We tell about the peculiarities of warm ventilated facades, montage of the frame, insulation, wind and moisture protection and finishing finish.

Today, most new multi-storey houses are erected using facade insulation. Such facades and low-rise home buildings are in demand.

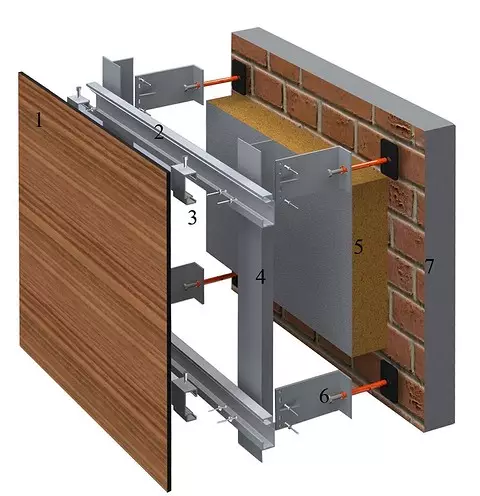

Construction of mounted facade

Hinged facade systems are usually divided into "classic" (oriented mainly on multi-storey construction) and "under siding" (for low-rise houses). These structures are very similar and perform the same tasks: the walls are insulated (the mounted facade without insulation is rare today) and serve an outer decoration.

Elements of the mounted facade of the "classic" type:

1 - panel cladding;

2 - horizontal profile;

3 - hidden clip for fixing the panel;

4 - vertical guide profile;

5 - insulation with weathered protection (glass oxided);

6 - steel bracket;

7 - Building Wall

The general principle is: to the building wall, with some referring from it, with the help of a frame (doom) fasten the facing from panels, rails or slabs, after completing the empty space under it with insulation. Between the insulation and facing, the ventilation gap of 30-50 mm is left to ensure evaporation of moisture penetrating and from the street (when rain with wind, high humidity), and from the room. The air should freely fall under the cladding from the base and go out of the eaves. It is impossible to overlap the clearance, but you should install from below and above the corrosion of the grid or grid.

The difference between the city and the "Sale" is to be used materials, fastening systems, installation nuances. However, the venifassad of urban type is appropriate in cottage construction, especially when cladding the walls with heavy materials, so we will talk about it.

Pros and cons

The mounted facade allows to improve the heat insulating characteristics of the walls of the already built house, protect them from moisture and separate the most different materials, and with new construction, in addition, it is possible to reduce the cost of the foundation. The design is quickly mounted, and work can be carried out at any time of the year. If necessary, it is easy to disassemble and repair. As a rule, it is planned to replace damaged cladding parts.

But the hinged facade consists of a variety of elements, and its reliability depends on the quality and correctness of the installation of each group of components. Errors When installing a framework lead to the appearance on the facade of visible irregularities, the wrong choice of hydraulic protection threatens with the convergence of the wall, the careless fastening of carrier profiles and cladding reduces the wind resistance of the design.

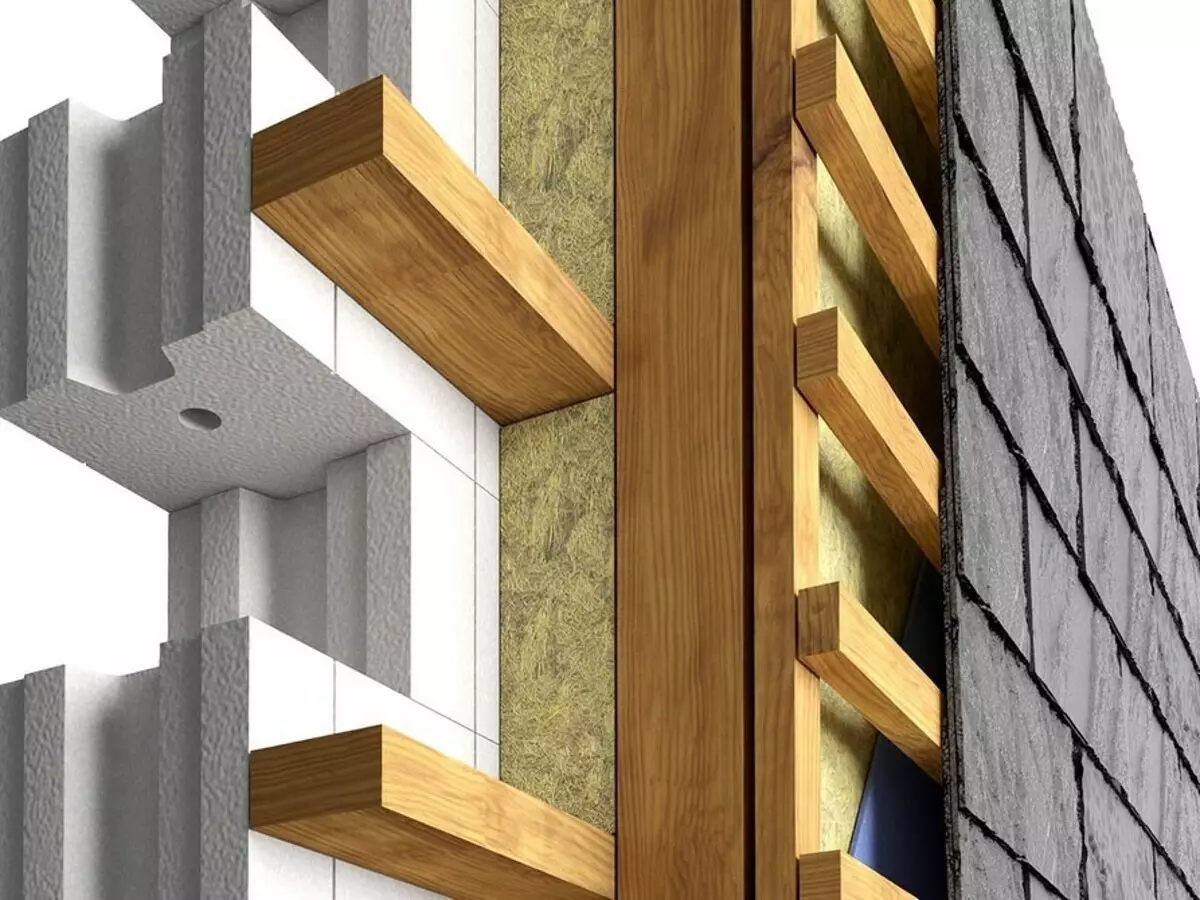

Hinged facade on a wall of structural cellular concrete. The system with a vertically horizontal wooden frame, two-layer insulation and shale tile facing allows you to perform modern requirements for thermal protection of buildings, weatherproofing.

In addition, it allows you to install trendy hidden drains and do without karnis.

Montage Karcasa

When covering with plastic or metal siding, the peel can be collected from coniferous bars, but only dry and highly durable (without large bitch, surveys, cracks). They must be treated with an antiseptic using a sprayer. The cost of a wooden lamb taking into account the installation will not exceed 250 rubles. for 1 m2.

For fastening the tile (ceramic, stone, composite), a vertical or vertically horizontal (laid) carrying frame is performed from steel hot-dip galvanized profiles with a thickness of at least 1 mm thick. This design will cost at least 600 rubles. For 1 m2 excluding installation. Also on sale there are aluminum products that cost at least 70% more expensive than steel, but there are almost unlimited service life. The framework of profiles is desirable and when finished with heavy fibrotent siding.

Hinged facade with vertical frame:

1 - wall of the building;

2 - bracket;

3 - insulation;

4 - vapor-permeable wind-hydrogen protection;

5 - plate plastic dowel;

6 - Frame profile;

7 - Klimmer;

8 - composite panel

The pitch of the framework of the frame varies within 350-800 mm, the mounting nodes to the wall (vertically) - 600-1,500 mm depending on the value of the one from the wall, the mass of cladding and the calculated wind loads.

Installation of the mounted facade does not require pre-alignment of the walls, but it is necessary to place the place of fastening of the frame. When finishing, the tile requires accuracy, since the vertical or horizontal joints of the tiled cladding elements should have to the profiles of the root.

How to fix and align the doom

For fastening both wooden drying and metal frame, it is desirable to use a stainless fastening from steel A2 or A4 stainless steel (in the DIN designation system). Mostly in low-rise construction, screw screws with a round or hexagon head are used, much less often (when installing heavy structures) - anchors.The most common way to align the wooden drying - with the help of linings from antiseptic wood, waterproof plywood or plastic. If you need to provide a significant (more than 40 mm) relating to the wall, do not do without brackets for facade systems. The most convenient adjustable brackets with sleds, which allow you to very quickly set the frame profiles in one plane (on lacers or laser level labels), but they cost at least 160 rubles. For 1 pc. The number of brackets is usually varied from 2.5 to 4.5 per 1 m2 (determined by the calculation).

If the facade is mounted onto the walls, not given the final shrinkage, the makeup is fixed moving - through vertical slits in bars and profiles or using sliding brackets.

When assembling facade structures, it is impossible to use profiles for GLCs, since they are not enough for corrosion and begin to rust under the influence of condensate, which is often formed under the trim.

Wall insulation

Mineral wool

Most experts recommend when assembling Ventfasad to warm the walls with mineral wool plates, such as "Vin Batts" and Light Batts (Rockwool), WAS (Paroc), Geo (URSA), and others. Adopted today. Installation technology allows you to avoid cold bridges in the element zone Frame, which is especially important if this carcass is metallic. The essence is that the brackets are fixed to the wall, then the insulation slabs (at the same time the brackets permeate the plates). Next, without disrupting the integrity of the insulation, the carrier profiles of the framework are installed, and then the facing.When choosing a thickness of plates from mineral wool, you should be guided by the SP 50.13330.2012 "Thermal Protection of Buildings". This standard contains a method of thermophysical calculation of mounted facade systems (Appendix L), which takes into account the region of construction, thickness and thermal conductivity coefficient of the structural layer of walls and other factors.

For prior calculation, you can use online calculators on the sites of thermal insulation manufacturers.

Styrofoam

Leaf foams, in particular EPPS plates with M-shaped edges, are well combined with a warm plaster facade, and it is bad for attached structures, since these materials are combustible, and their installation turns out to be too time consuming: it is necessary to cut hole for each bracket; All joints. And if we use spraying, it is difficult to withstand the uniform thickness of the layer. Another nuance: Most foam plastic possesses low vapor permeability, because of which it becomes necessary to steamize the design layer of the walls on the side of the room and install the modern supply and exhaust ventilation system in the house.

With a traditional scheme of mounting siding, the insulation is located between the shelter rails.

But recently there were systems with plastic profiles, which are mounted on remote brackets over a solid layer of plate insulation.

Choosing the thickness of the insulation in the facade design

| Material, thickness of the structural layer, mm | The minimum required thickness of mineral wool density is 32 kg / m3, mm |

|---|---|

| Block two-frequency ceramzite concrete, 190 | 130. |

| Block of a gas-concrete density of 500 kg / m3, 30 | 100 |

| Brick red slit, 380 | 120. |

| Block polystyrene bontic density 500 kg / m3, 300 | 80. |

| Coniferous timber, 150 | 120. |

Protection of the facade from wind and moisture

Some special mineral wool slabs, on the application of manufacturing companies, is allowed to close with cladding without creating an additional barrier from wind and moisture. These materials have a hard outer layer (as, for example, at the "Valtts D Optima") or glazed glass chickens (GEO). It is them that should be used in structures with a metal framework, to which it is problematic to fix additional wind-hydro-insulating layers.

If the bands of the wind hydrogen-proof material are mounted vertically, their joints should be sized with special scotch.

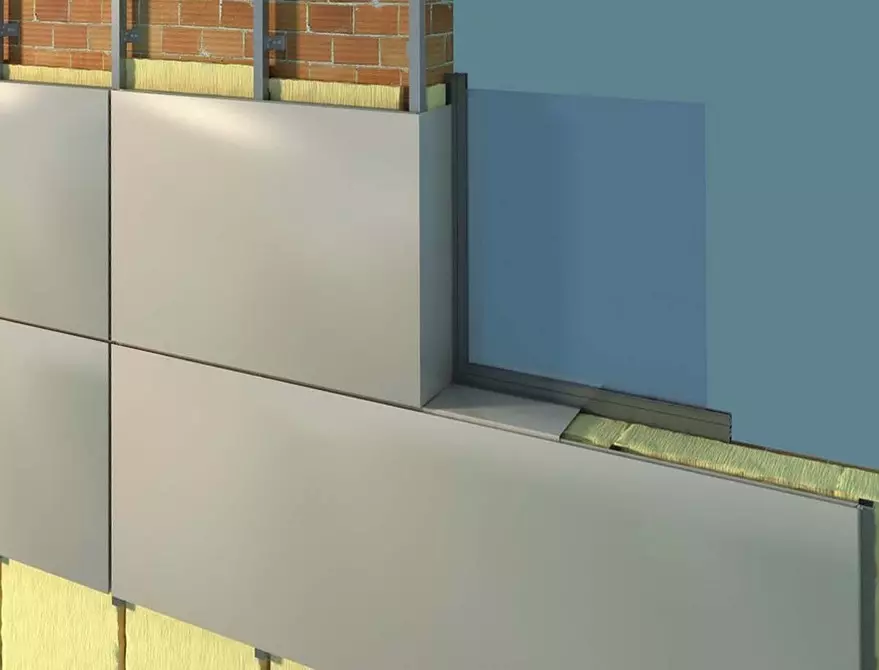

When finishing openings, it is necessary to thoroughly seal the seams between the sloping panels, otherwise the moisture will enter the inside of the design, and the insulation recks under the window.

However, the overwhelming majority of slab insulation requires protection against weathering and humidification. This goal is the vapor-permeable membranes - TYVEK and AIRGUARD (DUPONT), AQPRO FF and AF + ("Izospan") and others. They are mounted with horizontal bands from the bottom up with a falsestone at least 10 cm, first fixing the construction stapler, and then pressing the counterboots.

If there are open seams between the elements of the facing (as in the case of a wooden plaque), you need to purchase a light-fast windpower, such as UV Fasade (DuPont), Delta-Fassade and Delta-Fassade S (Dörken).

If open seams are provided between elements of the facing (as in the case of a wooden plaque), you need to purchase a dark light-resistant windpower, such as UV Fasade or Delta-Fassade (Dörken).

Finish finish

As a finishing material for a cottage house, you can choose light vinyl, metal or composite siding, plastic panels under the brick or stone. For construction in the classic style is optimal stone and clinker tiles. For a modern country-style cottage - weather-resistant wooden panels (for example, impregnated with antiseptic and painted at the factory), as well as fibrotent siding. The architectural trends correspond to shale, porcelain-proof, fibro-cement and composite large-format tile, aluminum and steel cassettes.

The materials for which the hidden edge fasteners are more appropriate in the low-rise sector.

Fibro-cement panels are able to imitate the painted board.

It is also imitation of stone and clinker tiles. Material non-combustible, durable and looks presenter of PVC products.