Floor designs on an outdoor terrace: Overview of materials used for fixed flooring, base construction, Wooden items Protection

Architect E. Penshikisslovo "Terrace" We are accustomed to consuming in different values. This can also be called a spacious porch, and a platform with a garden fireplace, and a "pier" at the decorative reservoir be called near the house. To the "family" terraces conventionally attribute verandas and gazebos, balconies and loggias, as well as operated roofs. In all these zones, it is necessary to equip a durable, beautiful and practical floor capable of listening to open-air. (I will not immediately consider the option with a glazed terrace in the article. We do not consider as deprived of most of the street specificity).

Approaches to the construction of such sex a lot from the "bulk" road technologies and ending with the construction of a full-fledged structure with the carrying base, intermediate layers and a fixed coating. As for the latter, it must satisfy a number of requirements, but first of all be safe and resistant to weathering. After all, even the roof will not be able to fully protect the floor of the terrace from rain, snow and ultraviolet radiation. We decided to identify the story from the review of materials used for the first flooring.

Photo K. Manko |

Strher. |

DLH Group. |

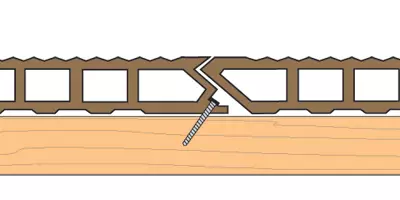

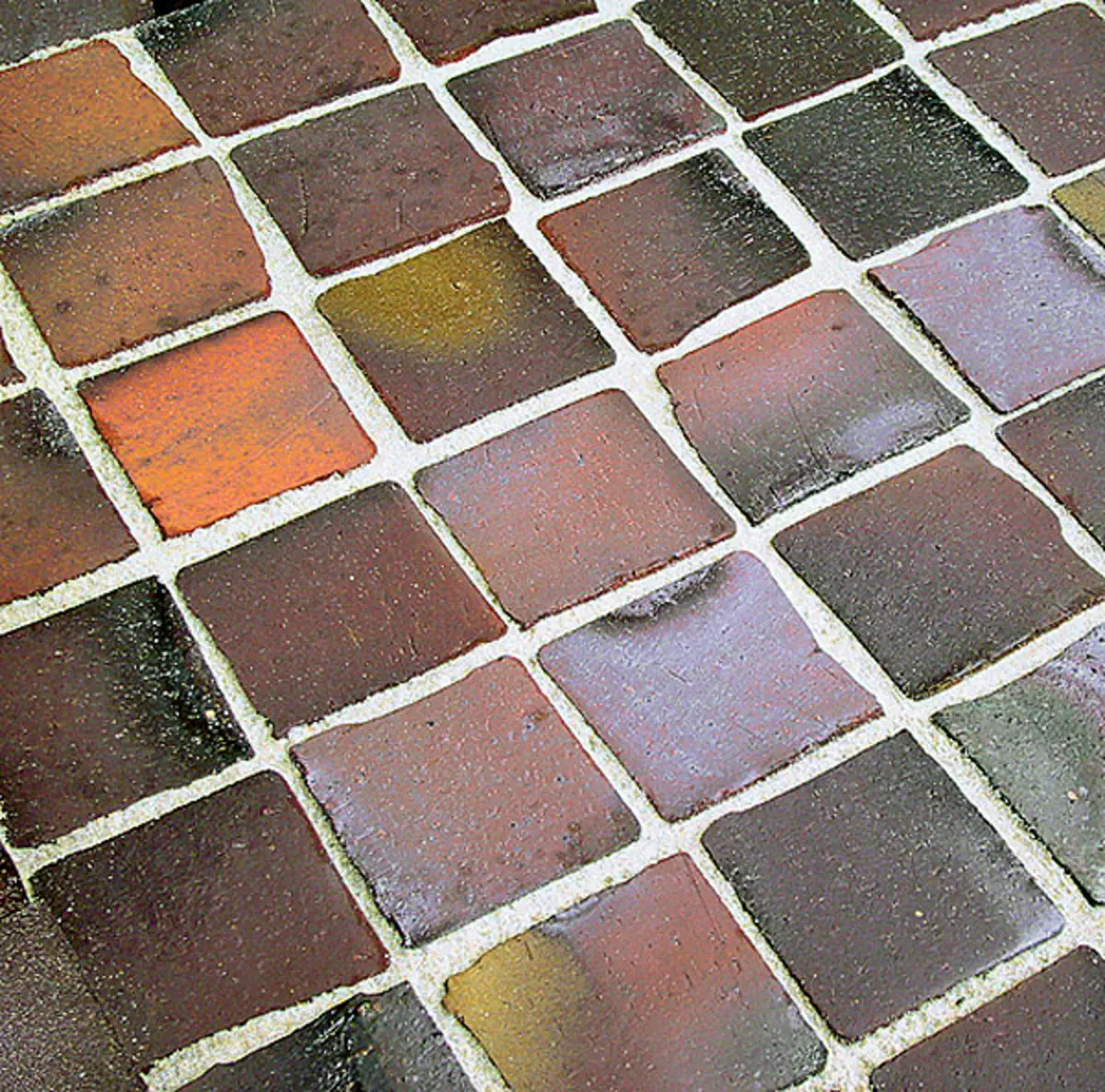

1-2.The tight tile (1) most often laid on a sandy pillow; Ceramic coating (2) requires a solid concrete base.

3. Sad parquet is easy to install and durable. Such a coating looks spectacularly both on spacious and small terraces, and it is nice to walk barefoot.

In a variety of accumulationThe most popular flooring for any rustic buildings remains a massive board. However, the usual pinned floor board made of wood of the most common coniferous pines and is felt suitable for flooring operated in the open air. It is susceptible to rotting and quickly loses its original gloss, and attempts to independently protect it with all sorts of paints and varnishes, as a rule, are unsuccessful. In addition, the drain floor creates the drain floor on the terrace (about which we will also describe below), and the puzzle of the water hinders the free flow of water through the gaps between the boards. Flooring flooring are relevant only on covered terraces, desired, it is desirable that the roof has wide overhaels. In this case, in this case, the slope of at least 1% is attached. Dry boards are covered with two-three layers of special paint or yacht varnish, and not only from the front side, but also with "insidious", and when laying, they do not share between themselves, but leave the gaps between them 3-5mm (otherwise the floor will certainly be in crude weather It will swell).

Millennium Decking. |

NES. |

DLH Group. |

4. The main board of DPK is perfectly combined with vinyl siding, it may soon be so affordable and popular.

5-6.Dextly flooring from the tropical tree species is able to become the core of the architectural or landscape composition.

For the street flooring, it is better to purchase special timber Terraced and deck boards . It's and others are often called Decking (from Eng. Deck- "deck"). Deck shot-smooth with rounded edges. The terrace has a corrugated surface ("velvet"), protecting from slip after rain. Her side is also provided with grooves wide, compensating internal voltages arising from moisture drops. The thickness of the boards of flooring is 22-40mm. A thinner board is designed for laying on a solid level base, and with a thickness of 27 mm and you can already use beams or lags.

NES. |

NES. |

NES. |

Photo K. Manko Designer I. Grustiny |

7-9. The ideally smooth floor of the parquet modules is easiest to be easiest using polypropylene screw supports, such as Buzon (Belgium). They do not rust and capable of carrying the load up to 1200 kgf each. The base with this installation method can serve as a reinforced concrete plate or concrete pillars (for each support), and on non-empty soils, fine gravel or the rammed sand.

10.Plock for the street should have anti-slip properties (be rough, unlawed). Sometimes it makes sense to lay the heating cable under the tile.

Terraced and deck board are made of wood-resistant to rot. The most available products from the Siberian larch - 1m2 boards of a variety AV thickness 32-35mm will cost approximately 800 rubles. Board of very dense wood of tropical breeds (Bangkirai, Garapa, Ipe, Itauba, Kempas, Merbau, Massanduba, Yatob Idr.) It is 3-4 times more expensive. In our market, these lumber offer DLH Group, Nes, Country Paul, "Redles", "Resource", "Scanner" (all- Russia) IDR. Such a board is extremely durable - for service life, it is comparable to ceramic tiles, although, like any other tree, under the influence of UV rays, changes color over time. Installation of flooring from exotic breeds of time consuming: such boards are quite difficult to saw and drill. However, due to the large mass of 850-1100kg / m3, it requires a high bearing base for them (when laying on balconies and console construction terraces, it is necessary to calculate whether the maximum allowable load on supports will be exceeded).

|

|

|

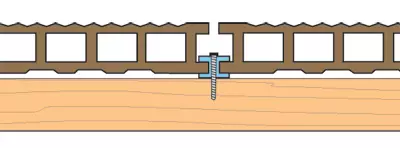

Decoping Mounting Methods from DPK:

11-specific metal or plastic clamps (COMPODECK, KLEINE WOODFIBRE IdR.);

12-sizing a puzzle connection (Millennium decking);

13-through "cliking" castle (Werzalit).

To the highest price category (from 8 thousand rubles. For 1M2) includes lumber from tick-rocks with a very beautiful texture, relatively easy to process and at the same time practically non-decumbenting.

In addition to the boards, some companies are "Labyrinth" (Russia), Hortus (Italy), Osmo Holz Und Color (Germany), DLH Group- produce and square modules called Garden parquet . These are scored from the planks (the base is a plastic grid) of a section of 300300 or 500500mm and 25-30 mm thick. A particular section is fastened by "cliking" locks located around the perimeter of a plastic base. Parquet with sections scored from identical parallel planks, according to the cost is almost equal to decoction, and modules with a complex pattern are about 1.5 times more expensive.

Opinion of a specialist

The cost of building a terraced floor of solid, resistant to rotting tropical woods always justify itself. After all, perhaps, no other material compares with such a beauty coating, and its service life is very long. However, it is very important to observe the laying technology of the flooring. No effort to use rust fasteners. But stainless steel hats do not adorn the gender, so we advise you to apply hidden fasteners or special plugs from the same tree breed as the board. Do not save on the support elements - logs should be made of the material no less durable than the flooring board.

The best composition for processing massive terraced and deck-based special oil protecting against ultraviolet radiation, as well as underlining color and wood texture.

Installation is better entrusted with an experienced specialist who will conduct an examination of the grounds and will recommend the optimal design of the floor. Only under this condition the potential of the material will be fully implemented.

Svetlana Pryzgin, DLH Group Sales Manager

Relatively recently, a new coating for terraced floors has appeared on our market. This board and parquet based on Polymer composite (DPK) . Similar products are produced by UPM-Kymmene (Finland), Kleine Woodfibre, Werzalit, Deceuninck (Belgium), Millennium Decking (Canada), Labyrinth IDR. DPK boards are extruded hollow profiles with 6-8mm thick walls, equipped with internal rigidity ribs; They are released 100-150mm width, 25-30 mm thick and 2-6m long. The input of the initial mass includes wood flour (50-80%), a binder (polypropylene or PVC), modifying additives and dye. The flooring from the DPK is not subject to rotting and cracking, sufficiently durable (the maximum permissible load is 500kg per 1m2) and is able to withstand the temperature differences in the range of + 90 ...- 50c. Thanks to all these qualities, the material is very durable - it provides a ten-year warranty, the real service life of the DPK, according to manufacturers, is at least 25 years. Profiles are always equipped with a fastening system with stainless steel elements, and Werzalit has a lock connection. If it is required to make flooring with waterproof, there are special frost-resistant rubber sealing tapes between the boards (they are in the range of manufacturing companies). At the same time, the floor is sure to give a small slope.

Usually boards made of DPK screwed to wooden lags laid with 400mm increments. Some firms offer assembly lags from the same material, however, they are only suitable for perfectly even bases (for example, concrete slabs), as it is not enough to be flex. The boards are allowed to saw as across (ends are closed with special plugs) and along. With the appearance of small mechanical damage or contamination with chemicals, they can be grinding with a grinding skin.

Strher. |

San Genis. |

Hagemeister. |

Hagemeister |

Hagemeister. |

Gres de Agon. |

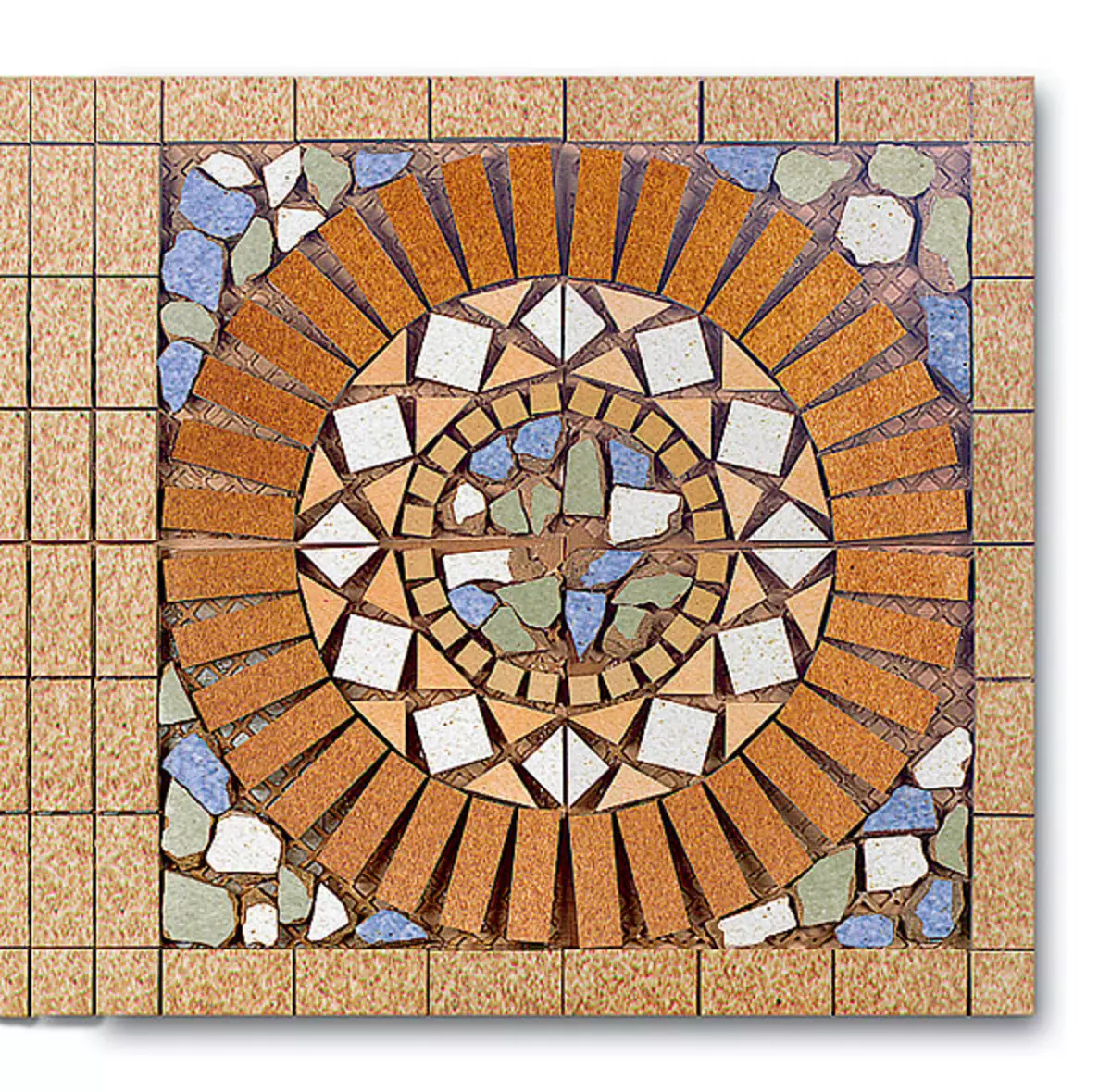

14-19. The modern market offers both a classic rectangular tile (14.15) and clinker of various colors and forms designed to create complex geometric ornaments and artistic compositions (16-19).

Externally and the board, and the parquet of the wood-polymer composite look very attractive. Although they do not have the texture of natural material, but they do not have bitch, resin pockets and other defects inherent in the tree. Ready modules made of DPK are painted in mass and do not require additional finishes. Color selection varies from three to seven. So, Kleine WoodFibre offers products of five tones: dark gray, red and three shades of brown, and UPM-Kymmene has even dark blue in the palette. The cost of products from DPK is 15-20% more expensive than Decking from the selected larch.

Ceramics for Street

The most weather-resistant floor covering is a ceramic tile. Choosing it, note that the water absorption of the material is no more than 3% (classes A I, B Ib according to ISO13006). The best option is a water stoneware or clinker with water absorption not more than 0.1% (class B IA). These racks are abrasion and withstand hundreds of freezing / defrosting cycles. Inspective conditions of the middle strip of Russia, they will serve in the outdoors at least 50 years. The variation of ceramic coatings is very wide: 1m2-600-4000 rub. and more.

From zero levelAs a rule, the terrace uses lightweight foundations. The simplest of them is the sand-gravity pillow with a thickness of 15-20 cm. Using such a base, the garden parquet can be asked (in this case, it is better to take a small river pebby as the upper layer) or to arrange a boardwalk in larch lags laid directly on gravel with sand.

However, on problem bubbly soils with a high level of groundwater, a more serious approach is required to build grounds. The most economical column foundation is most economical, with the erection of which the concrete supports are cast at the place or stick to the depth of freezing ready-made pillars, segments of steel or asbestos-cement pipes. The poles are laid by the beams. We advise you to use screw support fasteners. They can be made independently: the most simple variant is a heel with a length of 250-400 mm and a diameter of 14-16mm. It is witched in the post, supply nut and washer, and then put on her in advance drilled beam. Such supports are adjusted in height, which allows you to quickly and accurately set the beams at one level, and if necessary, to give the base to the water drain or eliminate the consequences of the possible sections of weakness of the weakness.

More expenses foundations from the monolithic reinforced concrete plate (as a rule, for the terrace sufficient thickness - 100-120mm). But for laying a natural stone-tile, ceramic tile and porcelain stoneware only such a base will suit.

Opinion of a specialist

Typically, the foundation for the terrace is quite easy to build it easy. Difficulties arise only on bubbly soils and mainly in cases where the terrace is attached to the ready-made building. With a "floating" foundation (tape or slab) to predict how to "coexist" a massive home and a light extension, not just. If you entrust the work of nonprofessionals, most likely sad consequences will not make himself wait. For example, after a year or two, the floor of the terraces can acquire a bias to the main structure, which leads to periodic moistening and, accordingly, reducing the service life of its foundation. AESLI The extension was supplied under the roof, "tied" to the wall of the building and at the same time resting on the pillars with a support for the foundation of the terrace, the whole design will almost certainly glance.

The base under the terrace must be erected in such a way that the movements of the foundations of the house and the extension are not affected by a friend on the geometry of the building. Most often, the easiest and profitable solution is to use adjustable supports (screw jacks), which are selected, based on the calculated load. In love case, the competent decision will be able to recommend only a specialist after the study of the soil, the foundation of the house and carry out appropriate calculations.

Damir Abdiev, Chief Engineer of Stroy-Bosh

Not a drop of waterOn the terrace should not accumulate rain and thawed water, and at the same time it is desirable that the flooring be smooth (the floor with a clear bias is not too easy to operate). It makes it possible to achieve this drain flooring, it is most often arranged on terraces adjacent to the house. At the same time, the upper finishing flooring is placed so that he fluctuates water into a thoroughly waterproof solid base. The latter give a bias away from the main building, due to which the water relief on the ground either into the drainage system. Vrolley foundations can perform a concrete slab overlap, the boardwalk flooring on the beams, the draft floor of three-layer puzymal panels from an OSP on adjustable supports of IT.P. Waterproofing, as a rule, is performed from two layers of bitumen-containing rolled materials (rubReroid, glazing IDR), glued on a layer of bitumen mastic or weed. On top of the base protected from moisture laid aligning lags. Their position is adjusted in height using special plastic wedges, screw supports from plastic or stainless steel or dies from a resistant to rotting wood protected by coating waterproofing. The boards of the first flooring screwed to the lags, leaving the gaps of 3-5mm width.

NES. |

DLH Group. |

Varathane. |

Varathane |

20. The open terraces in the summer can become a great place to relax. However, in winter, from the whole area of the floor, such structures will need to regularly remove snow.

21. Dark woodnastils are perfectly combined with other materials: plaster, natural stone, nickel-plated metal, etc.

22-23maslo penetrates the structure of the tree to a depth of 1-2mm, and small damage on the finished surface will not be noticeable.

European defenseThere are two technologies (they came to us from Finland and Germany), allowing much to extend the life of wooden parts operated in the open air. The first impregnation with an antiseptic under pressure. It is suitable for low-cost conifers, due to the porous structure of well absorbing protective composition. The wood treated in this way is not susceptible to rotting, and the life of its open-air service reaches 10-15 years, however, the tree acquires a grayish tint and needs tinting.

The second method is to obtain the so-called thermoderev by treating sawn timber at 220-240 ° C; The superheated pairs decomposes polysaccharides that are nutrients for microorganisms and insects. Such technology reduces the water absorption of the material 4-5 times, so after the rain wood dries very quickly. It is possible to eliminate another problem: wood ceases to be prone control (with moisture drops, ordinary boards from some tree breeds are able to "pull out" from the lag and beams of nails and even screws). So treated, as a rule, wood of hardwood: oak, ash, IT.d. The only nuance tree becomes more fragile, therefore it cannot be used for supporting structures, and when laying the flooring from heat-treated lagows, it is necessary to have a fairly frequency, with a step of maximum 500mm (with a thickness of a 35-40mm board). Thermoderevo offers the firms "Bikos-Termoderevo", "West-Wood Rus", "Wood-XXI Century", "Termodrev", Trade Forest (all- Russia), Barkett (Germany) IDR.

The cost of impregnation with an antiseptic in a vacuum chamber and heat treatment is approximately the same: 8-11 thousand rubles. For 1m3. Thus, both increases the cost of sawn timber by 1.5-3 times.

|

|

|

|

|

|

|

|

|

Installation of terraced larch flooring:

Pick up the durable coating for street flooring is very difficult. The market presents many protective-decorative polymer compositions for external work, but mainly they are intended for walls, eaves and other elements of the building, "working" not in such extreme conditions as the floors. On the boards of terrace, most of these coatings will not last and two seasons, and from the protruding ribs "velvet" board they will begin to flap through the parties.

Much more efficiently the so-called yacht varnishes, withstanding atmospheric effects and operational loads for 3-6 years. They are published by Poly-R, Finnish-FC (both- Russia), Tikkurila (Finland), Beckers (Sweden), International Concern Akzo Nobel Idre. But these varnishes are usually colorless, and their few firms call.

Universal special oils suitable for processing any solid wood species, including thermally processed. They come in different colors, protect the surface from cracking and "forgive" errors in inexperienced malaries. The main ideas are the high cost (at least 900 rubles. For 1l) and the need to update the coating 1-2 years 1-2 years, pre-cleaved the surface from dirt and dust. Oils for the impregnation of wood are in the Brita assortment, Land ARK, Varathane, Osmo Holz und Color Idr.

The cost of materials for terraced flooring| Type of material | Thickness, mm. | Price 1 m2, rub. |

|---|---|---|

| Larch, board terrace, grade av | 35. | From 750. |

| Larch, terrace board, Extra variety | 35. | From 1400. |

| Pine Heathedral, Board Deck | thirty | From 1500. |

| DPK, garden parquet | 25. | From 1600. |

| DPK, board terrace | thirty | From 1700. |

| Massandububa, board deck | 27. | From 2800. |

| Kumaru ("Brazilian Tick"), board deck | 27. | From 3000. |

| Ipe, board deck | 27. | From 3200. |

| Tick Burmese, board deck | 22. | From 6800. |

| Tick Burmese, board deck | 40. | From 9000. |

| Name of works | Volume | price, rub. | Cost, rub. |

|---|---|---|---|

| Waterproofing device | 8.5 m2 | 200. | 1700. |

| Installation of flooring | 8.5 m2 | 700. | 5950. |

| TOTAL | 7650. | ||

| Name of material | number | price, rub. | Cost, rub. |

| Glassizol | 18 m2 | 40. | 720. |

| Bituminous mastic | 2 kg | 120. | 240. |

| Bar 2000 by 60 per 50 mm, larch | 6 pcs. | 180. | 1080. |

| Plank terrace, larch | 8.5 m2 | 760. | 6460. |

| Special fasteners | 72 pcs. | eighteen | 1296. |

| Cuprinol Decking Oil Oil | 1 L. | 980. | 980. |

| TOTAL | 10 776. | ||

| Total | 18 426. |

The editors thanks the company DLH Group, Nes, TD "Vikom" for help in preparing the material.