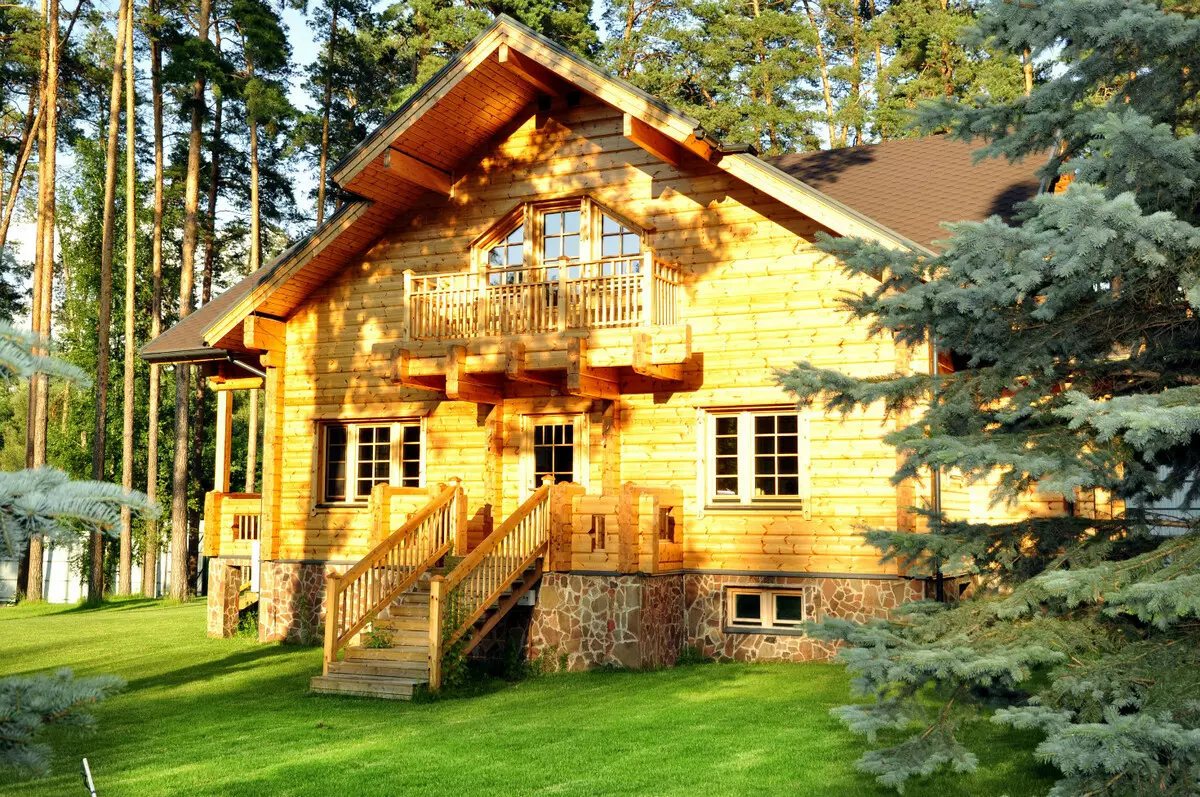

The procedure and the choice of mothers depends on the qualities of the tree as a building material. We will tell you more about how to make a wooden house cozy.

Benefits and disadvantages of wood

Photo: Depositphotos.

The tree is chosen as a building material due to its indisputable advantages. It has high strength, but relatively low density, so it is treated with cutting tools. The tree is well holding heat and does not skip third-party sounds. It is glued, painted, lacate, polished. It is resistant to the effects of acids and alkalis. Beautiful texture of wooden surfaces creates comfort and comfort in the house.

However, like other building materials, the tree has drawbacks. When drying, the sizes of wooden elements are reduced, and under the action of moisture, on the contrary, increase. Due to uneven removal of moisture in the wood, mechanical stresses arise, due to which cracks appear. And finally, the tree is afraid of fire, insect-tree and fungi. These features of the tree take into account the construction of buildings and subsequent decoration.

General rules finish

Covering the inner surfaces of wooden walls with finishing materials is not necessary. They are used to insulate the premises, or if the bar or logs look unesthetically. If you close wooden walls, keep in mind: the technology of this process differs from similar to concrete and brick walls. Differences are dictated by wood properties.Let's start with general recommendations:

- In order to avoid deformations of covering materials, the trim starts after the end of the active shrinkage of the house;

- Before finishing the wall is poverty;

- so that the mold is not formed in the house, the air passing materials are used (when using hermetic materials, forced ventilation is assembled, but this leads to additional costs);

- In small houses to prevent exceeding the calculated load on the foundation and walls, lightweight materials are used;

- Concrete floor is made according to the fact that concrete after drying becomes a fixed monolith, and the tree continues to move the entire service life of the house, which is why deformations and damage to structural elements are possible;

- The old wall is preliminarily assessed in the old house. Pay attention to the sections that differ in color, density and texture;

- If the wood crumble, it destroys it from the inside. For example, her point of beetles, wood ants or it rotes from dampness. In such cases, refer to the specialists of the construction company engaged in the construction of wooden houses. They will determine the cause of damage and help them eliminate them.

What is shrinkage and when does it end?

Shrinkage is a sealing of the compounds of the structure that occurs under the influence of its weight. Shrinkage reduces gaps between logs or a bar, making the house stronger.Shrinkage occurs throughout the life of the house, but most intensively - in the first months after the construction. The duration of the active period depends on the tree of the tree, its humidity at the construction stage, thickness and type (rounded log, normal or glued bar), the time of year in which construction works were conducted.

A wooden house with a height of a series of 3 meters, built from a conventional log, in the active phase settles about 10 cm, from the incompeted timber - by 6 cm, from a bar dried in a special chamber - by 2.5 cm.

During the actively shrinkage, finishing works are not performed not to deform and not damage materials. After its end, the change becomes insignificant and do not affect the finishing work.

On average, the shrinkage shrinkage of wooden houses is as follows: The house from the glued bar ends the shrinkage after 3-4 months, from the usual bar and logs - at least one year later.

The end of the active shrinkage is determined by measuring the height of the walls. If within 1-2 months when measuring tape measure, the height does not change, shrinkage ended.

Why canopate walls?

Photo: Depositphotos.

Walls canopate to eliminate the gaps between the logs or the bar and increase the heat shield of the house. As sealing materials use a jute cord, felt, pass, moss, flanutin and other materials.

Jute is durable, he does not damage insects, he does not rot. But it is flattened, which is why the gaps between the logs are formed again. Some masters claim that the jute cord is not at all insulating material. Therefore, it, they say, is used with internal finishing as a decor, and between the crowns are laid "real" insulation.

Pacle has a low thermal conductivity, is not susceptible to fungus, but labor-intensive in work, and the seams treated with it have an inesttic form. In addition, the passage is plucking the birds when they come with nests. Punch protects from feathered, sheathing walls outside with clapboard.

Felt keeps warm and does not miss odors. Of the minuses - it is susceptible to rotting and is damaged by Mol.

Moss has antiseptic properties, durable, but it is like a pass, love birds.

The best material for the cacopa is sisal, which is made from the leaf leaves of the Agava growing in countries with a subtropical climate, and the so-called "Manila Rope", made of Abaki fibers (plants of the banana family). But these materials are more expensive than the above.

Breed walls canopate twice: after a couple of weeks after the construction of a cut and a year after the end of the active phase shrinkage. Houses from the profiled bar are cavalous once - after the end of the shrinkage.

Canopate outside and inside. Start below. To avoid skewing walls, processed the crown on one side and immediately go to the other side.

After the cacopa, the house becomes above several centimeters. But over time, the material laid between the crowns is condensed, and the structure will fall. It is at the expense of this compaction that its thermal insulation properties increase.

To fix the end of the shrinkage after the cacopa, the height of the walls is periodically measured. Shrinkage is considered suspended if the height does not change within two months. So you can start finishing.

What materials are used for interior decoration?

The most common finishing materials are lining, wall panels, plasterboard. They skip air, preventing the formation of mold and the appearance of fungus.Regardless of the selection of wood, it is pre-protected from fungus and mold by antiseptic compositions, and fire resistance increases with flame impaired impregnation.

How to fix finishing materials?

Fasten materials on the surface of the walls or on the frame. The second option allows you to put the thermal insulation material, hide the wiring and create a space between the wall and trim to circulate the air and dried by the walls.

Between the walls and the ceiling leave the gap of 2-4 cm wide in case of deformations and seasonal skills of the structure. The clearance is closed with ceiling plinth.

If the framework is used, rodents and insects can be started in the space between the finishing stove and the wall.

The mice under the finish is placed by the EcoWhat layer, which these "cohabitants" do not like. To protect the wiring from their sharp teeth, the wire is placed in metal pipes.

To protect the house from tree beetles, the walls are treated with antiseptic compositions that contain biocides. These impregnations are deeply penetrated into the structure of the tree, creating a protective layer, through which pests do not penetrate.

Ants on antiseptics do not react. From them, the house is protected at the construction stage, packaging in a small grid the first crown of a church.

Clapboard

Photo: Depositphotos.

The lining is thin sheaving boards connected to each other on the principle of "spike-groove", that is, the protrusion (spike) of one board is inserted into the recess (groove) of the other. For years ago, the inner walls of passenger cars were crushed by such skids, from there and the name went.

By profile, the lining is divided into ordinary and Eurovantia. Wooden eurry card is equipped with longitudinal ventilation strips to remove condensate. In addition, it has a deeper groove so that when drying, the gaps between the boards do not occur.

Wooden lining, if it is dried by natural drying, gives shrinkage, because of what the gaps appear. The lining dried in a special chamber furnace, a visually significant shrinkage will not be. Conclusion: Get chalks of chamber drying.

Fasten the lining with nails, screw screws or on the chipimens.

Fasten perpendicular to the crate frame. Horizontal casing visually expands the room, the vertical makes the ceiling above.

When horizontal workshop, work starts from the ceiling, directing the grooves of the boards down so that dust is not stuffed there.

Vertical trim lead from the corner. The first board is fixed with nails, subsequently closing the place of attachment site with a decorative plank.

The last board is also nailed with nails, closing the decorative plank. Such straps, decorative corners and plinths are closed with all external and internal angles and joints.

The lining is covered with primer, then paint or varnish.

Finishing with wall panels

Photo: Depositphotos.

Wall panels are used when finishing large rooms. They are easy to assemble and allow you to quickly cover large areas. Designers love them for a variety of colors and textures that allow creating various accents in the interior of the premises.

Size distinguishts, tile and leafy panels. According to the manufacturing material - wooden, bamboo, panels made of fine fractions of wood (MDF), chipboard (chipboard), glass, plastic, leather.

In a wooden house with natural ventilation, air-permeable panels are used: wooden, MDF, chipboard. These materials prevent the formation of mold.

Glass - heavy material, it is not used on thin partitions. In addition, the glass does not skip air.

Plastic panels air permeable, are not afraid of damp, temperature drops. Release options "under the tree" that appropriate look in a wooden house.

Leather panels also "breathe". They give the room a special chic and luxury, so not in every wooden house look organically. In addition, they are roads.

Fasten the panels on the frame or on the surface of the walls, if it is smooth. Molding methods depend on the material. Light panels are glued or planted for brackets, heavy nails are nailed and screwed up with self-draws.

Features of the use of plasterboard

Photo: Depositphotos.

Plasterboard is a gypsum stove, which is placed on both sides with a dense cardboard. Plasterboard sheet can be cut, saw and stag.

Clean the walls with plasterboard, observing the following rules:

- Mounted on floating (sliding) frame. With a shrinkage, it does not change the height, so the plasterboard sheets are not deformed and are not damaged. This method is used when finished at the end of the active phase shrinkage, since the wooden house is subject to seasonal progress.

- Sliding frame make so. Vertical frame racks are not addicted to the floor and ceiling, but with a gap of 4-5 cm on top and bottom. In the profile, the vertical grooves are 5 cm long, which screw the fastening screws on the washers, but not "tightly". If the wall goes down, then screwed into it will slide along the groove up, and the frame with the sheets attached to it will remain on the spot.

- There are 2 mm gaps between the sheets of drywall - again as insurance on a possible movement of various sections of the walls. The gaps are smeared with putty.

- Plasterboard sheets are painted or covered with wallpaper, pre-sawing the joints.

How do concrete floor in a wooden house?

Photo: Depositphotos.

Concrete floor has advantages over wooden. The latter creaks, buys, pulls cold from him in frosty days. Concrete deprived of these shortcomings, and any coating can be stacked on it.

Concrete floor in a wooden house pour:

- for an earth basis, if lags were rotten;

- on top of the lag, if the lags are strong;

- On top of a wooden floor, that is, make a tie.

Wooden house Even after the end of the active period, the shrinkage is subject to seasonal movements, so concrete floor is made without a tight connection with the base, leaving the gaps between the concrete and the walls.

Paul on Earth

Before the fill on the floor, the lands are removed, the soil falls asleep with gravel or rubble. On top of a powder sand. Then weaving the waterproofing material, for example, polyethylene for greenhouses, with a wall at the walls above the future floor.The waterproofing is placed on the waterproofing, sharing the surface on the strip 1m wide. The bands are poured with concrete, leaving the gaps along the walls in case of deformations, then make a screed - also with gaps, or dry.

Paul on lagha

Before laying the floor, on top of the lag, the space between them is filled with sand or gravel, tamper and poured concrete. Then make a screed, as in the previous case.

Screed on a wooden floor

The screed on the wooden floor is made after its careful preparation. Plinths are dismantled, looseled boards attach to lags by self-drawing, the cracks close up acrylic putty. The gender is then covered with waterproofing material on the walls, poured waterproofing with a leveling screed with a thickness of at least 5 cm with gaps between the walls.The finish coating is laid on the tie: linoleum, laminate, parquet, boards.

Finishing the ceiling

Photo: Depositphotos.

For ceiling decorations, plasterboard are used, plastic panels, MDF panels, wood wall panels.

The ceilings are mounted from two layers of the trim material. There are insulation, steam and waterproofing between the layers. The main types of structures are stitched, flooring and panel ceilings.

The cable ceiling is attached to the beams of overlaps with the help of bars or racks. Small irregularities eliminate, laying wooden wedges under the crate. Wiring hide under the trim.

The flooring ceiling is mounted on the crown of a cut, and not on the beams overlap. Apply with the arrangement of the ceilings of small square. Make a thickness of 1.0 cm thick. On the boards, hydro and heat insulator are laid.

Panel ceilings are made of panels. Collect them on the floor. Then installed on the bearing beams, fixing again with each other. As a result, a one-piece design is obtained.

So, you now know that the interior of the premises in the wooden house has features. They are due to the properties of wood as a building material. If you consider them, the wooden house will serve you for a long time without repairs and alterations, and it will be comfortable and cozy at any time of the year.

The editors thanks the company "Repair Express" for help in the preparation of material.