We suggest, from which material and with which furnace to choose the precast furnace.

The first team furnaces from stone fittings introduced in our market the Finnish company Tulikivi in the 1990s. Then she had competitors - Brunner, Wolfshöher Tonwerke, Nunnauuni and others. Gradually, manufacturers began to use the heat-resistant concrete and ceramics along with natural stone, which made it possible to reduce the cost of furnaces.

A relatively small LEILA furnace from talcomagnesium modules weighs about 1600 kg and needs the foundation

The advantages of the modular design in front of the brick are considerably at a significantly higher construction rate, fewer seams and elegant appearance, over which professional industrial designers worked. However, the modular furnaces were and remain substantially more expensive bricks - especially this concerns classic stone models. From them, we will start a story, but first let's talk about the features of the device of a modern modular (block) furnace and its differences from the foci of another popular type.

TLU 2000 with oven (from 540 thousand rubles)

Oven against the fireplace

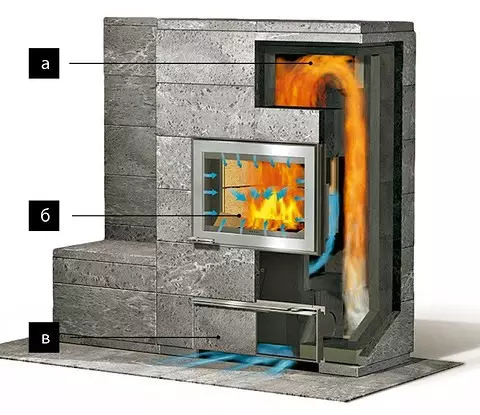

Today, the heating door with glass and air dampers for adjusting the combustion speed are present in both the furnace and the fireplace. Both the other aggregate are equipped with a modular warmed chimney. But the oven has built-in smoke channels, which are not in the fireplace. Usually they are vertical with countercurrent, less often - horizontal or inclined, located in the form of a serpentine. In addition, the furnace housing is usually massive, and the walls of its firebox are made of stone or ceramics, while most fireplaces are equipped with a metal cassette.

Koli oven with automatically closing firebox door (from 445 thousand rubles)

Manufacturers are recommended to equip the furnace with ceramic chims, which forms a minimum of condensate. However, nothing prevents installing and metal warmed tubes

These features of the furnace are very important: they allow you to increase the combustion temperature and achieve the most complete burning of firewood, while ensuring the use of heat of flowing flue gases. In the outlet of the furnace, their temperature is about 60 ° C, while most of the fireplaces are more than 200 ° C. As a result, fuel is used by 15-20% more efficient: according to the applications of manufacturers, the efficiency of modern stone, concrete and ceramic furnaces reaches 80%, while in the fireplaces this indicator does not exceed 60%. The housing of the furnace isolates and accumulates heat, so the temperature differences in the room are not so cutting, as when working the fireplace; In addition, mild radiation from stone walls is more comfortable than the heat from the metal furnace in the lightweight casing.

Fiorina large oven is ordered.

When the main heating is disconnected, the furnace will fully cope with heating one or more premises in the house. At the same time, it is not necessary to constantly, including at night, put the firewood - it is quite good to make the stove 2 times a day.

BRUNNER HKD-2 furnace-fireplace with 9 kW pig iron furnace (from 240 thousand rubles. Excluding cladding)

With deficiencies, the furnace always requires a stronger base, it costs more and more complicated in maintenance (you need to clean the channels).

When installing ready-made furnaces, fire retreats, determined by the manufacturer of the unit, should be observed. For most stone models, these distances do not exceed 50 mm

Stone furnaces

The traditional material for modular furnaces is a natural talco chlorite (otherwise - talcomagnezite), which in Finland is called potter, and sometimes soapy stone. The major deposits are not so much, and the main careers are located in Finland and Karelia. The stone is easily processed, it does not crack under the influence of high temperature (at the same time withstands the quick heating) and quite beautiful. The quality of the material is no less valuable for the cooking - high heat capacity (approximately one and a half times higher than that of a red brick): The furnace housing after the end of the furnace is very long enough to give heat to room air.

Modern furnaces work in pure burning mode, due to which they are most effective and do not pollute the environment.

The classic oven is completely, including the furnace, collected from stone plates of different formats and fittings, which, nimmeroving at the factory, are delivered to an object in the form of a kit. The main elements of the design are fastening with metal brackets by inserting them into the grooves that are coated at the production. The seams are sealing with silicate glue, and the technological gaps are filled with soft refractory materials (kaolina cotton wool, asbestos cord, etc.).

Large FIMMA oven. Such furnaces weigh more than 1.5 tons and require the foundation, the design of which depends on the type of basement overlap.

In the design, a hoarse box and grate are usually present, and sometimes an oven (as, for example, in the line of multifunctional GoutmetA aggregates from Unna Nuuni), and in the assortment Tulikivi there are even models with a small bed (for example, Valkia). Such a furnace, as in a modern fireplace with a metal furnace, provides air dampers, allowing to adjust the burning intensity. The cost of aggregates of this type (including the assembly price) starts from 380 thousand rubles.

Brick stove

The main disadvantage of the traditional brick / stone furnace is clay masonry seams that have the properties to crack and sharpen, opening the path of sparks and smoke gases. Meanwhile, today the leading cookies, members of the professional guilds, are used not clay, and much more reliable silicate solutions. The design of the heating device was improved. A modern brick oven, folded by a good master, is no less durable, safe and functional than modular, and it can be bonded by any heat-resistant material, including stone tiles. As for domestic finished stoves from Karelian Talco chlorite, they are still inferior in the quality of products of Finnish companies.

Sometimes powerful ceramic stoves are embedded in the walls so that heat is better distributed throughout the house

Concrete furnaces and ceramics

The heat-resistant concrete is obtained by different ways, for example, in a mixture of special additives, the use of alumina cement, fillers from staining of rocks, etc. Ceramic chimney blocks are formulated from chamotte clay. All these materials are available everywhere and are much cheaper than stone. Meanwhile, they are withstanding the heating to 1300 ° C, they have the necessary strength and almost one and a half times lighter than stone.

The furnace made of concrete or ceramic (chammatory) plates and blocks on the heat accumulating ability somewhat inferior to stone, but it is also significantly cheaper. The unit with a nominal capacity of 6-7 kW, such as "Wolfshöher Tonwerke) or Raita Regata (Tulikivi), can be purchased for 180-220 thousand rubles.

The general principle of the device is the same here as in the stone construction, but there are differences. Thus, the strength and tightness of the compounds are ensured by dressing of seams, grooves and ridges on the plates, and the metal fastener is usually absent. The masonry leads on silicate glue, practically excluding the formation of cracks.

The cooler in the furnaces of this type is absent, and the air flow is carried out through the gaps and holes in the door or at its perimeter. Such furnaces often have an extended form, which contributes to the flue gases.

Karelian stone ovenhouse will cost 120-180 thousand rubles, and the Finnish Hile Ban Stove is 150 thousand rubles.

How to decorate the oven.

Stone stoves do not need finish. In production, the external surfaces of the modules are polished or, on the contrary, give them relief, sometimes impregnate with a heat-resistant composition changing the shade of the stone. Novelty Tulikivi - texture grafia and Rigata, as well as dark color with a pronounced Nobile texture.

The chamomot furnace is cheaper than all shuffle (for this purpose there is ready-made mixtures on sale), and then paint, adding the design with decorative elements - shelves, framing doors and coil, inserts from other materials, etc., but when developing such a project, it will be necessary to help professional designer.

Scratches on facing of soft talco-magnesite and its analogues It is not difficult to stick to the skin, while damage to the metal enameled case can not be eliminated independently

In addition, the design can be fed by sawdow. At the same time, it is not necessary to buy expensive talco chlorite - suitable and quite affordable sandstone, slate and shell. Suitable for cladding artificial cement and gypsum stone, as well as clinker tiles, but these materials have a higher thermal resistance than shape, and slightly reduce the KPD of the furnace. Finally, you can turn the modular furnace in the tiles.

The fastening of tiles to the masonry wire according to the classical technology in this case is impossible, but nothing interferes with order a set of tiles without RMSP (protruding onto the back surface) and lead a facing in the same way that is used for tiles.

When finishing with any tile, special stoves should be applied, such as Universal HKM (Wolfshöher Tonwerke), ScanMix Fire (ScanMix), etc. In addition, the wizards advise to strengthen the glue layer with a masonry grid. If the tile has a significant thickness and mass, it is desirable to lay it with its stages, two to three rows, with rearrangements for curing glue.

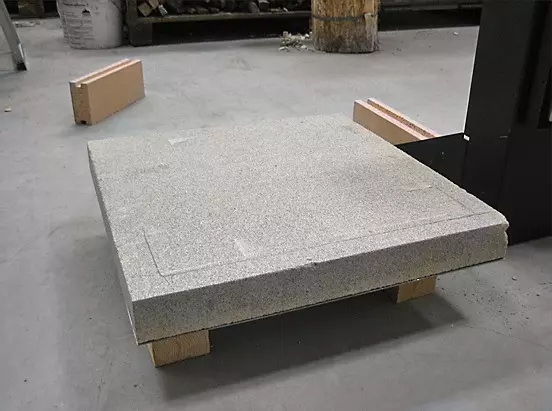

The most economical design of the foundation for the furnace is a columnar or pile with an upper support plate. The latter is removed on the level of the first floor and waterproof from above and from the sides

Convection ovens

Furnaces manufacturing also offer light convection fireplaces with stone facing. Externally, such models, such as Pielinen (Tulikivi) or Deco (Nunnauuni) collections, are very similar to the furnaces, but they differ fundamentally from them. The design is a cast iron or steel firebox without smoke channels. Lined with gap stone plates, which are held by special frameworks and brackets. Such a fireplace quickly heats the room, but after the fire went out, the same quickly cools.

Cost of convection fireplaces - from 140 thousand rubles.

What is better than the firebox?

There are three types of furnaces: grate, with burning on the course and combined. In the furnace of the first type, the air flow comes through the grille on which the firewood is perfect. In the second case, the air is supplied through the holes provided for in the door, above it or by its perimeter. Combined furnaces, as easy to understand, are combined with grate and inlet holes in the door or above.

Stone furnace design: smoke channel (smoke rotation) (a), vortex type firebox (the supply of base air for combustion is carried out around the perimeter of the door) (b), thoughtfully, which are opened during the ignition (B)

The grinding helps to quickly and quickly melt the furnace and, if necessary (for example, if raw firewood fell) to speed up their burning. This is necessary not so much to increase the heat transfer, how much to reduce the amount of soot and carnage in the furnace channels. But when the air is supplied through the top holes, the furnace is easier to translate into long-burning mode. Thus, the combined option is optimated, in which the lower grinding valve opens at the ignition stage, and when the firewood will be warm well, the air goes through the holes in the door or above it.

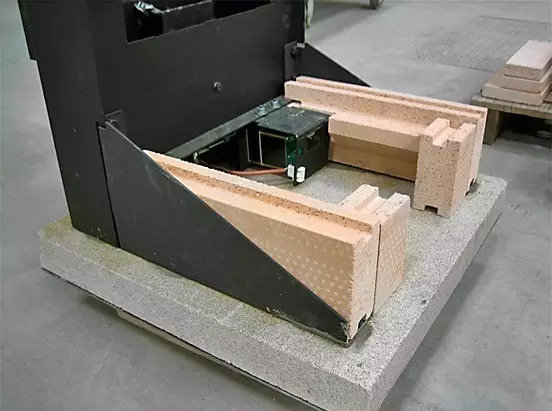

Assembling furnaces from chammed modules

First of all strictly horizontally installed the base plate

It was located on it a metal flue door, a stand and a frame of which simultaneously serve as lower strapping and masonry guides

Collected lateral walls of construction

Collected smoke canal

The surface rows were folded from blocks with lock angular compounds.

Stuck and painted oven