---|---|

| Bituminous | 120-160 | 4-5 | five | 3-6 |

| Bituminous rubber | 80-95 | 4-5 | five | 10-20. |

| Bituminous polymer | -20 ... + 50 | 2-3. | 2-3. | 15-35 |

For example, the well proved bitumen-latex emulsion mastic "BLEM-20", which releases CJSC "Ryazan Cardboard and Ruberoid Plant". Polymeric materials of foreign production are approximately three or four times more expensive than Russian products.

To apply surface waterproofing cement-polymer mastic, consisting of dry cement mixture with a mineral filler. The mixture shuts water special binder emulsion or an aqueous dispersion of polymers (acrylic, silicone or vinyl). Thanks to the cement component, these coatings have good adhesion to the base. Plasticizing additives help the material successfully operate not only on rigid surfaces, but also in places exposed to deformities and vibrations. The water-proof binding components penetrate the pores of the base and tight them tight. The thickness of the layer of such coats is small - 1-3 mm.

From the materials of this series you can call Covercol AB Rapid from Index (has adhesion more than 40kg / cm2 and W22 water resistance), ThoroOal Thoro, Barralastik manufactured by Heidelberger Zement. Waterproofing from OSMOLASTIC (INDEX) and Aquafin-2K (Schomburg) withstands crack opening at a base to 2 mm. High-quality materials have waterproof not lower than W10, that is, they can resist water under pressure to 10thm. Of course, there are no such jets in the ground. But the pressure of solutions of salts penetrating the inside of the foundation (osmotic pressure) can reach a comparable level.

Similar domestic materials- is "Lahti" Obmazochnaya "(OOO" Gidrokor "), a series of coatings" Gidroteks "(NIIZhB)" Germolastik "(AOOTOZSS). Probably, here also should include a mixture based on cement series" Hydro-S ". True, the thickness of the layer of such material should reach 30-50mm.

The coating waterproofing is used, as a rule, to protect the surfaces from capillary moisture (inside the house) and soil water (outside) with draining soils and pressure to 0,2thm.

Caution materials based on closed dry mixtures

| Manufacturer | Name | Consumption, kg / m2 | Price 1 kg, rub. |

|---|---|---|---|

| Thoro, Belgium | Thoroseal | 3-4.5 | 66. |

| HEIDELBERGER ZEMENT, GERMANY | Barralastik | 1.5-2 | 59. |

| KEMA, Slovenia | Hidrotes-94. | 3-4 | 38. |

| Index, Italy | Osmoflex. | 2. | 62. |

| Schomburg, Germany | Aquafin-2k. | 3-4.5 | 37. |

| LLC "Hydrogen", Russia | "Lachta" Caution " | 3-4.5 | 40. |

| Glims, Russia | "Glims-waterstop" | 6-12. | nineteen |

| NIIZB, Russia | "Hydrothex-B" | 4-5 | 24. |

Waterproof waterproofing

Its waterproof cover is performed from rolled or film waterproofing materials glued on the base and on each other using waterproof mastic. The most familiar ear is the name-rubkeroid, only pergamine. These materials are non-breeding, non-abroad and, accordingly, are short-lived. They are gradually replaced by representatives of a new generation of rolled waterproofing: Isoelast, isoplast, Mostoplast (Izoflex Plant, LLC Kirishinefteorgsintez), EcoFleks, Bikroplast, Tehnonolist (Tekhnoflex plant). As the basis, synthetic materials (polyester, glass cholester, fiberglass) are used in these coatings. The bitumen is modified by the polymers of SBS (styrene-butadiene-styrene) and the APP (atactic polypropylene), which significantly increases its elasticity and heat resistance.Imported rolled materials (from Icopal, Index, Firestone) are distinguished by high and stable quality, but are four to five times more expensive than Russian.

Structuring and practitioners note that rolled waterproofing is reliable and durable, but the capriciety performed. It requires a carefully prepared surface-unacceptable irregularity of more than 2mm, a dry base is needed, primer a bitumen emulsion, extremely neat sticking or watering material. In the case of applying such waterproofing from the outside (with a positive water pressure), it is necessary to protect it (for example, using screens, panels or geotextiles) from possible mechanical damage.

Domestic rolled waterproofing materials

| Manufacturer | Name | Retains elasticity at temperatures, with | Price 1 m2, rub. |

|---|---|---|---|

| Factory "Izoflex" | Isoelast | -40 ... + 90 | 70-80 |

| Isoplastic | -25 ... + 90 | 60-90. | |

| CJSC "TEKHNONIKOL" | Uniflex | -15 ... + 110 | fifty |

| Technoelast | -25 ... + 100 | 40-70 |

Waterproofing penetrating action

Refractory waterproofing on a cement basis spawned penetrating (from the English. Penetrate- penetrate) materials. The first compositions of this class developed the company VANDEXINTERNATIONALTD. (Switzerland) in the 40s of the XXVEK.Penetrating material made from a blended cement chemically active agents and especially particulate sand. Used to reduce the capillary conductivity of concrete. Supplements together with capillary moisture fall through open pores into the thickness of the sub bases, where they interact with the components of the concrete and form the crystals of a thread shape. Pores are significantly narrowed, the water permeability becomes lower. And this is despite the fact that vapor permeability decreases slightly and the ability of the walls to "breathe" is preserved. The thickness of the waterproofing layer ranges from 1:3mm. It is believed that these materials can be used both outside and inside the building.

Penetrating compositions are good for fresh concrete. When repairing an old concrete, when the external pores are grilled or clogged with limestone, it is necessary to carefully clean the surface from plaster and degrease, opening access to the capillary system. Moreover, the scraper or wire brush for this operation is not enough. It requires a shot blasting or water jet, operating at a pressure of at least 15-20thm.

Practitioners' opinion »width =" Fixed

At the heart of each particular case of construction, despite many options for its implementation, there are always common, typical solutions developed by years of practice. This is what experts are advised by CJSC Convent Center for two rather complex construction cases. In this case, the risk of capillary suction and high pressure of rainwater is high. So the protection of the basement should be combined with a drainage system with waterproof waterproofing. First, they cast the sole of the foundation and lay the reinforcement for its walls. Then the perimeter is carried out drainage pipes, they put the walls of the foundation and cast the floor. The floor is made multilayer and placed on sandy (and better gravel) preparation. On the sabe soils, the maintenance is additionally covered with geocan. A concrete reinforced tie with a thickness of 100-150mm is placed in a layer of polymer-bitumen membrane (Flexter Testudo). Her sheets are welded with a gas burner with an overlap 100mm. Next are the thermal insulation, the separation layer and, finally, the concrete screed for the trim. Outside, the foundation is treated with an oxidized bitumer primer (indever) and lay the sheets of membrane waterproofing, from the drainage pipe and up to 300-500 mm above the ground level. The insulation layer is closed with geocal or protective panels and make backstage. The construction cycle lasts at least 4-5 weeks.

Penetrating shifted mixes

| Manufacturer | Name | Consumption, kg / m2 | Price 1 kg, rub. |

|---|---|---|---|

| VANDEX INTERNATIONAL Ltd., Switzerland | Vandex Super | 1-1.5 | 95. |

| Index, Italy | Osmoseal | 3. | 46. |

| LLC "New Technologies", Russia | "Calmatron" | 1.6-3,2 | 45. |

| Xypex Chemical Corp., Canada | Xype | 0.8-1. | 182. |

| LLC "Hydrogen", Russia | Penetron | 1,2 | 159. |

| "Lachta" penetrating " | 1,2 | 60. |

Mounted waterproofing

Another waterproofing technology is the creation of protective screens. From a long time, a compacted clay (layer 40-50cm) is used for this purpose - the material is widespread and easily accessible.The natural development of the idea was the so-called bentonite waterproofing. Bentonite clay has a pronounced colloidal properties, is capable of playing the role of a shield even when the thickness of 1-2 cm. Bentonite layer enclosed between sheets of cardboard (like bentonite panels Volclay) or geotextiles (e.g., bentonite mat Rawmat HDB). The cardboard shell during operation decomposes in the soil. As a result, the entire bell surface is surrounded by clay.

On the domestic market there are Nabento insulating mats (Akzo Nobel Concern), as well as the Bentomat panels and VOLTEX mats (Cetco). Prices for bentonite mats - approximately $ 10 per 1m2.

Last development in the field of protective screen technology - polymer geomembranes. Their undoubted advantages - durability, neutrality to aggressive media, resistance to the deformation of the structure and the movement of the soil. The screen consists of a web with rounded spikes up to 8mm and filtering textiles. Textiles protects the system from the soil particles with particles, and rounded spikes form drainage channels for which the filtered water is sent to the drainage system. This decision prevents the building drawdown, provides good waterproofing of the walls, and also serves as protection plates of the base from the capillary moisture supply. Drainage screens are successfully operating only in the complex with a drainage system and cease to function when the groundwater level rises above the level of removing pipes.

In the Russian market popular products Fundalin (ONDULIN, France), Protefon Tex (INDEX, Italy), Delta (DORKEN, Germany), Blackline (MONARFLEX, Denmark), and others. The price of 1m2 of the polymer membrane with geotekstilem- $ 4-8. But the total cost of arranging the drainage system, including preparatory and earthworks, of course, is significantly higher.

Thermal insulation of foundation

There are often cases when efforts, money and materials on waterproofing are spent a lot, and in the basement still damp. The culprit may be condensate falling on the "cold" wall of wet air. Therefore, the walls of the basement from the outside must be insulated, and inside the ventilation. Can be covered by porous walls special "warm" plasters which reduces condensation of the vapor on a cold surface (e.g., Hidroment, KEMA; Poroge, Deumisan from INDEX; Dry Seal D. S. company DRY WORKS). They are obtained by adding pore-forming additives to a plaster solution) or embed from the finished mixture.

For thermal insulation of foundations used rigid sheets of extruded penopolistirola- say, Styrodur (BASF), "Ekspol" (NGO "EKSPOL") - as well as foamed (porous) PPP. The first works at the same time as a waterproofer, and the second, in a pair with geotextiles, as a drainage device.

Systems approach

The variety of funds suggested suggests that the only best way to protect the construction of moisture does not exist. In each case, depending on the construction conditions and the operation of the building, you need to create your own integrated system of waterproofing.This approach is typical for INDEX firms (Italy), DRY WORKS (Netherlands), REMMERS BAUCHEMIE (Germany), by KEMA (Slovenia), FEB MBT (United Kingdom), SEMIN (France), SCHOMBURG (Germany) and others. And if, for example, In the assortment Index, Vandex International Ltd. And Delta has 1000 items of materials related to waterproofing, they are more than enough to compile a recipe for "treatment" of any crack. Comprehensive measures may seem expensive ($ 12-60 per 1M2), but they guarantee success.

Practitioners' opinion »width =" Fixed

Let's just say: a plot with such properties a gift of fate is not. Not only that water will actively look for the slightest slit at home, so also the deformation of the parts of the foundation will be significant. Therefore, the whole foundation is required to isolate. First of all, it is necessary to pump water on the construction site. At the bottom of the excavation, concrete preparation is performed. It is mounted on the formwork for the outer walls of the foundation and laid the waterproofing material with a reserve of 500-700mm around the perimeter, to then start up the wall. In order not to damage the insulating "carpet" with further work, it is protected by a layer of concrete with a thickness of 30-40mm. Then they mount the reinforcement, formwork and cast the base of the foundation, its walls and gender. After disassembly, the formwork perform vertical waterproofing. From above, leave the stock of 300-500mm to make a horizontal cut-off from the walls of the house. Downstairs, the vertical insulation is welded with horizontal. In this case, an elastic polymer-bitumen membrane HELASTA P4 4mm thick, reinforced with polyester fiber, can be an insulating material. All surfaces are treated with primer (indever). The membrane is placed in two layers. Horizontal waterproofing on the walls are protected by panels and sprinkled with soil. The working cycle lasts at least 7-8 weeks, if the isolation is carried out for not fully solidified concrete.

Work on bugs

Suppose the house is barely built, and the basement already fills with water. Even for this case there are many special methods and materials capable of restore comfort.First of the materials. It should be noted here that their division on construction and repair conditionally, - in the fight against leaks and dampness all means are good. In our text, the separation is made exclusively for the convenience of presentation.

In most cases, the restoration of the external waterproofing of the bellped parts of the building is difficult due to the impossibility of excavation. Output protection from the inside. There is a significant difference between the arrangement of external and internal waterproofing. In the first case, water pressure from the outside presses the coating to the base, it is second off from it. Thus, bitumen mastic and rolled coatings do not apply for internal waterproofing. Here are appropriate cement-based materials with good adhesion to concrete or brick supporting design. In the internal works, still coating, penetrating compositions, plastic drainage with water removal with a pump, etc.

Injection materials and technologies

There is a waterproofing technology that developed in the USSR since the 30s of the XXVEK. It uses through holes in the walls and the foundation that allow you to pump a solution of cement or liquid glass with a hardener from the inside of the building outside, to the area between the foundation and soil. So the waterproof "sarcophagus" is formed, and the external waterproofing is restored without carrying out earthworks.

The number of problems associated with waterproofing, methods for their solution and the applied funds are not exhausted by the above list. But about this, the next time.

The editors thanks at Atomstroy, "Gidrospetsproekt", "Convent-Center", "Spetsgeostroy", "Templesystem", Tesserevis, Triad Holding for help in the preparation of material.