Glazing of the loggia or balcony using aluminum profiles. Comparison of aluminum profile and hollow profile from hard PVC.

In the last issue of our magazine (article

"In the Hubber of My Heat"), we showed how to glash balcony or loggia with a hollow profile from hard PVC. Now we will tell about the use of aluminum profiles for the same goals and try to designate the pros and cons of both options.With the glazing of the loggia or balcony of the urban apartment, the owner of such a housing, caring for the strength of the design, about heat and noise insulation, about the convenience of using the sash, only last time it is wondering how the whole design looks from the street. That is why the facades of many houses gradually begin to resemble a multicolor patchwork. At the same time, if firms mounted new translucent fences thought in advance about the attractiveness and uniformity of the loggias and balconies, the architecture of the houses and the appearance of the neighborhoods from this only won. We will tell you about turning the loggia into a summer veranda in an ordinary city apartment with the help of a glazed frame from aluminum profiles on the example of the work of the Russian company "INTERTEKH" in Obninsk Kaluga region. Inash Choice is not accidental.

Wood, aluminum or plastic?

What to choose for frame, frames and flaps- Wooden bars, aluminum or plastic profile? To give preference to some kind of material is very difficult. Veverop, for example, the volume of the displayed window profile has approximately such a relation: 35% of wood, 35% from PVC and 30% from aluminum. Let us give a few "for" and "against" when choosing each of these materials.Aluminum profile is the most durable, solid, light, it is perfect for glazing a balcony or loggia. The plastic profile of PVC, amplified to increase the stiffness of steel reinforcement and called sometimes metal plastic, is noticeably heavier than aluminum and more suitable for glazing of the loggia. Wooden designs are equally good for glazing both balcony and loggia.

Aluminum flaps are usually sliding, while they are easily removed from the opening, while less rigid wooden and heavier metal-plastic are more often a swivel-folding. The sliding design of the sash ensures not only the convenience of using and care for them, but also saves the area of the loggia or balcony.

How much is it worth glazing the loggia?

The manufacture of standard structures from the aluminum profile with the installed glass will cost $ 35 to75 in 1.2. The difference in the price is determined by the ratio of the "deaf" frames and moving sash, as well as the form of binding. Mounting works are 13-19% of the cost of the structure, depending on the contours of the opening of the loggia or balcony.The execution date of the order is up to two weeks, but in any case the final calculation should be performed only after ordering. The company "INTERTEKH" provides a three-year warranty on the design of the glazing of the loggia.

Aluminum profile has a high thermal conductivity, so poorly retains heat and it is often used for cold glazing. Wooden and plastic frames, on the contrary, have a low thermal conductivity, so it can stay warm inside the room for a long time and they are usually used for "warm" glazing. In addition, it is not very nice to aluminum frames during the cold season, and wooden and plastic frames are always "warm" to the touch.A widely advertised aluminum profile with the so-called "thermal explosion" in recent years, which provides a thermal separation of the reinforced polyamide, has the same thermal conductivity as wooden or plastic structures, but more than 1.5-3 times.

The coefficient of temperature expansion of PVC is higher than aluminum and wood, therefore the left gaps between the profile and the building wall must be greater.

Aluminum in the presence of coating is not oxidized in a wet atmosphere until the coating is broken. Warranty on the plastic profile of PVC for the middle strip of Russia, up to40 years, but for the northern regions it is only 15 years. Wooden design should be periodically handled by antiseptic, as well as tint so that it can serve you not one dozen years.

Aluminum does not burn, and wood and PVC are one of the combustibility group (G3) and are characterized by a high smoke-forming ability, but the tree is flammified in the case more easily than PVC (according to IC "Fire Resistance" of GPCNIYSK them. Kechrenko).

Wood and aluminum- environmentally friendly materials, while the production of PVC profiles is associated with the use, although in small quantities, very harmful to human health substances.

Aluminum profile on the Russian market supply companies such as Belgian Reynaers, Dutch Reynolds, German Schuko, Hartmann, Hueck, Italian New Tec, Indinvest, Spanish Provedal, as well as domestic, for example, CJSC "Mosmek plant", "Vernenevdinskoe" and "Intertech ". Inash, and their profile is manufactured by the extrusion of an aluminum alloy, close to the Russian alloy MarkaD31.

NCS Color Design System (Natural Color System)

When selecting colors around the world, "computer" color designation systems, or color palettes, such as NCS, RAL, Monicolor, Renolit, Pantone, are widely used. The first three of them are used to select paints in construction, Renolit system for film coatings, and the PANTONE system in printing. Each of them includes over one and a half thousand colors and shades, with the help of which it is easy to choose the desired paint. Systems help to quickly determine the proportions of the components to obtain the desired flaper.According to the decree of the Government of Moscow N940 OT26.11.96. "The approximate improvement of Moscow: Colorics, lighting architecture and landscape architecture" The international NSC color designation system has been adopted in the capital (NCS abbreviation is taken from the phrase of Natural Color System- system of natural colors).

Booklets with paintings and digital codes of paints in a particular system are in large firms and shops selling paintwork materials. There they can help with the translation of color designation from any other system into the NCS system.

Cold Glazing System

The IT series aluminum profile system is developed by the company "INTERTEKH" and certified by FCsminstroyarf. Moreover, the company "INTERTEKH" - not only the developer of the profile, but also the manufacturer and itself performs installation. The system is designed specifically for the "cold" glazing of balconies and loggias, there are only 20proophiles, while the cost of glazing is 2-8 times lower than the cost of the same works, but from the profiles of more complex systems of other firms listed above. The thickness of the profile walls is from 0.2 to 1.6 mm with a width of 60mm.

Thermal losses of translucent fencing depend on the thermal conductivity of the materials of a particular design, air convection of the room with atmospheric air and heat radiation through the glass. Due to the high thermal conductivity, the first type of loss is sufficiently significant for aluminum. Of course, it is possible to apply a low-emission coating to one of the glass windows to reduce heat losses, but for a conventional aluminum profile, such a measure is less effective than for PVC frames. However, when using an aluminum profile with a thermal explosion, this method becomes relevant.

Thousands of shades

On the aluminum profile in the factory conditions, a durable weather-resistant protective and decorative coating, oxide or polymer film is applied. The oxide film with a thickness of 0.015-0.02mm is formed during anodization, and a polymer film with a thickness of 0.05-0.06mm (for internal surfaces) and 0.07-0.08mm (for external surfaces) - with electrostatic paint powder enamel. Usually, the anodizing is used to obtain a color for gold, silver and old bronze, and painting with powder enamels - for all sorts of colors on the NCS scale. Both types of coating have high anti-corrosion and impact-resistant properties in the temperature range from -60do + 150c, do not eat and do not fade, eliminating oxidation over a long exposure time moisture.We choose the design

After measuring the glazed opening of the loggia, the design of the aluminum frame is determined: the number of "deaf" frames, movable sash, the need to install the upper expansion part, the number of sings - one (lower) or two (lower and upper) - and their width, the method of filling the gaps between the frame and walls of the building.

The number and height of the flaps are chosen by such criteria: the convenience of their movement, sufficient rigidity and the ability to remove for washing. Usually their height does not exceed 1800 mm, and the width is 1500mm. The rest of the place in height is filled with the "deaf" frame, and the width of the flaps is determined by dividing the total width of the opening on the number of sash (it is usually the same, for the possibility of installation in any order).

The flaps are combined by height with handles, conveniently "recessed" flush with the inner profile plane. The gear side of the profile of the handles is not visible at all. We can combine these knobs of the sash in the section, each of which moves as a single integer.

The gap between the circuit of the opening and the frame outside is filled with rubber seal, and from inside the installation foam.

Nor a drop!

In the design, you can provide a windowsill from a board with a thickness of 30-50mm and up to 120-300mm wide, having a curly converge from the front side. The windowsill serves as an aligning support for the frame installed on it. The tree is impregnated with antiseptic composition to avoid rotting and warping under the action of atmospheric moisture.From the outside, the frame and the windowsill are protected by metal places. Before installing on the top, the sealant layer is applied, which additionally closes the gap between it and the concrete slab of the upper floor overlap. The lower sump should be submitted under the frame to eliminate the risk of penetration of capillary moisture; It is fixed with screws to the bottom guide frame. The atmospheric moisture appears in the guides through the holes of the holes immediately flows to the lower sump. The width of the sumps defines the wizard when removing the size of the opening, it is from 120 to 300mm.

Easy and quiet

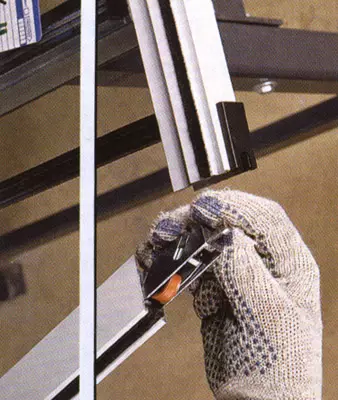

Rollers on radial ball bearings in a plastic framework are attached to the lower profile of moving flaps in a plastic clip. They are freely rolled on the guide of the lower profile of the frame, so sufficient effort to move the sash. Plastic clip provides a silent course, protects bearings from clogging and formation of rust.

Several practical recommendations

Do not save on window handles! More expensive and high-quality window handles with safety focus will protect your hands from the danger to be pinched between the sash.

The width of the sumps should not be done too large: the wide top of the top will give a large shadow, and under the bottom of the lower it will have to install an additional supporting profile, so that the dummy does not rush over time.

At temperatures on the street below -15s sash it is better not to use due to the possible formation of a land in the guides. This will prolong the life of the rollers and will protect the rods of the directions from scratches and deformation.

Periodically examine the state of the coating applied to the profile that protects the aluminum alloy from oxidation. When a deep scratch appears to squeeze its acrylic paint of the appropriate color or colorless weatherproof varnish with a thin brush.