Self-leveling formulations for floors: types of dry mixes for the arrangement of various types of screeds, their characteristics and properties, the process of creating a bulk sex

As practice shows, compliance with the regulatory requirements for the arrangement of the foundation, almost impossible task for many domestic developers. Therefore, any laying of a new flooring is preceded by alignment of the base of the floor. Slipping with this term "self-leveling mixtures" sounds very promising ...

Knavel-type type material depends on many factors. To get a smooth, but inclined base plane (for example, for arrangement in the bathroom floor with a drain ladder, where water should be stroke), a simple level is suitable. It will help level local recesses on a flat surface. If the timing of the repair work is rather tough, choose the so-called fast-hardening mixtures, on some of them the finish coating can be stacked after 4 h.

"Bolls" additives included in self-leveling mixtures and providing good spreadability, do not allow them to quickly dry. Although in this case "quickly" - the concept is relative: according to some, it is possible to walk after 4 h (on the bulk sex "Skorlight T-45", "Bests", Russia, already in 2- 2.5 hours!), And lay out the floor covering - after 1 week. Single Just the level is difficult to achieve a smooth horizontal surface, while self-leveling mixtures make it easy and fast. Some of them are used to eliminate significant irregularities (10-300mm), others, for a thin or finishing alignment with a minimum layer from 1-2 to 5mm. Materials suitable for machine application are extremely effective when working on large areas. Using a special solution mixing machine, three people per work shift are able to pour up to 1 thousand m2. This method is used in spacious (from 100m2) apartments and houses.

Knauff |

"STROYMONTAZH MS" |

"Ark-parquet" |

1. PFT G4 power machine is a small-sized unit that is continuously working with dry mixtures.

2. For the preparation of the solution into the container with the desired amount of water, they fall asleep dry mixture and stirred by a construction mixer before the formation of a homogeneous mass. Excess water leads to a decrease in the strength of the coating, disadvantage of the deterioration of the fluidity of the solution.

So pour ...

"Saint-Goben Construction Products Rus" Vasserin Large manufacturers of dry mixtures are necessarily present by self-leveling. The domestic market has presented products of companies KNAUF (Russia- Germany), Saint-Goben Construction Products Rus "(Russia, Finland, Brand Weber-Vetonit), Litokol (Russia-Italy)," Glims "," Bolls "," Experienced Factory dry mixtures "," Bests "," prospectors "," Henkel Batechnik "(Thomsit trademark) (all- Russia). Price of standard packaging (25kg) - 200-600 rub.

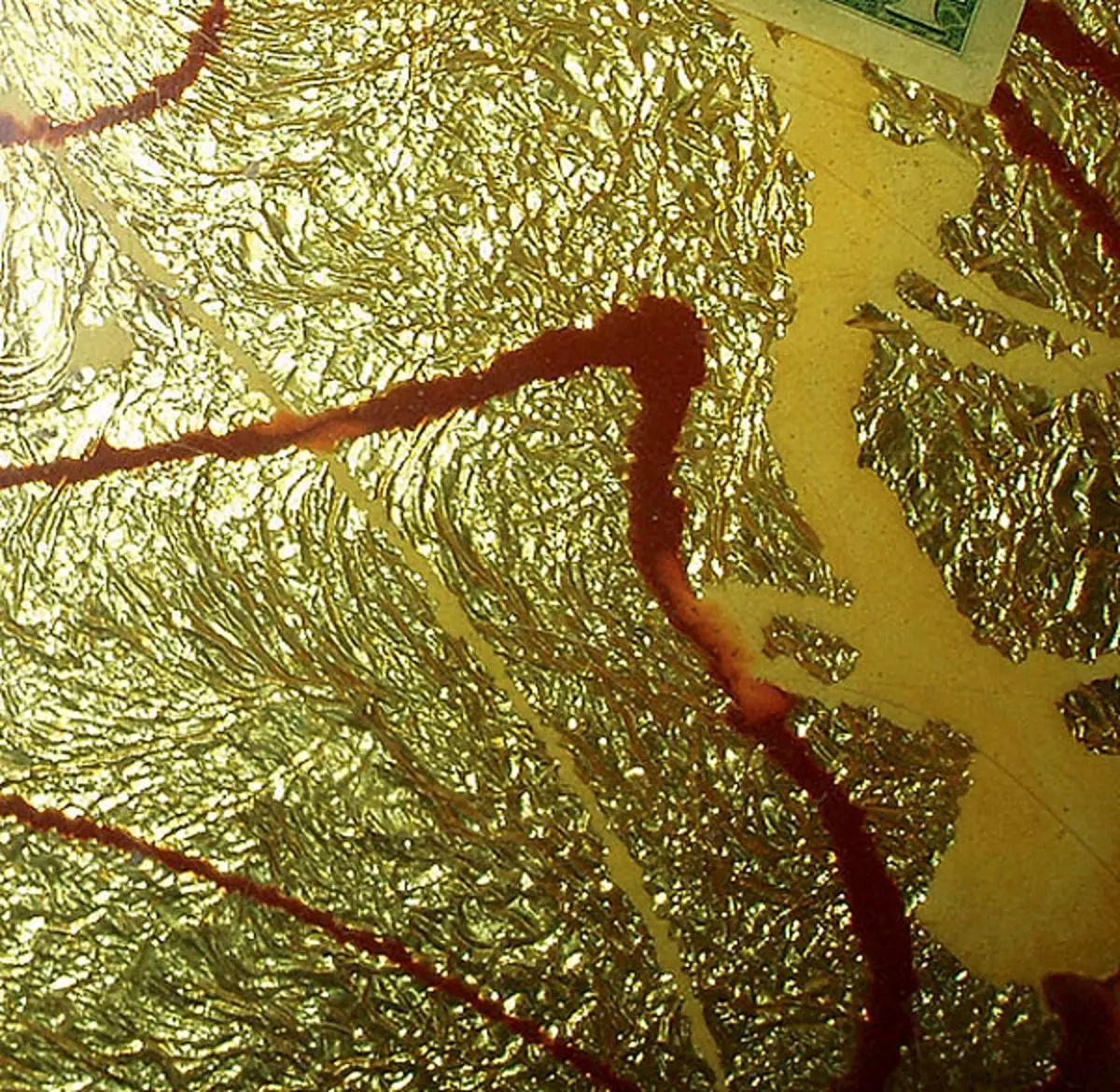

Note that such materials are sometimes called not only self-leveling, but also self-determined mixtures or bulk floors. Some experts believe that these are different types of floors, but there is no clear difference between their characteristics and properties. However, it is not necessary to confuse them with a group of polymer (industrial) bulk floors, which, after fillings and opening, it is not required to lay any finish coating. These compositions are used where the floor is subjected to chemical, mechanical and other loads, as well as in those places where it is necessary to ensure high surface cleanliness (hospitals, clinics). Ensure their interiors are rarely used, although knowledgeable people sometimes pour floor indoor garages, loggias or balconies with industrial filling cement-based fumes with high resistance to shock and scratch. The books include, for example, DUROTOP 4610 (Vetonit) with compressive strength of 40 MPa, easily withstanding the effect of studded rubber. Bulk floors based on polyurethane and epoxy resins of various colors - from snow-white to black or in the form of a transparent layer with decorative elements in it (sand, seashells IT.) attract the attention of lovers of non-standard design solutions. (See, for example, the article "Stop, Moment!" In this issue.) The minimum price of 1M2 of such sings- 800 rubles.

Alignment of concrete floor with a mixture of "Glims-S3x"

"Glims-production" |

"Glims-production" |

"Glims-production" |

"Glims-production" |

The purified surface is ground with a composition for strongly absorbing bases (4) using a rigid pile brush (5). The prepared solution is flooded with floor to the desired level (6). The compounds of the compound of individual portions are treated with a needle roller to evenly distribute the mixture (7).

Cement, Gypsum and others

The most self-digging mixtures of the binder (binder) substance is cement, less frequent plaster. Punching of aggregates use quartz sand and ground limestone of various fractions, usually rounded shape (this allows for high mobility of the composition). Mixes with larger fractions (up to 1.2 mm) are used with rough alignment, with small (up to 0.3-0.5 mm) - with finishing. Modifying additives (plasticizing, water-holding IDRs.) Improve the adhesion and spreadability of the material, do not give it to flavor.

The finished base obtained after the self-leveling mixture will clarify as a result of chemical processes, has sufficient compression strength (10-30 mg) and stability of the form. These qualities are necessary for subsequent laying of finishing coatings: ceramic tiles, parquet, laminate, linoleum, carpet. Night most self-leveling mixtures - widely used non-combustible substances: cement, plaster, quartz sand.

Preparation of the base on the separation layer using the self-leveling mixture "GLIMS-S3X"

"Glims-production" |

"Glims-production" |

"Glims-production" |

"Glims-production" |

"Glims-production" |

"Glims-production" |

"Glims-production" |

"Glims-production" |

"Glims-production" |

On the wall of the pencil, the height of the mixture is noted using level (8). They dilute on the basis of an insulating film, it is shown onto the wall and fix with scotch (9). Install beacons-tripods around the room (11). Adjusting the central beacon rod, expose the height of the future floor. Align the lighthouses in terms of the level and adjust the height of the central rod (12). The bubility is poured water, then the mixture is poured, mixed with a mixer, waiting 2-3min and again interfere with (13). Pull out the finished mixture to the floor, quickly knead a new portion and pour it again to the floor until it reaches the desired level (14). The surface is treated with a needle roller (15). According to the manufacturer's instructions, you can walk on the floor in a few hours (16).

When choosing a particular mixture, many nuances should be taken into account, first of all, the purpose of the room. Weight plane cement mixtures are more versatile, and plaster- for example, a self-leveling screed "Boden 30" (KNAUF) thickness is more than 25mm- used only in rooms with normal and dry humidity modes. Note that material supporting grounds are intended: concrete, cement-sand screed, gypsum, anhydrite or asbate cement, drywall sheets, wooden floors IT.D. For some formulations, the finally dried concrete is required, the age of which is not less than 6 months. Others can be poured on fresh ties with a slightly high humidity or on a "young" concrete. The cooler base is compatible only highly elastic aligning materials and special primers to improve adhesion, such as Vaateri Fine (Vetonit) - a self-leveling mixture on a cement basis, reinforced with fiber. Therefore, it is always worth clarifying the conditions for applying a particular product, especially if this information is not on the package.

Opinion of a specialist

With the arrangement of the "floating" screed, before the bay of the self-leveling mixture, the separation tape is packed around the perimeter of the room, and then the special film is laid, which will be separated by the base and the created screed. When using cement-containing screeds, it is necessary to take into account processes occurring in them during drying, namely expansions (such are also present!) And shrinkage. The magnitude of the shrinkage is small, 0.3-0.8mm per 1Pog, but on 10pog.m it will be already 3-8mm. These characteristics are important for the correct choice of the level, depending on the strength of the base. The smaller the strength of the base, the more with a smaller coefficient of shrinkage, choose a self-leveling mixture. To level the processes of shrinkage, it is important to leave the compensation gap around the columns and other obstacles. Cracks in the leveling layer, divergent from columns, is one of the examples of unqualified work with bulk floors. Before purchasing a self-leveling mixture for warm floors, make sure that the product is compatible with such equipment.

Sergey Loktev, Saint-Goben Specialist Construction Products Rus »

Sometimes it is necessary to use a complex of materials. Thus, for the alignment of a thick layer or with large surface irregularities (20-25cm), a light polystyrene foam mixture "Glims-LS" was developed ("Glims"). Its low share of more than 50% reduces the load on overlappings and carrying the walls of the buildings compared to conventional screeds. Such a base is quite strong to serve as the basis for subsequent cladding from ceramic tiles or porcelain stoneware. But when laying soft coatings (linoleum, carpet) over "Glims-Ls" poured a layer of a mixture of "Glims-SL" with a thickness of 3-5mm. It increases compression strength up to 20-22 mp.

"Glims-production" |

"Glims-production" |

"Saint-Goben Construction Products Rus" |

Henkel |

"Bolls" |

"STROYMONTAZH MS" |

17-19. Drying and solidification of self-leveling mixtures depends on the thickness of the layer, as well as temperature and humidity in the room. The layer obtained from cement-based compositions must be protected from drafts and air thrust acting on the floor surface.

20-22.Some-digging mixtures easily levelerate small irregularities and flooring drops in different rooms.

Contact? There is a contact!

Self-leveling mixtures are used to arrange various types of screeds:

contact, flexible directly to the primed bearing base;

"Floating" (on a divided layer or non-pretend basis).

When creating contact screed, it is important to follow the recommendations of manufacturers to prepare the foundation. It should be durable, dry, purified from dust and oil spots, without cracks and deep depressions that are close in low-cost mixtures. The surface is treated with a special soil (the choice of it depends on the absorbency of the base).

Opinion of a specialist

Requirements for the strength of the base are sharply rising in the inapproprical laying of parquet or massive board. A similar method is used throughout the world, but in Russia he is still very slow. The use of a layer of plywood is not so much outdated technology as the reaction is often unsatisfactory quality of the screed (such a layer serves as a kind of damper that reduces risks). But it should be noted that today there are wooden coatings in fashion near the pools, in SPA-zones or bathrooms. Exotic rocks with very dense, oily wood, which has passed special processing, water is not terrible, and plywood from plywood (even the waterproof), worst, will rot. It is intended to apply a self-leveling mixture as the base, the architect or contractor should pay attention to the characteristics of its strength in bending and compression, as well as the adhesive properties of the parquet glue and its behavior during curing. So, for two-component glue, a more reliable service man is required than for dispersion. From an insufficiently durable surface, it will most likely break away or tumble the top layer. Such a nuisance can occur when driving wood caused by change in humidity, temperature, loads. Therefore, it is desirable to use self-leveling mixtures that not only make the base of the floor smooth and smooth, but also strengthen it.

Mikhail Sorochkin, Head of Special Projects of the Company "Arkheg-Parquet"

The screed on the dividing layer is separated from the base with paper or film transmitting air, but impermeable to water, with the adhesive strips of at least 8cm. Pre-around the perimeter of the room is fixed with the edge ribbon. In this case, the thickness of the filling floor should be at least 3 cm. This design is often used on weak and wooden bases, which are noticeably "walking" with temperature and humidity drops.

Opinion of a specialist

Gypsum self-leveling mixtures, in contrast to cement, almost do not give a shrinkage. The value of the longitudinal deformation during the collapse is less than 0.1 mm / m. It is possible to work with them even with low negative temperatures (water only did not froze in the container when applied by machine method), since the gypsum hardens and under these conditions (as opposed to cement). But it will be longer than usual. The hardening gypsum compositions are not afraid of drafts and elevated temperatures. If necessary, drying can be accelerated using heating elements. Walking on a self-leveling mixture, filled under normal conditions (temperature 20 ° C, relative humidity is 50%), it is possible through 6h, and loaded after 3 days. In its properties, the finished gypsum base is not different from cement, such as, for example, in self-leveling screeds of the "Boden" series (KNAUF). Apply such mixtures in apartments and country houses, with the exception of rooms with constant humidity, and "Boden" is suitable for any systems of warm floors.

Sergey Lukoyanov, Head of the Training Department

"Knauf Marketing Krasnogorsk"

On the "floating" floor on a non-rival base (polystyrene plates, mineral wool IT.P.) The layer of self-leveling mixture is separated by a film from an insulating material laid onto the overlap, and the edge ribbon - from the walls. Thus, it is isolated from the carrying basis, but at the same time, it also plays a similar role.

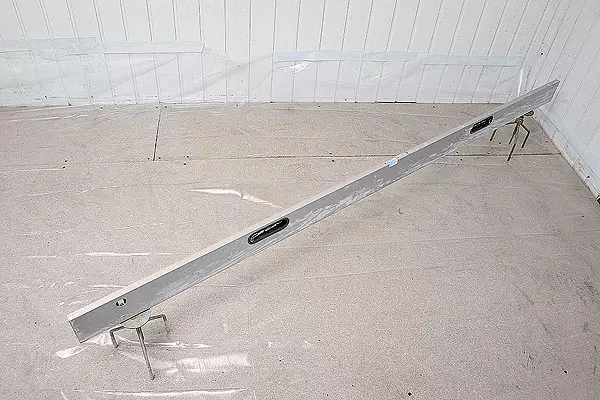

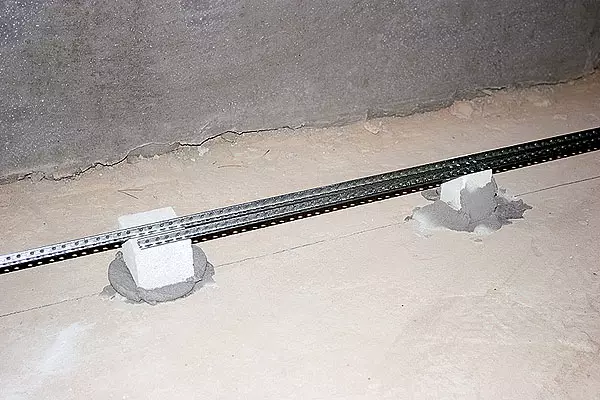

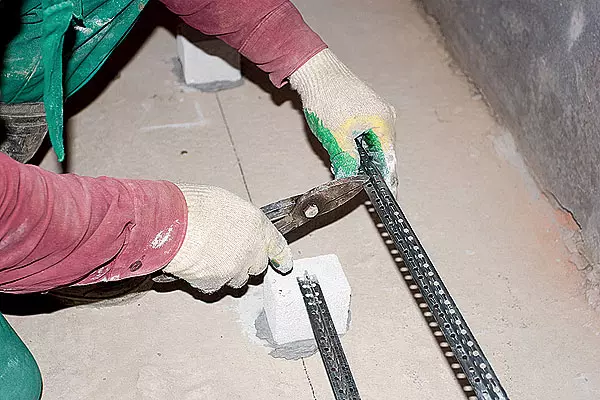

Installation of light lines for bulk sex

Photo Vikovaleva |

Photo Vikovaleva |

Photo Vikovaleva |

Photo Vikovaleva |

Photo Vikovaleva |

Photo Vikovaleva |

Initially, intermediate supports are installed, made in the form of cubes of suitable size from undergraduate building materials, under profiles - lighthouses (23). Their height is controlled by the construction level (24), line. Then the cubes are glued to the base with a solution, according to the composition of a similar bulk sex. Again check their upper border (25). Light profiles lay out that their joints fall into cubes (26), if necessary, cut (27). All communications must be laid in advance (28).

Optinc universal literacy

The reason for most errors when using self-leveling mixtures - neglect manufacturer's instructions and recommended by it process technology, and sometimes a banal reluctance to read the inscription on the package. A typical example: a unskilled worker buys a regular levelover, but for some reason he believes that this is a self-leveling mixture. It breeds it with the necessary amount of water and gets a pretty thick mass. Not at all doubting, again adds water and ... can not align the surface of the floor. After all, the mass does not spread anyway, and the main thing - the finished floor does not gain the necessary strength, since the mixture diluted more than it was required.

Opinion of a specialist

Self-leveling mixtures are extremely convenient in operation. Despite the limited lifetime of the finished solution (on average it is 20-60min), a brigade of four without problems fills the room with an area of 20m2 by hand. Two bottled and slightly spill a mass of a needle roller, and the rest are preparing a new portion of the solution (for this, large containers are used, which accommodate two bags of dry mixture and the corresponding amount of water). The cost of preparation of 1M2 bases with the help of self-leveling mixtures begins from 200 rub. Suventure of the thickness of the applied layer, as well as when using special cars, the price increases. We warn that there are a lot of fake mixes on the market. A poor-quality cement bulk gender sticks poorly even to the processed primer, "breathes" and after 2-3 days after the fill is covered with a grid of cracks. Therefore, buy self-leveling mixtures only in well-proven retail chains or official dealers of large manufacturers.

Olga Filatova, Eurasia Engineer

Aligning floors manually, be sure to take into account the flow time (lifetime) of the mixture used. It is usually 20-60min, during which it remains mobile, easily levels and mixed with the following portions. Often, a single portion is not enough for the room by a 20m2 by the room, especially if a significant layer thickness is assumed. You need to have time to prepare several portions of the solution and for these 20-60 minutes to pour the entire area, and therefore it is not to do without a large tank for mixing and a powerful mixer. In the opposite case, the late layers will be stirred poorly with the earliest (there has already begun the stabilization process), and the surface will be not even, but a buggy. Another option is possible: the floor of the room is blocked into several sections (cards) and poured in turn. True, there is a possibility that the surfaces of the cards are slightly coincide in height and will have to pour them with a thin layer of self-leveling mixture. It is not by chance that the cost of arranging 1m2 of the bulk gender depends on the method of application and complexity of work. It fluctuates in the range of 200-400 rubles.

Designer L. Biserova Photo E.Lichina |

DARTA-STROY |

DARTA-STROY |

DARTA-STROY |

29-32. Polymer bulk floors based on polyurethane and epoxy resins are completely not afraid of shocks. Whatever they drop on them, dents and cracks will remain on the surface.

It is worth carefully treating the conditions of work. Suppose winter, in the new house there is no heating, but I want to start repair as soon as possible. The inhouse put a heat gun. When it heat the air to 15ce, they begin to pour the floor, although the base has not yet warmer and its temperature may have less than 5C. Aveted in the instructions clearly stated: when performing alignment, the temperature of the base and air should be within 5-25c.

The time through which the floor can be walking, important. While the humidity of the layer is still large, it is impossible to lay an finishing coating on it, but during this period other finishing works can be carried out.

In a word, only the confidence in the smooth floor arrangement of a qualified brigade, you can evaluate high speed, ease of installation and get a solid smooth cauldron for any flooring.

Characteristics of some self-leveling mixtures

| Title, type of base, manufacturer | Recommended layer thickness, mm | Compression strength, MPa | Bending strength, MPa | The viability of the solution, min | Material consumption on 1m2 with a layer thickness 1cm, kg | Time, after which you can walk on the surface, h | Packing mass, kg | price, rub. |

|---|---|---|---|---|---|---|---|---|

| "Boden 30" on a plaster basis (KNAUF) | More than 25. | More than 25. | More than 5. | At least 60. | nineteen | 6. | 40. | 400. |

| Weber.niv F30 on cement basis ("Saint-Goben Construction Products Rus") | 5-30 | 25 * | There is no data | Not less than 20. | sixteen | 8-10 | 25. | 860. |

| Vaateri Plus on a cement basis (TM Vetonit, "Saint-Goben Construction Products Rus") | 2-30 | twenty* | More than 6. | At least 20-30. | sixteen | 3-4 | 25. | 660. |

| "Glims-SL" on a complex mineral binder ("Glims") | 2-50 | twenty | 7. | At least 30. | fifteen | 3-4 | 25. | 620. |

| "Rovina T-46" on a cement basis ("basics") | 1-10. | twenty* | five | At least 60. | sixteen | 6. | twenty | 370. |

| Thomsit DA on cement basis ("Henkel Batechnik") | 1-10. | twenty* | four | At least 30. | sixteen | 3-6 | 25. | 615. |

| Fat bulk floor on cement basis ("prospectors") | 30-80 | fifteen* | five | At least 40. | 18-20. | 48. | 25. | 180. |

| Litoliv S30 on Cement Base (Litokol) | 3-30 | thirty* | 7. | At least 30. | sixteen | 7. | 25. | 480. |

| "BIRS 34" on a cement basis ("Experienced plant dry mixtures") | 5-10. | twenty* | 7. | At least 20-30 | 14-18. | 24. | fifty | 840. |

| Bolls SV-1050 Express on a cement-sand-based ("Bolls") | 5-100 | fifteen | At least 4. | At least 30. | eighteen | 5-6 | 25. | 315. |

| * This strength is gaining the coating after 28 days. |

The editorial board thanks Bolls, "Glims-Prodakshn", "Darta-Stroy", "Eurasia", "Ark Parquet", "Saint-Goben Construction Products Rus", "Stroymontazh MS", "Henkel Bauthechnik", and also Group of CNAUF CIS for help in preparing the material.