We tell how to choose sawn timber, make fitting, glue to shuffle and paint the staircase from the tree.

In Russia, it is customary to build houses on a high base and build a porch with a staircase. Today you can buy ready-made elements of stairs (sticking, risers, testers, bales, handrails), but they are sold only in construction hypermarkets and in large building markets, and cost from 600 rubles. For the temporon meter. At the same time, defective products are not so rare. An annoying when the expensive steps brought from afar begin to breed and crack. In this material, we will tell how to make steps for a porch of wood with their own hands.

Making a tree steps

Glue steps- Selection of sawn timber

- Fitting

- Gluing

- Ostrodging and grinding

- Painting

Design without gluing

Production of Balyasin and Hanging

Recommended dimensions

Glue steps for a tree porch with their own hands

In principle, when making a staircase on a porch made of wood with your own hands, you can make a stage of a step from very wide boards (slab), but it is difficult to get it, besides there is a risk that such wooden stages for the porch will be sworn or cracked. It is much easier and reliable to dial the desired width of narrow bars or boards (no more than 100 mm wide). You will need a desktop and tools (at least a square, saw, plans and grinding), as well as lumber and glue. Next, we give step-by-step instructions with photos, how to make a porch with steps of wood.

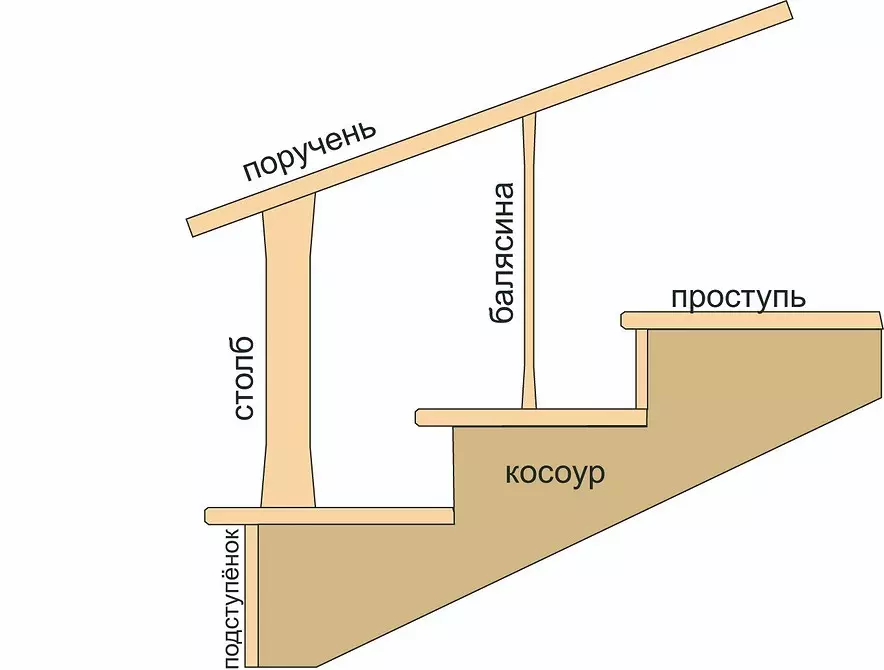

Details of the stairs

Porch and cowrs

Piold and Assembly

Selection of sawn timber

In the construction markets are sold mainly by the boards of natural humidity. Try to choose a sawn timber without large bitch and reviews, with a uniform all-line structure (without a pronounced fiber pattern) - when drying it, it leads less, and it cracks less frequently. You need to dry the boards in the ventilated stack of at least two months (in summer) in the shade under the roof, giving the load from above to reduce the likelihood of warping. After this period, it is desirable to control the moisture of the electronic moisture meter (optimal values are in the range of 15-25%). With a march width of no more than 90 cm for sticking, there are enough boards with a thickness of 40 mm, with a march 90-110 cm - 50 mm. If the march width exceeds 110 mm, additional (median) Kosur is required. The normal thickness of the oppon date is 22 mm.

On lumber I grade there are no surveys, large bitch and rot

Before gluing, it is advisable to control the moisture of wood

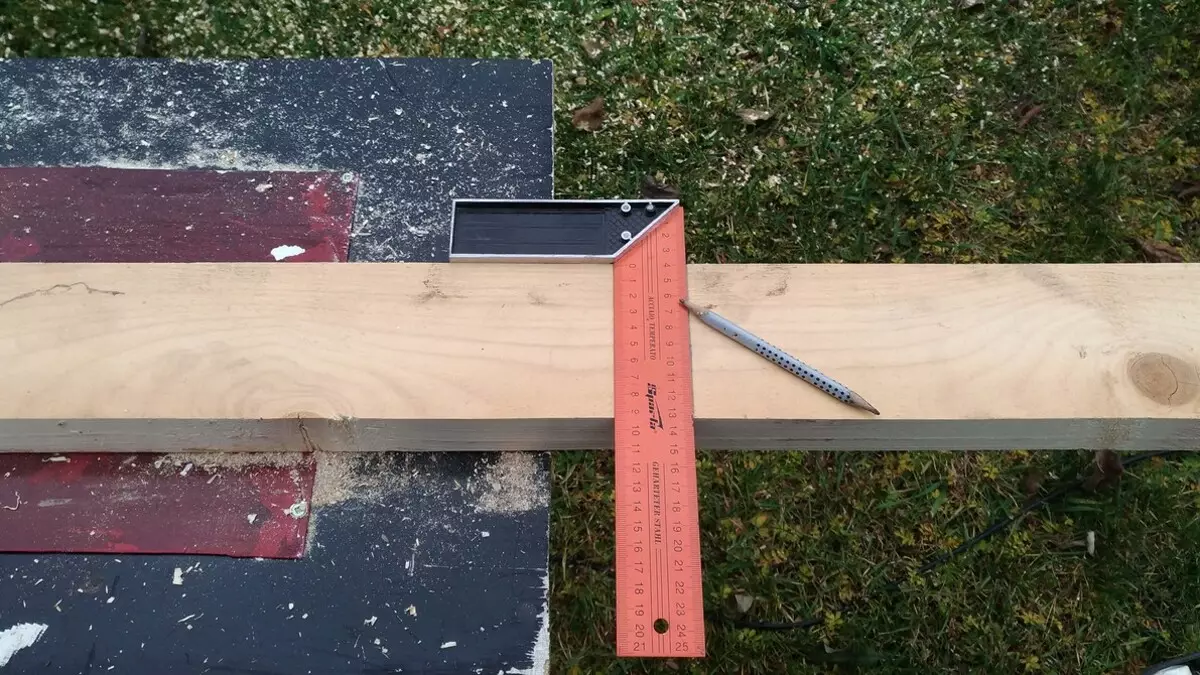

Fitting

Before gluing, you need to handle the side edges of the boards. They should be smooth, perfectly straight and strictly perpendicular to the plas. It is best to perform the operation allows a flight or a fugoval machine, but few people have such equipment in the country. It is necessary to use the usual or electrical exchanged and visually control the quality of processing. It is impossible to rush at this stage: with substantial gaps (more than 0.2 mm) and the rolled edges of the part of the stage will not be able to glue.

With the help of the kit, it is easy to measure the thickness difference and determine the defects of the edge

When fitting only the edges of the board

The edge must be strictly perpendicular to the plastic

Gluing

By making wooden steps for the porch with their own hands, it is very important to choose the right glue. The highest strength has seam from two-component polyurethane composition. You can use any other carbonate weather-resistant glue, for example, polyvinyl acetate, but only proven brands (Kiilto, Soudal, Titrbond, etc.). But it should not be applied to the epoxy resin, because after a complete curing, it loses elasticity - such a seam is poorly opposed by bending and dynamic loads. It is recommended to glue at temperatures above + 10 ° C, using screw or lever clamps to glue.

PVA glue must be made abundantly on both bonded edges.

Lever-free clamps are comfortable, but the screw is reliable and provide greater effort.

Ostrodging and grinding

A day later, two can be processed to surface treatment. At first, the stage is sharp, striving to make an ideal plane (for control use a flat rack, a ruler or a square). Further, it is necessary a rough grinding of the P80 skurt (one can apply both tape and eccentric grinders). After that, it is necessary to seal cracks, highlands and other defects with a putty, which they buy ready and mixed on their own from any weatherproof varnish and wood dust (if you plan to paint the steps into the dark color, you need to immediately smoke the shtclotch). The finish grinding is carried out by the P120 skurt, for the perfect result - also P240.

Stronging the stage takes no more than a minute

Slightly more time to grind

The eccentric machine allows locally to lay defects, but has a relatively low performance

Painting

The best protective and decorative compositions for street steps is a yacht varnish and terraced oil. It is better to paint the details before the assembly, protecting the zone to which the glue will be applied, painful tape (otherwise then they will have to be cleaned).

When toning, it is important to apply the composition evenly, preferably - several layers

Toned surface need to be covered with weatherproof varnish

The guards and cosomes glue along the same technology as the steps, but only of thicker boards or bars (50-70 mm).

The heat-treated pine board has a beautiful dark color for a long time and is not covered with slippery fungal rod.

The lattice will ensure the ventilation of space under steps, so that they serve longer.

The gaps between the boards are needed for water drain.

Steps to the porch of wood and composite without gluing

With a ready-made concrete or brick staircase or wooden platforms, it is not necessary to glue the wooden stages at all. It is easier and reliable to strengthen on the basis of individual boards, moreover with gaps that allow rain and melt water to drain from the porch.

Primitive bearing design of wrapped terrains of Brucks is suitable only for a temporary porch

Brick porch with wooden flooring on lags

Edge invisible fasteners for Decing

Ideal for street terraced boards (Deoping) from wood-polymer composite or larch. The advantage of Decking in front of the usual board is that its corrugated surface prevents slide.

Modern design of the railings implies a simple shape of the pillars and details of the fence

Screwed steps with a set of concerns helped to decorate the porch

When installing the boards, it is better to use invisible edge fasteners, while the finish of a concrete or brick porch starts with the installation of lag from the antiseptic larch. The terrace board is best fixed by invisible edge fasteners. Decing from larch does not hurt to cover with terraced oil, high-quality composite can usually not paint. However, the polymer decoping (especially inexpensive marks) in winter becomes fragile and is often damaged when walking, and then it is necessary to change the steps, as it is difficult to repair the hollow products.

Terraced plaque from larch is cheaper composite and even reliable

Stone porch decorated with composite decoing

Composite decoing is enhanced with ribbies, and still its working wall may not withstand a large load

Production of Balyasin and Hanging

Very few have a latch and skills of work on it, so it is unlikely to make striped balasins and pillars. However, you can take advantage of the available technique of slit thread or milling of the shaped edges. It looks very good and railing from ordinary boards, if only pick up a beautiful pattern, combining vertical and inclined elements, and then finely polish the parts and paint into a good color (they can be combined, for example, with platbands and cornices).

With a minimum of visible fasteners, the porch looks neat

The railing of this design is difficult to establish obliquely

Too wide handrail uncomfortable

For the handrail, you can take the usual dry bar section with a cross section of 50 × 70 mm (although the glue products are preferably preferred), it is preferable to stall and polish it, if possible, to remove the chamfer by the mill. Next, in the lower surface of the handrail, the longitudinal groove for the mortgage river, to which the balusters are fixed. The bottom of the baluster is fixed by the ducts and self-stakes through the step.

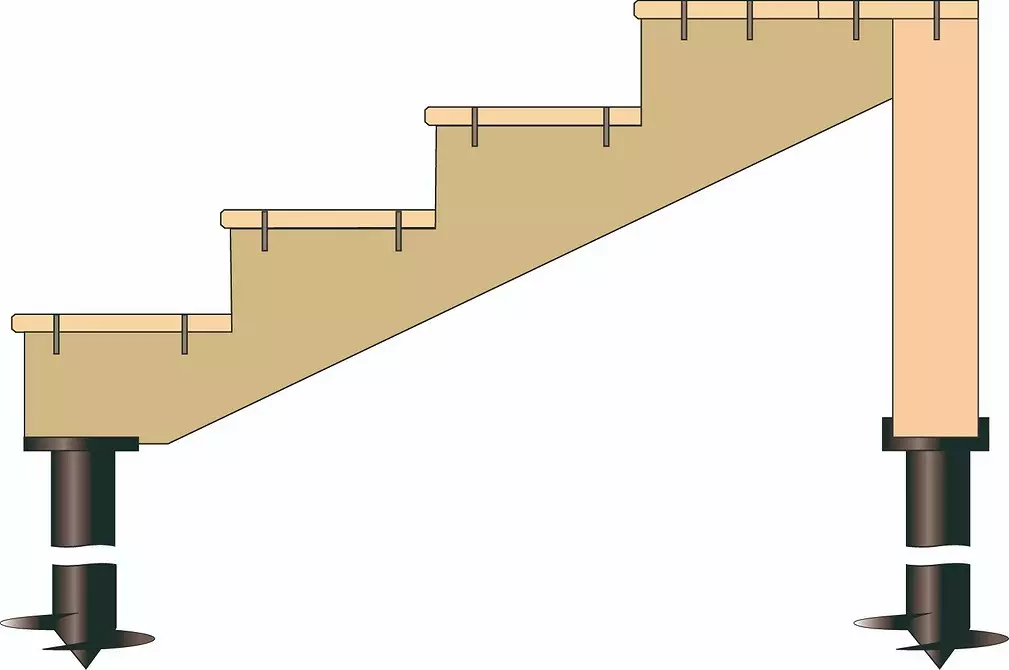

The porch can rely on drilling piles of asbestos-cement pipes filled with concrete

Recommended dimensions of stairs

| The size | Optimal value, see | Permissible value, see |

| Concerns | 15-17 | 15-25 |

| Come out | 32-35 | 26-40 |

| Width Marsha | 100 | from 80. |

| Step Balyasin | fifteen | 12-17 |

| Height Peril | 90. | 85-105 |

| Width of the handrail | 7-8 | 6-10. |

Artem Avakamov, Head of Esg Professional, ArtLine, Stroycontrol:

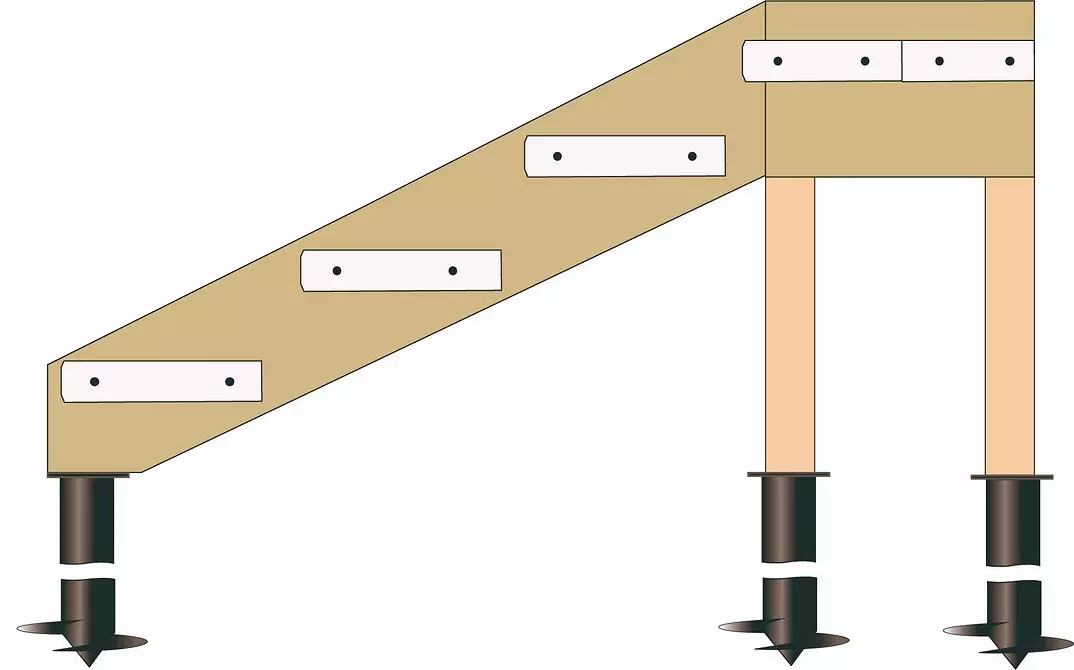

The first stage of construction of a durable porch is the construction of the foundation. Before construction is important to carry out a geological study. If the ground on the plot of pumped, in the winter it will definitely raise the light finished design, if it rests on a not enough base. A common option is the porch on the screw piles. Installation takes a record little time and can be installed on the simplifying ground, which is a big advantage. In addition, steel piles are significantly cheaper than a concrete plate or tape. Finally, the pile base excellent confronts frosty bent. Cheaper option - pillars, but wooden supports quickly rotate, and concrete with insufficiently gluke with time can be lifted or shifted. The main carrier elements of the stairs are oblique beams - the tents or boosters. Kosur has gentle outlines and, as it may repeat the silhouette of the steps, and in the theetics, smooth edges, when viewed, it completely hides the steps. Both structures are widely used in construction. How to determine the choice? The staircase on the rods looks visually easier and requires smaller labor. The ATTA assumes special grooves through which steps is carried out. For their samples, a milling mill or a long work of the chisel will be required.