Features of the Canadian construction technology on the example of the construction of a two-storey house with a total area of 299 m2. The story of a frame house-building, the differences between the Canadian technology from the European

Once, among the proposals to build a house on Canadian technology, we caught somewhat non-standard: "This Canadian House". What is this advertising trick? We called on the announcement and heard: "The house is really Canadian, there it was made, and then brought here, and here it will be assembled." We simply could not visit such a construction site. AO is the fact that they saw it, told in this article.

The term "Canadian houses" because of its advertising attractiveness has recently become in Russia some kind of vague ... So, without thinking, they call the buildings built according to various technologies. What is he, really canadian house?

Why is the frame house called Canadian?

When thousands of European immigrants went to conquer new lands of America and Canada, the framework technology survived the second birth and was somewhat simplified. Racks, beams and disclosures of a significantly smaller cross section than in half-timbered structures, began to sow on two sides by boards, and cavity - poured with a soft sweater material (for example, hop cones). Conditions of gradual migration of the population from East to West, such a carcass turned out to be very by the way: the technology allowed to fully disassemble the house, fold it on the carts, and then collect in a new place. Judge, after it disappeared the need to travel along with the housing, people habitually continued to build buildings on a simple and economical framework, which came across America and Canada and exist here for several centuries.

|

|

|

|

1. For a high level of groundwater occurrence builders built an unusual foundation: created a warmed waterproof monolithic slab (engineering communications were laid under it), on top of which tapes and support pillars made of bricks.

2. And the top was leveled with a concrete tie: it was flooded with a removable formwork, held on the wall with steel spring brackets.

3. The first columns on the waterproofing layer laid the composite "main" floor beams.

4.Cyrpic basement tape through a layer of waterproofing anchor bolts attached an antiseptized strapping board.

CHXXV., After World War II, a sharp jump occurred in the development of technology of frame house-building. People needed housing, and the skeleton wooden house allowed many to solve this problem. The growth in demand has stimulated new developments. The government of Canada has invested in them huge funds at the time and continues to do it so far. That is why most of the latest methods and equipment used now for the construction of frame wooden buildings, invented and first embedded in Canada. Feature such houses around the world canadascular, the term is fixed by the design, and not behind the manufacturer. From Canada, the framework technology fell into Europe and again perfectly passed on there. At the same time, Europeans were not just borrowed, but improved the Canadian version. As a result, two concepts of construction of frame wooden houses coexist in the world.

|

|

|

|

5-7. Suitable beams and blockage steel support for the frame of the overlap platform from the board of 23538mm (it is intensified by wooden struts around the perimeter). The frame was put on the frame with a solid flooring from the OSP-slabs with a thickness of 18mm.

8. On the flooring of the OSP-slabs caused marking, facilitating the assembly of frame elements into a single design and its installation in place. The first collected design has become a large wall of a two-sweat living room with many windows and a bomber.

Two ways to one goal

Modern varieties of framework technology construction of houses can be divided into two groups: frame-frame and frame-panel. For the first embodiment (in a different way, it is called open panel technology) from the factory, a set of collected frameworks of panels having a trim with one side-outdoor is supplied. Roof and overlap farms are also brought with flat gear plates. From the panels and farms at the construction site, the framework of the house is collected, which is then insulated (at the same time, the insulation from the inside is protected by vaporizoation and trim). Builders team builds a building area of 200m2 for 1.5-2 months. Framework technology (it is it considered to be classic) gained distribution in the USA and Canada.

The frame-panel option (or the technology of closed panels) is characterized by the fact that the factory supplies completely ready-made panels of walls and overlaps. They are also assembled on a wooden frame, but insulated and trimmed from the outer and inside. On the construction site, these panels remain only to be copped with each other. Collect the house of 200m2 in this way it is possible for 1.5-2 weeks. Frame-panel technology is popular in Europe.

Pneumatic hammer

It is curious why in such an advanced country, like Canada, do not use closed panel technology. It turns out that everything is in very tough rules for acceptance of the house, which is performed by the Canadian State Inspectorate. This happens when the frame is assembled, the insulation is laid in it and it is covered with membranes on both sides (they form a solid carpet due to skinning the jacks of clothsch tape), but there is no internal sheathing. The inspector brings through each batch of panels and tracks its condition using a thermal imager. Not finding marriage, puts the signature under the act. The second stage of acceptance is carried out when the house is ready for delivery, and it is even more serious than the first. Install the "damper", equipped with a pump, which pumped out air, creating a vacuum. The inspector notes, at what speed the air flows back through the slots. If this happens faster than it is supposed, it does not sign an acceptance act. Is it important to have under documents a signature inspector? There will be no signature, the bank will immediately stop financing construction. Hard? But very effective! And in Europe there is no such severe check, therefore the technology of closed panels is dominated here.

|

|

|

9-11. Theten was collected from several elements and fastened a moisture insulation membrane (9) on it so that the latter covered the overlap frame (10). The wall was attached to the flooring (11).

House of container

So, the real Canadian house is a structure collected using a set of frame-frame and frame panels and rafting farms of factory manufacture. You can order such a set using a typical project (it is cheaper, since there is a necessary production documentation) or an individual (the second option is naturally more expensive).

I must say that in Canada, large house-building firms are trying not to be limited to supplying a set of panels and with it they offer to purchase windows, doors, insulation, moisture and vapor barrier films, OSP-plates, plasterboard, roofing material IT.P. Buy everything in one place is beneficial not only because wholesale cheaper. The owner is convenient, because one company is responsible for delivery. Ithem who will collect the house, it also fits. The masters open a container brought in the car (parts for the house with an area of 200m2 occupy three or four such extensions) and with the help of a scanner similar to the one that is used in supermarkets, barcodes from each part are read during unloading with packaging conducted. As a result, they know exactly how many products are brought and what it is.

This was done by the builders of Weisroe Home Distribunysh (Russia), having received containers who arrived from outside the ocean with a set of details, which was manufactured by Viceroy Homes (Canada). Our further story is about how in the village of the village of them housed an area of 299m2. Moreover, most of this process is shown in the photographs, and the text describes only the distinctive features of the present Canadian home are described.

|

|

|

|

|

|

12. After a thorough leveling of vertical, the panel was fixed in this position using temporary wooden ships, brought by one end to the panel frame, others attached to the flooring.

13. Installing the panel to the place allotted to her facilitates pre-applied to the flooring overlap.

14. The press was collected and installed in the upright position the next panel. Its frame fastened with a frame already mounted, applying nails with screwdrough.

15-17. Panels behind the panel- and the external (15) (15) were first drawn, and then the inner walls of the house (16). At the junction of two or more panels, reinforced bearing elements have occurred. The most powerful carrier support was the framework of the plating of the future fireplace (17).

Characteristics

Feature 1: Foundation. The most frequently used in Canada (and recently in Russia) the type of foundation is a lightweight small-breeding belt, and the monolithic reinforced. The tapes in it are located only under the outer walls (around the perimeter of the house). Powerful columns (the distance between them is no more than 3m) serve as a support of the inner walls. The height of the ribbons and columns are chosen with such a calculation so that in space under the overlap could relatively freely move the person.

Creating such a "techpodolone", pursue two goals. First, being in it, the workers will mount the insulation (the latter can only be laid after the frame and the roof of the house are ready, otherwise there is a risk that the material is wary). Secondly, it will give an opportunity at any time to inspect the designs below the level of overlap.

|

|

|

18-20. When the walls of the first floor were completely mounted, the workers under the leadership of the Canadian specialist began to install a power frame of overlapping, which consisted of longitudinal and transverse beams (18) and the support of the poles (19). The beams are made of LVL wood glued from thick veneer (resembles Paneur), racks - from PSL wood glued from thin chips (20).

In the case, such a foundation could not be erected due to the high level of groundwater. Therefore, designers and builders applied the original solution: built a monolithic insulated (using extruded polystyrene foam 80mm thick) plate, the base of which was at a depth of 0.7M (about the device of such foundations, see "IVD", 2008, N 11), and then on She was laid out of brick ribbons and pillars. Before starting the assembly of the house, on the tapes outside the waterproofing layer applied. It was tied with a layer of waterproofing under the foundation slab, and thus fully protected the space "TechSeproi" from the penetration of soil moisture.

Feature 2: Housekeys at home. In Nakanad, a non-metric (inch) measurement system is distributed. This imposes an imprint of the size of not only the buildings itself, but also dried to humidity of 15% of sawn timber. So, the frame of the bearing walls is created from the boards 14038mm (62 inches), the frame of partitions and the rafter farms - from the boards 89g 38mm (42 inches), the beams of overlapping (including the flattening, which are collected in place) - 23538mm (102 inches) .

It is curious that the frame was not processed. For the dried material, this operation is considered practically useless: after 5-6 years on the tree, there is no trace of any impact on the tree, and it will not be able to re-conduct it. The exceptions are wooden parts that are on the street (beams and terraces), and also in contact with concrete (strapping board): They are still impregnated with organic biocide (quaternary alkaline copper).

|

|

|

|

|

|

21-22. Kleken racks builders were easily installed manually, and for lifting heavy longitudinal beams from LVL wood (21), a winch took. The transverse beams (22) in the section are significantly less than longitudinal and therefore easier, and the workers raised them too manually.

23-26. After the power frame of overlapping was mounted, the workers laid the beams-lags with a cross section of 23538mm. One end of their end was based on the wall, the second was fed to the beams of the power frame using metal elements and self-tapping screws (23,24). On top of the flora frame, there were osp-plates with a thickness of 18mm. At the same time, the wooden struts of two types were installed in the middle of the spans between the beams for rigidity (the type of space required was defined at the design stage): lightweight cross-forming (25) and solid (26).

Feature 3: Use glued materials. The outer walls panels are squeezed by moisture-resistant OSB-plates (Oriental Strand Board, Russian abbreviation-osp, i.e. oriented chipboard) 15mm thick. These plates are also used to create flooring and roof flooring (thickness 18 and 16mm, respectively).

The reference pillars for the overlapping power frame are made of PSL-timber (Parallel Strand Lumber) - material from pressed and glued parallel wood chips. Embossed beams of overlappings and skate runs are made of LVL-bar (Laminated veneer lumber) based on a glued veneer with a parallel or perpendicular location of the fibers in the layers (the direction of the direction determines the properties of the material).

Well, what do you say? Canadians will protect their forest, instead of wooden elements (including powerful power) successfully and widely used glued materials made from almost the fact that we are familiar with the waste.

Feature 4: Insulation. We will not say what exactly the insulation use other Canadian manufacturers, and in Viceroy Homes homes use Johns Manville (USA) based on fiberglass. Its thermal conductivity is 0.04W / (M C). The breather of the insulation includes 20% of the secondary glass, but there is no formaldehyde, it replaces its binder on the basis of acrylic (the material has a natural white color). The thickness of the insulation in the outer walls is 150mm, in interior partitions - 100mm, in inter-floor overlaps - 200mm (in the ceiling of the first floor - 216mm), in the roofing "pie" - 400mm.

|

|

|

|

|

|

27-28. To facilitate and make safer work on the installation of panels for the walls of the second floor, mounted the staircase, which, like the panel, was delivered to the container, but disassembled. After the end of construction, it is cleaned, polished and paint - in this form and the owners of the house will receive. If they want, replace themselves. The Apokok workers will raise the panel on it and mount the walls of the second floor (28) by the same technology as the walls of the first.

29-32. The docking of the vertical panels between them was paved with a Polytarp-Super polyethylene layer (29.30). This material is so environmentally friendly, which is also used for the manufacture of tourist equipment and packaging products. When they prepared for the installation of the panel for the walls of the second floor, the moisture insulation membrane on their lower part was fixed with the nasha (after installation, it covers the ends of the blocking shield) (31). Drinks, retaining panels in a vertical position (29.32), removed only after the end of the roof mounting

Feature 5: insulation insulation. In order to preserve the properties of the insulation, it should be reliably protected from purging and penetration of moisture. Before installing the panels in place, the sound-hydro-proof membrane Tyvek Homewrap (DuPont, USA) is fixed on the outside. After the end of the assembly of the joints of the panels is sick with a special scotch. From the inside, the insulation prevents a layer of vaporizolation. It is a canvas woven from thin polyethylene strips and laminated with film from the same material on both sides. As a result, the insulation turns out to be as sealed in the wall. Due to this, the so-called thermos effect arises, providing high heat-saving characteristics of the structure.

About Russian Swamp

When assembling panels in a single design, perhaps the most difficult to close them to each other, to then beg, applying a pneumatic gun with screw nails. It is possible that for this in Canada there are some special tools (screw manual or mechanized clamps IT.P.). Away of our conditions for this purpose, a set of three original lever clamps was used. The welder made it from the reinforcement with a diameter of 30mm directly at the construction site literally for 15 minutes. It turned out and cheap, and a fairly effective tool.

|

|

|

But no matter how qualitatively, vaporizolation, water pairs (they always stand out in the process of human activity) is sooner or later they can nevertheless penetrate inside the insulation. It is in the framework of frame houses that must be installed forced supply-exhaust ventilation. Thus, in Canada, a complex air heating system is usually used, including ventilation and air conditioning. However, domestic developers still refuse to apply such equipment, motivating it its high cost and high levels of the noise published. They are rejecting mechanical ventilation systems, limited by the device of natural hoods in the bathrooms and the kitchen. Azry: After 5-7, the moisture is accumulated in the insulation, it will lose its properties, and the frame will start rotting.

Feature 6: Layout. The internal layout of Canadian houses also has its own distinctive features. For example, there are rooms, called Loft. What it is? LOFT translated from English means "pigeon", "attic" or "Senal under the roof". The whole of this term began to sign a special (and not cheap) type of dwelling, re-equipped from the former workshop or warehouse. Canadians also refer to the so-located space of a kind of interior balcony. It is there that a person falls, climbing the stairs, and then - in any of the rooms of the second floor. Housing such a room is not and serves as a kind of living room. From here you can see the interior of the house, in particular, to ensure that it is happening in the representative zone on the first floor (for example, without breaking away from work, watch the children playing there).

|

|

|

|

|

|

|

|

33-34.In the layout of the built house we found one very significant, in our opinion, disadvantage: the walls of the second floor in some places rise above the ceiling level of only 60-70 cm. As a result, the undercutspace adjacent to them has a very small height and can be used except for creating storerooms (33.34). This layout is traditional for Canadian houses in which the second floor area is significantly less than the first.

35-38.stropyl structure was collected from finished farms: W-shaped (35), triangular (36) or flat-parallel (37), in the most responsible places they were made dual. IMPROVE SPRAIN over the veranda (38) was created by a construction method.

29-40. The surcycle rafal was laid down from OSP-slabs, a layer of waterproofing was placed on it, and then-soft bitumen tile (39). The pitch of the roof adjustment to the walls in each row of tiles was installed metallic tint (40).

Feature 7: windows. There are single-chamber windows with argon filling and soft selective Low E2 coating. These windows in the United States and Canada are assigned an Energy Star sign, indicating extremely low heat lines associated with them. Of course, panoramic glazing, made using even such windows, needs additional heating. But for this, it is enough to establish ineplex convectors under them.

Feature 8: attic. As it is neither paradoxically, but in the Canadian house, the affiliated roofing is used only in cases where it is not possible to solve the problem of ventilation of the undercase in a different way. So, in the house under consideration, it was created only over a two-lifestyle living room. The apode is mostly a multi-line roof due to the considerable height of rafting farms and insignificant compared to it the thickness of the ceiling of the ceiling between the farms of the insulation (400mm), an attic space arose. It is the attic space, and not a attic: to move here it is difficult to interfere with the farms towering over insulation installed in 400mm increments. Ventilation of this room is carried out by a classic method - auditory windows or grilles embedded into the fronttones.

|

|

|

41-43. To install the Canadian plastic window, builders only need to insert it outside the house in the opening, align and secure self-taverns (41), and then booze the clearance: on the window profile around the perimeter there is a perforated edge, and the mounting plates (42) . By installing the windows, the builders have begun laying the insulation, which covered with vapor insulation. On top of it mounted laid in color PVC communications (43)

Feature 9: documentation. Engineering communications pipes are laid directly under thin drywall. Therefore, the owner in the composition of the documentation on the house is not only the heat and energy passport (it contains the heat-stations of the structure and its power consumption), but also the instruction manual for the building. Twin contains information about the location of the hidden elements of the frame, cables of wiring, engineering networks IT.P.

|

|

|

|

|

|

|

|

44-49. Engineering communications laid not only on the walls, but also in the ceiling (44). The center, which converges the heating pipes, was the boiler room (45), where the usual gas boilers were installed instead of air. From the inside of the house to the wooden frame, galvanized profiles (46) were attached and crushed them with plasterboard (47), sissing communication. Outside the base was insulated with extruded polystyrene foam (48) and created a warmed gentle. The springs of the porch and the veranda were leveled with a concrete screed (49).

50-51. According to the request of the Customer, the wall outside was additionally insulated with extruded polystyrene foam (layer 30mm), which was placed on a plastic grid, and then tied with artificial stone (50,51). The frontones were covered and covered with light facade paint.

Feature 10: Question price. The cost of 1m2 of the Canadian house is 27900 rubles. Ito, taking into account the design (900rub. / M2), manufacture and delivery in containers across the ocean (13500rub. / M2), Foundation devices (3 thousand rubles / m2), build buildings (3 thousand rubles / m2), engineering gaskets , including electrician, plumbing, hot and cold water supply and water heating system with a universal boiler (3 thousand rubles / m2), as well as facade (1500rub / m2) and interior decoration of economy-class (3 thousand rubles / m2).

Most likely in Canada, 1m2 is still less such a house, which means that they have already decided the issue of affordable housing. Maybe if you introduce an independent rule of quality of construction, we will also have an affordable and decent accommodation?

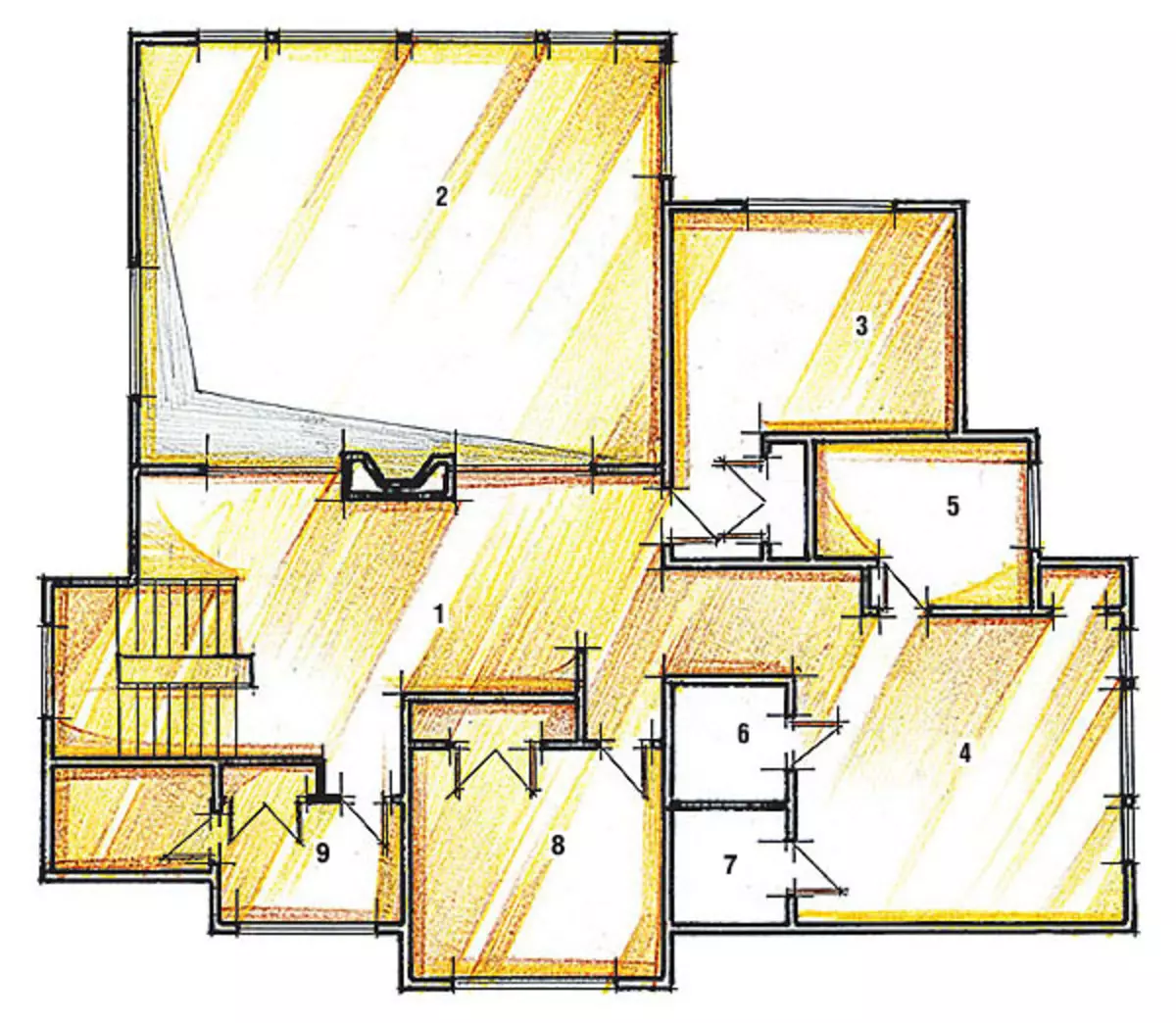

Explanation of the first floor

2. Tambour ........................................................... .6,9m2

3. Toilet ................................................. .3m2.

4. Cabinet ............................................... .15m2

5. Hall ................................................. ......... 7m2

6. Living room ............................................... .47.9M2.

7. Restroom .................................... 22,3m2

8. Dining room ............................................................. 15.3m2.

9. Kitchen ........................................................... ....... 16,4m2

10. Hall ................................................. ...... 3,4 m2

11. Laundry .......................................... 4.1m2

12. Garage ................................................. .... 46,1m2

13. Covered terrace .................................. 9.9M2

14. Open terrace (optional) .............. 24m2

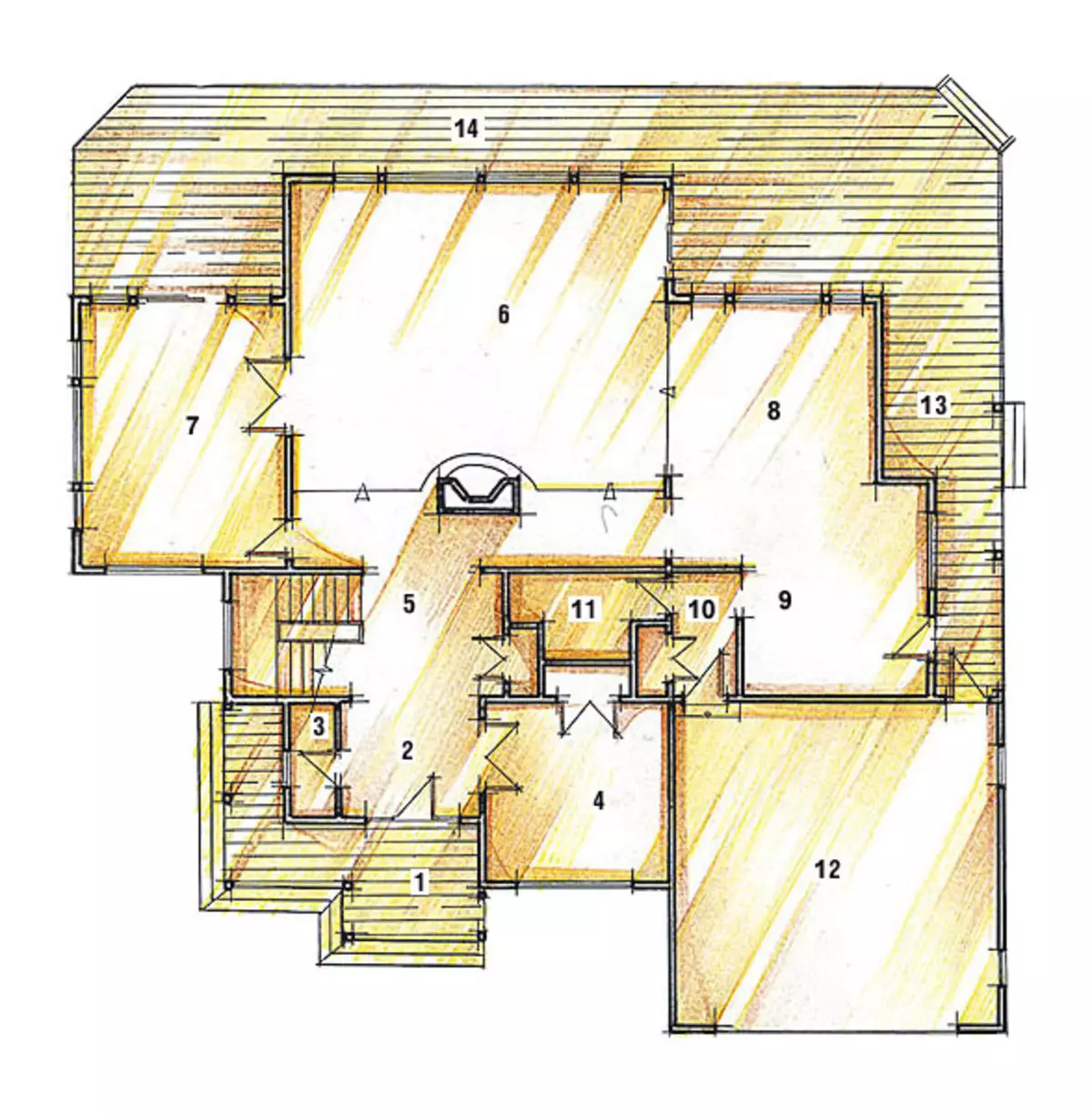

Explanation of the second floor

2. Second light

3. Bedroom ............................................... .17,2m2.

4. Bedroom ........................................................... .31,5m2.

5. Master's bathroom ........................ 5,4m2

6. Wardrobe owner ........................ 2.8m2

7. Wardrobe hostess ........................ 2.8m2

8. Bedroom ............................................... ... 14,2m2

9. Bathroom ............................................... ... 4,5m2

The editorial board thanks the company "Weisroy Hohamz Distribusch" for help in preparing the material.