We tell about the peculiarities of the slag blocks, the intricacies of the design and give step-by-step construction instructions: from the fill of the foundation and to the walls of the walls.

Bath of slagoblock is not a luxury, especially if you compare it with wooden or brick. She has its advantages. One of them is low cost. The material does not have good decorative qualities and does not differ in high strength. The thermal conductivity is lower than the aerated concrete almost one and a half times. The surface quickly absorbs moisture and therefore needs waterproofing. Water, falling into emptiness and freezing at a negative temperature, expands and has a strong pressure that leads to the appearance of cracks. All listed disadvantages do not interfere with the minimum cost to build reliable walls. The building will last long. After waterproofing and insulation, its operational characteristics will not be worse than the brick or wooden.

Bath of slagoblocks do it yourself

Properties of materialStage design

- Planning options

- Number of prefabricated elements

Construction works

- Ribbon foundation

- Bearing structures

- Roofing system

- Outdoor coating

- Interior decoration

Product specifications

The basis is a mixture of concrete mortar and waste of metallurgical enterprises. The ratio of waste with cement is 10: 1.

Types of material

- Full - full and hollow. Standard dimensions - 390x190x188 mm. The weight of full-scale - 25-28 kg, hollow - 20-23 kg.

- Half-terminal - only hollows are produced. Standard dimensions - 390x120x188, 390x90x188 mm. Weight - 10-13 kg.

- Products with embossed decorative surface. Some manufacturers are injected into the mixture dyes and decorative additives.

Types of material by strength

- M 35 - Used only as thermal insulation.

- M 50, m 75 - used for partitions and bearing walls.

- M 100, M 125 - are suitable for creating foundations.

Frost resistance can be 15, 25, 35 and 50 cycles. The outer part must have frost resistance not lower than 35 cycles.

The thermal conductivity at an average density of 1050 to 1200 kg / m3 is 0.35-0.48 W / m · ° C. It is about the same as a brick, and one and a half times higher than that of analogs from porous concrete. Characteristics of Baths from slag blocks, its pros and cons are determined primarily in thermal conductivity. What it is less, the lower the strength. For construction, material is used with hollowness up to 30%.

Prefabricated elements can be made independently on a plot of cement and aggregate. The solution is immersed in the form and defends until a complete set. In production conditions, special vibropresses are used for molding, allowing to achieve maximum particle seal. The strength depends on the density.

Each party must have a certificate of compliance with state technical standards. The waste used in production may contain toxic and radioactive impurities, so when buying is better to use the gamer counter.

Shlakoblock Bath Project

The structure of the structure, as well as the texture and color of the decoration, can be chosen by photo. Specialized magazines offer many interesting technical and design solutions.When planning, natural factors will need to be taken into account - humidity and mobility of the soil, the depth of freezing. The design of the foundation depends on them. It is necessary to think in advance draining, water supply, determine the location of the fuel, prepare the electrical wiring scheme.

Select layout

In the preparation of the project, high water absorption should be taken into account. Even if waterproofing is installed on the outside, additional protection will be required. There is always the likelihood that the insulating layer will be damaged during operation. So that the water does not flow into the coating, the roof is better to do with large skes.

The basis, as a rule, has a rectangular shape. Standard dimensions - 3x4, 4x4, 5x5, 6x4. Height - from 2 to 3 m.

The most simple structures are a carrier box separated by a partition into two equal parts. The first is a steam room, the second is a seating area with an entrance door. The steam room usually takes a window 0.5x0.5 m, in the rest room - 1x1 m. The standard width of the inner doors is 0.7 m, external - 0.8 m. Before building a bath from the slag block, you must select a specific model. Otherwise you have to customize the width and height of the openings under its dimensions.

In the steam room, the furnace is installed for which a special place is given. When bookmarking under it, a strengthened foundation is supplied. They have it near the partition so that the heat does not go outside through the outer wall. This half can be divided and degraded the washington with the shower. When choosing the proportions and sizes of each site, you should consider what they are less, the easier it is to warm them. Length and widths in 2 m enough for equipment of lying places.

The box with dimensions of 5x5 or 4x6 m is divided into three main departments - the hallway, the recreation area and the steam room, next to the shower. The extended layout is divided by parallel straight walls, the square is distinguished by straight and angular. The windows will be needed in all rooms. An exception can be made a steam room, but it is unsafe. If a person with a working oven becomes bad, he will urgently need a flow of fresh air.

If the garden area allows, a terrace on a column or tape base is attached to the main building.

A sketch is drawn on paper or draws in an application that allows you to quickly make 3D visualization. Experience with the program is not required.

Calculation of the number of materials

Knowing the sizes, it is easy to determine the number of prefabricated elements necessary for the construction of a boat from the slag block with their own hands. Mobile applications often use automatic calculation. Sometimes it is more convenient to spend them yourself.

For example, we take standard products with the front side of 390x188 mm. The thickness of the masonry solution is 1 cm. Rounded the length and height, we get the side of 400x200 mm. The outer side area is 0.08 m2.

To find out how much rows needed for a wall 2 600 mm high, divide this number 200 mm. We get 13 rows. Similarly, we know the number of elements in the row. Next, we carry out the calculation for the entire box and its partitions. The area of windows and doors is deducted from the total.

Order material follows with a reserve of 10% in case of marriage or damage during construction work.

Construction works

Design and fill foundation

The design depends on the mass of the building, as well as the properties of the soil. As a rule, it is a ribbon base. For stony sustainable dry soil, reinforced concrete pillars are suitable, connected on top of the reinforced belt. Such a scheme saves building materials. The porch is installed on wooden piles or a concrete pillow.

In the middle band, the climate is wet, so the porous structure must be protected from groundwater. The ribbon belt should not be designed below 40 cm above the ground level, otherwise the masonry will be constantly in a wet environment. It is possible to make it lower, and top lay out a silicate brick that is not afraid of dampness.

At the design stage you need to determine the locations of the breaks in the concrete belt. They are needed for laying communications and runoff.

First you need to prepare the platform - to clear it, to provide access to it, determine the place for storing building materials. Trench under the ribbon base and wells under the columnar should be digging on the markup. Flags and ropes, stretched between them, there are contours of future walls. They are installed so as to determine the width of the trench. It is usually 0.5 m.

Depth should be 20 cm below the level of primer of the soil. It is installed in terms of avoiding distortion. The bottom fall asleep with sand and wet you to catch. Then the crushed stone is falling asleep. Pillow thickness - 20-30 cm. It is needed to protect the ribbon from groundwater, as well as from uneven expansion of the soil during freezing. The surface is lined with rubberoid or solid polyethylene. Down the reinforcement frame. It consists of thick steel rods located horizontally in the corners. They are connected by more subtle, mounted vertically with a pitch of 40 cm. For a ligament, a special knitting wire is used or a welding machine.

Steel frame elements are combined in a solution to a depth of 2 cm. When contacting the surface, the steel quickly rusts and collapses. To arrange it at the necessary depth, the lower rods are put on special plastic racks or make supports from undergraduates. The formwork is peeled from the boards. They are nailed to the pillars covered in the ground, located so that the boards are not strifted under pressure. It is better to strengthen them with additional backups, and the walls of the formwork connect the rails.

Make a foundation for a bath from a slag block with your own hands, it is not difficult if you work as a brigade consisting of several people. Concrete will leave a lot, and you need to have time to put it until he grabbed. It is impossible to pour the mixture into two layers, because there will be no clutch between them.

The mixture is prepared based on the cement of M400 or M500 brand, rubble and sand. One part of the cement will require 3 parts of sand and 4 parts of rubble. The composition is gaining strength for four weeks. Work should be carried out in the warm season. In the heat, the formwork is closed from the sun, so that the seizure takes place more evenly. With too rapid drying, the surface cracks.

After grappling concrete, waterproofing the upper side of the tape is carried out. It is needed to prevent the injection of moisture from the foundation to the masonry. To do this, it is used rubberoid laid in three standing on hot mastic.

A reinforced base is made under a massive stone oven. If it is connected to the ribbon, cracks will appear - the box and the furnace create different loads and cause different shrinkage.

Masonry walls and creating openings

Masonry start with corners. First, two blocks forming angle are fitted to the solution. Top in the dressing with a displacement of half the length is set the third. Such structures perform the function of beacons. They must have the same height. A rope is stretched between them, which serves markup. You need to work with a building level, checking every step. In order for the unit to take the right position, it is confrontated by the knob of the Kelma or rubber hammer.

The mixture is prepared from sand and cement M400 or M500 brand. The amount of water and aggregate depends on the properties of cement and is indicated on the package. The mixture is placed with a layer of 20-25 cm. After installing the precast element, it decreases to 10 cm. The excess is removed by the trimmer and stacked in the next row, or goes to fill the seams.

When using hollow products, the mixture is applied to their longitudinal ribs. It is necessary that the inner space remains free. Air layer improves thermal insulation properties. If you fill it, they will noticeably deteriorate.

When the first row is ready, the lighthouse is raised above. Thus build the entire box. To sprinkle part of the precast element, use a circle with a circle designed for cutting concrete.

With the phased construction of the baths from the slag blocks with their own hands in the masonry laying fittings. Some blocks have a special gutter under the reinforcement rod. If there are no grooves, metal grids are used. They are produced in rolls of the desired width.

Over the window and doorways poured formwork or put steel jumpers. The latter option saves the time required to set concrete. The jumpers are welded from the corners and plate. It is more convenient to mount the finished channel.

The upper row is coated with solution. Hollow products installed on the reinforcement grid are filled with waste, concrete lay on top. Strength increases after pouring the upper monolithic belt with a height of 10-15 cm.

Laying roofing and overlap

A simple two-tie roof is suitable for the bath. For a single one will have to build a higher wall. The construction will be too cumbersome. If you reduce the slope, the air layer will be thinner from above, and the heat from the steam will go faster. In addition, a flat attic is difficult to equip for storage.

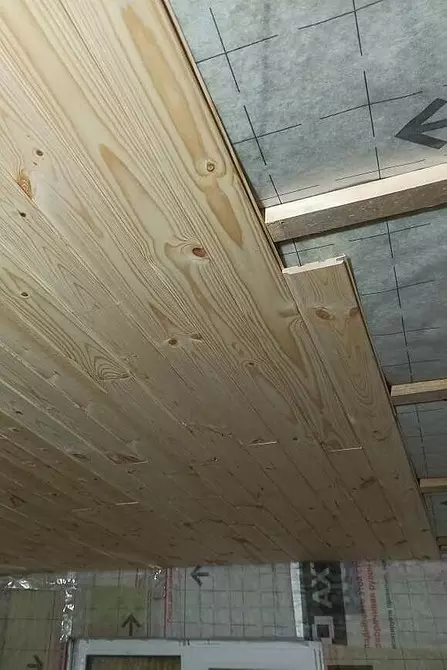

The rafter system should be light, since the carrier ability of the box is small. Maurylalat - Wooden heavy supports for rafters - it will not stand. It is better to restrict the installation of ceiling beams. For them, the box leaves the grooves and mix the beams when laying, or cut out the grooves with a grinder, and only after that the carrier elements of the overlap are mounted. This design allows you to make wide skes covering the vertical surface from precipitation.

The overlap is a lightweight wooden frame, withsting human weight. Its cells are filled with non-flammable heat insulators that do not excrete toxic compounds when heated. Mineral wool is usually used, closed with film waterproofing.

Installation of protective coating for the outside of the walls

The slag concrete tolerates dullness and despite the high porosity spends the temperature well. To give the ground the necessary properties, it is necessary to insulate and waterproofing from the inside and outside.Protection options

- The simplest solution is waterproof facade plaster. She does not miss moisture and has good decorative qualities.

- To protect you can use siding - wooden, composite, metal or polymer panels, imitating natural materials. They are mounted on the frame under which the rubberoid or polyethylene layer is placed. The thickness of the frame will allow the layer of mineral wool panels.

- Sometimes it is more convenient to assemble the frame on your own and tinkering with the clapboard, setting insulating the insulating pie.

Mounting the frame will have an unusual way. The porous base does not hold dowels, so they are mounted using "liquid nails" or plant a cement solution. For a more durable attachment, spacer anchors expanding in the wall array are used. Butterfly dowels when screwing into a screw are compressed, spreading stitching, which allows them to seal the loose texture and hold in a crumbling basis.

The heat insulating plates from the inside and outside are closed with a polyethylene film that protects them from wetting. It stacked in one layer with the allen between the canvas at 10-20 cm. The joint is stuck with a waterproof mounting scotch.

Internal trim Baths from slag blocks

Warm the box follows only safe non-flammable materials. Polyuretomol is not suitable for this. All the necessary properties have a mineral wool.

To the base on the polyethylene layer, a metallic or wooden lamp is mounted. Cells are filled with insulation. If plates are used, they are fixed using a cord stretched to the crate. Mineral wool closes with a film and with external, and from the inside.

For decoration, plaster is rarely used - it weighs too much. Most often cells are truncated.