We tell how to reduce the noise from the neighbors with the help of acoustic sandwich panels, rolled materials, floor screeds and other modern materials.

In a high-rise building, we are quite often hearing noise from the neighbors. Alas, sound, especially low-frequency, is able to overcome even thick concrete walls and overlaps. As a rule, attachments are used for additional sound insulation in high-rise buildings, the thickness of which is at least 50 mm, and more often 80-100 mm. After their installation, the room becomes quieter, but also noticeably closer. Is it possible to improve the soundproofing of an apartment or room without loss of useful area? As an alternative to the company engaged in construction acoustics, they offer more subtle frameless sound insulation. One of the main advantages of frameless systems - in the absence of racks that become sound bridges (especially if they are hollow and toughly attached to the wall or ceiling). But it is not easier to mount an efficient frameless design than framework, and the components will even be somewhat more expensive.

Types of noise

In the construction acoustics, it is customary to talk about three types of noise - air, shock and structural. The first arises as a result of oscillations of solid bodies in the air, the second - after mechanical impacts on the elements of the building. The shock noise in a multi-storey house is often extended to each other walls, overlaps, the details of the reinforced concrete frame, that is, turns into structural oscillations. The air noise of high volume and low frequency is also capable of calling them. To protect the room from structural noise, it is required to mount the insulating structures on all its walls, the floor and ceiling. In this case, it is necessary to apply the combinations of acoustically soft (sound-absorbing) and acoustically hard (reflective) materials, as well as to use elastic gaskets that quench vibration. The more layers in the protective design and the thicker it is, the better sound insulation.Soundproofing walls

Thin-layer rolled and leafy materials

In the Internet, thin-layer (up to 5 mm) rolled and sheet materials are widely advertised for additional sound insulation of walls made of polyethylene foam, polystyrene foam, cork agglomerate. The material is fixed on the concrete surface by glue, and then it can be painted or caught by wallpaper. However, additional insulation of structural noise will be only 2-3 dB, which is not always noticeable. At the same time, if used materials with low vapor permeability, there is a risk of worsening the microclimate indoors.

The mate from the glass cholester can be mounted under the trim from GLK or cardboard panels.

Multilayer structures

Multi-layer designs are much better. As a rule, they include a soft substrate (for example, a self-adhesive membrane of mineral felt), noise absorbing panels and sheets (GCL, GVL). The main element of the system - panels - can be made of fiberboard, extruded mineral fiber or cardboard (shell) and compacted sand (filling); They are produced under the trademarks "Sonoplat", "Economicalizol", "Ecocovers", Phone Star, Ticho, etc.

Panels should be attached to the wall with special acoustic dowels. Next, using conventional self-tapping and polyurethane glue or silicone sealant, the shears of the sheath are recorded; They need to be screwed only to panels, and not to a concrete basis. The described design has a thickness of about 30 mm and allows you to achieve an additional reduction in air noise by 10-12 dB (the same result gives a frame soundproofing with a thickness of 60 mm). However, taking into account the installation, it will cost at least 2800 rubles. For 1 m2, moreover, in contrast to the frame, it will require a thorough alignment of the base surface.

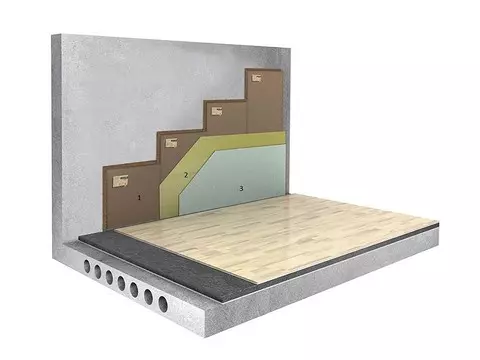

Concrete Wall Soundproofing Option

1-heavy panels from cellular cardboard filled with sand ("Sonoplate Combi");

2 - Mineral Acoustic Membrane "Texound";

3 - Gypsum Carton

Acoustic Sandwich Panels

Finally, the market presents acoustic sandwich panels, consisting of a soft noise absorbing layer (usually a mineralized matte of high density) and a rigid trim (GWL) glued to it. Panels are mounted directly on the wall or ceiling. Their thickness can reach 133 mm ("zipssinem"), and the value of Δ Rw - 18 dB.

The panel is attached directly to the wall (permissible to the ceiling) with a dowel through the built-in vibrational rubber washers

The "SIPS" panels are well protected from air noise, and due to the presence of the edge lock tightly adjacent to each other and easily mounted

Soundproofing floor

Wet floating screed

The most popular soundproofing design for the floor is a wet floating screed. It helps protect your apartment from the structural noise emitted by the overlap, and prevents the transmission of shock noises to the following rooms.

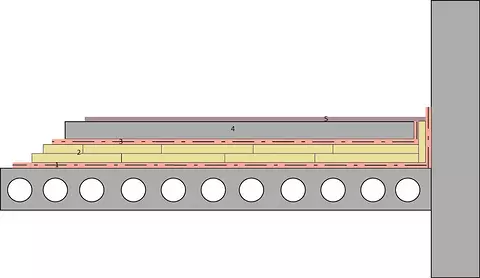

Flooring Floor Floor Design Option:

1, 3 - waterproofing film;

2 - slabs made of mineral wool "SHOYSTOCK-K2", laid in two layers;

4 - reinforced cement and sand tie;

5 - Flooring

The substrate under the tie is performed from a material that can extinguish shock oscillations, - porous rubber, polyethylene foam, fiberboard, mineral wool, plugs, extruded polystyrene foam.

Most often for air noise isolation, mates from glass and stone wool are used

Materials based on flax and wool will be much more expensive

The "Vibroflor" substrate from polyester fiber can be placed under a tie, laminate or parquet board. Reducing shock noise will be 17-27 dB

It is advisable to purchase a universal single and two-layer substrate, which not only exhaust vibration, but also protects against leaks to the lower neighbors. The choice of substrate thickness depends on the type of material and the desired effect. For example, a layer of polyethylene with a thickness of 5 mm reduces the shock noise under the overlap of 18-20 dB, and the fiberboard with a thickness of 40 mm - by 28-32 dB. When installing the substrate necessarily roll on the walls (arrange a curb) for the entire height of the screed to isolate the solid layer from the walls. Its minimum thickness in such a design is 50 mm, and necessarily reinforcement of a frame from a rod with a diameter of 8-10 mm or two rows of road grid. Wet screed should dry at least 3 weeks.

When laying a mineral mat under the screed, a concrete layer reinforced the road grid

The cork substrate with a thickness of 4 mm under laminate reduces the shock noise by about 22 dB

Clamps made of cork agglomerate are manufactured without using synthetic glue. The material perfectly quenches the vibration and is suitable for creating acoustic podiums and floating floors

Dry screed team

The prefabricated dry ties are mounted much faster, several times less weigh and at the same time they have a good soundproofing ability. Thus, the classic version with a claying frost (50 mm) and HBL sheets (25 mm) reduces shock noise by 18-22 dB, and the design of mineral wool mats of high density (50 mm) and plywood (20 mm) - by 30-35 dB .Soundproofing ceiling

It is noticeable to mucify the impact noise transmitted by interleaved overlap, only thick (at least 40 mm) layer of fibrous noise absorbing material is capable. Special acoustic slabs from mineral wool "Technoacoustik" (TechnoNIKOL), ISOVER "sound protection" ("Saint-Goben"), "Isolat-l" (ISOROC), SSB 4 (Paroc), etc., which are attached to the overlap of dishes Dowels, and then masked by a tension ceiling made of polyester cloth.

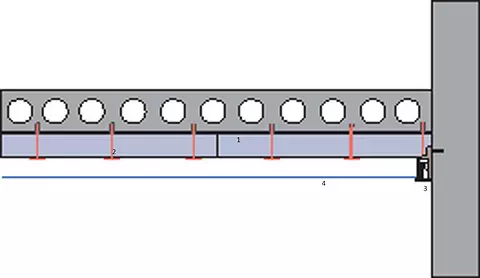

The design version of the soundproof ceiling:

1 - noise absorbing mats from basalt fiber;

2 - plastic plate dowel;

3 - Baget profile;

4 - stretch ceiling of polyester nonwoven

This design cost from 3,400 rubles. For 1 m2, it will reduce the level of shock noise by 10-16 dB - depending on the thickness of sound-absorbing mats. But for its installation, as well as for installation of the "SIPS" panels, a set of holes are required in the overlap: each mineral wool plate is attached at five points, the sandwich panel is in eight. It is a long and noisy job, besides there is a risk of weakening overlap.

Sound-absorbing plates are fixed to the overlap of plastic plate dowels

Two-layer panels need to be fixed with steel anchors

Poorly sealed seams between panels and slabs of overlaps, as well as all the joints between the elements of the soundproofing design should be filled with an acoustic sealant

The task is simplified if the use of light firmware mats made of mineral fiber (for example, "Inexer", "Basaltin") or Singrytegone, which is allowed to be mounted with short dowels in a step of up to 1 m. True, the soundproofing increase will be significantly less - only 6-8 dB.

If you hear the voices or sound of the TV from the neighbors, do not rush to mount an insulating structure: most likely, the sound is seeping through the bogged or separated during the shrink between the elements of the walls or overlaps. To detect it, it is necessary to remove the finishing material, and sometimes plaster; Another option is to refer to the construction experts, which examine the designs with an ultrasonic flaw detector. The fracture found must be sewed and close at the entire depth (using a plunger pistol) by a repair cement mixture or silicone sealant.

Sound insulation materials for frameless mounting

| Name | Sonoplat. | Ticho Standart. | "Zipse-vector" | "Zipse module" | Tecsound 70. | "Texound SY 50" |

| Sizes (width × Length × Thickness), mm | 600 × 1200 × 12 | 800 × 1200 × 12 | 600 × 1200 × 40 | 600 × 1200 × 70 | 122 × 5050 × 3.7 | 122 × 6050 × 2.7 |

| Δ rw, dB | 8-10. | 6-10. | 9-11 | 12-14 | 1-3. | 1-3. |

| Structure | Fiberboard + sand | Cardboard + sand | Glass gaming + gypsum fibrous leaf | Stone wool + gypsum fibrous leaf | Acoustic felt from mineral fiber | Acoustic Membrane from Mineral Felt |

| Price, rub. / M2 | 1500. | 1200. | 1475. | 1475. | 1910. | 750. |