Basic principles for building a heating system on diesel fuel, to which you should pay attention to when choosing a modern boiler for the cottage

Heating on a diesel fuel alternative to gas. As the prices for diesel fuel are decreasing, interest in consuming boilers is growing. What are the basic principles of building a heating system on such a fuel and what should pay attention to when choosing a modern diesel boiler for a country house?

Boilers on diesel fuel: pros and cons

Pros:

the ability to fully automate the operation and control of the heating system;

You can choose a boiler for heating a modern country house of any square;

For their installation, special permits are not needed (as for the installation of gas boilers);

High efficiency diesel boiler

Minuses:

Need a special tank for diesel fuel at 2-5 tons;

For the boiler, a separate room with exhaust is necessary;

The boiler requires high-quality timely and very checked maintenance.

Let's consider?

Approximately the same as the solar carries, it is heating using electricity (in the villages of settlements, for example, its price comes to 4.5 rubles. For 1 kWh). Heating with electricity is the most comfortable and environmentally friendly. However, these serious hopes for electrical installation in Russia, especially in the regions distant from the center, no one risks. Why? The fact is that too often (several times for the heating season) and for a long time (sometimes weeks) in tall frosts in consumers there is no electricity in country houses. If it is, the quality of power supply is lame: instead of the laid 220V- 120 or even 250V. Attachment deviations from the norm does not even withstand very reliable electronics. Inesl take into account that the house in rural areas is usually not relying more than 2kW of electric power (no more without the construction of a new substation is often simply to take), talk about the electrical installation of the whole building becomes inappropriate.

Heating with firewood is significantly cheaper than diesel. It is best to heat birch, oak and beech firewood, giving much more heat than pine, aspen or olhovy. Wood 60% (natural) humidity, which, actually, is most often buying and used for the needs of heating, allows for approximately 1.5 kWh when burning 1kg. Provided that 1kg of birch firewood of natural humidity, for example, in the suburbs costs about 2,8руб., 1 kWh heat obtained during its combustion will cost about 1,8rub. So why, how in the old good times, not to use for heating the cottages of the railway? Alas, the process of burning firewood at the level of the Country House should not automate: even if the "long-playing" boiler with pyrolysis of wood is installed, it is necessary to visit the boiler room at least 2 times a new portion of fuel, straw ash. That is, you will have to spend weight of time and master the professional profession, and the latter is incompatible with the modern ideas of the majority of developers about the necessary level of comfort outside the city.

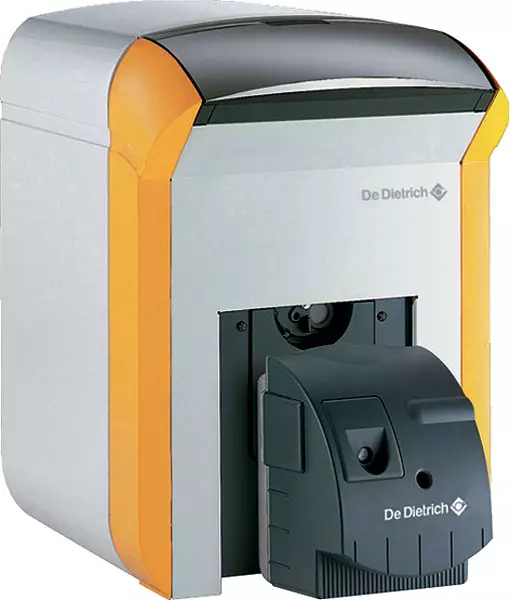

De Dietrich. |

Ferroli. |

De Dietrich. |

Viessmann. |

1-2. The modern boilers on diesel fuel series GT120 (de Dietrich) (1) and GN1 (Ferroli) (2) with hinged burners.

3. GTU series boiler (de dietrich) in the basement of the house.

4. For trouble-free operation, the diesel boiler must be regularly maintained.

Be vigilant: choose fuel

For heating using a liquid fuel boiler only a high-quality and appropriate diesel fuel. According to the state standard, summer, winter and arctic diesel fuel should be represented in the oil products market. Summer ("L") is intended for operation at ambient temperature not lower than -5C, winter ("s") is calculated on -20 ...- 30s. Finally, the Arctic diesel fuel ("A") maintains performance in frost to -50c. In practice, alas, an elementary inconsistency of fuel with climatic conditions is observed too often. It is unacceptable to mix summer diesel fuel and gas stable gasoline (gasoline) to use this mixture in winter; It is also impossible to use furnace fuel for heating. Do not take the diesel fuel at a suspiciously low price (substantially cheaper than at the gas station), otherwise you risks to heat the burner pump and other components of the fuel system.

Another tempting option is heated using a pellet fuel that first appeared in the twentieth century. (Pellets are dry sawdust compressed under high pressure in the granules and in shape resembling small fragments of the pencil). The cost of heat obtained by burning 1kg pellets is approximately 1.5 times lower than when combustion of a similar amount of absolutely dry wood. With a sufficient reserve of this bulk material in the basement of the house (or in a hermetic capacity next to it), the heat generation process can be automated, and then in the boiler room will be able to visit no more than 1-2 times a week. However, with affordable diesel fuel pellets, it is difficult to compete: the domestic market of pellet fuel produced in Russia in significant volumes is not yet developed. Most of the pellets goes to export - to Germany, Austria IT.D. AB of our country Pellets is in free sale far from everywhere (in some regions they did not even hear about them).

Perhaps the only alternative to liquid-fuel heating for most of the developers aspiring is heating using a main gas. It is the trunk, since the imported liquefied propane-butane, which is kept in areas in underground gas storage tanks (Gazgoldiers), despite a number of indisputable advantages, is characterized by a fairly high price (1 kWh heat obtained when burning propane-butane The mixture is only 15-30% cheaper than when using diesel fuel). Yes, and relate to this fuel alert. The gas tank, walked into the ground near the family nest, for some reason, is associated with other homeowners with a slow motion bomb, a sudden explosion of which will leave after himself only a deep crater. Nobody compares the acister with diesel fuel with a bomb: many since childhood know well that the suolars are not settling with a match.

Heating on the main gas costs the consumer in the Moscow region just 0.2-0.3 rubles. For 1 kWh heat. This type of fuel allows you to build a boiler room, which will work absolutely without the participation of a person on the stretch, automatically. However, the presence of a gas pipeline near the site does not mean that it is possible to use without problems. Lyomes located on the outskirts of old towns, where the pipeline pipe was held at Soviet power, gas today is sometimes not enough to connect to another building, even for big money. Aesley has yet been able to connect, another trouble is the drop in gas pressure in the winter. Methane in the pipeline seems to be, and it is impossible to use it for heating, since the static pressure of the gas in front of the burner is not enough, because of which the burner works, but not in the calculated mode, and it breaks prematurely (roars).

When choosing gas heating, the developer expect high costs of lining gas from the highway to the boiler in the house. Significant funds go to pay the project of the boiler room. Without approved and agreed with the relevant project documentation services, the gas connection is prohibited. These costs significantly reduce the effectiveness of cheap payment during operation.

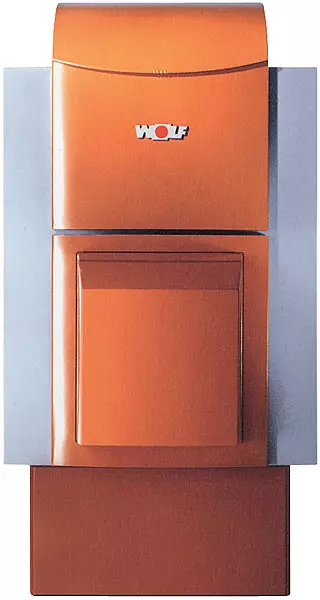

Wolf. |

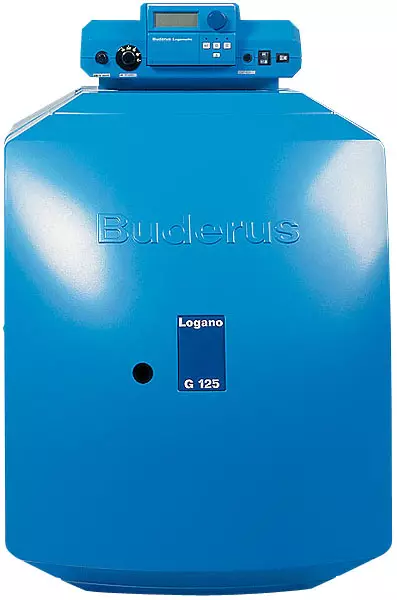

Buderus. |

Vaillant. |

Nova Florida. |

5-7. CHU (WOLF) Copper with PREMIO / TH (5) hinged burner (5), as well as Logano G 125 (Buderus) (6) and IROVIT VKO (Vaillant) (7) with built-in burners.

8. Lyra C (Nova Florida) with a built-in burner and a flow heat exchanger for DHW.

Thus, a liquid fuel boiler is a well-competitive device for heating a country house, if there is no main gas, it cannot be bought due to the bureaucratic difficulties or the use of methane due to the winter reduction in the gas pipe is unsafe for boiler equipment. Well, if the supply of the gas line to the site is only planned (let's say, after 2 years), it is also quite logical to acquire a liquid fuel boiler, but necessarily with a mounted (outer) burner. After the house is given to the house, it will be possible to clean the furnace and chimney from the soot, install the gas burner, reconfigure the automation and proceed to heating. No changes in the strapping of boiler room (except for connecting gas and the conservation of the fuel system) will not be required.

How much suolars buy?

Let's try to calculate how much the diesel "bisses" a liquid fuel boiler for the heating season in the house of 200m2. We will proceed from the fact that the heating season lasts 7 months, the boiler operates on a complete coil of about half of the total time, and in the remaining period, standby and diesel does not consume diesel. Approximately for heating 10m2 well insulated room requires approximately 1kW power. Consequently, for the house of 200m2, you need a 20kW boiler. If the aggregate worked continuously, for 1 month it would give the heating system: 20kvt24h30 days = 14400 pulse thermal energy. However, since we agreed that the boiler operates only half of this time, 14400 pulse must be divided into 2-time 7200 pullees. Multiplying for 7 months of the heating season, we get 50400 pulverity for the heating season. For the production of 1 kWh thermal energy consumed approximately 0.1 liters of diesel. Thus, the flow of diesel fuel for the heating season can be approximately 5 thousand.

The approximate consumption of diesel fuel for the burner of any household boiler can be calculated according to the following formula: fuel consumption (l / h) = burner power (kWh) 0.1.

According to the materials of the company "ABC of heat"

Before you pay

Today, the cost of the boiler room on liquid fuel and heating system with a circuit of radiators and warm floors for a country house (taking into account the costs of equipment, delivery to the object, installation and commissioning) - approximately 370-700 thousand rubles. (at the rate of 1850 rubles. for 1m2 heated area for buildings by Metrah 250-500m2). The boiler house for the house with an area of 250-300m2 with a fuel supply system and a small "budget" fuel-eyed will cost approximately 250-350 thousand rubles. WTU sum includes the price of a liquid fuel boiler with a burner and automation system, which makes up about 20-35% of the cost of boiler room (a lot depends on the brand, the degree of automation of the IDR). In love, save on the choice of equipment and design and installation organization, which will select it, install and regularly maintain, is clearly not worth it, because there is a miser, as you know, pays twice.

The designer specialist is able to choose the boiler suitable for heating a country house and all the elements of the strapping and without the participation of a homeowner (most likely he will do), but to put a signature under the estimate, and therefore, to make a fundamental decision on the system's configuration. The latter will be able to do this consciously only if he has at least superficial knowledge of the system and its components, in particular the storage facilities with liquid fuel, the type of boiler, burners and automation.

Viessmann. |

Ferroli. |

Ferroli. |

9.Vitola 200 paired with Vitocell 300 boiler (Viessmann).

10-11. BF series BF (Ferroli): 300 and 500l with built-in thermometer (10) and 100, 150 and 200l without thermometer (11).

Data for selection of equipment boiler

A two-storey country house is built from a pine bar of 150150mm, without additional insulation. The heated area is 200m2, the heat loss of the building is about 25kW. The thing is one heating contour radiators. Diesel heating is constant, gas supply to the site in the near future is not scheduled.

The room under the boiler room is located next to the garage, area - 7m2 (32.33m). Requires the installation of the boiler to the boiler.

Water supply: three people live in the house (two adults and one child), which are accustomed to economically enjoy hot water.

Refueling fuel tanks: The visits of the tanker to the site should be carried out no more than 4 times a year.

Drilling lake

Saloary boiler consumes from a tank with fuel, which can be located outside the house (for example, in an extension, or zeroped in the port of IT.P.), or in an heated building, indoors next to the boiler room. The owner will have to regularly (usually no more than 2 times a season) replenish it. It is better to order one or more tons at once (depending on the volume of the tank) - the supplier at a convenient clock will send to you the tanker; The main thing is that the access ways to the place of dislocation of the fuel neck of the tank were free. The most demand of the population is used by 1000-1500l, but more voluminous tanks are also available on sale - until 18-20 thousand. However, it will be possible to create a fairly spacious capacity and from small tanks, combining them with each other with the help of the so-called fix packets. There are 1000l tanks about 10-15 thousand rubles. for 1pc. To install in the ground, you can buy a tank of durable reinforced fiberglass, for example, model Labko 10000 (Labko, Finland), which accommodates 10 thousand. When installing on the heated area of the country house, first of all pay attention to polyethylene tanks (they are made using blowing or rotary machines). There are models of TRIO-TANK, TRIO-SystemTank (Dehoust, Germany) models. The wide range of the tanks of the company "Anion" (Russia) is also presented - these products with a capacity of up to 2t are easily carried to the standard doorway. A component of several tanks combined with the use of fix-packets allows you to create a capacity of larger volume (for several tens of tons of diesel fusion). Polyethylene tanks are not only mon-, but also two-bednous, and sometimes with a flickering of galvanized steel sheet, such as the DWT model (Roth, Germany), - with such a coating of the tank, are perfectly protected from UV radiation, durable, Practically do not allow fuel diffusion and the appearance of its smell indoors.

Buderus. |

De Dietrich. |

CTC. |

Baxi. |

12-13.Alements of automation of liquid fuel boilers: Room regulator RC20 (BUDERUS) (12); Programmable weather-dependent DIEMATIC3 series panels (Dedietrich) (13).

14.ctc Wirbex 20-200 with a hinged burner (a) and CTC 1100 Aegir with a built-in boiler by 100l (b) (CTC), as well as Crysalis Xenium (BAXI) with a hinged burner and a 150 liter boiler (15).

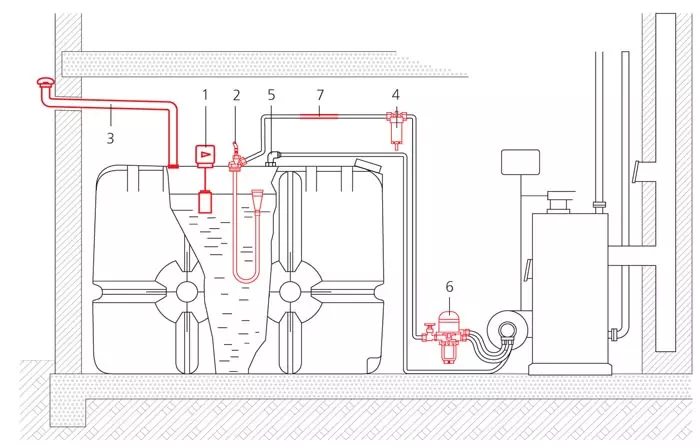

From the tank over copper pipes, the solard is served either directly to the burner, or in the intermediate container installed in the boiler room. Diagram of connecting the burner pump to Baku depends on where it is located. If a substantially above the pump axis (up to 10m), use the samotane diagram: the fuel is used under the action of gravity, and its excess is returned back to the tank or in the fuel filter housing (the latter is mounted in front of the burner and cleans diesel fuel from unnecessary impurities) with Use the built-in burner pump. The absorption of the suction capacity of the liquid fuel burner fuel pump is enough to raise the diesel fuel from a small depth, but if the tank is 4-6m below the axis of the burner pump, the latter will be required. Then apply connected to a tank loop with an additional circulating pump with a power of several dozen watts installed in the rings deployed through the boiler room. From this circuit, the burner pump will select the amount of fuel required for heating and DHW.

Fix-Package Connection Scheme for Capacity up to 2000l

With the "street" installation, the fuel line "Burner" or "Storage-Intermediate Tank for Fuel" is kept below the depth of the primer of the soil (1.4-2m), since the viscosity of the fuel in frosty weather increases and it is difficult to pump it on fuel supplies. In addition, water, which is almost always present in the diesel, can freeze, and then the boiler will rise, and most likely, at the most inopportune moment. To avoid this, sometimes even use special self-regulating heating cables (temperatures- 50c) to heal the fuel line.

Water from the following numbers we will end in more detail on the design features of liquid-fuel boilers manufactured by KUDERUS, Vaillant, Viessmann (all Germany), de Dietrich (France), Ferroli, Fondital (Obaalia), CTC (Sweden) IDR.

Approximate boiler room costs on liquid fuel *

| Name of product | Units. change | Number of | Price including VAT, rub. | Amount taking into account VAT, rub. |

|---|---|---|---|---|

| Boiler Logano G125-25 SE with built-in diesel burner | PC. | one | 93 297. | 93 297. |

| Logalux LT 135/1 tank water heater | PC. | one | 58 698. | 58 698. |

| Management system Logamatic 2107 "RU" | PC. | one | 30 822. | 30 822. |

| BANK SAFETY BANK V / N SG160S 3/4 8 Bar | PC. | one | 5289. | 5289. |

| KSS / G1115 / G125 boiler security group | PC. | one | 5511 | 5511 |

| Connection Group G115 / G125-LT 135/160/200 | PC. | one | 14 886. | 14 886. |

| Set for connecting an expansion tank AAS / G124 / G115 / G125 | PC. | one | 5289. | 5289. |

| Fuel tank ST 1000L | PC. | one | 21 888. | 21 888. |

| Fix-package main, type G | PC. | one | 8235. | 8235. |

| Kit for connecting tank V / n AS1 | PC. | one | 1113. | 1113. |

| Quick disconnect connection R 3/43/4 | PC. | one | 1415. | 1415. |

| Threaded Connection R 1 / 2G1 (brass) | PC. | one | 382. | 382. |

| Pump Logafix Buz 15 | PC. | one | 5642. | 5642. |

| Mounting for expansion tanks | PC. | 2. | 603. | 1206. |

| Membrane expansion tank 35/3 | PC. | one | 2578. | 2578. |

| Membrane expansion tank DHW 12/10 | PC. | one | 4342. | 4342. |

| TOTAL | 260 590. | |||

| * - According to Buderus, at the end of December 2008. |

The editorial board thanks Buderus, De Dietrich, Ferroli, Vaillant, Viessmann for help preparing material and provided photos.