What is the difference between steel, brick and ceramic chimneys from each other and why traction disappears in them - tell us in our article.

Do you think about creating a chimney in the house? Before proceeding with the case, let's figure it out how to correctly design it and mounted.

All about chimneh

Requirements for chimnetsViews:

- Chimney of bricks

- Chimney from Steel

- Sandwiches pipes

- Ceramic chimneys

Pipes and fireplaces

Is it possible to connect two pipes to chimney

How to improve cravings

In which pipes condensate is formed

General requirements for chimneys

Fireplace inserts can be connected to an existing chimney, but in this case the selection of the windbox power is dictated by the cross section of the smoke channel. General requirements for chimneys are found in Snip 41-01-2003 "Heating, ventilation and air conditioning". This regulatory document allows the use of chimneys from double-gray steel pipes with thermal insulation from non-combustible material (at a temperature of asshastable gases not higher than 500 ° C) and installed umbrellas, deflectors and other nozzles on flue pipes, if these devices do not interfere with the free exit of smoke (in this His difference from SNiP 2.04.05-91).

The height of chimneys from the mouth to the grate grid should be at least 5 m. The height of the parts of the pipes rumped over the roof is not less than 0.5 m above the flat roof, as well as over the skate or parapet at a distance of not more than 1.5 m; not lower than the skate or parapet at a distance of 1.5-3 m; Not lower than the line conducted from the skate down at an angle of 10 to the horizon, at a distance of more than 3 m between the pipe and the skate.

Trucks are allowed at an angle to 30 to a vertical to a distance of not more than 1 m. Pipes on buildings with roofing from combustible materials should be equipped with sparkling from a metal mesh with holes of no more than 5 g 5 mm. The distance from the outer surfaces of brick or concrete flue pipes to rafters, crates and other roof parts made of combustible materials should be at least 130 mm; From ceramic pipes without insulation - 250 mm, with insulation - 130 mm. As for the walls and elements of overlaps from combustible materials, the distance from the inner wall of the smoke channel is normal: 500 mm to unprotected structures and 380 mm - to protected.

However, the application to SNiP operates the term "cutting", that is, we are talking about a brick tube. For modern modular systems, there are no clear standards, and the developers usually follow the instructions of manufacturers.

Types of chimney

Chimney of bricks

Brick chimneys until recently both in urban and rural construction were practically non-alternative. Being a universal structural material, the brick allows you to vary the number of channels of chimneys and wall thickness (you can make the necessary thickens in places of passing overlaps, roofs, as well as when building the street part of the chimney).

The main problem for the outer chimney is good insulation.

The masonry fireplace with an open firebox has a low (15-20%) efficiency, and it is quite difficult to heat the room with it. But it will help to create an atmosphere of a medieval castle in the house.

When compliance with construction technologies, the brick chimney is very durable. However, he has disadvantages. Due to the significant mass (pipe with a cross section of 260 130 mm and a height of 5 m, laid out in the Pollipich, weigh about 1.5 tons) have to arrange the foundation. And to build all this construction, it will take a lot of time and effort. Channel section (rectangular or square) is not optimal for thrust. In addition, during periodic use during the cold season, the service life of the brick tube is greatly reduced due to the aggressive effect of condensation.

For a device of a brick chimney, a very high qualification of builders is needed.

Common Errors

- The choice of poor quality or inappropriate bricks (weakly burned partition or wall).

- The thickness of the masonry seams is more than 5 mm.

- Masonry on the edge; Application stepped ("gear") masonry on inclined areas.

- Incorrect preparation of the solution (for example, if the ratio of clay and sand parts is chosen excluding the thickness of the clay), an inacker rod or a cutting of bricks.

- Inattentive filling and supply of masonry seams (the presence of emptiness and dual vertical seams).

Masonry pipes close to structures from combustible materials. The condition of the brick tube requires constant control. Before, it was certainly bleel, because on the white surface it is easier to notice the soot, testifying about the presence of cracks.

Alexander Zhilikov, Sauna and Fireplaces:

The brick tube faithfully served a person for centuries. The laying of furnaces and fireplaces from this material is almost art. The paradox is that during the period of mass country construction in our country, skill suffered a serious damage. The consequences of "work" of numerous burn-and-chickens were sad, and most importantly - they threatened distrust of brick and chimney. Therefore, favorable conditions arose and maintained to promote the domestic smoking factory readiness systems.

Chimney from Steel

Stainless steel pipes can be safely attributed to the most widely used type of chimneys. Steel modular systems have a number of indisputable advantages. The main points are a small mass, ease of installation, a rich selection of pipes of different diameter and length, as well as shaped elements. Steel chimneys are manufactured in two versions - single and two-circuit (the latter - in the form of "sandwich" of two coaxial pipes with a layer of non-combustible thermal insulation).The first are intended for mounting in heated rooms, connecting the fireplace to an already existing chimney, as well as the reservation of old brick pipes. The second is a ready-made constructive solution, the chimney is equally suitable for the installation of the chimney both inside the building and outside. The special type of stainless steel flue channels is flexible single and double-wall (without thermal insulation) corrugated sleeves.

For the production of single-circuit chimneys and inner chimneys of type "Sandwich" type, alloy steel and acid-resistant leaf steel are used (usually with a thickness of 0.5-0.6 mm). Single-mount chimneys from carbon steel, covered outside and from the inside with a special enamel of black, because of the heat resistance even superior to stainless steel pipes; Condensate is also not terrible, but only subject to the integrity of the coating that is easy to damage (let's say, when cleaning the chimney). The service life of the pipes without coating from the "black" steel with a thickness of 1 mm does not exceed 5 years.

Sandwiches pipes

The casing (shell) of pipes "sandwiches" is usually made from the usual (non-stainless) stainless steel, which is polished by an electrochemical way to a mirror glitter, and some manufacturers offer enamel color in any color on the RAL scale. The use of galvanized steel casing is justified only when the chimney is installed inside the building. Outside, such a pipe, if actively exploited chimney, will last long: due to periodic heating, corrosion is enhanced.

Alexey Matveyev, NII KM:

Stainless steel used for chimneys are divided into two categories: Magnetic ferrite (in the American ASTM standardization system is AISI 409, 430, 439 IT.D.) and non-magnetic austenitic (AISI 304, 316, 321, etc.) . According to our tests of steel AISI 409 (Composition: 0.08% C, 1% Mn, 1% Si, 10.5-11.75% CR, 0.75% Ti), critical temperature in the inner tube of the heated fragment of the chimney At which the effect of intercrystalline corrosion was noticeable, it was equal to 800-900 C. For 4 hours of effects, the inner wall of the pipe was covered with a kind of "crocodile skin", which indicates the beginning of the steel destruction process. At 650, no traces of corrosion were observed. Up to 1000, the temperature in the pipe rises only during the heat of the soot (the phenomenon is extreme and adversely affecting almost any chimney). At the working temperature to 600, the chimney of stainless steel is capable of listening to dozens of years.

The layer of thermal insulation in the pipes- "Sandwichs" decides at once three tasks: prevents the flue gas supercooling negatively, does not allow the temperature of the inner walls of the chimney to drop to the point of dew and, finally, provides a fireproof temperature of the outer walls.

The choice of insulating materials is small: it is usually wool - basalt (or siliconorganic, pearlit sand (but it can be filled only in the process of chimney mounting).

Stability, making stretch marks, towering over the roof areas of pipes from several modules.

Steel module chimney

Such a very important characteristic of the chimney, as the gas content, depends on the design of the joints of the pipes, so each manufacturer seeks to bring it to perfection. Thus, the sealing of some flue pipes provide centering couplings; A dual ring protrusion formed on the junction, crimping the clamps included in the delivery of each module. In other chimneys, a cone-shaped connection is provided in combination with an annular protrusion.

The overwhelming majority of stainless steel chimneys are mounted in a traditional way, and here much depends on the quality of the parts. Typically, the upper module is put on the lower, but one-contact, and with outdoor gasket and double-circuit modules you should dock, inserting the upper in the lower, which will avoid condensate leaks through the joints.

Ceramic chimneys

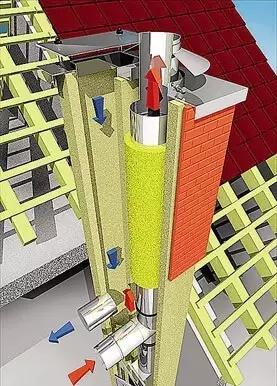

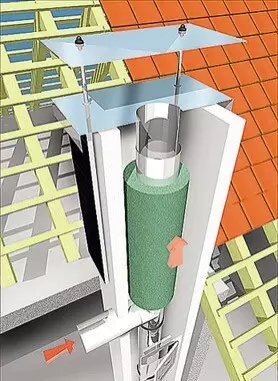

Ceramic chimneys are the same "sandwiches", but "cooked" in a completely different recipe. The inner tube is a pottery of chamotte mass, the middle layer is a constant basalt wool, outdoor - sections of light concrete or a mirrored stainless steel.

Chimneys from ceramics are resistant to high temperatures (up to 1000 ° C), the effects of condensate and at the same time they have the main advantage of modular systems - they can be quickly and easily assembled.

Ceramic systems and their minuses have. Chimneys with a casing of concrete have a significant mass (1 m. M weighs from 80 kg), can only be used as indigenous (separately), do not allow to bypass obstacles. "Weak link" such chimneys is a connection node. Manufacturers provide for the use of a metal module (modules), which has a smaller service life and therefore will require a replacement in the future that it is necessary to provide for the construction of the fireplace.

Raab chimneys with inner stainless steel pipe and concrete casing: with ventilation channel ...

... or without it.

Finally, the metal is not too well combined with ceramics, because it has a high thermal expansion coefficient: around the perimeter of the steel pipe where it is included in ceramic, it is necessary to leave quite large (about 10 mm) a gap, which is filled with asbestos cord or heat-resistant sealant.

However, the high reliability and durability of ceramic chimneys (the factory warranty is 30 years old, and the actual service life, according to manufacturers, is more than 100 years) allow you to close your eyes to the listed flaws.

What pipes are suitable for the fireplace

The degree of reliability and efficiency of the chimney is largely depends on the heating devices connected to them, and vice versa. Therefore, for each type of fireplaces, there is an optimal variant of the chimney.

The use of thermally insulated modules along the entire length of the chimney (ranging from the furnace) is justified in those rooms where the fireplace performs mainly decorative functions. Usually, to use the heat of the assigned gases, the first 1.5-2 M chimns are collected from single-axis pipes in compliance with the necessary fire safety measures.

The following requirements are presented to the chimney of a classical masonry fireplace with an open furnace: the channel can only be direct-flow, with a cross section of at least 1/10 of the cross section of the fuel opening. Skin-focus, which has a firebox from two or more sides (its "extreme" variety - The "island" fireplace) is supplied with a smoke-chimney passing into the chimney. The latter should have an enlarged section, and it is often equipped with a hood and exhaust device (chymososa).

The most common fireplaces with closed firebox are most common. Their fundamental difference from the classic is that the air required for burning does not act through the flue opening, but simply, and, manipulating the flaps, you adjust the burning intensity. You can establish a modular chimney from stainless steel on the vast majority of fireplace floors.

In many fireplace floors, the outlet is equipped with a damper (schiber). In the burden, it partially overlaps the chimney, limiting the thrust, and the burning process slows down.

If the flap is open, the flue gases go unobstructed - this is required at the ignition stage, as well as when it comes to throw the firewood in the furnace. Sometimes the flap opens automatically simultaneously with the furnace door.

Finally, the last type - Caminoxes. The main distinguishing feature of such devices that gives them similarity to the real oven is the presence of a built-in smoke channel, passing through which flue gases is cooled to a rather low temperature. Allegedly arises the need for a massive masonry or well warmed modular chimney.

Type of fireplace | Feature burning | Efficiency,% | The temperature of the assigned gases, ° C | Type of chimney |

|---|---|---|---|---|

With open furnace | Air access is not limited | 15-20. | Up to 600 * | Brick, from heat resistant concrete |

With closed firebox | Air access may be limited | 70-80 | 400-500 | Brick, from heat-resistant concrete, modular insulated stainless steel or ceramic, within heated rooms - single-ground steel enameled |

Caminox | Air access is limited, gases are cooled by passing by integrated channels | Up to 85 | 160-230 ** | In addition to those listed above: from talcomagnesite or talco chlorite - massive or internal pipe (steel, ceramic) |

* - when used as a fuel of hardening rocks, coal, as well as with excessive temperatures, the temperature may exceed the specified value;

** - for transcription from talcomagnesit; For metal - up to 400 ° C

Is it possible to connect two pipes to chimney

The question of the possibility of connecting two fireplaces to one chimney refers to the category of controversial. According to the requirements of SNiP 41-01-2003, "for each furnace, as a rule, it should be provided for a separate chimney or channel. It is allowed to connect to one chimney two furnaces located in one apartment on the same floor. When combining the flue pipes, it should be covered in them (the median walls dividing chimney into two channels. - Ed.) Height of at least 1 m from the bottom of the pipe connection.

As for the wretch, it can be done only in a brick chimney. If the chimney is modular, it is enough with the help of a tee to connect the pipe of the second furnace to the first pipe (if the smoke channels have different diameters, then smaller cut into more), after which it is necessary to increase the channel cross section. How much? Some experts believe that if simultaneous operation of the furnace is planned, the cross-sectional area is determined by simply summation. Others believe that it is enough to "throw up" 30-50% enough, since two fireboxs warm the total pipe and the thrust will increase, but this concerns only chimneys with a height of more than 6 m.

Dual-circuit tees and adapter, with which the pipes of different diameters are joined.

Steel modules allow you to design the chimneys of a complex configuration, collect and remove the smoke condensate, provide easy cleaning of pipes.

Some modular systems allow the installation of pipes of a pipe up to 3 m with no additional fasteners.

When connecting to one chimney two furnaces located on different floors, everything is much more complicated. Practice shows that such systems work, but only with a thorough calculation and numerous additional conditions (an increase in the height of the chimney, setting the spikes after the lower furnace and on the inlet nozzle, compliance with the crash of the extracts, or the complete exception of simultaneous operation, etc.).

We draw your attention to the fact that all of the above in this section applies only to the fireplaces with a closed firebox. Open furnace is more fire and demanding to the thrust, so it does not allow any "liberties" and requires the construction of a separate chimney.

How to improve thrust in chimney

Bad thrust, as a rule, arises due to errors in the design of the chimney. The desire to explain its adverse weather conditions (atmospheric pressure and air temperature) is unreasonable, since these factors are also taken into account at a competent decision.Causes of bad traction

- The insufficient height of the chimney in general is either the part of its part that rises above the roof.

- Incorrectly selected channel cross section: too narrow pipe cannot provide the entire mass of the resulting gases; It is too wide wider worse warming up, it is possible to join the stream of gases, and the cold street air can form reverse streams.

- Bad insulation tube.

- Too much length of the wrong sections, especially in the upper part of the chimney.

- A shortage in the air room for burning (in the design of the chimney, an additional trim channel was to be provided).

Tipping the thrust of the wind occurs due to the insufficient height of the pipe above the roof. Cocking roofs arise airflow; On the sub-rope, it is directed down and is able to blew the flue gases back into the pipe.

It is much more difficult to determine the cause in each particular case, since several factors often act at once, none of which plays an independent role. To improve the craving, it is necessary to change the design of the chimney, sometimes not too significant (for example, increase the thickness of thermal insulation in the last one and a half or two meters of the pipe). There is such a problem as excessive thrust. You can cope with it using a chiber. It is only necessary to foresee its installation before starting the chimney mounting.

In which pipes condensate is formed

The main gaseous products of combustion of carbon-containing fuels are carbon dioxide and water vapor. In addition, the moisture is evaporated during the burning, which is available in the fuel (firewood). As a result of the interaction of water vapuses with sulfur and nitrogen oxides, pairs of low concentrations are formed, condensing on the inner surface of the chimney during their cooling to a temperature below the critical (when the wood burning is about 50 ° C).

The amount of condensate is directly dependent on the area of this surface and in the reverse - from its temperature. If you drown in the cold season, a fireplace with an outer dismayed metallic chimney, the amount of condensate can be measured by liters per day.

The brick tube is able to accumulate heat, so it behaves otherwise: condensate is formed only at the stage of heating the pipe (true, it is quite a large period of time). In addition, the material partially absorbs condensate, so the latter is not too noticeable, which, however, does not prevent it from the destructive impact on the masonry. If the intensity of burning is small, and the ambient temperature is low, the brick can cool, and the condensate will begin to form again.

With an insufficient thickness of the insulation and the low temperature of the assigned gases (the firebox is adjusted for long burning) condensate is able to appear in the Sandwich modular chimney. Anyway, it is impossible to completely get rid of condensate, it should only be reduced to a minimum of its number (the main tool for this is the use of more efficient thermal insulation) and prevent leaks.

Condensate leaks through masonry seams suggest that the temperature of the internal surfaces of the chimney dropped below the dew point

Changing the color of the roof from high-quality metal tile indicates the high aggressiveness of the smoke condensate, traces of which can be completely removed except from the surface of glass or ceramic tiles.

Due to the installation of the condensate neutralizer, you can dwell into the sewer system. The inclusion of the active substance in such devices uses a special granulate or ion exchange resin, which must be periodically replaced.

The use of casing made of light concrete allows you to provide an additional trimming channel, thanks to which room air is not consumed for burning and a stable thrust is created without risk tipping.

We touched on only a small part of the problems associated with the coexistence of the pipe and smoke. Try in one article to answer all the questions that arise from the owners of the fireplaces - the task is impossible. The individual approach is often required, and, as specialists note, the correct solution can sometimes tell only the experience and professional intuition.