Abanikazi bathola indlu evikelweni elingapheli lezitini elinqunu izitini ezigandayiwe. Eminye yemisebenzi esemqoka ebheke kubabhali bephrojekthi kwakuwukudala izindlu ezifudumele, ezintofontofo kakhulu. Imibuzo ye-Aguudoma, ukuthi yini u-heater ongayikhetha nokuthi uyihlelela kuphi, sasukuma kakhulu.

Ukufaka kuphi?

1. Kuhlanganiswe uhlangothi lodonga. Le nketho inezinzuzo zombili nobubi.Izinzuzo:

Ukusebenziseka lula ekufezeni umsebenzi (ukufakwa kwenziwa ezakhiweni, futhi kungenzeka ukwenza lokhu nganoma yisiphi isikhathi sonyaka).

Kungenzeka ukusebenzisa ubuchwepheshe obukhulu banamuhla nezinhlobo ezahlukahlukene zezinto zokwakha (ngokwesibonelo, ukufafazwa kwe-polyurethane Foam IT.p.).

Ukuqeda kwangaphandle kwangaphandle.

Okubi:

Ukulahleka okungenakugwemeka kwendawo ewusizo. Okukhulu kune-coefficient eshisayo yokufakelwa, lapho kulahleka khona lokhu.

Kungenzeka ukwandisa umswakama wesakhiwo esisekelayo. Ngokufaka phakathi kokufakelwa, okuyinto evunyelwe yi-vapor evunyelwe, amakha amanzi adlula ngokukhululeka, ngemuva kwalokho aqala ukuqongelela emngceleni "obandayo odongeni" noma ngokukhuluphala kodonga. Ngasikhathi sinye, kubambezela ukubambezela Ukugeleza kokushisa kusuka egumbini kungene odongeni, ngaleyo ndlela kwehlise izinga lokushisa kwalo, okubuye kukhulisa ukuhola ukuzuzisa.

Uma ngasiphi isizathu, okuwukuphela kwenketho yokufakelwa kokufakwa kokufakwa kwe-thermal kusuka ngaphakathi kwendlu, kuyadingeka ukuthatha izinyathelo eziqinile kakhulu zokuvikela izindonga zomswakama, ukusungula i-steam barlasting egumbini, ukuhlela umoya wayo ophumelelayo.

Izindonga ze-2.tright (izakhiwo ezibuyiselwe eziningi). Ukufakwa kufakwa ngaphandle kodonga futhi kumbozwe ngezitini ezibhekene. Uma ukwakhiwa kokwakhiwa kwengqimba enjalo enezinto eziningi kusetshenziswa ngempumelelo nokwakhiwa okusha, khona-ke sekuvele izakhiwo ezikhona, kunzima, ngoba kuholela ekwandeni kobukhulu bodonga, okuvame ukudinga ukuqiniswa (ukuguqulwa) kwesisekelo.

3. Izinhlangothi zodonga. Izisombululo ezinesisindo nazo zinezinzuzo nezinzuzo zalo.

Izinzuzo:

Indawo yokuvuselela ama-Vapors asafufusa (ama-Dew Point) yenziwa ngalé kodonga oluthwala - ekufakweni. Izinto zokufakwa kwe-parPural okushisayo aziphazamisi ukuhwamuka komswakama odongeni kuya esikhaleni sangaphandle, okunomthelela ekunciphiseni komswakama wesakhiwo futhi kwandise impilo yaso iyonke.

Ukufakwa kwe-thermal kuvimbela ukudlula kwe-flux yokushisa kusuka odongeni ophethe ngaphandle, ngaleyo ndlela kwandise izinga lokushisa kwesakhiwo (ngenkathi uhlu lodonga olufakiwe luba inqola yokushisa, luyasiza ukonga ukushisa ngaphakathi kwegumbi ebusika bese upholile ihlobo).

Ukufakwa okushisayo okushisayo kuvikela udonga kusuka ekushintsheni kweqhwa futhi kuncishiswe, kuqondanisa nokushintshashintsha kwezinga lokushisa ku-array yalo, okukhulisa ukuqina kwesakhiwo esisekelayo.

Okubi:

Iphuzu lamazolo liphenduka libe seleveli yokufakelwa, okuholela ekutheni kuholele ekunyuseni umswakama wayo. Insindiso ukusetshenziswa kwama-insulators okushisa ane-vapor ephezulu, ngenxa yokuthi umswakama owela ngaphakathi kungqimba uhanjiswa ngokukhululeka kuwo.

Ungqimba olungaphandle lokufakwa okushisayo kufanele luvikeleke ekuvutheni kwezulu okuhlala emkhathini kanye nomthelela wemishini we-detable, kepha umhluzi ovumayo (insiza ye-lo-okubizwa ngokuthi yi-facade noma ukulungiswa kwayo kuyadingeka).

Ukukala zonke izinzuzo nokubi ngakunye kwezindlela ezintathu zokuhlelwa kokufakwa, abalobi bephrojekthi bafinyelela esiphethweni sokuthi ukufakwa kwangaphandle okulandelwa ngetshe lokufakelwa kanye nokuvalwa okuyingxenye kuyisixazululo esinengqondo kuwo wonke amaphuzu okubuka.

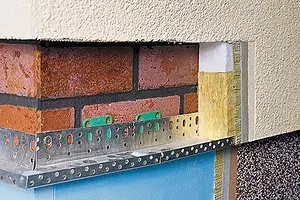

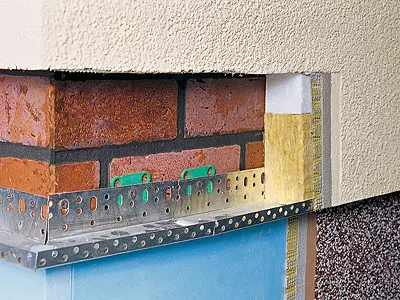

Ukuhleleka komsebenzi kulokhu kufakwa kungukulandelayo. Unqenqema oluvelelayo lwesisekelo noma onqenqemeni lwe-slabs egcwele kungaba ukwesekwa komugqa wokuqala wezinto zokufakelwa okushisayo. Uma kungekho ukusekelwa okunjalo, khona-ke ngosizo lwama-dowels, kufakwa isitimela esisekelwe esigabeni noma sokhuni ngaphambi kokukhishwa). Ukusetshenziswa kwe-glue, ngokwesibonelo, ngoba isisekelo ngesimo se-Brickwork sisuka ku-3.5 kuye ku-5kg / m2 futhi kuncike ekungaphathekisweni kwesisekelo. Amapuleti okufakwayo asondele kakhulu komunye nomunye ngokugqoka komthungo, njengalapho ubeka izitini. Kufanele ilungiswe ngamapuleti ngomshini, kusetshenziswa ama-spacer ama-spacer epulasitiki ngenduku yensimbi engenasici.

Uma ngokuzayo kuhlelwa ukucacisa i-facade, khona-ke ngenqubo echaziwe yokufakelwa, asikho isidingo sokusetshenziswa kwezinto zomoya nezinto zokufaka umoya, isakhiwo sokuqala esizothathelwa indawo nge-coefficient evumayo eyethusayo , ungqimba lwesibili luka-vapor-avumelekile udaka. Inani elincane lomphunga wamanzi, noma kunjalo, elibanjwe ngaphakathi kodonga (olungenakugwenywa), luzophazanyiswa lungaphandle ngongqimba lokufakelwa nodaka.

Yiziphi izinto okufanele ukhethe?

Ngokuqaliswa kohlelo oluchazwe ngenhla, izinhlobo ezimbili zezinto zokwenza izinto ezisebenzayo zokufaka okushisayo zingasetshenziswa: Uboya obuncane kanye nohlobo lwe-polystyrene Foam.

Ake siqale ngoboya bezimbiwa, okungukuthi, ukugembula kwamatshe kanye nengilazi. Ochwepheshe bakha izidingo zalokhu:

1. Isilawuli kufanele silondoloze ubukhulu baso bejometri yokuqala (ukunganikezi ukushwabana futhi hhayi ukuhlawula) kukho konke impilo. Izinto zokufakwa okushisayo ezikhiqizwa ngendlela yokuthi imicu ingekho endaweni efanayo, kodwa isiphithiphithi.

2. I-Vapor Vapor Permeability ayikho ngaphansi kuka-0.3 mg / (MCPA), ukumuncwa kwamanzi akubanga ngaphezu kwe-1.5% ngevolumu.

3. Ukwelashwa Kwezinto Ezihlinzekwa Ngayo Ngazo Amacebo Azobhekwa Kukhethwe ngokuya ngemibandela yokusebenza kwayo, okuthinta izidingo zokwenziwa (kuthinta amandla okuqukethwe kokucindezelwa), amandla okuthola amandla Izendlalelo (umzamo odinga ukunamathiselwa ungqimba lwangaphandle ukuklebhula kulo lonke isisindo).

Manje mayelana ne-polystyrene enwetshiwe. Ukuvuselelwa okushisayo kwalokhu okuqukethwe kuphansi kunalokho okufakwayo koboya bezimbiwa (okuvumela ukunciphisa ubukhulu bokufakwa kwesendlalelo sokushisa), futhi kubiza okushibhile. Okubi kwalo kungukuthi umfutho omncane we-vapor, ukuqina okukhulu komsebenzi (kunzima ukulingana ngosayizi ngesikhathi sokufakwa) kanye nokuhlanganiswa okuphezulu (igwebu elinwetshiwe lezinto ezivuthayo). Isimo sokugcina sibangela ubunzima lapho befaka:

Ezungeze iwindi neminyango kufanele isetshenziswe kuphela ngoboya bezimbiwamayini;

Kuyadingeka ukuhlela ukuvikelwa komlilo (ukuphakama komlilo (ukuphakama kwe-150mm) kusuka oboyeni bezimbiwa ngezikhathi ezithile ukuphakama.

Akuyona i-polystyrere ecacile eqondile eyandisiwe esetshenziselwa kakhulu ukufakwa kwama-facades: kubiza izikhathi ezi-3-4 ezishibhile kunoboya bezimbiwa.

Izidingo zalokhu okuqukethwe:

Density 15-25 kg / m3.

Isakhiwo kufanele sibe mnene, amagremu ahlobene ngokuqinile (endaweni evulekile ngenhla kokufakwa kwamanzi, kanye nemifino ehlukene ngosayizi, futhi kuhlobene kahle, njengoba kulungile ukuthi izinto ezifanele zizothi, " ukubhujiswa ngokomzimba ".

Amapuleti kumele abe nobukhulu obunembile bejometri lobude nobubanzi be-2mm, umehluko omkhulu ungaphezulu kwe-1mm, amapuleti angabi ngaphezu kwe-0.5% (isikhathi esinembile, isikhathi esincane sichithwa lapho kufanelekile wezitofu).

I-shrinkage evunyelwayo eqondile ayikho ngaphezu kwe-0.2% (amapuleti ahlobene ngaphandle kokupakishwa okungenani amaviki).