Scope roofs perform not only a protective, but also decorative function. About the types of roofs, materials, prices are our material.

Photo by E. Lucia, V. Nekrasova

It is the roof as an integral element of the architectural appearance provides the designer with tremendous opportunities for creating a new, modern and even original appearance of a country cottage house

Photo K. Manko.

Photo K. Manko.

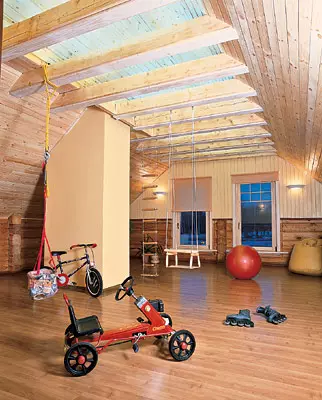

Tightening hanging rafters visible in the interior. Sounds scary. But in the interior of the children's - the thing is irreplaceable

The roof of the roof of houses under a soft bituminous tile serves as a solid flooring of boards, waterproof plywood or oriented chipboard

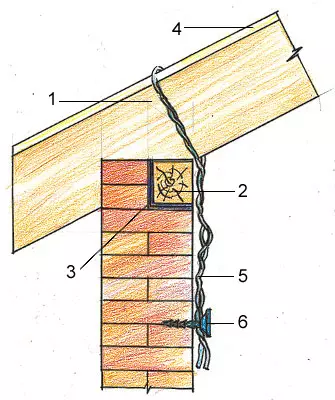

2- Mauerlat;

3- moisture insulation;

4- doom;

5- twist

from wire for fastening the rafter foot to the brick wall;

6-crutch or mortgage element

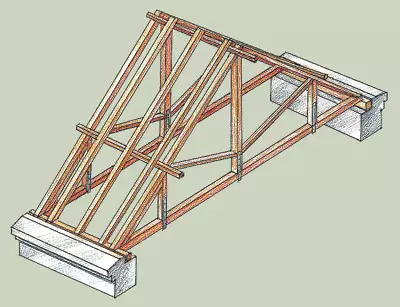

To increase the strength and hardness of the rafter design, the most loaded elements are increasingly manufactured from the metal. Spans between metal parts are filled with wooden elements

Photo M. Stepanova

The difference in the interior of the rafter is the easiest way to handle the versatility and varnish or biolalect composition

Heat the roof can be both during its arrangement and after- inside the attic room

In recent years, the roof finally began to be perceived as an equal element of the entire architectural appearance of the building. And today the average of the cottage owner, wanting to give the house not only respectable species, but also expressiveness, individuality, at the same time should decide not only the strength, stability, fire resistance, reliability of protection against adverse external influences (in more often, wind and waterproof), but Design of roofing design.

The roofs are flat and scanty. The premises are taken to relate the structures with an angle of inclination of the roof surface from 1 to 2.5, and to the scope-with a large angle. We must immediately warn that in this review we will discuss only the pitched roofs, because besides protective (due to the slope on the skates, precipitation does not accumulate) they perform a decorative function. I am expressed by the language of specialists, they are more architectural and expressive, and therefore prevail in cottage construction. The amount, size and shape of the rods depend on (not afraid of Paphos) of the designer and personal interests of the hosts, as well as from climatic conditions and operational requirements.

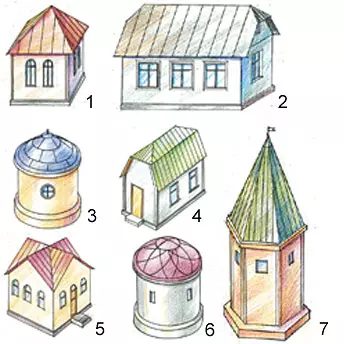

Types of scanty roofs

The roofs are taken to subdivide on one-sided, double, hollow, tent, multi-line, these shapes of the roofs are most often (see Roofs of houses in the photo). It is less likely to meet vaulted, dome and conical roofs. Naturally, the easier the form of the design, the easier it is to erect it. With a complex (for example, multi-type), the roof occurs a lot of rosters of rods forming internal angles. These are the so-called endanders that are the least reliable place of the roof. The fact is that the slopes of the funds are significantly less than the slopes of the rods. However, it flows the greatest amount of water, which is why the waterproof of these nodes requires the closest attention. In addition, snow accumulates in Enders, which increases the load on the roof. And build such a roof, and it is quite difficult to watch it. No wonder old specialists say: "It is desirable that the house from the roof of a complex shape had a ventilated Cold attic. Then the roof will last longer because it is easier to follow it. "In its pure form, all the above (relatively simple) forms of the roofs are applicable mainly for small summer houses, cottages. SZOORODAL HOMES, intended for permanent residence, the situation is more complicated.

Modern houses

Today, when country houses have become a permanent residence for their owners, they have increased greatly in size. There are several reasons here. The first and basic fatigue of the owner from the cramped conditions inherent in the urban apartment. Secondly, building a cottage less than 250m2 is economically unprofitable: the reduced value of 1M2 is too high. The more floors, the lower this value. Moreover, the modern owner of the cottage no longer wants to build a simple, but a huge house under a two-tie roof. Similar house-monsters, which were erected at the beginning of the nineties of the twentieth century, can be found in any corner of the country. They look pretty slaughter. The anecutors are still unfinished - the hosts did not have enough funds on such a scope. It is also impossible to sell them, no one takes.

The natural desire of the homeowner of the new time is built a house with an interesting, if you want, an attractive architecture. But the appearance of the building is not only the facade, but also the roof, which, together with the facade, performs an architectural and aesthetic function. Our architects argue that the appearance of a modern cottage to the maximum extent depends on the roof, which should be harmoniously completed the structure, being optimal in shape. Moreover, the silhouette and color of the roof should be harmonized with the surrounding landscape. And they respond about the roofs are not otherwise as another facade of the house.

There is even a fashion on the roof, which changes approximately every three years. For example, if 10-12 years ago, the Customer almost necessarily demanded the turrets and other "increments", now (perhaps, looking at the houses abroad or appreciate all the technical difficulties in creating and operating such "increments"), he noticeably talked his requests. But at home acquired elegance. A kind of classic has become a multi-sighted and multi-level roof of a complex profile. This design is particularly relevant when embedded in the attic space of additional indoors. Without them, almost no modern country house is not bypassed. Even in very large buildings, where there is enough space inside the capital walls, the household cinema, guest rooms, bedrooms, etc. are arranged in the attic, and so on. Who will refuse additional residential meters, and cheaper than those located on the main capital floors ?

It must be said that the roofs that are now being distributed in our country differ from the erected, for example, in more southern countries. If somewhere in Spain or Greece, architects easily go to the complication of the form for the sake of architectural winnings, our designers will not do without the need. The reason is a simple climate. Here and tightening rains, and the snow lying on the roof almost six months. That's why experienced architects Designing the future at home will begin ... Yes, it is from the roof. Naturally, first they give an architectural idea, develop a plan at home, determine the number of floors. But then immediately begin to work out which carriers (and not only external, but also internal) must be removed under the roof so that it can be opened with roofing design. Appears and can not: the magnitude of the spans cannot be limitless.

As a result, the architect is constantly looking for a compromise between the architectural idea and the form of the roof, creates the slopes necessary for draining water and carefully ensures that the so-called snow bags are not formed, where snow will accumulate. At the same time, it makes up a roof as it were from individual elementary fragments, from which the most two-tie, hip, tents and the like designs are built. Each fragment relies on the bearing walls (for this they are removed under the roof), connecting them into an architectural integer. One or another roof bias (in the scanty structures it ranges from 10 to 70) is attached not only depending on the design (more precisely, architectural) considerations, but also taking into account climatic conditions. For example, under the abundance of atmospheric precipitation, the bias always increase, but in reasonable limits, since more materials are in the cool roof.

Naturally, the simpler the plan and the architectural idea of the house, the less difficult roof turns out. And it means more reliable. All as in the above-mentioned "relatively simple" roofing structures. Its influence on the complexity of the roof (as we will see in the future) also applied material. Therefore, going to the architect, try to first decide what kind of material the roof of your future house will be made.

Design

If a box of low-rise country house is built from traditional materials (logs, timber or bricks) and is calculated from the point of view of providing heat saving requirements, the carrying ability of the walls will be ensured by automatically. And 200-250%, that is, with a large margin.With the roof design, everything is different. It must be sure to calculate. The opinion that it is enough to rely on the experience of the neighbors or a brigade of builders who have erected not one roof, often turns out to be in the root of erroneous. This option somehow passes for a house of 66 m in size, where for the manufacture of rafters during their step in 1 m, almost any edged board is suitable, which you find on the market (for example, 50150mm suits, even with a margin). But if you have a house of 250m2 and more, with such a short-sighted approach, the error will certainly arise. Errors that during operation will turn into problems. Aih decision may require significant capital expenditures. In general, "the miser pays twice."

The design of the pitched roof begins with the calculation of the rafter feet. Their section is determined based on the existing loads (the severity of the design itself, roofing "pie", snow and wind load) and angle of inclination of the roof, and with a safety margin (at least 1.4). The calculation also determine the distance between the rafters (step). But this is no longer an architect, but a designer-designer. It calculates the spans, develops the farm, if necessary, checks the supporting ability of the supports and the corresponding foundation under them. Decides, urban apply rafters or hanging. Determines whether there is a need for intermediate elements: disclosures that allow to unload rafters, or tightening designed to prevent the "traveling" design. It is possible to predict in advance what the rafter design will be only if it comes again about the "box" of 66 m. For this kind of buildings, a mass of typical solutions has been developed, and errors in the design, since the house is small, will be easily corrected.

The cross sections of the rafter are largely dictated by the market offering lumber of a certain size set. If standard dimensions do not satisfy the developer, then resort to additional triggers. For example, the legs are increasing (when there is not enough length) or drive beams to enhance them. There is an option to use typical (glued) rafting legs that can be much longer and more powerful than usual.

The designer determines measures and for additional moisture insulation, which is necessary, for example, at the angle of inclination of the roof is less than recommended for a particular roofing material. So, for natural tiles, the minimum inclination angle of the roof is 22. On the roofs with a slope from 16 to 22, it is recommended to lay an additional layer of moisture insulation under the tile. With a bias from 10 to 16, when it is possible to bloody under the tile of rain, a solid crate of the boards are placed under the roofing material, and the so-called the so-called roofing floor (rolled materials on a bitumen basis forming a solid carpet) are taped. Water that fell under the tile, just rolling along this extra roof. This technique can also be used on roofing from metal tile or "erector".

Main parts of the rafter design

The roof is maintained by a special design consisting of a crate, directly by the roof of the carrier, and rafters (rafting farms) transmitting the load from its own weight of the roof, snow, wind on the walls and internal supports. The design of the rafter depends on the shape of the roof, the presence and arrangement of the internal supports, the amount of the span, as well as the existing loads.

The main figure in the rafter design - triangle. He is most cruel. The main element of any farm-plumbing feet stacked along the scope and supporting the crate.

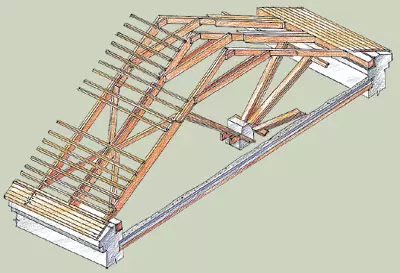

Hanging rafal Rely only on two extreme supports (for example, only on the walls of the building without intermediate supports). Their rafting legs work on compression and bending. In addition, the design creates a significant horizontal sawing force that is transmitted to the walls. Reduce this effort helps a tightening (wooden or metal), connecting the rafting legs. It can be located like a rafted base (and in this case serves the beam of overlapping, it is precisely this option that is most often used in the construction of attic roofs) and above. The higher it is, the more powerful it is supposed to be. And the more reliable should be its connection with rafters.

Slopils Install in homes with a medium carrier wall or columnar intermediate supports. Their ends are relying on the outer walls of the house, and the middle part is the inner wall or support. As a result, their elements work as beams only to bend. With the same width of the house, the roof with sputum rafters is easier than any other (requires less lumber and, accordingly, cash costs). When installing over several spans of a single roofing design, rolling and hanging rafting farms can alternate. Where there is no intermediate supports, hanging rafters are applied, where there is, - weed.

Maurylalat. Stropile legs are not based on the walls themselves, but on the support bar- Mauerlat. The depressed constructions by Mauerlat is the upper crown of a church (log, timber). With brick walls, it is a specially installed flush with the inner surface of the wall of the timber (from the outside, it must be protected by the protrusion of the brickwork). Between Mauerlat and brick, there is necessarily a layer of moisture insulating material (for example, two layers of rubberoid).

The upper ends of the rafting legs, if necessary, can be maintained by the system of racks and squeaks. To task, unload the rafter legs by passing the load on the inner walls or support pillars, as well as ensure the structures of rigidity.

In the absence of bearing walls, the heel of the rafter feet can rely on powerful longitudinal beams, the length of which is limited to the load acting on them.

Ski run. The plot of the rafter design of any roof lays a run, connecting the rafyled (farm) among themselves. It is on it that the lip cover will be arranged in the future.

And two more independent details. If the rigidity is provided in the plane of the rafter legs, it is provided by the rapid farms themselves, then for confrontation with wind loads acting, for example, from the nipper side (front), in each rope of the roof, the required number of diagonal ties are set. They can serve as a thickness of 30-40 mm thick, nailed to the base of the extreme rafter foot and to the middle (or above) neighboring.

So that the roof does not demolish the wind, the rafter legs together with the Mauerlat must be filled with the walls. To do this, steel studs (rams) are closed in the masonry under the rafter foot or in advance the mortgage elements to which the rafter foot is attracted by a twist of steel wire with a diameter of 6mm. For cutters, this technique is considered optional: the upper crown with the rest of the wall is always connected securely.

Forms of pitched roofs

2-semi-haul;

3-cone;

4- Dricaping roof with half-haired; 5-four-fetch;

6- dome;

7- Pyramidal Single Roof It is an inclined plane fixed on the walls of different heights. Skat, as a rule, addressed to the windward side.

Two-tie, or forcep, roof Consists of two slopes aimed at opposite sides. Triangular end walls formed with such a design are called forceps and the name of the roof itself. This option is easy to manufacture, reliable in operation. One of the varieties of the two-tie structural construction is the "indulgent" roof. It consists of two gentle slopes closed in the top, and two steep skates, which are continuing them. This form allows you to fully use the attic space, but harder in the manufacture.

Four-sheet roof. All her skates having a view of an equally chained triangles are converged at the vertices at one point. Four-tight roofs for buildings, square in terms, were called tents.

Walm roof It is a variety of four-tie roof for a rectangular building. It received its name from the slopes, fully slicing tongs-valves. The surface form two trapezoidal skate along the long sides and two triangular - short. Compared to the previous, such a form not only emphasizes the protective function of the roof, but also gives the building a more representative appearance. Walm Semi-Walled Roof . Side skates are cut only part of the forceps (from here and the name-half-haul), and also have a significantly smaller length along the line of the slope than the main skates. The half-haul can be located at the top (triangle) or below (trapezium).

Multi-line roof Used for houses of a complex configuration. For example, it is formed over a square building as a result of the intersection of the two-tie roofs at right angles. It is possible to create a roof and with a large number of forceps. Advantageous appearance and overlapping of several rooms with single-level roof. Disadvantage of performance.

Vaulted roofs can Have circular or parabolic outlines (for private houses are rare).

Dome and conical roofs Apply to overlapping a building (or its parts), which has circular outlines in terms of. Can resemble a spherical dome, a flat or sharp cone.

Materials for rafal structures

The main material for the manufacture of rafting structures in the individual cottage construction is still the tree remains. Therefore, already at the design stage should be provided (and during operation strictly observed) constructive and protective measures that extend the life of the wood. Kontstructive activities include: a device of gaskets from waterproofing materials in places of contact of the tree with brick, preventing the roof leakage, creating and maintaining in the safety of moisture insulating (from the roof side) and vapor insulation (from the operated premises) of the layers, as well as equipment of ventilated gaps that provide removal Moisture vapors with a stream of air raising on these gaps. Strategic measures include wood processing with antiseptics or flame-protected drugs.Loads on rafyla

The rafters perceive constant and temporary loads. Cutting loads include their own weight of the roof, crates, runs and rafters. Krophennoe snow, wind, as well as payload (if it is). The calculated value of snow load is 180kg / m2 in the horizontal roof projection. The resulting snow bag can increase this indicator to 400-500kg / m2. With the bias of the roof over 60, the snow load is not accepted. The design value of the wind load is 35kg / m2 (the norms of snow and wind loads are given for the middle band, which includes the Moscow region, on SNiP 2.01.07-85 * "load and exposure"). The amendment to the wind contributes to the calculations only when the roof is biased over 30. The values of the listed loads can be adjusted by introducing correction coefficients that take into account local climatic conditions. Own weight of the roof and the underlined design is determined in accordance with the material used and the size of the entire structure. The utility load on the rafter is taken into account, in the case of using the design of suspended (to the rafter farms) ceilings, or water tanks installed on them, ventilation chambers, etc.

The designer conducts two calculations. The first is strength (where it is guaranteed that the rafter foot will not break), the second - on deformation (where it turns out how such a beam can be fed). So, for the attic structure, the magnitude of the deflection of the rafter should not exceed 1/250 from the length of the site. For example, on the length of 6m, the deflection can reach 2 cm. It seems a bit, but if you exceed this value, the deformation will become noticeable with the naked eye. Aprics of large roof deflection can start reminding Chinese pagoda.

In the previous times, a log or semi-crust was used for the manufacture of elements. To date, most designers and builders prefer to use a ready-made rectangular bar with a cross section, corresponding to settlement loads, or a cross section of 50150 (50200) mm, which, if necessary, are solid. The entrance is mainly the wood of coniferous rocks (pine, spruce, larch) without vices, with humidity no more than 18-22%.

In order to increase the rigidity and immutability of the geometry of the rafter structures in some sections, metal elements are introduced, for example, as a support for the most loaded skate runs. Spans between metal parts are filled with wooden elements. Such a combination design is not only stronger than wooden, but also allows wooden rafters to work on a faded-sleeve scheme.

The customer, as a rule, does not object to the use of metal (the Russian man loves to be a clue). However, it should be remembered that certain difficulties are associated with the operation of the combined design. The fact is that due to the daily temperature difference on the metal surface, condensate can be formed, which leads to the reinforcement of the adjacent wooden elements. And here will save only the treatment of wooden rafted by moisture-proof compositions and the use of film waterproofing materials, insulating metal from the tree. But in this case, for the state of wooden rafters, it is necessary to constantly monitor that it is possible only if there is a attic.

In mansard structures with metal, their difficulties, for it is an excellent cold conductor. Consequently, the standard method of insulation (when thermal insulation is laid between the rafters) may not come up. The insulation must be laid so that the metal parts are either outside its layers, or entirely inside the room (with all parts of the roofing "pie" - roofing, ventilation gap, heat, moisture and vaporizolation, the inner sewing is outside). Both ways have their drawbacks. Forward, the case is lost quite significant volume of the room (for which they fought?!), In the second rafter it is necessary to somehow decorate (clapboard, gypsum sheets, decorative panels, etc.).

In some cases, the solid construction is entirely made of metal. Such an option is practical: there is no caring with a metal tree. Technology of insulation is the same as in the previous case.

Production of rafal structures

As already mentioned, the rafter structures can be wooden, metallic and combined. Let's start with wooden. Possible ways of their receipt are two: the first- Order of the rafter farms in the workshop or at the factory, the second way to make them in place.Wooden farms in the factory conditions are mainly produced using metal gear (nail) plates. They are offered in our market of Mitek Finland (Finland), Wolf System (Austria), "Technomplekt" (Russia) and others. The plates themselves are stamped from galvanized or stainless steel with a thickness of 1.2-2.5mm. Stropile structures using similar plates are manufactured on the installation and press equipment. Plates are put on both sides of the connection. Such technology makes it difficult to make rafal farms for the roofs of almost any complexity. It can be done both the farms of the whole and their separate linear components that are deposited on the construction site.

The second way has two solutions. The first is the manufacture of a rafter design by the "groove-spike" method or with the use of nails, brackets, bolted and the like connections, as well as clamps. The most common, certainly fastening rafted with nails and brackets (but it should be remembered that as the wood drying, this connection loses a little in strength and reliability). Bolts allow this disadvantage to avoid (though, the holes that are drilled under them, somewhat weaken the timber). The second solution is fasteners of wooden elements using steel stamped shaped parts and screws. Vagerika such technology is known for quite a long time, for us it is currently a novelty. For example, the company WKRET-Met (Poland) offers a collection of mounting parts of various purposes, and therefore different form, from universal elements (plates, corners) to purely special (so-in, including reinforced). The scope of their application is determined by the circle of technical problems and creative fantasy of the wizard. The task of creating a complex wooden structure at the same time is reduced to the level of the children's designer: the timing of the desired section and the required length prepared, purchased the required metal fasteners and self-tapping screws, and then, as they say, Winni on health.

Steel rafting structures are also made in two ways. The first way - production in the factory conditions. There are already quite a lot of firms on the market at the market, on this specializing. For example, rafter farms are becoming increasingly popular (more precisely, whole rafter systems) from thin-walled galvanized rolled Z- or C-shaped section (material thickness, 0.7-1.5 mm, profile length- 2, 4 and 6 m). Profiles are offered both domestic and overseas production. They weigh compared to conventional black rolled products are much smaller, which allows them to mount them with a light machinery and even without it. The fastening of structural elements is carried out without applying welding-self-straining with high-strength steel. Alternatively, the manufacture of steel farms in the factory conditions can be ordered, and then raise them with the help of the crane and the final installation to produce in place.

The second way is the production of metal rafters directly on the construction site. We purchase steel 2, channels and corners of the corresponding section, hire a faucet and a qualified welder (possibly a brigade of welders) and work (however, there are some tricks, but somehow somehow). By the way, it is this path that is used in the manufacture of most metal-treated structures.

Installation of crates

The rafters support the crate, the device of which depends on the type of roofing material. But before it starts to install it, the underpowering waterproofing layer is stacked directly on the rafter, which is fixed by the counterclaim (the wooden timber is nailed along the rafter). The second task of this operation is to form a guaranteed ventilated clearance, which will remove pairs of moisture from the insulation. The prerequisite of the BRUSEV, laid on the rafter feet perpendicularly attached to the counterclaim. Its appointment is to directly perceive the load from the roof and transfer to rafters (and those in turn transmit the load on the walls).

If the rafters are visible in the interior of the rooms

Such a phenomenon is characteristic of double and attic structures. Wayfish wooden rafters should be well succumbed in advance and resolved. If they are located high enough on the floor, the easiest way to be treated with a veneer and varnish or complex biolaiming composition. At the same time, the texture of the tree is emphasized and it is attached to any desirable color. Thus-processed rafters will bring heat and vitality in the interior of any style - classic and ampir, modern and high-tech. But if this is not a solution for you, the output is only one-to-hide the cutting ceiling. For this, in their lower edge, any sheet or wrapper material (drywall, chipboard, lining, all possible panels, etc.) are taken.The type of crate is due to the type of roofing. For example, for natural tiles, metal tiles and light wavy materials ("erector"), it is mounted from bars 3050 (4050, 5050, 6060, etc.) mm, which are stacked at a certain distance from each other (cross section of bars and the distance between them It is indicated in the technical documentation for the roofing material). For soft bituminous tiles, it is no longer a doomer, but a solid flooring from the edged and even tipped boards with a cross section of 25100 or 25150mm (the gaps between the boards should not exceed 5mm), waterproof plywood or oriented stove (OSB-3). If the work is carried out in the winter, then when using plywood solid flooring or OSB-3 plates between sheets, it is necessary to leave a 3mm gap to compensate for a linear expansion in the warm season.

Roof ventilation

On how to arrange a ventilated roof in mansard structures, our magazine has already told in detail in N 6 for 2003, so we will not repeat. I will add only a few words about the ventilation of the attic structures.

In winter, the attic remains cold, but the attic floors, of course, should be well insulated. Sufficient ventilation is ensured by the influx of air in the area of the eaves or through the auditory windows and its extractor in the area of the skate. Chimneys and pipes of the heating system must be thermally insulated. The difference between the temperature in the attic and the street should be minimal. It reliably protects your roof both from the formation of icicles and from avalanche-like snow from it.

Roof value

The costs of the construction of the roof are made up of the cost of the carrier structure, roofing material and materials of the undercoal "cake" and, of course, the cost of the necessary work.Let's start with the fact that the number of purchased lumber (and, consequently, the cash costs) will directly depend on the type of roof. There are no longer the opinion that the most tree is on the manufacture of truss structures under natural tile (mass-about 45kg / m2). With the mild roof, the bar is significantly less. And we, honestly, were already ready to accept this statement for Axiom. However, when our review was preparing, Braas specialists proved the incontinent of this approval. If you calculate the total load on the rabbown meter of the rapid leg, then at natural tile it will be most of only 15-20%. And often this load is completely withstanding even a rafter foot with a cross section of 50-150mm. Yes Yes. These are the very bars that are widely used for the manufacture of rafters under all light roofing materials. Although, possibly natural tile will require a smaller step of rafters and strengthening the places of likely formation of snow bags. But no more. Solid side, construction under a soft bituminous tile is accompanied by a solid trint of rafters. Because of this, it is difficult to definitely say what more tree will go.

Tips for private developer

Here are the advice we received from the specialists from Anna: Typical error Is an attempt to somewhat expand the dimensions of the building under construction compared to the design and in proportion to this increase the elements of roofing design. Do not risk. It is safer to refer to the designer who recalculates the roof and will make the necessary changes in the drawings that you can safely embody into reality.

If there are doubts. There are many firms in which you can call asking you to check the project documentation provided to you or recalculate the design that you have at the moment. For example, for the house 1010 M, the project check will cost approximately $ 100. Recalculation of the design, naturally, more expensive, as you have to pay for the departure of a specialist in a place where it will make the necessary measurements, and then, returning, will perform the necessary calculations. In the same firms you can:

- Order a roof project to the already built house;

- Hire a specialist to carry out technical control over the construction of the roof and, if necessary, showed builders, what and how to do (author's supervision).

How to find arguments in dispute with builders? The phrase "I have these rafters seem to be curves!" For builders are not an argument. It is better to purchase Snip 3.03.01-87 "Bearing and Fencing Constructions", where in the section "Rules of production and acceptance of work" details the methods of verification and regulations of deviations of building structures are detailed. Then the deviations detected, expressed in numbers (degrees, centimeters, etc.), will become a reasonable argument not only for builders, but also in court.

If there are complaints To the firm that served as construction under the contract, the ways of solving disputes two. You can go to court, and it will appoint an independent examination. You can contact immediately to experts. Such experts are usually well-known firms with great authority in wooden construction. For example, Moscow region residents may contact the department of wooden structures MGSU or in the Laboratory of Wooden Designs of TsNII.

Where to find a handbook for the construction of a wooden house. There are quite a lot of modern literature on this topic. Experienced specialists prefer to enjoy the book "The design of civil buildings" editions of the Academy of Architecture of the USSR, 1947.

Now about the complexity of the roof. It is clear that this factor directly affects the cost of materials. Moreover, if at the cost of materials for the undercoal "pie" it affects slightly, then the flow of wood and roofing material increases with complex structures very noticeable. This is especially true of roofing material. Experts in one voice say that, for example, metal tile on the roofs of special difficulty is used completely unprofitable, for up to 60% goes simply into waste. But practical piece materials, such as natural and bituminous tile. Waste they give a lot less. True, a complex roof from any material requires more of the challenges and, consequently, large cash costs. In general, beauty requires certain victims.

With the cost of work the picture is about the same. The increasing opinion that the payment of wages of masters is about equal to the value of the materials spent, it turns out faithful not always. Work can be difficult and therefore expensive, and materials, on the contrary, cheap. Or vice versa. That is, rates for carrying out work directly depend on the complexity of the roof (and complex roofs require relevant qualifications of masters), and the payment of labor can fluctuate within $ 9-20 per 1M2. It should also be borne in mind that the cost of work in a solid construction company, as a rule, exceeds the rates of the "Shabashnikov" brigade 2-3 times (taxes, staff training, tools and overhead, somehow: office content, advertising, etc. ). But the company is good because it is a firm. There is someone to present complaints, since such will arise. The hired workers in this case will simply be removed and will go away. And even to sue will not be with whom.

Selection of roofing material

One of the most expensive components of the construction is roofing. Burnes are the highest requirements. How to choose a roof suitable for all the parameters for your home? First of all, it is necessary to make a choice between heavy and light roofing materials. Under heavy, we mean, such materials such as cement-sand and ceramic tile, and everyone else belongs to the easy. And this choice you have to do even before the design start. The use of heavy materials contributes its adjustments to the roof design, and maybe at home as a whole (for example, it will have to increase the carrying ability of walls of frame structures). You can still refuse the heavy roof in favor of the easiest you can still, but the opposite is unlikely.If you stop the choice on lightweight materials, then you will still have the opportunity to replace one material to another. True, it is impossible to say that such a replacement you will be created easily, - each of the materials involves its features in the design of the crate and roofing "pie", so the replacement of the material "on the go" can entail additional costs.

In general, it is always better to choose a roofing material in advance and take into account this choice when designing. Choosing a roofing material, it is important to clearly imagine, for what time the building is designed for the service itself and separately roofing, as well as the roof configuration. The criteria for selecting a specific material are:

- Appointment of the building (whether it is built, summer country house, cottage for permanent residence, an extension, etc.);

- conformity of configuration material and constructive features, roof complexity;

- local climatic conditions;

- The durability of the material and its compliance of the planned durability of the roof and the building as a whole;

- Aesthetic requirements and personal preferences of the developer;

- compliance with the material to the economic possibilities of the developer; Here the value of the material is estimated, the complexity of its laying, the number of waste on complex roofing;

- noise insulating and heat-saving properties;

- complexity of care (maintenance) and repair work;

- The behavior of the material in relation to snow cover: on the one hand, it is very important that snow on the roof is not selected; On the other, so that it does not have an avalanche-like me, because it can cause a breakdown of drain gutters and drain pipes, etc.

What exactly choose is not to pay. There are no ideal or universal material, and the determining criteria for choosing each of their own. For one person, everything solves the price, moving the rest to the background. For another, the main thing is to get the entire package of positive consumer qualities, and the price is interested in so far because. The third chooses the roof according to the principle: if only such as the neighbors. The fourth, on the contrary, recognizes only that material that would have harmonized with a neighbor on the right and with a neighbor on the left.

Our glossary

Endovma - Crossing the skates forming internal angles.

Konk - upper horizontal edge, which is the intersection of longitudinal rods.

Roof - Upper enclosing building design, perceiving external effects, as well as performing carriers, waterproofing, and with underacted (attic) structures- and heat-insulating functions.

Roof - Upper roof element. Coating (single-layer or multilayer), a prevention building from all types of atmospheric influences.

Stropyl farm - Flat lattice design, serving for overlapping large rooms. It is a geometrically immutable system of rods located in one plane and interconnected at the ends. The rods of the farm placed on the upper contour are called the upper belt, along the bottom contour of the lower belt. Internal vertical rods are called racks, inclined disclosures.

Ribs - Crossing the rods of the roof forming the protruding angles.

Slope slope Depending on the roofing materials used, the methods of their laying and the climatic conditions of the area in which the building is erected. Denotes: 1) in degrees; 2) tangent angle of inclination, that is, the ratio of the rifle of the roof (H) lift to the length of its horizontal projection (expressed in simple or decimal fractions, and for the roofs with a small bias, in percent).

The review of the roofing materials offered by the market in our journal was published quite recently (in the article "Roof, Roofing, Roofing" Pie "). In order not to repeat, this time we offer the readers to readers a consolidated table, compiled according to Ekobusinessstroy and Unicam . In addition, we have already presented to traditional roofing materials, and also listed their technological, functional and operational features.

Make out the readings read, produce your criterion or a combination of criteria, weigh everything in and against and only after that go to the architect or acquire roofing material.

How many roofing material to acquire? Do not suffer! Take a project in the hands and go to the "serious" seller, the specialists will calculate you all. No project? We will arrive at the place and measure the rods of the roof and will produce the necessary calculations (however, you will have to pay to the place in place). How to distinguish a "serious" seller from "non-serious"? Yes, very simple! "Serious" seller offers all the services listed above. In addition, it usually has in stock not one roofing material, but everything, but they exist on the market. And it proposes a complete set, from the roofing coating itself (naturally, with the necessary enough elements) to the most suitable for it to it, from self-drawing to the fluger. His specialists not only need to know everything about the roofing material you are interested in, but also to be able to work with it. And, of course, carefully treat the customer, not forgetting to provide it with necessary and not imposing too much.

| Type of material | Natural tile (ceramic and cement-sand) | Metal proficated sheets (metal tile) | Soft bituminous tile | Light bitumen wavytelists ("EuroShorter") |

|---|---|---|---|---|

| Manufacturers | Braas, Bramac, Tegal, Coppo, Baltic Tile, Ormax, Benders, Vittinge Tegel, Tondach, Eternit, Nelskamp, Rupp Keramik, Roben, etc. | Rannila, Lindab, Weckman, Gasell Profil, Metal Profile, etc. | Icopal, Katepal, Tegola, Pikipoika, Bardoline, Iko, Certain Teed, Bpco, Ilco, Klewa, Teknonikol, etc. | Onduline, Bituwell, Ondura, Aqualin, etc. |

| Mass: Material / Taking into account the weight of the crate, kg / m2 | (45-50) / (55-70) | 5/10 | About 8/20-25 | About 3/10 |

| Manufacturability | Requires careful and accurate installation of the crate. Minimum waste on any types of roof. Diamond disks. Increased 10-15% load on rafters. Under small slots, additional waterproofing is required to prevent moisture to prevent moisture in the underpants | Fast laying of sheets on ordinary roofs. The possibility of reconstructing old roofs without amplifying a rafter design. Work hampers the high sail of sheets. A lot of waste on complex roofing (up to 60%) | Applicable on the roofs of any complexity - the amount of waste does not exceed 3-5%. Installation at a temperature not lower than +6 C. Laying in the rain is impossible. Requires a solid crate (waterproof plywood or edged board). We need a lining carpet. Requires careful installation, otherwise the deformation of individual "petals" is possible. | Simple installation. Convenient for reconstruction. Sheets are easy to drink a regular tree hacksaw |

| Minimal angle of inclination | 12 | 12-14 | eleven | five |

| Service and repair | Practically does not require care. Reliable movement on the roof. Repair is easily carried out by replacing any of the elements. | For movement on the roof, ladders are required. Requires a thorough sacrament of cuts and assembly scratches. Perhaps the gradual fading of the polymer coating. The large-sized sheets (up to 8m2) due to the temperature expansion weaken the fastening self-tapping screws - the annual broach is required. Static static electricity accumulation | Stripes under the action of the sun sin themselves, providing complete waterproofing. Reliable movement on the roof. Easy repair. Perhaps the gradual darkening of the color due to the diffusion of bitumen in the external sprinkle | You can move on the roof only by traps or stairs. Easy repair. Perhaps gradual fading |

| Fire safety, sound insulation | Non-combustible material. Excellent sound insulation | Non-combustible material. Low sound insulation (even in combination with insulation) | Fuel material. Harvesterness is provided by mineral sprinkling. Good sound insulation | Fuel material. Good sound insulation |

| Condensate education | Good thermostat: in summer under it cool, winter is warm. Minimum formation of condensate | Abundant formation of condensate on the inside of the material (additional guide waterproofing is necessary) | Minimum formation of condensate | Minimum formation of condensate |

| Snowmanship | Eliminating the danger of avalanche-like snow | Avalanche-like snow gathering is possible, because of what caused damage to the drainage systems and injuries of people | Eliminating the danger of avalanche-like snow | Surface roughness makes it difficult to avalanche |

| Durability: official guarantee / real service life, years | 30 / to 100 | 15 / to 50 | 10-25 / to 40 | Up to 15 / to 20 |

| Price of material / installation / roofing system as a whole (including fair elements and water supply system, $ / m2 | "Braas" (5.9-11.9) / about 9/56-70 ceramic tile (17-37) / (9-11) / (75-120) | (4.3-12) / about 7 / (18-30) | (7-10) / about 8 / about 30 | (6-7) / about 7 / about 20 |

The editors thanks the firm "Western Roofing Center", "Anna", "Ekobusinessstroy", "Braas DSC-1", "Unicam", "Technonol", "RSM-Stroy", as well as Personally Shepelev V. G. for help in preparing material.