History of the construction of a small and inexpensive house of 79 m2. The basis for the building was the insulated construction "car".

Houses are built in different ways. Single season, others slowly, as far as the ability of the owners. Our story about how to build a small and inexpensive house.

In deficiency conditions

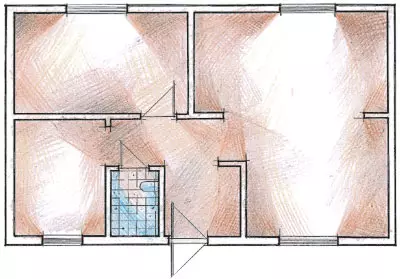

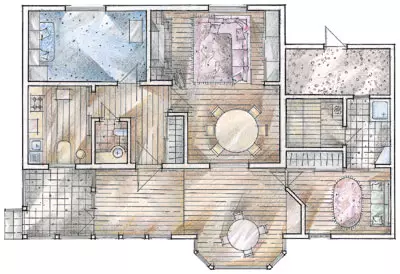

Construction ideas came to appetite during food, in the process of real estate development. Only only a roof above his head appeared, the goal was: to create a foundation for a house with amenities in which you can live in summer, and in winter. The planning solution was assumed to appear the bedroom, living room, relaxation rooms, kitchen-dining room, bath complex and summer veranda. The main idea of the architect was to achieve maximum comfort. Iclays boiled ... Almost all construction operations performed the owner and members of his family. That is why it was possible to significantly save money.

How it was

Holding to build a country house, Sergey bad remained faithful to his profession. Being a real carpider joiner, he thoroughly handled every wooden design detail. The first time in the hotel had to live, and work, and store the tool. Soon there was an extension around her. The premises joined the framework technology until the total area of the building was 79m2. The new construction of the builder covered with hanging rafters, on top of which the roof was used from the wavy bituminous sheets of Ondulin (France).

The windows and the door in Motovka Sergey replaced, leaving their size for the same. Saved the natural supply and exhaust ventilation system. True, the air duct brought off the roof of the new construction, but in the attic space. Vehi part of the attic there is a window-lunet with blinds, air through it and comes out.

The designer and worker in one person, Sergey added to the main building (construction tractor) frame structures, the floor and the walls of which insulated mineral wool. The floors in the "car" and an extension are derived to the overall level. On the veranda, the floor was left cold, in the warm zone (in the pre-banker, sauna, rest room) is thermally insulated. The floor of the insulated household owner did not reconstruct, in the new premises made the following. On the foundation of the beam laid lags in increments of 0.8m; Beams nailed (from the bottom side) cranial bars. On top of them there was a draft floor from unconditional boards, and only then put Parchment and layer of mineral wool URSA (Russia). CUTTING rooms parquet floors are laid on the walls wall on the lags (20mm thick). In the kitchen, in the bathroom, shower and on the porch, the floor was lined with a tile - the plywood layer is not a layer of hydrohoteloisol, the chain grid is placed on it, which is made of a five-axis screed from a ceramzito concrete. Then, with the help of the "Unice Plus" composition, a tile was pasted.

The walls of the offerings Sergey gathered according to traditional technology. The frame of wooden bars (1510cm) was cut outside with a t-shirt (which was subsequently painted in white), and from the inside-plasterboard under the subsequent pasting with wallpaper on the flieslinic basis. In the insulation and the mineral wool URSA served here. It is closed on both sides by the pergamin while maintaining a five-point meter ventilation gap between the outer layer and the outer skin.

Editorial note. Bilateral isolation is a pergamin-low, but not the best option of salvation from moisture. Indeed, there will certainly accumulate couples between the layers of Pergamin and condense. Now there are modern materials on the market that are capable of performing two functions at once: protect outside of moisture and not to prevent the output of water vapor from the room. That is, they are vapor-permeable waterproofing (for example, "Tailer", "Izosanas", "Yutavek", "Yutafold").

Windows in residential rooms swing, with wooden frames, made according to old technology. For veranda and erker, wooden frames with frequent binding are specially made.

As for the ceiling overlap, the builder left it in horizontal execution only in the former household. In the kitchen, in the sauna and bathroom, an inscrutable warmed roof is made. For her manufacturer, Sergey nailed to the rafters of cranial bars and laid out of them polished and covered with varnish boards. The space between the ceiling and the roof insulated the mineral wool URSA, the bottom and on top of closing it with a pergamine. Under the roofs of the wavy bitumen sheets, nailed to the crate, the owner left the ventilated space. The eaves laid the board-lining and mounted a waters-felting system on the cornesses. Since the roof and floor of the veranda did not need insulation, hanging rafters in this room master made part of the inner architecture of the building, giving them the form of high-quality joinery. To do this, every detail of the rafter had to overtake and polish, and then covered with varnish. The rafters collected on Earth were installed in place in the finished form. Their small mass allowed to do without lifting devices.

All subsequent actions of our hero were aimed at mounting communications and finishing the house outside and from the inside. At first, Sergey took heating. By purchasing the cast-iron furnace Supra (France), it installed it into an energy-efficient furnace-fireplace of its own design. This furnace, built into the interior partition, heels at once two rooms living and bedroom. For greater return of heat, Sergey laid the furnace with masonry with special air channels, like a Dutch furnace. Air passes along them, heating from hot bricks. From the side of the furnace, a burning fire is clearly visible, covered by the side door with heat-resistant glass. The portal of the fireplace is made manually. He though looks like a stone, but is made of wood covered with Levkas, and then painted.

True, as the experience showed, one fireplace for heating at home in winter is not enough. Therefore, our architect had to be resorted to tricks. He decided to use the warmth of a small sauna existing in the house. Typically, the heat sauna heated with the Harvia electric oven (Finland), after people leave it, goes through the ventilation hole on the street. But Sergey sent a dry hot stream through the bypass channel right in the living room. Forced by force, with the help of a fan installed in the wall of the former "car", the air is closed from the top of the sauna and on the corrugated aluminum pipe with a diameter of 15 cm, wrapped in mineral wool, is displayed in the living room from the floor. This turned out to be enough so that in the 15-degree frost in the rooms it was warm and comfortable. Plus, the electrical "heat gun" with a power of 3.5 kW is used to the forced heating of the premises in winter. As a heating device, it, of course, is effective, but raises a lot of dust. Therefore, the owners try to use it as much as possible - only in very strong cold.

Water in the house owner spent from a well in the courtyard-shallow, four rings. From there it takes her pumping station. Water is supplied to three cranes (in the kitchen, to the toilet and sauna), as well as in the drain tank and the electric boiler with a capacity of 100l. All equipment is mounted in a small chulana next to the sauna and shower. Water from the well is used only for technical purposes. Drinking water has to be brought, because there are no cleaning filters in the house. Sewer drains fall through a pipe in a septic tank, removed from the water intake 20m point.

Punching of electrical wiring is applied PUNP wire in metal pipes laid in the walls and interior partitions. Wiring with a cross section 2,5mm2 withstands the load of such energy-intensive appliances, like a microwave, electric heater, boiler and professional power tools, which the owner of from time to time uses for the repair of a particular component of the house. The safe operation of the electrical appliances is provided by the protection machines, the Uzo and the local grounding system (the metal structure lined into the ground, the zero protective conductor is connected to the slot.

Internal finish and design of premises, Sergey did not rush. A part of the situation (inexpensive sofas, chairs and chairs of Russian production) acquired in furniture stores. Being a furniture restorer, much made with your own hands, such as all kitchen furniture. Curtains sewed wife and daughter. The result of the house turned out to be cozy and beautiful, despite the small sizes and the lack of expensive things.

Wamperic nature

Simultaneously with the construction of the house, the owners began to master the landscape. The summer cottage has a rectangular shape without any elevations and downsions. For the construction of such a territory, just a find, but in terms of landscape design it is nothing but a faceless plane. The architect had to pretrate his head pretty, how to transform it. To visually change the relief, a low alpine slide was built from a light bright stone. Around it were planted Tui and coniferous trees, and a flower garden broke next. Plants are chosen so that blooming continuously, from May to November. Separate places are successfully located groups of pink bushes, and along the pickup trees and shrubs. Away from the house "hidden" the beds on which the strawberry grows. Free space is given under the lawn, which after three years of regular haircut looks almost like a golf course. In the host of the house with the classic facade, the house was similar to the pavilion in the corner of the traditional English garden.The enlarged calculation of the cost of work and materials on the construction of the house similar to the presented

| Name of works | Units. change | Number of | Price, $ | Cost, $ |

|---|---|---|---|---|

| Foundation work | ||||

| Takes up axes, layout, development and recess | m3. | 2.8. | eighteen | fifty |

| Device base for sand foundations | m2. | fourteen | 2. | 28. |

| Device of the foundations of tapes from concrete blocks | m3. | 7,2 | 40. | 288. |

| Horizontal waterproofing | m2. | 12 | 3. | 36. |

| TOTAL | 402. | |||

| Applied materials on the section | ||||

| Block foundation | PC. | 10 | 32. | 320. |

| Career sand (with delivery) | m3. | fourteen | fourteen | 196. |

| Bituminous polymer mastic, hydrohotelloisol | m2. | 12 | 3. | 36. |

| TOTAL | 552. | |||

| Walls, partitions, overlap, roofing | ||||

| Delivery and installation of cabins | PC. | one | 160. | 160. |

| Frame cutting of exterior bearing walls, a device of frame partitions with a trimming, board coatings | set | - | - | 2400. |

| Installation of the rafter design | m2. | 110. | eight | 880. |

| Isolation of walls, coatings and overlaps insulation | m2. | 240. | 2. | 480. |

| Device of vaporizolation | m2. | 110. | one | 110. |

| Paper coating from bitumen sheets | m2. | 110. | nine | 990. |

| Filling opening windows and door blocks | m2. | eighteen | 35. | 630. |

| TOTAL | 5650. | |||

| Applied materials on the section | ||||

| Sawn timber | m3. | nine | 120. | 1080. |

| Window and Door Blocks | set | - | - | 1900. |

| Bituminous profiled sheet "Ondulin" | m2. | 110. | 6.3. | 693. |

| Mineral wool insulation URSA | m2. | 240. | 2.6 | 624. |

| Pergamine | m2. | 300. | 0,3. | 90. |

| TOTAL | 4387. | |||

| Total cost of work | 6050. | |||

| Total cost of materials | 4940. | |||

| TOTAL | 10990. |