Decorative textured coatings: the main properties and features of working with different types of coatings, preparation of the base and tips of the master.

Remembering the inevitably repetitive troubles on updating old wallpapers and irradiated paint, unwittingly begin to dream of something eternal and beautiful on the walls of its apartment. We will show how a few steps come close to the embodiment of this dream. It will be about wall decorative texture coatings.

Coatings can be applied to the base of concrete, brick, drywall, plaster, ceramic tiles, metal, wood and other materials. They are used both for internal and outdoor finish (this should be indicated on the package).

Decorative coatings on the Russian market offer more than ten manufacturers, such as Viero (Italy), Markem, Bayramix, Duo, Proset (Turkey), Caparol, Tex-Color, Alligator (Germany), Texsa (Spain), Softramap (France ), Plastone (Russia) and others. The range reaches several dozen species, each of which has an average of 5 to 25 colors.

Features of textured coatings

Different types of coatings can be distinguished by three common basic properties:- Polymer binding basis.

- Punching filler uses natural materials: marble crumb (granulat), quartz sand, lime. The volume of the filler in different types of coatings ranges from 40 to 85%, their consistency depends on this.

- Liquid base of all coatings - water.

Properties and features of each of these elements in the composition of the composition give the coating of certain consumer properties, and in general, it is environmentally friendly, reliable and technological materials. In advertising prospects, firms meet the terms "acrylic binder" and "latex binder". Without going into details, we note that in these cases we are talking about acrylated copolymers in the form of fine-dispersed water emulsions. The main thing is that these emulsions are water. After evaporation of water, the polymer particle under the action of oxygen and light is converted into a solid mass, which reliably fastens the particles of the filler and holds them on the base. After solidification, the polymer is no longer dissolved with water and withstands the effect of chemicals, frost and mechanical load.

In addition, due to water based, the coating does not smell. Therefore, the repairs can be done at any time of the year and do not open windows to carry out the risk of cold.

However, the water base causes some restrictions. For coatings, both surpluses and lack of water are harmful: it can be added no more than 3-5% (usually one liter on a weasome of 25 kg). It is necessary to apply coatings on a dry surface, and outdoor work cannot be carried out in rainy or windy weather. As it dry out, the material hardens and changes the plasticity, it complicates the receipt of homogeneous texture throughout the wall. Therefore, it is necessary to work with it quickly, without interruptions, at a temperature not higher than + 35s and not lower + 5c. True, the same properties can be used specifically to create interesting effects on different sections of the wall, but such a reception should be planned in advance.

Store these materials in a tightly closed container with minimal air access. Storage and transportation of most coatings brands under negative temperatures are undesirable, and sometimes unacceptable (manufacturers' needs). But if the material was stored correctly, after hardening it would be frost.

Coatings have high wear resistance, resistant to salts, waterproof, withstand the temperature differences from -55Sdo + 60C, do not fade, fireproof and fairly fire-resistant (in any case they are not damaged if they have a cigarette. In addition, they are essential enough to resist the deformations of the walls without the formation of cracks. There are also coatings with soundproof properties and antifungal additives.

Their color and texture depend on three factors: the column range of the filler, the composition of the binding base and the technology of applying material. If you wish or need, they can be easily covered with paint or non-acidic varnish.

4-6 hours after applying the coating to the walls, it is already possible to touch, after a day, the premises are ready for operation, but the final hardening occurs only a few days (from3 to 24 days, under the terms of the manufacturer).

All coatings must have the appropriate hygiene certificate of the Russian Federation.

The developers of new finishing materials successfully use the remarkable properties of natural stone and mineral materials when creating decorative texture coatings based on modern polymer-durable, colorful and easy-to-use.

What to choose?

First of all, it is necessary to decide that for you it is preferable: traditional types of finishes, that is, wallpapers, paints, ceramic tiles, or material with new decorative properties.

Wallpapers are clearly losing textured coatings in practicality, but won in a decorative plan. Like paints, they require a more thorough preparation of the base, and the textured coatings easily mask small cracks and hide the wall defects. Paints for a number of properties are not inferior to coatings, but their decorative possibilities are limited only by the color range. The pauses are expanded by the relief and surface texture.

Ceramic tile on many properties is comparable to textured coatings, but more laborious and requires good skills. Decorative textured coatings are so technologically that even the newcomer is quickly mastered, and it has a space for creativity.

Hall, toilet, bathroom, stairways, wall, which prefers for their "exercises" your four-legged favorites are all suitable objects for the use of such coatings. Combining texture and color, they can be successfully used to create copyright color panels, especially when you work with a material containing painted particles.

Depending on the type, the coatings are applied to the walls with different tools. Using steel smooth, you can get a flat surface with the texture determined by the size and color of the granules. Plastic ironing creates textured surfaces, roller-relief and wavy, and sprinkle-relief type "fur coats".

Class coatings are the easiest of all on the main factory-forming feature, the size of the granules (grain). There are the following types:

- C calibrated marble (sometimes granite) granules;

- mixed graininess, when a small amount (5-15%) of a coarse fraction (1-2mm) is distributed in the mass of fine-grained granules (0.2-0.5 mm);

- with fine-grained uncalibrated granules;

- with fine mineral fillers.

As part of these types, gradation can be continued (for example, graininess 1.5-2.0mm, 0.9-1.2mm, 0.2-0.5mm, and so on). We can use different consistency with a subgroup (diluting the finished weight of water) and modify the finishing technology.

How to work with different types of coatings?

It should be borne in mind that only four factors affect the texture of the surface:- Tool type;

- The time interval between coating and final finish (usually from15 to 30 minutes);

- Technique work with a tool;

- Fantasy Master (the only thing that is not limited).

Coatings with calibrated marble granules. The material has a pasty consistency in a stirred state. It is applied to the wall with a steel ironing smooth layer. The layer thickness in the ideal case should be equal to the size of the grain, but if it is necessary to hide the wall defects, apply a layer to 3-4mm. After the coating lights up slightly, it is burned with the same ironing.

Granulate transfers the beauty of natural stone and combines well with other types of coatings, expanding the palette of paints and textures. It is used as a facade and interior coverage of cottages and offices. In the apartment it is better to use it fragmentary or on small areas, on complex elements of wall structures: openings, niches, protrusions, boxes, racks.

Coatings with mixed grain granules. The introduction of a small amount of large granules in the mass of fine-grained expands the decorative capabilities of coatings. Most often, they are applied with ironing, and those that have a more liquid consistency - a roller or spray method.

The main effect is the imitation of the stone "Substarin". The greatest creative freedom gives the method of smoothing the surface with the help of plastic ironing. In this case, large grains are rolled along the base, creating a groove. Variating their shape, size and density can be achieved by various effects. The nature of the tool movement can be straight, circular or wavy. The length of the time between the application of the material and its alignment, the thickness of the layer, the concentration and size of large grains, all affects the final result, providing the ability to create their original patterns by imitating a natural stone. For illustrations, we used exactly such a visolcalcethin brand coating with a limescale filler.

Coatings with fine-grained unchanged granules. Punching filler in such coatings is used fine-grained quartz crumb, quartz sand or lime. They have increased mechanical strength, so more often used to finish facades. They are applied by a pneumatic sprayer, the diameter of the nozzle of which can be varied. The change in the pressure and flow of air allows to obtain surfaces with different reliefs, such as wavy or type "fur coat".

Coatings with fine mineral filler. These coatings are mainly made by decorative functions. The books refers and known to all "Venetian plaster". Fine fillers, usually based on lime, and pigments allow you to create the finest color nuances. If they are applied by several lesing (transparent) layers, each of them can have its own color, the visual effect of the drawing depth occurs. So obtain the imitation of marble coating. Apply to them with a flexible spatula, and a more liquid consistency, a tampon, sponge, roller.

How to prepare the foundation

The surface on which the textured coating is applied, should be dry, clean, if possible, smooth and not shuffling. All that has a water-repellent ability, or unable to keep the weight of the applied coating, for example, dirt, dust, fats, oils, moisture stains or mold, wallpaper, varnish, peeling paint and the like, should be removed (metal brushing or sandpaper). Metal surfaces are purified from rust and twice cover the alkyd paint of the corresponding tone.

Large defects, wiring shorters need to sharpen. Sharply cracks and non-core defects that do not exceed the depth of two values of the thickness of the applied layer are allowed.

Then the surface should be coated with primer on an acrylic basis in the tone of the coating. It should be done if the base intensively absorbs water, such as plaster, gross, old, creaping plasters. It is more correct to apply the soil recommended by the manufacturer. To cover with mixed grain granules, the base should be made more even to facilitate the rolling of large particles and get a fishur grid of grooves.

In our case, the old walls were closed with plasterboard, which significantly reduced the complexity of further preparation of the foundation. They painted the coat screw screws and thoroughly embroidered joints (especially angular) using a construction bandage and putty Stucco Extra. Then the walls were covered, dried, polished with sandpaper and covered with soil Prymer ACQ.

When working with such coatings, there is little experience of painting work, it is necessary to show a fantasy and artistic taste. Why not try to separate in a new way at least a piece of a suitable wall, for example, in the hallway?

Our advice

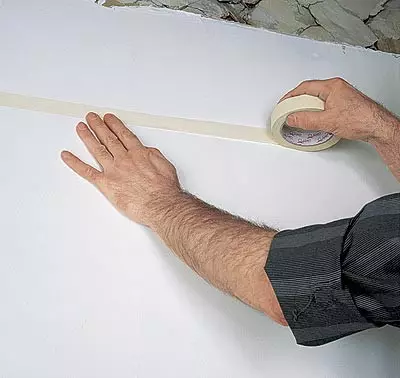

The material of the pasty consistency is applied with steel ironing, starting from the top of the wall, as if waving from the bottom up. Then the smooth layer is distributed on the basis of the movement of the cross-cross. Apply the coating is better from the corner to the angle of the wall. A large surface can be divided into areas area around 5m2 using a mounting tape. When aligning, it should be strongly pressed on the smoothness, holding it at a low angle (up to 20) to the wall of the wall.The site you started must be separated completely. If necessary, several people lead work. If for some reason work has to be interrupted, the edge of the processed area is protected from drying with a mounting ribbon. It is necessary to remove it until the material is completely drying.

Coatings from fine-grained granules of sour cream-like or slightly more thick consistency can be applied by a pneumatic sprayer (air pressure 0.2-0.7 MPa, air flow to 16 l / s, the diameter of the hole of the nozzle nozzle from 4 to7mm). Sprinkle is made by shuttle movements with moving from top to bottom and left to right, in one pass. The sprinkler should be kept perpendicular to the surface at a distance of 30-50 cm. To get a smaller face relief and reduce the consumption of the material, it is recommended to increase air consumption and reduce the pressure. To obtain a relief of the "fur coat" or "lamb" type, you need to reduce air consumption and increase the pressure. To eliminate spaces, you can make a second pass, but not earlier than 1-1.5 hours.

Do not forget to wash all the tools at the end of work.

Required tools

Spatula, fur roller, floss brush, roulette, level or twine, long ruler, pencil, steel and plastic ironing, painting paper tape, sandpaper, stewing, bucket with water.

| Carefully squeeze the white pentaphthalic enamel of the shirts of the fastening of plasterboard plates. |

| Sews at the joints of the plates and in the corners, prcribpt, dry and proof by the construction bandage of PVA glue. |

| The next day, after shtchecking in two layers and grinding sandpaper, wipe the walls with a dry cloth, determine the upper boundary of the coating (1-1,5 cm above the line of the projected suspended ceiling) and turn the painting paper tape according to it. |

| The desired amount of Prymer ACQ soil, determined at the rate of 0.05 l / m2, pour into the plastic container, add 5 times the water and thoroughly stirred manually. |

| Apply the soil with fur roller evenly into one layer on all the walls. The soil dries 1.5-2 hours. |

| Squeeze the vieroquartz pre-coating (Viero) based on chopped quartz, corresponding to the selected tone, based on the flow rate of 0.2 kg / m2, and dilute with water in a 1: 1 ratio. Apply it with roller, if possible evenly. |

| The edges of the walls in the corners, by the floor and the ceiling, blame the brush-flirt. |

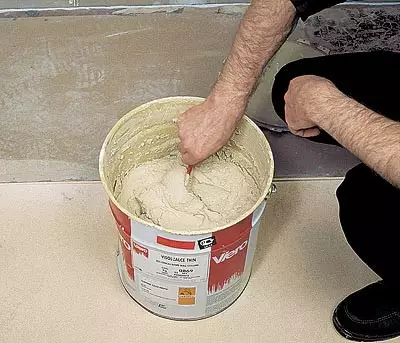

| After three hours, when the pre-coating Vieroquartz will dry up, open the metal jar with the basic coating of Visolcalce and mix it thoroughly to the pasty consistency. Do not forget to periodically mix the material and in the process of work. |

| Materials with a spatula on the working plane of rectangular ironing stainless steel portions of 150-200cm3. |

| Apply the coating at the beginning moving-up, and then accelerate the cross-shaped movements of the smooth. Try the thickness of the layer to make the size of large granules. Thus, cover a plot of 1.5-2m2. |

| After 20-30 minutes, when the material on the processed section begins to push (slightly change the color), start to pelt it with a flat plastic ironing with alternating circular and rectilinear movements. Watch that the working surface of the tool is not dry, we can slightly wet it with water. |

| If, when aligned, the wall portion is slightly denaked, type a few material on the plastic gladon and scream it on this site. |

| After full finish of one wall, start processing adjacent. Run the coating by movements from the angle inside the surface area. |

The editors thanks the Moscow Firm "Crete" for the materials provided and assistance in conducting photography.