Sikhuluma ngezinzuzo zamanzi ngaphansi komhlaba, izimiso zemithetho yokusebenza nokufakwa.

Ochwepheshe bakuqinisekisile ukuthi uMuntu onethezekile unomuzwa wokuthi izinga lokushisa komoya lifinyelela amanani ka-22-22 ° C, futhi ezingeni lekhanda ngo-18-20 ° C. Ukusabalalisa okunjalo kuqinisekiswa kangcono ngokushisa kwaphansi. I-Design Design eklanywe kahle igcina kuze kufike ku-20% wemithombo yamandla. Ukushisa okufanayo kwe-perimeter yazo zonke izikhala kuqeda ukwakheka kokugeleza okuhlanganisiwe, kuvimbela ukwenzeka kokusalungiswa. Njengoba ama-radiator kanye nezimpikiswano ezivela egumbini ahlanzwa, umakhi kanye nomqambi babonakala amathuba ezixazululo ezintsha zokuhlela. Kubalulekile futhi ukuthi ukuhlanzwa kwezakhiwo kulungiswe kakhulu. Kodwa-ke, indawo efudumele yamanzi inemizuzu yayo. Silandisa ngayo yonke into ngokuhlelekile.

Konke mayelana nokufakwa kanye nokusebenza kwamanzi phansi

IziciIsebenza kanjani

Ukusongoza icebo

Izinto eziyinhloko

- Ipayipi

- Ukujikeleza kwegazi

- Ukufudumeza contours

Ukufaka

- Vusa

- Isikali sikakhonkolo

Izici zokushisa kwamanzi

Kunezindlela eziningana zokwelapha kusuka ekuqedeni. Kunzima ukusho ukuthi ngabe uhlelo lwe-Hydraulic lunezinzuzo ngaphezulu kwama-invitters amancanyana afihlwe ngaphansi kwama-laminate uma esetshenziswa efulethini lasemadolobheni. Okwezinkinga ezisobala, ngokuqhathanisa okunjalo, ukusebenza kahle okuncane kungabikwa. Amapayipi afihliwe ngaphansi kwe-tie asebenze kuphela izindlela ezisizayo. Ezindaweni ezinesimo sezulu esipholile, sekwanele ukudala izimo ezintofontofo, kepha ebusika obandayo ukufudumeza umoya, kudingeka i-radiator ejwayelekile.

Esinye isici yisidingo sokufaka i-boiler, uketshezi lokushisa olugeleza eziteshini ezingenhla kokugqagqana. Ukufakwa kwalo kungenzeka hhayi ezindlini zangasese kuphela, kepha amafulethi kukhona i-analogue kagesi yepayipi, ethatha isikhala esincane futhi ayidingi ukufakwa kwemishini enkulu. Enye yezinto ukuthi kungenzeka ukuthi kukhiphe i-contour kanye nezikhukhula zomakhelwane. Yehlisa ubungozi kuzosiza ukugoqa amanzi amanzi.

Ezakhiweni ezisefulethini, phansi kwamanzi afudumele anqatshelwe ngokwezigaba ohlelweni lokushisa oluphakathi. Kulokhu, uhlelo lufaka phakathi ukushisa okushisa kokushisa lapho kukhulunywa ngokuxhumana nezokuxhumana efulethini. Lokhu kufaka hhayi i-radiator kuphela kanye nokukhuphuka, kodwa futhi ne-DHW. Kumele kwaziwe ukuthi lolu hlelo aluhlukile ekusebenzeni kahle kakhulu uma kuqhathaniswa nefilimu elibi noma umjikelezo kagesi, ofihlekile ngaphansi kwe-laminate.

Ekadeni ekhishini elinjalo lokufudumeza kuvame ukuba yinhloko futhi ebekwe esigabeni sokuklama. Kuchaza amanye amapharamitha, njengokuphakama kophahla, ubukhulu bokugqagqana noma uhlobo lwe-boiler esetshenzisiwe.

Izimiso Zokusebenza

Ukushisa kungenxa ye-coolant - amanzi noma olunye uketshezi. Ihamba epayipini elivala yonke indawo yokugcwala noma ingxenye yalo. Ngokushisa okudingekayo, okokusebenza kwegesi kuvame ukusetshenziswa kakhulu. I-distribul manifold ixhunyiwe kuyo, okuyinethiwekhi enamagatsha amaningi phezu kwayo yonke indawo yegumbi, noma leyo ngxenye yayo, lapho kudingeka khona. Ukunyakaza kuvaliwe futhi kuqinisekiswe ngokuvamile ngepompo yokujikeleza. Ukudlula ngayo yonke indlela, isibarisi esipholile sibuyela emuva ku-boiler, futhi inqubo iqala kuqala. Ukulungiswa kulula kakhulu ukukhiqiza ngama-thermostats azenzakalelayo athola imiyalo evela ezinzwa

Umehluko obalulekile ovela ohlelweni lwe-radiator ukuthi ngokwandisa indawo yokukhadelela inyamalala isidingo sokushisa kwayo okuqinile. Ukuze i-radiator yakwazi ukudlulisa amandla ayo ekhoneni elikude lekamelo noma ekhishini, kufanele lishise. Lokhu akudingi lokhu, ngoba i-radiation energy idlulisa imitha ngayinye yesikwele.

Izinzuzo zamanzi afudumele

- ukusatshalaliswa okungathandeki kokushisa komoya ngaphezulu kwevolumu yegumbi;

- Ubungozi buvutha ngengozi ngebhethri;

- Ukugeleza komoya okuqinile kakhulu okuvela ebhethri;

- Ukwenza ukuhlanza ngaphansi kwe-windows sill kuba lula kakhulu.

Ukungabikho kwamaconsi aqinile kuhle futhi iqiniso lokuthi ukuguquguquka okushisayo kokuqeda kuncishisiwe. Akunamqondo omncane odala ukugqwala nokwakheka kobumba ngenxa yokwengeza ukuncipha. Kuklanywe kahle futhi yakhelwe futhi yakhelwe uhlelo lokushisa kwamanzi "olufudumele" lungasebenza iminyaka engama-40-50. Le ndlela ilungele zombili ngemikhakha yayo yezobuchwepheshe kanye nethonya empilweni yabantu.

Ukusongoza icebo

Ukuze ukhethe kahle izingxenye namapharamitha wezobuchwepheshe, kuzothatha ukubalwa kobunjiniyela bokushisa.Yini ephendukela ebunjiniyela bokushisa:

- inani elidingekayo lamandla adlulisiwe;

- Ileveli yokulahleka kokushisa esakhiweni (ukuba khona komfaki we-thermal, amakholoni akhazimulayo, njll.);

- Amazinga okushisa a-fluid e-inlet nangaphandle;

- Thayipha nokuqukethwe kwemikhiqizo;

- Ubukhulu obukhonkolo obukhonkolo;

- Uhlobo lwezinto zokuhlangana.

Ngokusekelwe kule datha, uchwepheshe uzobala i-bandwidth kanye nesinyathelo sokufaka esifiswayo. Futhi, i-Master izokwakha uhlelo lokuhlelwa kokhiye. Lokhu kungaba ngumsebenzi onzima, ucubungula izidingo ze-wiring.

Izidingo ze-Wiring:

- Akunconyelwe ukuhlela imigqa emide kakhulu. Kuyinto efiselekayo ukuthi ayidluli ama-100 m, njengoba lokhu kungubude obujwayelekile bokukhishwa kwamapayipi we-polymer nge-16 noma 20;

- Zonke izinto ezenziwe ngezezimali kumele zibe nobude obufanayo (kanye nama-10%);

- Kufanele badlule ukuze zonke izingxenye zephansi zifudumale ngokulinganayo;

- Kuyadingeka ukusebenzisa inani elincane kakhulu lokufakwa nokuxhumeka.

Isinyathelo se-gasket singahluka ngokuya ngomthwalo we-thermal. E-zone yokulahleka kokushisa okusebenzayo (izindonga zangaphandle, amawindi), akuphansi (10-15 cm), futhi enkabeni yegumbi - Okuningi (20- 30 cm).

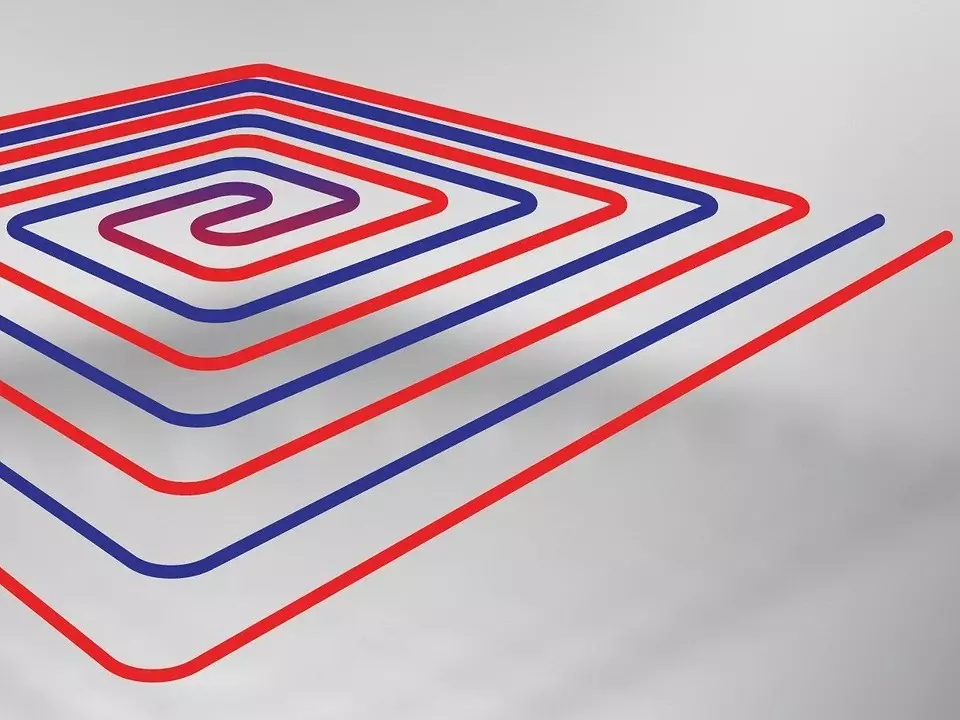

Isikimu sokubeka

Lapho uhlela uhlelo lokuhlelwa, naka ukujika lapho i-band radius kungafanele ibe ngaphansi kokuvunyelwa okuncane. Le pharamitha incike kokuqukethwe okwenziwe yinto eyakhiwe kabusha. Amacebo amabili ahlukaniswa: "Inyoka" ne- "Spiral"."Inyoka" kulula. Abakhi be-Neprofession Bakhi bavame ukuguqulwa. Isikimu esinjalo sisebenza kahle emakamelweni amancane kuphela anendawo efinyelela ku-10 m2. Ngokwanda ngosayizi wekamelo, umehluko wokushisa ezingxenyeni zawo ezahlukene uba khona okubonakala kakhulu. Kulokhu, "ukuvunguza" kufanelekile.

Ukubalwa okulinganiselwa kwephahla lokushisa lamanzi kungenziwa ngezandla zazo usebenzisa ama-online wokubala asezindaweni zezinkampani ezinkulu zokwakha. Kuzokusiza ekutholeni i-nomenclature kanye nezindleko zezakhi eziphambili. Ukuhlelwa kwemikhuba kumele ukubala uchwepheshe.

Izinga lokushisa elingaphezulu akufanele lidlule amanani athile (i-ISO7730 ejwayelekile):

- emakamelweni okuhlala +26 ° C;

- egumbini lokugezela + 30 ° C;

- Echibini nasezisekelweni +32 ° C.

Ukuze indawo enqunu ayizwa umehluko lapho ezungeza umjikelezo wokushisa, isinyathelo saso akufanele sibe ngaphezu kwe-0.35 m.

Imvamisa, uketshezi lufudunyezwa ku- + 35 ° C. Inani eliphakeme lingukuthi +55 ° C. Ukuze wenze lokhu, kufanele uhlanganise ukuhambisa kwamanzi okushisayo kusuka ku-boiler, ngokuphuma komqhubi wesifundo, sekuvele kupholile kancane. Lo msebenzi ulawulwa ngokuzenzakalelayo usebenzisa ama-thermostat valves. Kungumsebenzi wabo ohlelela impumelelo noma ukwehluleka ukudala isimo sezulu esifunekayo egumbini.

Kuyasiza kakhulu ukucabanga kusengaphambili mayelana nokuthi yikuphi ukuqeda okuzoba khona. Ngokumboza okukhadekile, kuzodingeka ukukhulisa ukushisa ngo-4-5 ° C, ngakho-ke kuphakamisa ukusetshenziswa kwamandla okungenani nge-15-25%. Ubukhulu ngakunye okwengeziwe kwe-10 mm bokwenyusa kwanyusa ukusetshenziswa kwamandla okudingekayo ngo-5-8%.

Yenza futhi ulondoloze ikhophi lesifunda elinenkomba yawo wonke amasayizi noma okungenani isinyathelo sesinyathelo nesikhundla sokuphenduka kokuqala. Lokhu ngeke kulimaze iziteshi ngesikhathi sokuvuselelwa ngokuzayo. Thatha kusuka kwidatha yomklami ngesilinganiso sokugeleza kwe-coolant, kuzodingeka lapho usetha uhlelo.

Ukufakwa kwenziwa okungenani ku-15 ° C. Ungasebenzi ngezikhathi ezibandayo egumbini elivulekile.

Izakhi zohlelo

Ipayipi

Imikhiqizo kumele ibe lula, ukumelana nokugqwala kanye nokushisa okuphezulu. Okuqukethwe kusetshenziswa ipulasitiki nensimbi:

- I-Stitched eqinile (i-PEX) - Ukubekezelela Ukuxhumana namanzi ashisayo futhi kungasebenza ku-80 ° C. Njengayo yonke imikhiqizo yepulasitiki, ayikhonjelwa ekugculweni. I-radius yokugoba okuncane cishe amawazi ayishumi. Izakhiwo ezithuthukisiwe zinamapayipi we-pex ngokuvikelwa ekungeniseni komoya-mpilo. Ukuvikelwa okungcono kakhulu kunikeza izindonga ezinobungqingili. Zithembekile kunezendlalelo ezintathu ngaphandle kokuvikelwa okwengeziwe kwangaphandle okudingeka ubhekane nalo ngokucophelela.

- Insimbi Engagqwali Engagqwali - Ukusebenza kwayo okushisayo kungcono izikhathi ezingama-200 kangcono kune-polyethylene. Ibonakala ngokuguquguquka okuphezulu. Isibonelo, imodeli ye-Neptun IWS kububanzi obungaphandle bangu-18 mm ivunyelwe ukuvumela umsakazo wokugoba ka-30 mm. I-coefficion ebanzi ebanzi lapho ifudunyezwa ku-50 ° C i-20 izikhathi ezingaphansi kwe-PEX. Amapayipi anjalo angena ngaphansi kwamanzi abiza kakhulu, ngenkathi asebenza emhlophe futhi kulula ukuyifaka.

- I-polyethylene engamelana ukushisa ivalwa izici ku-pex, kepha inokuqina okuncane okushisayo. Umehluko uvuleke kuphela lapho ukufuthelwa ku-70 ° C, ngakho-ke ngezinhlelo eziningi lokhu okuqukethwe kufanelekile. Izindonga kufanele zibe nongqimba oluvikelwe umoya-mpilo.

- I-Copper ukuthuthuka okushisayo kwale nsimbi ngezikhathi ezithile eziphakeme kunalezo zensimbi. Inezinkomba ezinhle kakhulu zokuguquguquka nokuqina. Kepha ngenxa yezindleko eziphakeme, akuvamile.

- I-Metal Plastic - ingukuhlelwa kwezingqimba ezintathu ngesendlalelo sangaphakathi se-aluminium foil. Indawo yangaphandle nengaphakathi ingenziwa nge-pex noma i-pert polyethylene. Akunakufinyeleleka ngokuphelele komoya-mpilo, ukumelana nokushisa lokushisa nokuvezwa kwamakhemikhali. I-radius yokugoba okuncane icishe ibe ngamamitha amahlanu. Ukuguquguquka okuphezulu kakhulu yimikhiqizo, umnyombo wensimbi owenziwe ngaphandle komthungo. Bangagobeka kaninginingi ehlelweni elinomsakazo omncane olingana namanani amathathu wobubanzi obungaphandle.

Imikhiqizo inempilo yenkonzo ngokwesilinganiso iminyaka engama-50. Uma kuvuka umbuzo - yimaphi phansi amanzi afudumele amanzi, kungcono ukunaka umenzi. Ukuze ufake ukufakwa, azikho izinkinga, kufanele uthenge izingxenye zenkampani efanayo.

Ukujikeleza kwegazi

Kungcono ukuthola iphampu enamandla. Cabanga ukusebenza okudingekayo futhi uthathe imodeli nge-Reserve ngokuya ngobuncane bama-25-30%.Ukufudumeza contours

Ngenxa yezakhiwo, zihlukaniswe ngeMesere noma iZigzag kanye ne-Spiral. Ngokwesimo somnotho kuzo, ukulahleka kwengcindezi okufika ku-0,2 ATM kuvunyelwe, ngakho ubude obuphelele abungeqi amamitha ayi-15-20 kuphela endaweni yaphansi efudumele ngumqhubi oyedwa. Amakamelo amakhulu asebenzisa izinto eziningi. Uhlangothi lwangaphambili luxhumeke kumsabalalisi ngokuguqula ukuqiniswa, emuva kumqokeleli. Imvamisa, umsabalalisi kanye nomqoqi bangamafindo ngendlela ye-comb, efakwe nge-air Veverios.

Ukushintsha izinga lokushisa egumbini, alishintshile kwabanye, okuthiwa yi-hydraulic ukuqondaniswa kwenziwa. Ukuze wenze lokhu, entweni ngayinye, kunconywa ukufaka umlawuli wengcindezi noma ukusetshenziswa kwamanzi. Zilungiselelwe kanye, lapho ziqala uhlelo. Umsebenzi onjalo kufanele wenziwe ngochwepheshe ofanelekayo.

Ukufaka

Ukubekwa phansi kwamanzi afudumele kwamanzi

Isisekelo kumele sitholakale ngokuqondile. Ukwehluka okuphakeme okuvela ku-1 cm kungafaka ukwakheka kwezindiza ze-traffic jam ezinciphisa ukusebenza kahle kohlelo. Uma kunesidingo, kuthululwa ngokhonkolo. Izendlalelo zesisekelo sokufaka amanzi, ukufakwa okuzwakalayo, khona-ke ukufakwa okushisayo kuyabhalwa. Kungaba ifilimu ye-lavsan ye-lavsan, ama-cork noma ama-wol amaminerali, amapuleti e-polypropylene noma amanye ama-polymers. Kuyaphumelela kakhulu, ngokwesibonelo, ama-cork mat, anezelwe ungqimba lwezinto ezifriji, kepha ukufakwa okushisayo okunjalo kuzoba okubiza kakhulu. Kukhwalithi yokungena kwamanzi, i-polyethylene film noma i-bitumen mastic nayo ingasetshenziswa. Lapho kusondela igumbi emhlabathini, lapho kudingeka khona ama-infaulators. Ukuze phansi kwandiswa lapho kufuthelwa, phansi akukunqumi ezindongeni, igebe linikela phakathi kwalo. Ukuze wenze lokhu, ngaphambi kokufaka amalunga odongeni ngokugqagqana, kumbozwe ngeteyipu ekhethekile ngobukhulu obufinyelela ku-5 mm ngefilimu elingavunyelwe. Ama-seams avalwe ngo-mastic, ososha ngefilimu yepulasitiki ngokucophelela ahlelwe ngokucophelela nge-scotch.

Lapho-ke phansi kufakwa i-fastener yamapayipi. Kungaba yigridi ekhethekile yokuqinisa - inamathiselwe kuyo ngama-clamps. Ukufakwa kubuye kwenziwe ngamapuleti ePolystyrene ngezikhathi zokuphumula lapho umkhiqizo uhlelwe khona kalula. Kukhona ezinye izindlela.

Ngama-polystyrere mats kulula ukusebenza, anganconywa kubakhi abangenalwazi. Ngokusebenzisa kwabo, akudingekile ukuqhubekisela phambili ukufakwa okushisayo.

Isisulu sedivayisi esitezi samanzi esifudumele

Ukuhlanganiswa kokhonkolo ongenakho okufakwayo kusetshenziswe phezulu kwe-contour. Ibona umthwalo futhi isabalalisa kungqimba olungaphansi lokufakelwa okushisayo. Ngakho-ke, kufanele kube lukhuni ngokwanele, kepha uma kungenzeka kuncane, ukuze ungamukeli amandla ngamanani amaningi. Imvamisa ubukhulu obuncane ngu-40-50 mm. Lokhu kwanele okuqukethwe ukumelana nomthwalo kuya ku-2 Kn / M2 (200 KGF / M2). Amanye amafemu angeniswa engxenyeni ekhethekile yeplastidi ukwandisa ukuthuthuka kokuhlelwa nokuqondanisa ekunwetshisweni okushisayo.

Ngaso leso sikhathi ufike ku-40 m2 ebusweni. Uma le ndawo idlula la masayizi, isikhala sihlukaniswe ngezindawo ezihlukaniswe yizinxepheni ezinenxephezelo ngobubanzi obungu-3-6 mm. Umthungo ugcwele izinto ezibonakalayo, ngokwesibonelo, i-polyurethane. Uma umjikelezo uwela umugqa walo mthungo, kule ndawo ethafeni elivikelayo elivikelekile ngobude obufinyelela ku-0,5 m. Kuya phambili ukugcwaliswa, izinga lokushisa. Igcina i-concrete screed okungenani amasonto amane.

I-coolont ifakwe kuphela ngemuva kokuba zonke izinto eziqoqiwe, futhi ukuxhumana kuyahlolwa. Ukuze uqiniseke ukuthi zonke izindawo zisebenza kahle, udinga ukuhlola ekucindezelweni okuphezulu nokushisa okuphezulu. Kule modi, kufanele basebenze amahora ayisithupha. Kuphela ngemuva kwalokho ukufakwa kwamanzi ngaphansi komhlaba kungabhekwa kuqedwe futhi kuqhubeke ngedivayisi eswelekile.