We are talking about the advantages of water underground, principles of work and installation rules.

Specialists confirmed that the most comfortable person feels when the air temperature below reaches the values of 22-22 ° C, and at the head level 18-20 ° C. Such distribution is best ensured by floor heating. Competently designed design saves up to 20% of energy resources. Uniform heating of the perimeter of all overlap eliminates the formation of concentrated flows, prevents the occurrence of drafts. Since the radiators and risers from the room are cleaned, the architect and designer appear opportunities for new planning solutions. It is also important that the cleaning of premises is substantially facilitated. However, the water warm floor has its own minuses. We tell about everything in order.

All about the installation and operation of water floor

FeaturesHow it works

Design

Main elements

- Pipe

- Circulation pump

- Heating contours

Installation

- Stiring

- Concrete screed

Features of water heat

There are several ways to heal from the overlap. It is difficult to say whether the hydraulic scheme has advantages over infrared thin emitters hidden under laminate if used in an urban apartment. For obvious disadvantages, with such comparison, small efficiency can be attributed. Pipes hidden under the tie serve only an auxiliary means. In regions with a mild climate, they are quite enough to create comfortable conditions, but in a cold winter to warm the air, a standard radiator is required.

Another feature is the need to install a boiler, heating fluid that flows in channels above the overlap. Its installation is possible not only in private houses, but for apartments there is an electrical analogue of the pipeline, which takes less space and does not require the installation of bulky equipment. One of the factors is the possibility of leak out the contour and flooding of neighbors. Lower the risk will help waterproofing overlap.

In apartment buildings, water warm floors are categorically prohibited from the central heating system. In this case, the scheme includes a heat exchanger transmitting temperature when communicating with communications in the apartment. These include not only the radiator and riser, but also the DHW. It should be noted that this scheme does not differ in high efficiency if it is compared with an infrared film or an electrical circuit, hidden under laminate.

In the cottages such a method of heating is usually the main and laid at the design stage. It defines other parameters, such as the height of the ceilings, the thickness of the overlap or the type of boiler used.

Work principles

Heating is due to the coolant - water or other liquid. It moves in the pipeline closing the entire area of the overlap or its part. For the necessary heating, condensing gas equipment is most often used. A distribution manifold is connected to it, which is a branched network over the entire area of the room, or by that part of it, where it is necessary. The movement is closed and ensured usually with a circulating pump. Passing all the way, the cooled carrier returns back to the boiler, and the process begins first. The adjustment is more convenient to produce with automatic thermostats receiving commands from sensors. For emergency plums provide an additional device, for example, a small compressor or a cylinder for blowing with compressed air.

An important difference from the radiator scheme is that by increasing the radiating surface disappears the need for its strong heating. So that the radiator was able to transfer its energy to the distant corner of the room or kitchen, it should be hot. This does not require this, since the radiation energy transmits each square meter.

Benefits of water warm floor

- uncomfortable distribution of air temperature over the volume of the room;

- The risk is accidentally burning about the battery;

- too strong air convection flows arising from battery;

- Making cleaning under the window sill becomes much easier.

The absence of strong drops is good and the fact that thermal deformations of the finish are reduced. There is less condensate that causes corrosion and mold formation as a result of increased dampness. A competently designed and designed water heating system "Warm floor" can serve 40-50 years. This method is optimal both by its technical parameters and by influence on human health.

Design

In order to correctly select the components and technical parameters, it will take a heat engineering calculation.What turns on the heat engineering:

- required amount of power transmitted;

- Level of heat loss in the building (the presence of thermal insulation, glazing balconies, etc.);

- fluid temperature at the inlet and outlet;

- Type and material of products;

- Concrete screed thickness;

- Type of coating material.

Based on this data, the specialist will calculate the bandwidth and the desired laying step. Also, the master will build a key layout scheme. This may be a difficult task, considering the requirements for wiring.

Wiring Requirements:

- It is not recommended to arrange the contours of too long. It is desirable that it does not exceed 100 m, as this is a standard length for the roll of polymer pipes with a diameter of 16 or 20 mm;

- All prefabricated elements must have about the same length (plus-minus 10%);

- They should pass so that all parts of the floor warming up evenly;

- It is necessary to use the smallest possible number of fittings and connections.

The gasket step may vary depending on the thermal load. In the zone of active heat loss (external walls, windows), it is less (10-15 cm), and in the center of the room - more (20-30 cm).

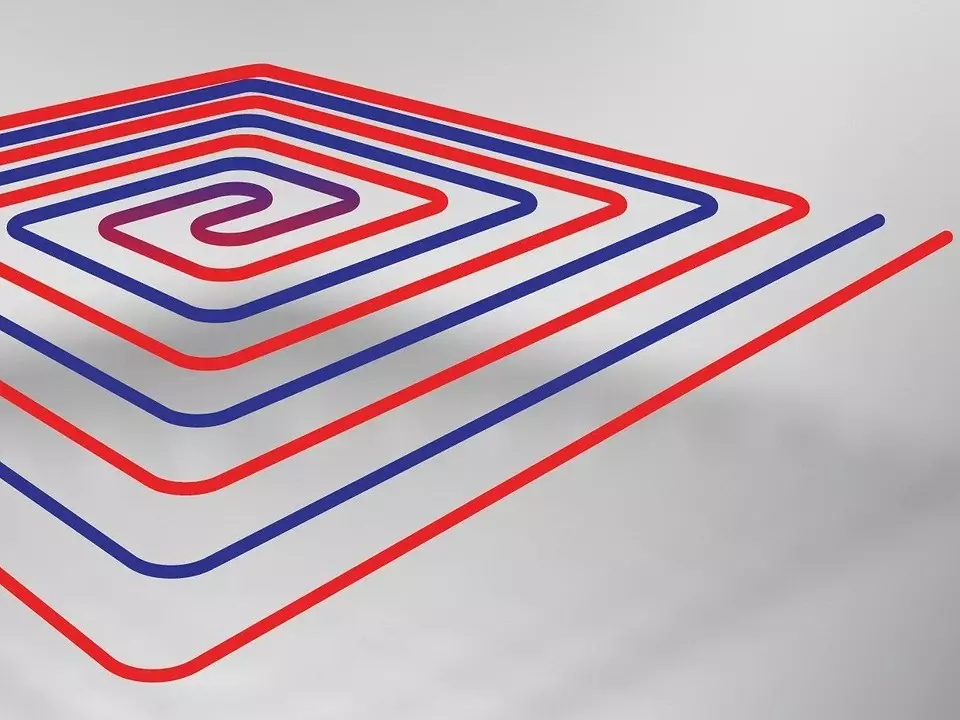

Laying scheme

When designing the layout scheme, pay attention to the turns in which the bend radius should not be less than the minimum permissible. This parameter depends on the material from which the prefabricated element is made. Two schemes are distinguished: "Snake" and "Spiral"."Snake" is easier. Neprofessional designers builders are more often resorted to. Such a scheme works efficiently only in small rooms with an area of up to 10 m2. With an increase in the size of the room, the heating difference in its different parts becomes a more visible. In this case, the "Spiral" is suitable.

The approximate calculation of the water heating floor can be made with their own hands using online calculators that are on the sites of large construction companies. It will help you determine the nomenclature and the cost of the main components. The layout of the contours must calculate the specialist.

The surface temperature should not exceed certain values (ISO7730 standard):

- in residential rooms +26 ° C;

- in the bathroom +30 ° C;

- By the pool and in basements +32 ° C.

So that the naked stop did not feel the difference around the heating circuit, its step should not be more than 0.35 m.

Usually, the liquid is heated to +35 ° C. The maximum value is +55 ° C. To do this, you have to mix hot water supplying from the boiler, with the exit from the conductor, already slightly cooled. This operation is controlled automatically using thermostat valves. It is their work that predetermines success or failure in creating the desired climate in the room.

It is very useful to think in advance about what finish will be. For carpet coverage, it will be necessary to increase the heating by 4-5 ° C, and therefore raise energy consumption at least 15-25%. Each extra 10 mm thickness of the screed increases the required energy consumption by 5-8%.

Make and save a copy of the circuit with the indication of all sizes or at least the step of step and the position of the initial turn. This will not damage the channels during redevelopment in the future. Take from the designer data on the flow rate of the coolant, then it will be necessary when setting up the system.

Installation is carried out at least at 15 ° C. Do not work in cold times in the open room.

Elements of the system

Pipe

Products must have ease, resistance to corrosion and high temperature. The material uses plastic and metal:

- Stitched polyethylene (PEX) - tolerate contact with hot water and can work at 80 ° C. Like all plastic products, it is not subject to corrosion. The minimum bending radius is approximately ten diameters. Improved properties have pex pipes with protection against oxygen penetration. Best protection provides five-layer walls. They are reliable than three-layer without additional external protection with which you need to handle particularly carefully.

- Corrugated stainless steel - its thermal conductivity is about 200 times better than polyethylene. It is characterized by higher flexibility. For example, the NEPTUN IWS model at an outer diameter of 18 mm is allowed to allow a bending radius of 30 mm. The linear expansion coefficient when heated to 50 ° C is 20 times less than in PEX. Such pipes for water underfloor are more expensive, while they are white functional and easy to install.

- The heat-resistant polyethylene PERT is close in characteristics to PEX, but has less thermal stability. The difference becomes noticeable only when heated to 70 ° C, so for most systems this material is suitable. Walls must necessarily have an oxygen protected layer.

- Copper is the thermal conductivity of this metal at times higher than that of steel. It has excellent indicators for flexibility and durability. But because of the high costs, it is quite rare.

- Metal plastic - is a three-layer design with an inner layer of aluminum foil. The outer and inner surface can be made of PEX or PERT polyethylene. Fully impermeable for oxygen, resistant to temperature and chemical exposure. The minimum bending radius is approximately five diameters. The highest flexibility is the products, the metal core of which is made without seams. They can be repeatedly bend on a plot with a small radius equal to three values of the outer diameter.

Products have a service life on average 50 years. If the question arose - which water warm floor is installed, it is better to pay attention to the manufacturer. In order for installation, there were no problems, you should buy components of the same company.

Circulation pump

It is advisable to get a powerful pump. Consider the required performance and take the model with a reserve in terms of a minimum of 25-30%.Heating contours

In view of the layouts, they are divided into mesere or zigzag and spiral. By the condition of the economy in them, the pressure loss of up to 0.2 atm is allowed, so the total length does not exceed 100 m, and only 15-20 m2 of the floor area is heated by one conductor. For large rooms use several elements. The front side is connected to the distributor with adjusting reinforcement, the rear to the collector. Typically, the distributor and the collector are a knot in the form of a comb, equipped with air ventios.

To change the temperature in the room, it has not changed in others, the so-called hydraulic alignment is carried out. To do this, in each element, it is recommended to install a pressure regulator or water consumption. They are configured once, when starting the system. Such work should be performed by a qualified specialist.

Installation

Laying of water warm floor

The base must be located strictly horizontally. The height differences from 1 cm may entail the formation of air traffic jams that reduce the efficiency of the system. If necessary, the concrete screed is poured. The base layers of waterproofing, sound insulation, then thermal insulation are stacked. It can be a metallized lavsan film, cork or mineral wool mats, plates of polypropylene or other polymers. Most effective, for example, cork mats, supplemented by a layer of refrigerant material, but such thermal insulation will be the most expensive. In the quality of waterproofing, polyethylene film or bitumen mastic can also be used. The closer the room to the soil, the more the insulators are required. In order for the floor expanding when heated, the floor did not prescribe onto the walls, the gap provides between them. To do this, before installing the joints of the walls with the overlap, it is covered with a special tape with a thickness of up to 5 mm with a waterproof film. The seams are sealed with mastic, the adolescent of the plastic film are carefully skidded with scotch.

Then the floor is placed fastener for pipes. It can be a special reinforcement grid - it is attached to it with clamps. The installation is also conducted on polystyrene plates with recesses in which the product is easily fixed. There are other ways.

With polystyrene mats it is easier to work, they can be recommended to inexperienced builders. With their use, it is not necessary to further arrange thermal insulation.

Device screed in the warm water floor

Concrete seamless coating applied on top of contour. It perceives the load and distributes it to a softer underlying layer of thermal insulation. Therefore, it should be rigid enough, but if possible is thin, so as not to absorb energy in excessive amounts. Usually the minimum thickness is 40-50 mm. This is enough for the material to withstand the load to 2 kN / m2 (200 kgf / m2). Some firms are introduced into a solution special plasticizers to increase the conductivity of the screed and alignment in thermal expansion.

At once poured up to 40 m2 of the surface. If the area exceeds these sizes, the space is divided into areas separated by compensation seams with a width of 3-6 mm. Seam is filled with elastic material, for example, polyurethane. If the circuit crosses the line of this seam, it is in this place in a protective corrugated tube with a length of up to 0.5 m. To and in the process of filling, the system is kept at operating pressure and temperature. Saving a concrete screed for at least four weeks.

The coolant is entered only after all the elements are collected, and the connections are checked. To make sure that all nodes work properly, you need to test at high pressure and maximum heating. In this mode, they should work for six hours. Only after that the installation of water underground can be considered finished and proceeded with the screed device.