Silicone sealants - solving problems of sealing slots, seals and sealing of joints. Some characteristics and technology of application.

Who did not come across the problems of sealing slots, seals and sealing various junctions?! Installation of plumbing and ceramic tiles, glazing of wooden, plastic and metal bindings, the manufacture and repair of aquariums - here are just some types of work, where a wide variety of sealants are applied.

Over the past few years, a large number of diverse materials for sealing seams, cracks, cracks and various joints appeared on the market. They can be divided into two large groups: boutique rubber sealants and silicone sealants. They are made from different substances, which determines the areas of their application. Kermetica also calculate acrylic putty, or, as they are often called, Fillers (Otangl. Tofill- filling), and polyurethane mounting foams. However, in fact, neither neither other sealants are not really.

These are large groups of special materials that deserve a separate detailed conversation. Therefore, in this article we will give them only a very short characteristic.

Mounting single-component polyurethane foam Designed primarily to fill the voids between the structural elements, which are subjected to relatively small progress. Foam gradually collapsed under the action of solar ultraviolet radiation. Therefore, they are applied only in those places where there will be closed, for example, plaster from external influences. The price of polyurethane foam is approximately $ 5.0-5.5 1. Calon with a capacity of 750ml.

Slika

Cartridge - Plastic cylindrical packaging with a movable bottom, designed to work with an assembly (plunger) pistol.Organic Extander (Otangl. Extender) is a substance added to glue and rubber to dilute or reduce viscosity.

Fungicide - Chemical substance destroying malicious fungi.

Ketoxym - Derivatives of ketones (the most famous keton-acetone), liquid or solids with low melting point, soluble in most organic solvents.

Silicone - Silicon organic polymers containing silicon atom in the elementary link of the macromolecule. The most widely applicable polyorganosiloxanes. One of their practical applications, silicon rubber, which are used for the manufacture of silicone sealants.

Curing - transformation of rubber into rubber, while rubber linear macromolecules interact with a vulcanizing agent, forming a three-dimensional "stitched" structure.

Acrylic masses Used mainly to putty cracks and seams in the walls inside the heated premises. Such masses containing fungicide can be used for sealing seams between tiles in bathrooms, toilets and kitchens. Hospitality, they are rapidly (for two or three years old) - become fragile, lose adhesion to the base and can begin to peel and fall out of the gap filled with them. Actual advantages include exceptional convenience in the work, the relative low cost- $ 1.2-1.7 of the Caxed capacity of 310 ml. They are easily painted by most colors used for repair. In the early time, acrylilicone masses are still on sale. Keeping all the features of acrylic masses, they have much greater durability and can be used both for internal and external work, but at the same time somewhat more expensive - from $ 2.5 by 300ml.

Sealants in the exact sense of this word-based materials based on silicones and butyl rubbers. Below we consider only those materials that are available for use at home, namely silicone sealants.

The main technical characteristics for all types of sealants are permissible application temperature and temperature, elasticity (lengthening at break), including at elevated or reduced temperatures, tensile strength, adhesion (sticking) to various bases and resistance to external factors, Such as long-term atmospheric effects and solar ultraviolet radiation, increased humidity and exposure to mold. Sealants must at any temperatures compensate for the movements of the seams that they compact.

Types of silicone sealants

Silicone sealants for sealing and compensating for the movement of the seams are perhaps the most perfect. Their is distinguished by excellent elasticity (lengthening - up to 1000%), a very wide temperature range of operating - from -50do + 200C (successive sealants The upper bound comes to + 300c), excellent adhesion to the most diverse basics (glass, concrete, metal, wood, Plastics and many other surfaces, with the exception of teflon and gromal), durability and durability.

Silicone sealants are viscous masses that are cured under the action of water vapors contained in the air. They are used for sealing and gluing all types of seams and joints when isolation is needed from external influences, high moisture resistance, strength and elasticity. Sealants are stained badly after applying, but they are produced in a wide variety of colors, which allows you to choose the material of the desired color.

Silicone sealants differ in the curing mechanism and the content of fillers (in most cases, the fewer fillers, the better).

Acid sealants are the most versatile and cheap, approximately from $ 2.5 percase capacity of 310ml, and, of course, they are most widely represented in the domestic market. Their marking in many firms includes the Latin letter "A" (English. Acid acid).

When cured, this type of sealants highlights a small amount of acetic acid (2-4% of the total mass) into the air, which limits their scope. They should not come into contact with such metals as lead, copper, brass and zinc, since the acetic acid released causes corrosion of these metals. When working with marble and cement containing materials that have alkaline compounds (lime, carbonates, etc.) and can be reacted with acetic acid, it is advisable to carry out a sample. To do this, apply a small amount of sealant to the surface of the material being processed at an invisible place. Using acid sealants, be sure to ventilate residential premises.

Neutral curing sealants are isolated by ketoxime or alcohol. They apply to all the basics, including the mramor and cement materials without restrictions, but are somewhat more expensive - from $ 4-5 of the Cart. Latin letter "N" (eng. Neutral-neutral) is present to the injection of such sealants.

Finally, alkaline curing sealants based on amines are used to solve special tasks and are practically not found on sale. These materials smell in stupid fish.

In order to determine if the silicone sealant contains the filler, weigh the cartridge. The standard cartridge with a capacity of 310ml with pure silicone weighs 300-340 g. With a weight of about 500g, there is reason to believe that it is a sealant with a high content of the filler and it should cost much cheaper.

In the case of acid sealant to materials containing alkaline compounds (marble, concrete, lime plasters), between them and acetic acid, released during vulcanization, neutralization reaction occurs. At the same time, the appearance of the surface is spoiled.

If it is immediately difficult to determine the type of curing sealant (acidic or neutral) on the marking or inscriptions on the cartridge, then turn it upside down, squeeze and sniff. Acid sealant has a characteristic smell of vinegar.

It is possible to distinguish a sealant containing an organic solvent if you apply it to a thin polyethylene film (for example, on the package). When interacting with the solvent swelling and wrinkles. Pure silicone does not interact with polyethylene. Using weighing, the presence of a solvent will not determine, since its density is approximately equal to the density of pure silicone.

Polyacrylate and polycarbonate subjected to deformation are the foundations that exclude the use of silicone sealants. Silicones adhere to these materials so well, which penetrate into microscopic cracks that are required on their surface. Silicone molecules "sweep" the walls of cracks, which turn into well visible cracks. In this case, the loss of tightness and strength of products may occur, their appearance is disturbed.

Some specific characteristics of silicone sealants

| Firm-producerDutyer | Trademark | By-product of volcanoes - Zoom | Referred Basin lengthening,% | Module of elasticity with 100% stretching, MPa | Recommended Scope application | Restricted applied to some materials |

|---|---|---|---|---|---|---|

| Dow Corning | DC 911. | Acetic acid | 500. | 2.5 | Sealing of seams and joints between elements of glazing, in the aquariums of the up to 200l, in the designs of window and door blocks | Concretes, Building Solutions, Copper Alloys, Lead, Zinc |

| DC 915. | Acetic acid | 400. | 2,4. | Installation of plumbing equipment, sealing of seams and joints in rooms with high humidity: bathrooms, kitchens, toilets, cellars | Materials separating oils, plasticism - Torah and solvents (dishes and aquariums - for DC915) | |

| DC 916. | Methyl-ketoxime | 400. | 1,8. | Sealing glazing interior partitions, window and door blocks, ideal for gluing mirrors | Also | |

| DC 917. | Alcohol | 375. | 0.5 | Sealing compensation seams in the designs of houses, sealing glazing interroom partitions, window and door blocks, ideal for gluing mirrors | Also | |

| Rhone- Poulenc. | SiliceX88. | Acetic acid | 800/600 * | 2.2 / 1.0 * | External and internal work. Sealing of seams and joints between glazing elements and ceramic tiles, aluminum, etc. Building structures from non-porous materials | Concretes, Construction Solutions, Copper Alloys, Lead, Zinc, Materials Mixing Oils, Plasticism - Torah and solvents |

| SiliceX89. | Acetic acid | 800/600 * | 2.2 / 1.0 * | External and internal work. Installation of plumbing equipment, sealing seams in rooms with high humidity | ||

| Silicex. | Acetic acid | 800/600 * | 2.2 / 1.0 * | |||

| FLM- Firmengruppe, Switzerland | Chemlux 9011. | Acetic acid | 550. | 1,6 | For external and internal work on sealing seams and joints of glazing elements | Copper Alloys, Lead, Zinc, Materials Mixing Oil, Plasticism - Torah and solvents |

| Chemlux 9013. | Acetic acid | 500. | 1,3. | Assembly of frame and frameless aquariums, terrariums and stained glass | ||

| Chemlux 9014. | Acetic acid | 500. | 1.5 | For sealing building structures, food equipment, with kitchen furniture installation, tabletop sealing and built-in equipment | Concretes, Construction Solutions, Copper Alloys, Lead, Zinc, Materials Mixing Oils, Plasticism - Torah and solvents | |

| Chemlux 9015. | Acetic acid | 550. | 1,6 | For sealing of seams and joints and other works in rooms with high humidity | Copper Alloys, Lead, Zinc, Materials Mixing Oil, Plasticism - Torah and solvents | |

| Chemlux 9016. | Acetic acid | 500. | 1,3. | For sealing seams between parts when repairing cars, in electronics and electrical engineering | It is not recommended to use for ethylene, polypropylene, movable seams between non-porous materials (tile, ceramic tiles) in front of the facade | |

| Chemlux 9018. | Alcohol | 300. | ** | For internal and external work on sealing compensation - seams and joints with high humidity | Materials separating oils, plasticism - Torah and solvents |

* Transparent / color (different amounts of filler) Silicone sealants.

** There is no data.

Criteria for the quality of silicone sealants

The best sealants are clean (100%) Silicon. It is they who have a combination of excellent mechanical properties, a small (2-4%) shrinkage when cured and large durability. Nevertheless, cheap stamps can often be found on the market containing significant amounts of fillers. The fillers introduced into the silicone mass in the process of production worsen the properties of the sealant. Three types of additives are known to clean silicones: organic extenders, mechanical fillers (chalk, glass and quartz flour IT.D.) and organic solvents.

Silicone sealants with a small (5-10%) amount of organic extenders are very convenient in manufacturing and further use, and their properties are only slightly deteriorated compared to pure silicone. The overwhelming majority of silicone, sanitary sealants for use in bathrooms, kitchens, toilets and in rooms with high humidity belong to this group. Fungicide is also injected into the sad sealants and fungicide so that the seams are not formed by Black Molden Mold. However, the presence of an organic component worsens the resistance of such sealant to ultraviolet radiation and limits its use for external work. The streak of silicone mass with a large content of extender resins is yellow and losing their mechanical strength. Interestingly, in Russia such sealants are widely used for the manufacture of double-glazed windows. By the way, their manufacturers are often curved with a soul when they report that they supply "vacuum" double-glazed windows. The fact is that, although sealants do not let the water, they pass the air. Therefore, the air pressure inside and outside the glass is equal.

Mode of application

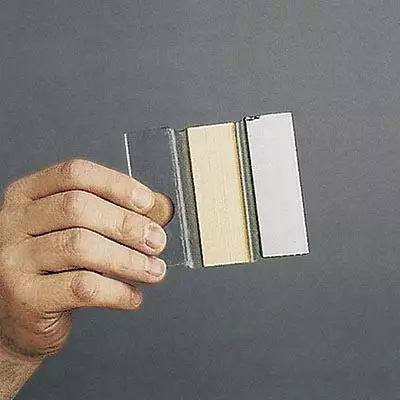

Remove the old seam area from the zone, which served the sealing material.Operating surfaces Clean contamination, degrease alcohol or acetone and dry at least 30 minutes.When using a 300 ml cartridge with a capacity of 300 ml carefully, without damaging threads, cut its tip, screw the mouthpiece on it, which trough at an angle 45 to get the necessary section of the sealant strips.

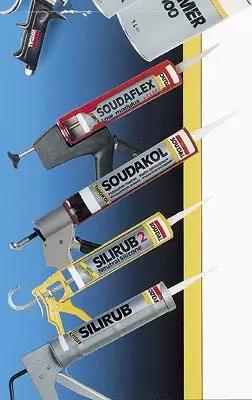

Fill the seam sealant, squeezing it out of the cartridge using a mounting (plunger) pistol.

Spatula moistened in water, form the seam according to the type of connection and remove the excess sealant.

Traces of sealant are removed with a dry or moistened with a cotton cloth with a cotton cloth. A number of firms for removing a thin layer of cured silicone developed special compositions that are supplied in tubes or aerosol cans.

Hands and tools after working with silicone sealant, until it hardened, flush with warm water with soap. If Silicone hardened in his arms, do not worry, after a while it will easily take off.

Sealants with mechanical fillers are difficult to distinguish from pure silicones: for example, quartz flour, mixed in silicone mass, does not change its transparency. However, these masses differ in density: in pure silicones, it is 0.99-1.05 g / cm3, and in filled with- can reach 1.6 g / cm3. Fillers significantly reduce all the qualitative characteristics of sealants, primarily mechanical: strength and extension when breaking.

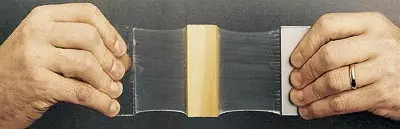

The ability to stretch for hundreds of percent of the initial size allows sealant to compensate for the movements of the seams, for example, as a result of temperature fluctuations. After curing, the most important characteristic of the sealant is an extension at break. The author met a sealant containing only 29% silicone and having an elongation at a break of about 45%, while at high-quality sealants this value exceeds 400%. It should also be noted that even the introduction of the color-forming additive leads to a slight decrease in tensile strength and reduce extension during break. Sealants with solvent additives have a shrinkage during curing, which, naturally, depends on the number of substances entered. The tumor materials decreases the plasticity and with significant deformations, the sealing layer is destroyed.

There are no reliable express methods for determining the quality of silicone sealants. One can recommend one, although not very reliable, but still a way to control the quality. Any product is unprofitable to sell at a price below its cost. Today, the price of one standard cartridge with a capacity of 310 ml of pure silicone sealant even in a small-winding construction market can not be below $ 2.5-3. This does not mean that for this money you will certainly buy a high-quality product, but for $ 1.5 you are guaranteed homemade an unknown composition and origin. In addition to plastic cartridges, silicone sealants are packaged in aluminum foil tubes with a volume of 300, 400 and 600ml. To work with such packages, special pneumatic mounting pistols are needed, designed for the appropriate volume of tubes.

For reliability it is advisable to purchase goods of well-known and large companies such as Dowcorning (Belgium), Wackerchemie (Germany) or Generalelectric (USA). They themselves produce silicone polymers and do not offer low-quality grades in the market with high filler content. Although, besides them, many famous European and American firms are supplied to the Russian market, which, in the manufacture of sealants, use polymers of leading manufacturers.

An important parameter of any sealant, except for the temperature, is the temperature at which the work can be carried out. As a rule, it is +5 ... + 40С. At such temperatures, the drying time "up to touch", or, more precisely, surface vulcanization is 5-10 minutes. This time, you can form seam sealant. It is always easy to remember that the curing process is the volcanization of silicone sealant long. It proceeds at a speed of 2.5-4 mm per day.

The shelf life of silicone sealants in a dry place at a temperature of + 5 o +25 s is at least 12 months.

Safety requirements when working with sealants

In the process of applying and vulcanization of acid sealants, the distinguished pairs can cause irritation of the eyes and mucous membranes, so carry out the room in which the work is made.If the sealant gets into the eyes, rinse them with plenty of warm water.

How to work with silicone sealants

Silicone sealants are very simple in applying, open the cartridge and squeeze its contents on the sealed surface. However, there are some difficulties. In order to use the elasticity of silicone mass (that is, to provide it with the necessary freedom of movements), the seam must be properly constructed using a painting tape. If the seam width is twice and more exceeds its depth, you will have to use the lining material in order to avoid trilateral adhesion of the sealant causing the seam break. Punching lining is used polyethylene ribbon or cord from foamed polypropylene. Only miniature seams (1-2 mm wide), which do not need to compensate for any significant adversaries, are processed by sealant without such linings. The forming seam of the painting tape should be removed immediately after applying the sealant.To determine the amount of sealant required for sealing a seam of various sizes, you can use the table where the approximate length of the strip is given, which can be squeezed from the cartridge with a capacity of 300ml.

Calculated yield of sealant from the cartridge with a capacity of 300 ml (wisp meters) depending on the depth and width of the seam *

| Seam depth, mm | Seam width, mm | |||||||

|---|---|---|---|---|---|---|---|---|

| 3. | four | 6. | eight | 10 | 12 | fifteen | twenty | |

| four | 25. | eighteen | 13 | 10 | 7. | 6. | five | 3.5 |

| five | twenty | fifteen | 10 | 7. | 6. | five | four | 3. |

| 6. | 17. | 13 | eight | 6. | five | four | 3,2 | 2,2 |

| eight | 13 | 10 | 6. | five | four | 3. | 2.5 | 1,7 |

| 10 | 10 | eight | five | four | 3. | 2. | one | 1.5 |

* The calculation is given for Silicex sealants of the company Rhone-Poulenc according to the company "Sealant Center".

It is interesting!

During the Cold War, silicon compounds (silicones) were aimed in the lists of strategic materials. According to the ban, they were not imported into the USSR, and the domestic silicones were almost completely absorbed by the military industry. Meanwhile, Silicons have an almost unlimited range of the most peaceful applications, from thickening additives to yogurts and hair care products to vacuum sealing spacecraft.Silicon compounds are made from sand, cooking salt and carbon. Disheska They inherited a molecular skeleton, and from carbon-phenomenal variety of properties. Of the result, these substances combine the amazing ability to maintain properties at very low and high temperatures, irradiation with ultraviolet and infrared light, under the action of aggressive substances.