We tell how to choose the heat-insulating material, determine the necessary thickness and strength and attach it to the foundation.

The need for an outer insulation of underground house structures arises in different cases. For example, when it is planned to arrange an arrangement of the basement, basement or to protect the foundation from frosty powder. After all, most of the soils in the middle lane of our country are clay and loam. Their meal often becomes the cause of deformation and bases of the foundation. The layer of insulating material will completely eliminate or level these negative processes. In addition, he will serve as a defense of the foundation from damage during the backfill of the soil.

Selection of thermal insulation material

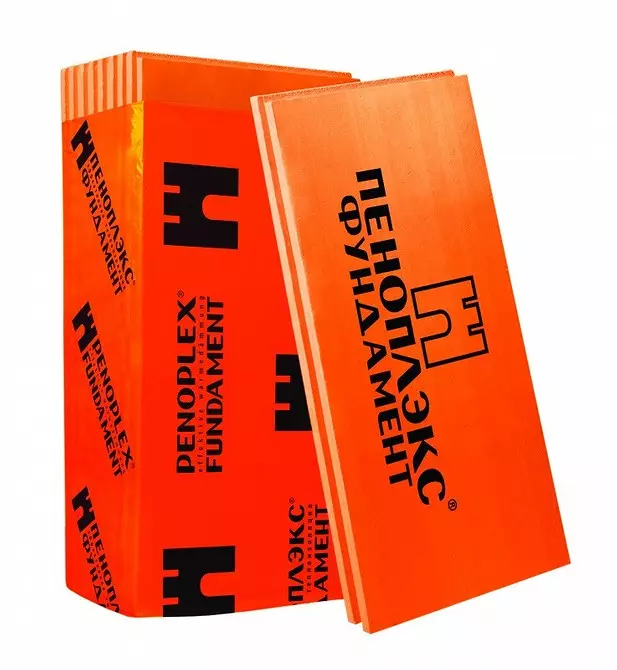

Most often, plates of extruded polystyrene (XPS), which consist of uniformly distributed closed cells are used to insulate the underground part of the house. The material has a low thermal conductivity - 0.028-0.032 W / (M • C), does not absorb water (the minimum water absorption coefficient is 0.2% in volume) and, as a result, has a high frost resistance. It is chemically racks, not subject to rotting, stable under load.

The service life of the plates of extruded polystyrene in the ground is at least 50 years. In our market, this type of thermal insulation is offered by Penopeles, Tekhnonikol, URSA.

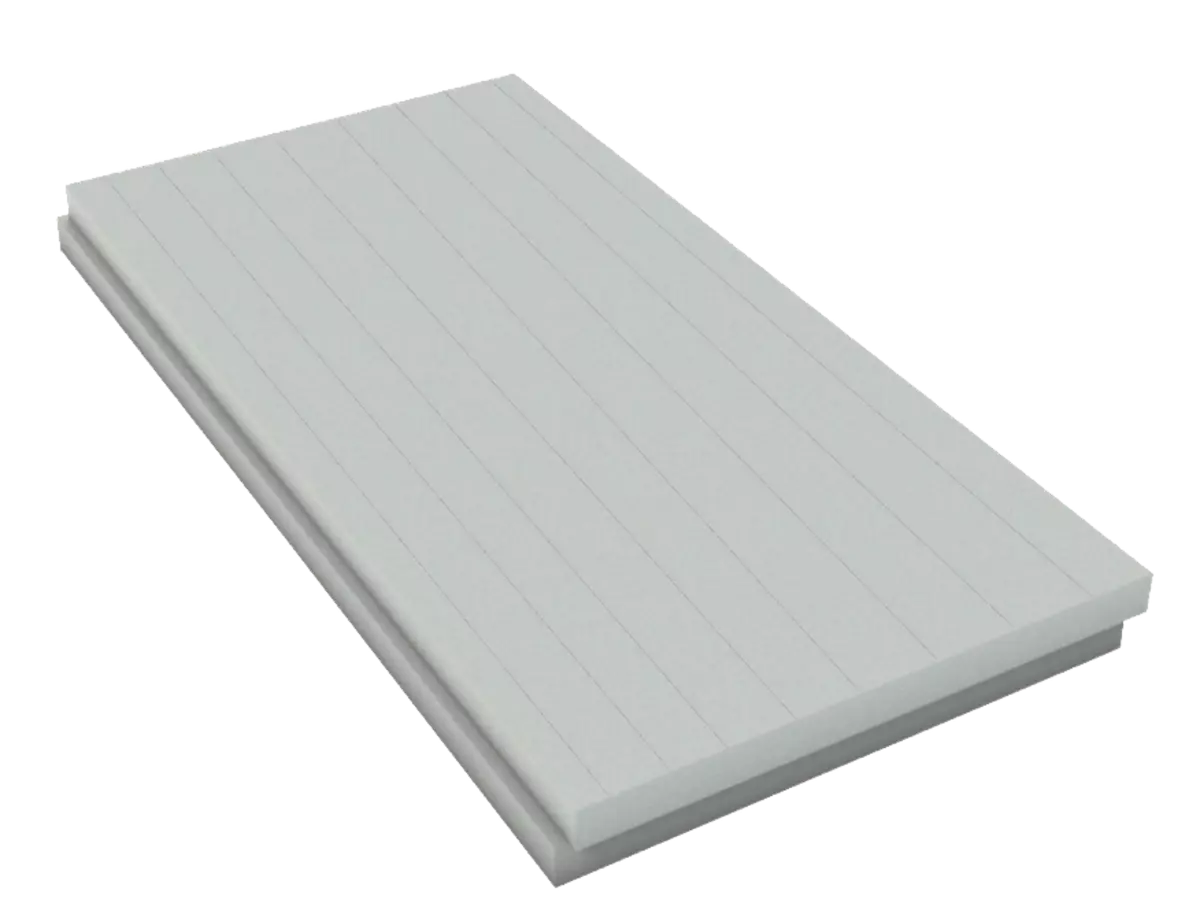

Extruded expanded polystyrene (XPS) TechnoNIKOL

The thickness and strength of thermal insulation

The optimal thickness of the thermal insulation layer for the foundation is determined on the basis of the calculation according to the method described in the SP50.13330.2012 "Thermal Protection of Buildings". In regions with different climatic conditions, this parameter of the insulation will differ. In the middle lane of Russia on the walls of the basements attach XPS plates with a thickness of at least 50 mm. But the corners that are implanted first of all, experts recommend to isolate the material of greater thickness (60-100 mm).

Extruded expanded polystyrene (XPS) URSA

If only vertical walls are expected to be insulated, then increased strength is not required from the insulating material. After all, only the load from the soil of backfill is valid for it. Therefore, sufficient compression strength parameter: 150-250 kPa. Loads on XPS plates laid under the slab foundation or under the "sole" of the foundation, significantly more and, accordingly, increase the requirements for their strength characteristics. In this case, thermal insulation plates are chosen, the compressive strength of which is 250-400 kPa.

On the ends of the plates of extruded expanded polystyrene there is a L-shaped sealing. Thanks to her, the joints of the neighboring elements form a castle, which avoids the formation of cold bridges. The joints of the crucified slab is desirable to lazinate with glue or mastic.

Fastening isolation to the foundation

The plates of extruded polystyrene foaming are fixed on the alleged outer surface of the foundation or walls of the basement, over the layer of coating or inlet waterproofing. For fastening the plates use special adhesives or mastic, which are not included in the organic solvents (toluene, acetone, gasoline, etc.). Otherwise, the glue will destroy the polystyrene foam.

In addition to adhesive compositions, experts recommend using mechanical fasteners, namely disc dowels. The lower row of insulating material relies on sandy-gravel filling. But it is better at the fill stage of the foundation to provide for this a small protrusion.