The owners acquired a house in unfinished video naked brick walls wrecked tiled roof. One of the main tasks facing the authors of the project was to create a warm, most comfortable housing. Agudoma questions, what a heater to choose and where to arrange it, we got up particularly acute.

Where to put insulation?

1. Included side of the wall. This option has both advantages and disadvantages.Benefits:

Convenience in carrying out work (installation is carried out in the premises, and it is possible to do this at any time of the year).

It is possible to apply the most modern technologies and a variety of types of materials (for example, a spraying of polyurethane foam IT.P.).

Fully retained outdoor finish.

Disadvantages:

Inevitable loss of useful area. Which is larger than the thermal conductivity coefficient of the insulation, the more these losses.

It is possible to increase the humidity of the supporting structure. Through the insulation, which is a vapor-permeable material, the water vapors pass freely, after which they begin to accumulate on the border "Cold Wall-insulation" or in the thickness of the wall. At the same time, the insulation delays the flow of heat from the room into the wall, thereby lowering its temperature, which further aggravates Mooring design.

If for any reason, the only possible insulation option is the installation of thermal insulation from the inside of the house, it is necessary to take very rigid structural measures to protect the walls from the impact of moisture, to establish steam barlasting from the room, to organize its effective ventilation.

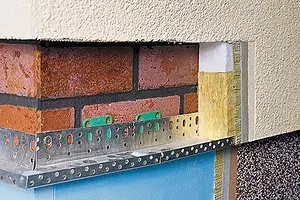

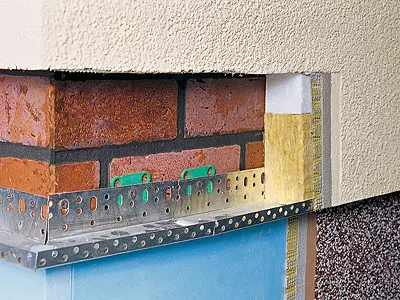

2.Tright walls (multi-layered structures). The insulation is placed on the outside of the wall and covered with facing bricks. If the creation of such a multi-layer construction is successfully implemented with new construction, then for already existing buildings, it is difficult, since it leads to an increase in the wall thickness, which often requires strengthening (alteration) of the foundation.

3. Wall sides. Weighted solutions also have its pros and cons.

Benefits:

The condensation zone of emerging vapors (dew point) is carried out beyond the bearing wall - in the insulation. Parpural thermal insulation materials do not interfere with the evaporation of moisture from the wall into the external space, which contributes to a decrease in the humidity of the structure and increases its life as a whole.

The thermal insulation prevents the passage of the heat flux from the carrier wall to the outside, thereby increasing the temperature of the structure (while the array of the insulated wall becomes a heat accumulator, helps to save heat inside the room in winter and cool in summer).

The outer thermal insulation protects the wall from alternating freezing and thawing, aligns the temperature fluctuations in its array, which increases the durability of the supporting structure.

Disadvantages:

The dew point turns out to be in the insulation layer, which inevitably leads to an increase in its humidity. Salvation is the use of heat insulators with high vapor permeability, due to which the moisture that fell inside the layer is freely evaporated from it.

The outer thermal insulation layer has to be protected from both atmospheric precipitation and a mechanical impact of a durable, but vapor-permeable coating (a device of the so-called ventilated facade or plastering is required).

Weighing all the pros and cons of each of the three options for the arrangement of the insulation, the authors of the project came to the conclusion that outdoor insulation followed by facing with artificial stone and partial shuttering is the rational solution from all points of view.

The order of work on such insulation is the following. The protruding edge of the foundation or the edge of the overlapping slabs can be the support for the first row of the thermal insulation material. If there is no such support, then with the help of dowels, a fold-based or wooden reference rail is installed (wooden before plastering is removed). The glue consumption, for example, for the base in the form of brickwork is from 3.5 to 5kg / m2 and depends on the irregularities of the base. The insulation plates are closely close to each other with the dressing of the seams, as when laying bricks. It should be fixed with the plates mechanically, using plastic spacer dowels with a stainless metal rod.

If in the future it is planned to plain the facade, then with the described method of insulation, there is no need for the use of vapor and wind-insulating materials, the first carrying structure will be replaced by a sufficiently high steam-resistance coefficient, the second layer of vapor-permeable plaster. Small quantities of water vapor, nevertheless, caught inside the wall (which is inevitable), will be unhindered to outwardly through the layer of insulation and plaster.

What material to choose?

For the implementation of the scheme described above, two types of efficient thermal insulation materials can be used: mineral wool and type of polystyrene foam.

Let's start with mineral wool, that is, stone and glass gambles. Experts so formulate the requirements for this material:

1. The controller must maintain its initial geometric dimensions (not to give shrinkage and not to settle) throughout the life. The thermal insulation materials produced in such a way that the fibers are not located in the same direction, but chaotic.

2. Auditable vapor permeability is not less than 0.3 mg / (MCPA), water absorption is not more than 1.5% by volume.

3. Treatment material for each of the schemes under consideration is selected in accordance with the conditions of its operation, which determine the requirements for the density (it is it affects the strength of the material for compression), vapor permeability and tensile strength of the layers (the effort that needs to be attached to the outer layer to tear Its from the rest of the mass).

Now about expanded polystyrene. The thermal conductivity of this material is lower than that of mineral wool insulation (which allows to reduce the thickness of the heat insulation layer), and it costs cheaper. Its disadvantages are smaller vapor permeability, a large labor-intensity of work (it is harder to fit into the size during installation) and a higher combustibility (expanded foam of self-fighting combustible materials). The latter circumstance causes difficulties when installing:

Around the window and doorways should only be used mineral wool;

It is necessary to arrange fire protection (150mm height) from mineral wool at certain intervals in height.

It is no less clear expanded polystyrene foam is quite widely used for the insulation of facades: it costs 3-4 times cheaper than mineral wool.

Requirements for this material:

Density 15-25kg / m3.

The structure should be dense, the granules are firmly related to each other (in a loose material above the water absorption, and the different granules in size, poorly related, is the right sign that the material will quickly undergo, as experts say, "physical destruction".

The plates must have accurate geometric dimensions of the length and widths in excess of 2mm, the thickness difference is more than 1mm, the non-plates of no more than 0.5% (the more accurate the dimensions, the less time is spent on the fitting of the stoves).

The permissible linear shrinkage is not more than 0.2% (the plates are withstanding without packaging for at least weeks).