Creation of bizarre forms with the help of curved and broken sheets of plasterboard: change in the shape of a sheet of plasterboard and installation of ceiling and arched structures.

The template, with which you can give plasterboard the desired shape, each wizard does in its own way from the primary sheet materials (plywood, chipboard, drywall IT.P.) with a thickness of 8-15 mm. The radius of the template should be slightly smaller than the radius of the formable surface, and the template is already already and / or in short, the bending sheet of the plasterboard.

Bending is performed surprisingly simple. Only before this it is necessary to figure out which side of the workpiece when it is bending will be compressed. Then, on this side, on the billet make a series of punctures in 10-20 mm increments and a depth of about a third of the sheet thickness or a little more. You can apply them with a shill, but professionals use a special needle roller. Next, this surface is wetted with water with a sponge or brush. Processing should be carried out several times before saturating the plaster core with water (it ceases to be absorbed at about an hour). In order to work conveniently and did not get the other side of the sheet (in this case, when flexing, raw cardboard breaks are possible), the blank is put on a punctured side up on wooden or rubber gaskets. Then the workpiece is carefully installed on the template symmetrically relative to its sidewall and smoothly bend on it.

In the bent position, the workpiece is fixed and left for drying. For example, it can be wrapped around several times with a sticky ribbon and remove the template from the template that is used for the next sheet. The duration of the drying of the workpiece is from 12 to 22.

For the manufacture of curvilinear elements with a small radius of curvature, another method is used from 100 to400mm. Its essence is as follows. On the reverse side (facial adds to the room) of the workpiece milling a series of P-shaped grooves, parallel lines of bending. The depth, width and step of the grooves depend on which radius of curvature is required to get. The smaller the step of the grooves than they are wider and deeper (up to cardboard on the front side), the more severely and smoothly bent is the surface. By the way, the grooves can be done on small on the area blanks using the chisel. The billet is then thoroughly cleaned from dust and stacked on a previously prepared groove pattern. At the same time, it bends, and to preserve the new shape of the grooves are applied. Best for this is suitable for the spacure "Uniflot". After drying the putty, the fragment can be installed in place.

Create stepped and broken surfaces that give additional opportunities for the formation of decor elements in the interior or hiding engineering communications, it is not at all difficult if the plasterboard sheet cut through V-shaped grooves up to the cardboard on the opposite side of the sheet (but the cardboard does not touch !!!) in those places where it is necessary to make a break.

Minimal Radius Flexible Plasterboard Sheet

| Leaf state | Radius bending with sheet thickness, mm | ||

|---|---|---|---|

| 6.5 | 9.5 | 12.5 | |

| Wet | 3300. | 3500. | 31000. |

| Dry | 31000. | 32000. | 32750. |

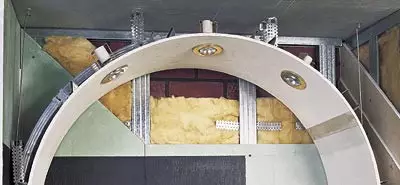

Installation of ceiling and arched structures

The main elements of these frames are the so-called profiles: ceiling types of PP (60mm wide and height 27mm) and arched type of various radii curvature. The shelves of such profiles can be curved both inside and outward, which allows you to give elements of the ceiling convex and concave shape. If you failed to choose ready-made bent profiles, then the necessary forms can be easily made by yourself. For this purpose, V-shaped cuts are made on the shelves of a direct profile and then bend it back. The framework of profiles is mounted to the ceiling until the curved sheet is attached. Separate curved profiles or frames are attached to the ceiling with a dowel or suspended on the so-called direct suspension (special design brackets), screwed by screws to the profile. To increase the length of the standard suspension, you can apply a special extension stud. The movement of the dowels depends on the shape, area and mass of the suspended structure, but it should not exceed 80cm. When installing on a highly skeleton, the curved sheet is first fixed using a T-shaped stand installed by the versius between the plasterboard ceiling and the floor. Then the sheet is attached to the frame profiles using self-tapping screws, ranging from the middle of the sheet and gradually turning to the edges. Screws should be included in the drywall perpendicular to the surface of the sheet and penetrate into a metal profile to a depth of at least 10mm, and in the wooden bar, on a depth of at least 20mm. The heads of the screws are removed by 0.5-1 mm in a sheet of drywall, and then necessarily applapped.

The jokes of plasterboard sheets should be on the carrier profiles or bars. When it is impossible, the steel stripes with a thickness of 0.5-0.6 mm and a width of 100 mm are imposed on the joints from the reverse side of the sheets. Next, seams are made according to the standard technology, and if necessary, then the shtlocking of the entire surface.