We tell what kind of paint will return aesthetic appearance of a bath oven, barbecue and a barbecue and will withstand the effects of high temperatures and open fire.

Features of heat-resistant paints

The main difference between heat-resistant paint materials (LKM) from others is that they retain physicochemical and decorative properties during and after exposure to high temperatures. Immunity to such extreme depends on several factors: coating composition (type of binder, type of pigments and fillers), quality of preliminary surface preparation, compliance with application technology. If the heat resistance of ordinary paints and enamel rarely exceeds 60 ° C, then the operating temperatures of the surfaces on which special compositions are used are only starting with this value and reach 1,000 ° C.

CERTA Patina.

Termal.

"Dali heat-resistant enamel"

"Heat-resistant enamel"

Srebrzanka.

"Celsit-500"

In the domestic market, heat-resistant LKM are represented by many companies and trademarks, among them Bosny, Elcon, Kudo, Sniezka, Tikkurila, Vixen, "Krako", "Rognda", "Spectrum". Of course, these specialized compositions are more expensive than usual. Moreover, the higher the operating temperature, the greater the price of the coating. In order not to overpay, it should be determined in which temperature range will be operated with a protective-decorative colorful film. The cost also affect the volume of packaging and the packing method. It can be small balloons with aerosol, banks or shoulder of impressive volumes (from 20 kg or more).

The difference of fire retardant colors from heat-resistant

Do not confuse heat-resistant and flame retardant paints and varnishes. The heat-resistant withstand high temperatures without contact with open fire. Firestrokes protect products just exposure to flames. Their main task to increase the level of fire safety of the house designs, including carrier metal and wooden frames, beams, overlap, supports, and canals with engineering communications. The mechanism of the work of the most popular in the group of fire-resistant, so-called thermal paints, simple. The antipyrenes introduced into the composition react to a sharp increase in temperature by a rapid increase in the volume of the paint layer. This foam mass turns into a kind of barrier with a low heat transfer coefficient, between the fire and the surface of the material.

"Flame-proof universal paint" ("Akvest") for metal, wood, cable (UP. 25 kg - 5 750 rub.)

White paint "Decoterm" ("Territory of Color") for metal structures (UE. 10 kg - 3,220 rubles)

OSB Interior Finish Decor (Soppka) paint for internal surfaces from OSB slabs, SIP, plywood (UP. 10 kg - 3 220 rub.)

Owners of country houses rated the flame retardant properties of paints and actively use them. But if on wooden supporting structures, the benefits of such compositions are quite obvious, then why protect metal? The fact is that with raising the temperature of the metal, the parts are lengthened, their plasticity increases, and the rigidity becomes less. When heated to 500 ° C, they lose the carrying capacity and are deformed, which is fraught with the collapse of the structures. Fire resistant paints pushed the heating time of structures to a critical value by 15-150 minutes. For the compositions of the first group of fire resistance, this is the maximum time - 150 minutes, then the time period is reduced to 15 minutes in the colors of the seventh group. In an emergency, this delay will help the inhabitants of the house to leave him in a timely manner and wait for the arrival of firefighters.

The term "heat-resistant" does not mean that the paint can be applied to hot surfaces. It will only heat the heat-resistant after drying and calcining.

The properties of the heat-resistant coating will fully comply with the declared manufacturer after thermal conversion. For this, the product with dried paint is heated to 250-300 ° C and withstand 0.5-3 hours. Accurate temperature data, heating rates, hardening time indicates the paint manufacturer. Make it with a gas burner, soldering lamp, by a test firebox. The chimney of the coating on the heated surface is the evidence of the normal movement of the heat conversion.

Heat resistant aerosols

With small volumes of repair work, spray springs are used with heat-resistant aerosols (up to 520 ml). To get an excellent result, you do not need to be a professional. Auxiliary tools will not need: brushes and rollers. Apply paints and enamels from a distance of 20-25 cm smooth, uniform movements, not allowing elements. The sprayed composition of the thin layer covers any, even hard-to-reach surfaces. After the process is completed, the balloon from the remaining paint can be kept for a long time (from year to 5 years) without worrying that it thickens, and at any time it is used again. The main thing is not to forget to shake the packaging for a few minutes before applying to mix well components.

Aerosol cans: "Enamel heat-resistant" (Kudo) (UE. 520 ml - 204 rub.)

"Heat-resistant enamel to 1000 ° C" (ELCON) (UE. 520 ml - 264 rubles.)

CERTA up to 1000 ° C ("Spectr") (UE. 520 ml - 342 rubles.)

Hi-Temp (Bosny) (UE. 400 ml - 289 rub.)

Heat resistant paints

| Name | CERTA Patina. | Termal. | "Dali heat-resistant enamel" | "Heat-resistant enamel" | Srebrzanka. | "Celsit-500" |

| Manufacturer, TM. | "Spectrum" | Tikkurila | "Rogned" | Elcon. | Sniezka. | "Krasko" |

| Viability of the solution, h | 2. | 3. | 3. | 2. | 3. | four |

| Foundation material | Tree, metal | Metal | Metal | Metal | Metal | Metal, mineral surfaces |

| Heat resistance, ˚С | Up to 700. | Up to 600. | Up to 600. | Up to 700. | Up to 500. | Up to 500. |

| Packaging | 0.5 kg | 0.33 L. | 0.4 L. | 0.08 kg | 0.25 L. | 0.9 kg |

| price, rub. | 1285. | 799. | 340. | 200. | 250. | 404. |

Tips for choosing

Choosing a heat-resistant composition, pay attention to the surface material for which it is intended. After all, not only metallic surfaces are exposed to strong heating. Unique protective properties of many LKMs help protect other than metal concrete, reinforced concrete, brick, asbestos and plastered surfaces from exposure to high temperatures and moisture.

The heat resistance of the coating is estimated at a maximum permissible temperature at which the colorful film retains the ability to perform its functions for a certain time.

The palette of heat-resistant paints from different manufacturers is small. The number of colors ranges from 6 to 250

The color of heat-resistant compositions also depend on the range of working temperatures of the product. The most resistant includes black, silver and graphite shades. The staining process Most manufacturers of heat-resistant LKM are recommended at a positive temperature (from 5 to 30 ° C). Although, for example, with blacksmith paints Smith and Patina, ELCON can be operated at ambient air temperature and substrates from -30 to +40 ° C and relative air humidity not more than 80%. However, in order to prevent the formation of an inlet and ice crust, it is necessary to monitor the temperature of the painted surface. It must be 3 ° C above the dew point.

Choosing a heat-resistant composition for use in the house, be sure to pay attention to the absence of substances harmful to human health. In the case of applying the coating outside the house, its protective properties, resistance to environmental and corrosion, are in the first place.

It is worth remembering that pigmentation reduces heat-resistant properties

Tips for applying

The optimal layer thickness for heat-resistant LKM ranges from 15 to 150 microns. Following the manufacturer's recommendations, it is applied to the treated surface from one to three protective layers using the paintopult, roller or brush. Regardless of the tool, it is very important to prevent the appearance of non-cristes.

Keep in mind: the thickness of the colorful layer, the higher the resistance of the product against corrosion, and at the same time the higher the heating temperature, the one should be thinner. An impressive layer thickness is permissible for paints working up to 100 ° C. For the extreme range of 700-1000 ° C, just just one thin layer (15-30 microns). It turns out better in spraying.

Before applying heat-resistant enamel, the base must be carefully cleaned, degreased and dried, as it affects the grip of the colorful film and its durability

The process of painting the oven heat-resistant enamel

- The rust layer is removed by a grinding skin or brush. The residues are covered by the Rust converter "Ecocin-P" ("Spectrum").

- The surface is then degreased by a cloth moistened in a solvent, and leave for drying to 30 minutes. Before applying the heat-resistant Enamel Certa ("Spectrum") (up to 900 ° C), a cylinder shakes 2 minutes. Coloring starts with welds and hard-to-reach surfaces. The paint is applied with a cross-spray from a distance of 25-30 cm in two or three layers with an intermediate drying of about 30 minutes.

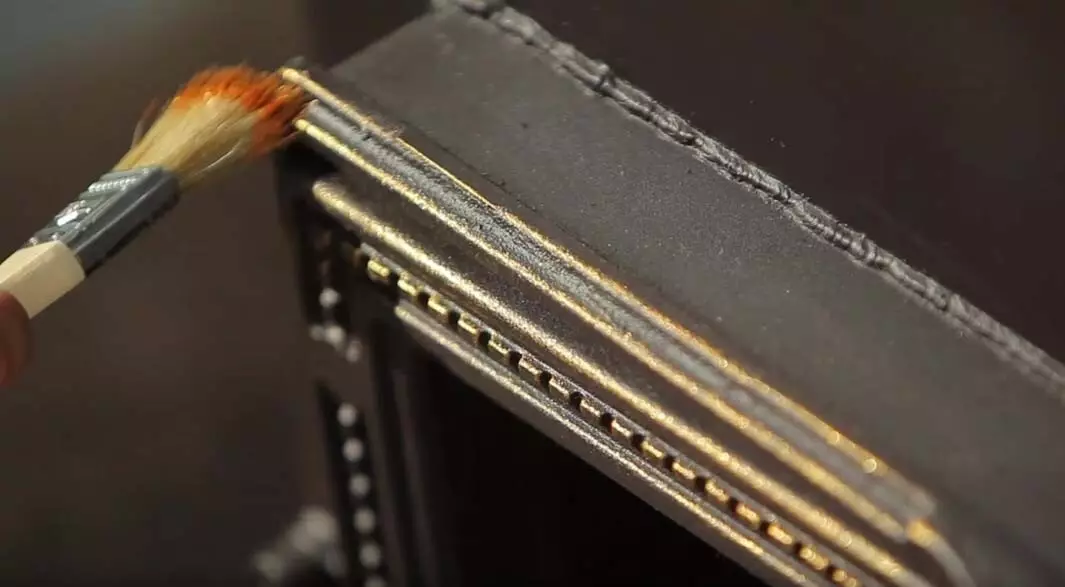

- The layers should be thin, without non-crushes and herds. After 1-2 hours, they apply a heat-resistant patina to create a decorative effect. A slightly moistened in the paint brush is easily carried out on the protruding parts, without blocking the previous colorful layer.

- After that, leave the furnace for a day until the paint is completely drying. The last stage is thermal conversion. The furnace is flipped over for 3 hours, gradually increasing the temperature in the furnace.