Pliers, Passatias, Pipes, Pliers and other manual articulated lever tools. Varieties, functions, several practical recommendations.

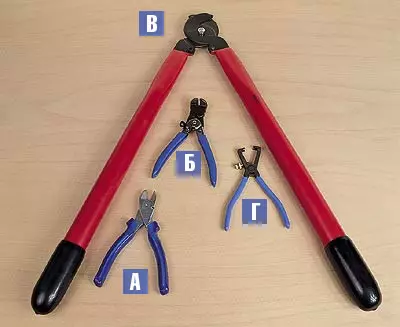

BUT -these,

B. - factory,

IN -Belive,

G. - Value

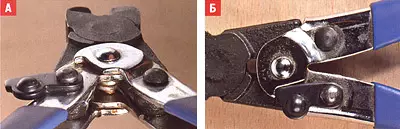

BUT -Adnamed retainer,

B. - guides, the number of which is equal to the number of positions of the lever,

IN - a swivel axis of a hinge with Lyk

G. - Comb with protrusions, the number of which is equal to the number of lever positions

B. - folding focus for fixing sponges closed

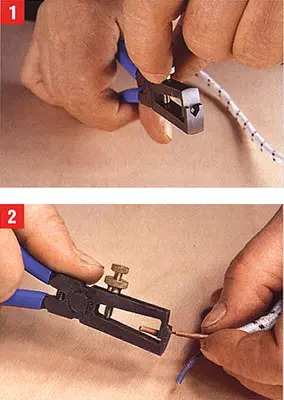

BUT - holes,

B. - Tile,

IN - Roofing,

G. - for square nuts

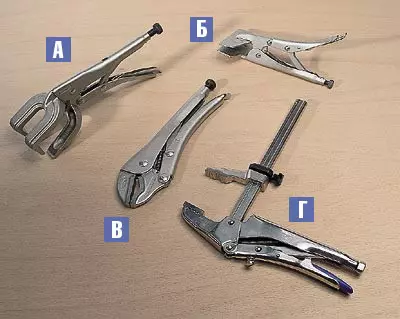

BUT - welding,

B. - for sheet metal (plumbing),

IN - with straight sponges,

G. - Poverty

BUT - diameter up to 16 mm and

B. - diameter of up to4mm

We are quite often complaining that we are not enough hands. A lot of things, and the possibilities of the human hand are limited. When performing carpentry, plumbing and plumbing works helps a manual articulated and lever tool, and in particular mites, passas, pliers, pliers and others.

In the home workshop there is always a hand tool that can "imitate" a person's hand in manipulating items with two rotary levers and a cylindrical hinge. At one end of each lever there are a blade or a sponge, and on the other, the hand to which the hand presses. The blade and the sponge have a higher hardness than the rest of the tool, and the effects of the arms are strengthened at the expense of the ratio of the shoulders. Such a tool is sometimes called a hinge-lever cutting or a hinge-lever compressive. Corde type includes secectors, suchkores, any kinds of scissors, and a report "A completely hand-made garden tool" was devoted to him in our magazine. Now we will tell about a hinge-lever compressive tool with a different shape of the cross section of sponges (flat, round, semicircular, with a pointed edge, with a cutting edge, with a toothed profile). It is intended to perform five basic functions: capture, manipulation, snacking, twisting and pulling nails, but not any design is adapted to perform all these functions. Therefore, there should always be pliers, and pliers, and round-rolls, and plys, and ticks, and manual vice and hinge keys should always be in the domestic workshop. Different types of manual articulated and lever compressive tools are shown in the table, but there is a purely professional tool that did not enter it.

Handicraft-lever compressive tool offer on our market as overseas firms - Swedish Sandvik, German Gedore, Knipex and Kstools, American Snap-On, Stanley and Proto, Slovenian Unior, Dutch Veto and Gebro, Indian Ajai, numerous Chinese and Russian Manufacturers, such as Novosibirsk, Pavlovsky and Izhevsky instrumental plants.

The same type of instrument of different manufacturers is distinguished by the degree of use, manufacturing technology, steel grade and its heat treatment, applied with a protective-decorative coating, material and form of covers for handles, as well as service life and price. Let us leave a special tool aside, such as plumbings intended for electronics, which are hardly suitable for snacking the cable. Now we are talking about the tool for carpentry, plumbing and sanitary work.

Kusachachi Designed for the capture and snacking of the material, but most often the wire. In addition to the position of the cutting edges on sponges, there are five main types of bodies: ipores, end, end, cable and credit. Stanley calls the first of them with longitudinal plugs, and the second "Russian" ticks. More often use and easier in contact with windows. To reduce the applied efforts, for example, at the snap-in (piano) wire, firms make either the distance from the cut line before the hinge as small as possible, or add more hinges. Sandvik, Knipex and Stanley enhanced the hinge, and due to the shoulder ratio, the force on the cutting edge increased by approximately 50% compared to the usual hinge while maintaining the force of the hand in 400n. The Gedore concern and SNAP-ON reached an even greater effect on the cutting edge, increased by 70% compared with a conventional tool. They applied several consistently active hinges in three-stroke nipples (boltology).

Firms adapt to the specific material and the shape of the cutting edge of the sponges of the side. Thus, symmetrical triangular cutting edges are most suitable for snacking solid wire, and when the wire is snacking, the wires from softer materials are obtained with obviously notable jar. For materials of medium hardness (bronze, non-ste steel) use nippers with extended bevels from the outside of the cutting edges, which ensures smoother edges of the wire, but reduces the strength of sponges. For soft materials (copper, copper-tin or aluminum wire), hydroes are used with short bevels from the outdoor side of the cutting edge or completely without bevels, while the quality of the edge of the wire is the highest, and the strength of the sponge is the lowest.

Cable nippers are characterized by powerful sponges in the form of a semi-colt ringing around one axis, with cutting edges. With the usual length of the handles, the diameter of the peroxilized aluminum or copper cable may reach up to 16mm, and with extended (up to 800mm), up to 40mm.

In each sponge, the enrolls are provided by a V-shaped slot with sharp edges for capturing, snacking and removing insulation from the end of the electric pipe. The previously adjusting screw is thoroughly exhibited the lumen between the tool slots, so that the metal conductor does not eat with insulation.

Anticorrosive Tool Surface Treatment

The surface of the steel tool is protected from rust with a special coating, which, like steel, is destroyed with time from corrosion, but much slower.Use several main types of coatings for steel, which differ in appearance and, of course, cost. Typically, these are metal films (chromium, zinc, cadmium, nickel) thickness of up to 25mkm or non-metallic layers (oxide, phosphate) with a thickness of 1-3 microns.

Coatings differ from each other by microhardness: what it is more, the harder it is to scratch the surface. Oxide and phosphate coatings do not increase the microhardness of steel, but serve as a good soil for applied protective paintwork. On zinc, cadmium and nickel coatings additionally apply the finest layer of chromium (up to1mkm), the microhardness is the highest.

The choice of coating is determined by climatic conditions in which the tool will be applied.

According to Russian standards in accordance with the shape (flat, semicircular, round) cross section of the tool sponges used for manipulation, pliers are distinguished by pliers, passage, pliers with semicircular sponges and round-rolls. The form of the work surface of the sponges is flat, concave, convex or with special recesses for capturing round items, and the surface itself is smooth or with notches that are performed with a certain step to ensure a stronger grip and harde.

Any of these types of tools in which the capture and snacking are combined, becomes universal. Moreover, the cutting edges are always located closer to the hinge than the compressive surfaces of the sponges, since the force on the snacking arms has to be applied much greater than when manipulating.

Passatii With high teeth with a step of 0.8 or 1,0mm on the work surface of the sponges of a special form, more complex parts can capture than pliers, as well as items with a threaded, screws, bolts, couplings.

Kruglog men It also hire a wire, and for the convenience of manipulating and twisting the ends of the sponges, they are sometimes made at an angle of 45 or 60. Upgraded round borders sponge with pointed ends, allowing you to remove and install locking rings.

Pliers With semicircular sponges, it is possible to use the inner plane of sponges, like pliers, and outdoor, like the round-heads.

All of these three groups of the tool are used to bend, performing edge and angular transitions of plastic sheet materials, such as tin.

Pincers Apply for capture and manipulation requiring greater effort, to pull out nails, and universal and wire peroves. In the early time, ticks are becoming increasingly distributed to perform special types of work, such as tiled, roofing and piercing holes.

Additional coating on handles

Starting cases on handles are applied another coating for two reasons. To work under the electrical voltage, any lever-hinge compressive tool requires its standard electrical insulation. The incidence of insulating material uses rubber, rubber, polyvinyl chloride (PVC), resistant to machine oil, gasoline and kerosene. It is applied by a layer with a thickness of 2-4 mm immersion of handles into molten insulating material or powder spraying on heated handles.

For the convenience of the user, thicker covers of the same materials are worn on the handles, which not only isolate, but also increase the surface of the contact with the palm, which reduces the pressure on the hand. Handles with such covers can be stronger compressed without painful sensations than handles without covers. A number of firms use combined covers, for example, the company Sandvik combines hard propylene with soft linings from thermoplastic, which reduces hand fatigue, especially when applying great efforts.

According to the international VDE standard for isolation, designed to 1000V, there are more stringent requirements. Covers supply thicketers located close to the hinge and which are an obstacle for random hand slipping into uninsulated steel. Sometimes these thickens are lengthened so as not to enable handles to climb to the end and pinch your fingers in the process of work. To eliminate the occurrence of cracks when the tool falls, the insulation layer on the end surface is always much thicker than on the surface of the handles.

Manual vice more often called clips. They are indispensable when grinding small items with electricity, when conducting welding, when sawing sheet materials, for a dense connection of two parts without clearance, for squeezing parts when gluing. The sponges of some clamp models are kept temperatures up to 480s, and others are still equipped with cutting edges.

The design of the hand tool is constantly being improved, and the evolution of rearranged pliers is very curious as an example. One of the levers can occupy two positions relative to the joint axis, which allows not only to breed, but also to shift the levers along a special groove, thereby expanding the range of the sizes of the excited items. The firms decided to lengthen the handles and the grooves, and it turned out that the possibilities of the tool were significantly improved both by the magnitude of the effort created and in the range of sizes of the excited items. It turned out a new tool. It is called and over-the key, and stopped ticks, and universal capture. Then they began to develop various devices to quickly displace the lever along its groove. One of the spring-loaded hinge, which first slept slightly "and rearrange the lever with a slide along the groove to the desired position (they5 or more), and then release the retainer with the spring, stop it. In order not to leave the dents on the metal surfaces of items when operating the key, they use nylon nozzles on the sponges and give them a special form.

First hinge Under the name "Steel Hand" back in 1888 patented the Swede J.P.Johansson. Obviously, therefore, the company Knipex This tool calls a Swedish adjustable key. Unas he is known as a gas key. Durable capture is created by sponges that need not to be rearranged, and smoothly move out relative to each other with the screw and nuts located on one of the levers. The key design is so tough, which ensures the transmission of a large torque. The inconvenience can be considered a significant effort of the hand, which should be applied to eliminate slippage of the rotated pipe relative to compressed sponges. This inconvenience is eliminated in different ways. Sandvic uses a special retainer that eliminates the need to constantly compress the handles, and the Gedore concern has developed a special form of the working surface of self-grade hardened sponges. When applying too much effort, such sponges even begin to work like cutters, cutting off the outer layer of metal from the surface of the pipe.

Handles Usually have a convex form that provides convenience of capture. Some firms, such as Snap-ON, give the handles an exotic form, which makes it possible to work in hard-to-reach places - in narrow simplests and under the ceiling. The key, manual vice and ticks often have straight handles, to the ends of which the force is applied. The slurries, the roundheads and the passage of the length of the handles are usually 1.5-2 widths of the palm, and the bustard and ticks can be 3-4 times larger, which allows the piano wire with a diameter of 6mm and more.

Several practical recommendations

1. Do not exercise long-term operation or work related to the application of significant effort. First, fasten the object in the locksmith vice or press to the flat surface with clamps.2. To eliminate damage to the clamping surface of the item, route between it and the tool spins are dense tissue or abrasive skirt (abrasive to the subject).

3. When fixing the object during grinding with manual vice, remember that the maximum retaining force is created only in the direction perpendicular to the plane of sponges, and the minimum along this plane.

4. Always wear safety glasses when snacking solid wire tool.

5. Keep the tool clean, dry and periodically lubricate the hinge with machine oil.

Hinge Must be geometrically correct and smooth rubber surfaces to ensure the ease of rotation of the levers under a significant load without deformations, wear and jamming and to exclude dirt and dust between them.

Levers It is calculated so that the magnitude and ratio of shoulders ensure the maximum force in the interval of 250-400 H (25-40 kgf), an affordable person's hand without significant muscle tension. However, there is such a tool for strength with a large margin - with efforts from 1120 to1550n (depending on the length). The ausube needed to disclose sponges should not exceed 9.8H (1kgs).

Steel From which the tool is manufactured and is called tool, and it provides strength, hardness and wear resistance of compressive sponge surfaces. The highest quality sponge of a special chromovadium steel with a subsequent high-frequency induction hardening.

The warranty period for the entire instrument on Russian standards is from 6 to 9 months, and the service life is 1.5 years, but with a careful attitude it will last much longer.

Main types of manual hinged lever compressive tools

| View | Functions | Main appointment | |

| Kusachachi | |||

|---|---|---|---|

| Conditions | Capture, snacking | Separation of parts of sheet material, wire and other thin objects | |

| Facial | Also | » | |

| End. | » | » | |

| Cable | » | Cable snacking | |

| Enroll | » | Insulation tipper | |

| Pliers | |||

| Normal | Capture, manipulation, crash | Manipulation of simple form subjects | |

| Restored | » | » | |

| Universal | Capture, manipulation, twist, snacking | Manipulating Simple Forms and Wire Parts | |

| Kruglogs. | |||

| Normal | Capture, manipulation, crash | Curl and Navigation Wire | |

| Universal | Capture, manipulation, twist, snacking | Twisting, Naving and Branch of Wire Parts | |

| Stoporn | Capture | Installation of locking rings | |

| Passatii | |||

| Normal | Capture, manipulation, crash | Manipulation of objects of complex shape and threaded | |

| Universal | Capture, manipulation, twist, snacking | Manipulating objects of complex shape and threaded, separation of wire parts | |

| Pincers | |||

| Normal | Capture, manipulation, pulling nails | Capture items of various shapes and pulling nails | |

| Universal | Capture, snacking, pulling off nails | Capture of items of various shapes, pulling off nails, separation parts of the wire | |

| Powdropurobivny | Punching holes | Performing special types of work related to the effort | |

| Riveted | Setting rivets | » | |

| Tile | Cutting a ceramic tile | » | |

| Hand hinge vice | |||

| Normal | Capture, manipulation | Holding items of various shapes | |

| Universal | Capture, manipulation, snacking | Holding items, Wire Parts Branch | |

| Hinge | |||

| Sliding | Capture, manipulation, crash | Capture and twist with a large torque application | |

| Reversal | » | » |