We disassemble the characteristics of the system, its pros and cons and give step-by-step instructions on the trim of the facade of metal siding.

The sheathing of the house with metal siding - the process is quite time consuming. Prefabricated elements weigh a lot, and to raise and hang them, strong hands will be required. One person is unlikely to cope with the task. In addition, the ordinary dacha is badly present, as the fasteners and the outer part are arranged. This is perhaps the main reason why owners of country cottages and light summer buildings prefer to seek help in repair and construction companies. It is worth noting that there is nothing complicated in the design. Sometimes it is harder to assemble the Ikeev cabinet at home. A set of external planks and internal parts is attached to a detailed description and step-by-step installation guide. If he exactly follows, everything should work out. But first it is necessary to study the technical support and the warranty card - it is possible that when the manufacturer's warranty is burning. The owner will not be able to prove that defects and damage arose not by its fault.

All about Metal Siding Mounting

Pros and cons of the materialSystem device

- fastep and doom

- Heat and sound insulation

- Outer side

Step-by-step instruction

- Required tools

- Preparation of the foundation

- Fastening the crates

- Sheathing

Pros and cons of the material

Benefits

- Large service life - it is about 50 years.

- Resistance to heat, frost and precipitation. Quality products do not fade in the sun.

- The material does not burn and does not distinguish harmful substances.

- Wide model line. The trim can be made to order.

- Prefabricated elements need to be processed like a tree or concrete. They are easy to care - sometimes it is enough to wipe them.

disadvantages

- Steel panels are not protected from cold and noise. Moreover, they are perfectly resonated, reinforcing sound coming outside. In hot weather, steel heats up strongly, transmitting heat into the room. Before installing, it is necessary to ensure insulation and sound insulation.

- Facing has a large mass. Choosing a certain model, the carrying capacity of the building structures should be taken into account. Perhaps you have to strengthen the walls and foundation. To make sure that the house will endure the weight of the facing, it is better to apply to the engineering company and conduct a survey. The main load creates a covering.

- Panels are not subject to recovery after deformation. Cement to fix it will be impossible.

- Products have a big length and area. They are difficult to store and transport because they occupy a lot of space and easily bent.

- Planks are mounted on wide and long anchors. They destroy the basis, relaxing it and reducing its insulating abilities.

How is the case of the trim

It is a set of planks and fasteners.Fasteners and doomle

As a rule, the frame is collected from the steel profile. Bar is used less often. The frame is fixed on the wall with anchors. Connectors differ from each specific model. As a rule, it is brackets, latches, perforated profile with screws for self-tapping screws. On the back of the external panels there is a mounting rail with mounting holes. The kit includes locks located between the "boards" and allowing the facade vertically and horizontally.

Heat and sound insulation

The inner space is filled with insulation and acoustic materials. Steel sheets are well resonated, reinforcing vibrations. They perfectly spend the temperature. The soft filler protects from cold and noise. On both sides it closes the waterproofing membrane. The coating improves the living conditions and extends the service life of the walls of the building - a tree, brick and concrete gradually collapse from the cold, heat and moisture.The finish should not be completely sealed. If the membrane does not "breathe", dampness will appear in the room, and condensate will be lingering inside the walls. Reiki passes air. Problems usually causes impenetrable insulating film. When the wooden house is trimmed with metal siding without hermetic interlayers, conditions inside will not change.

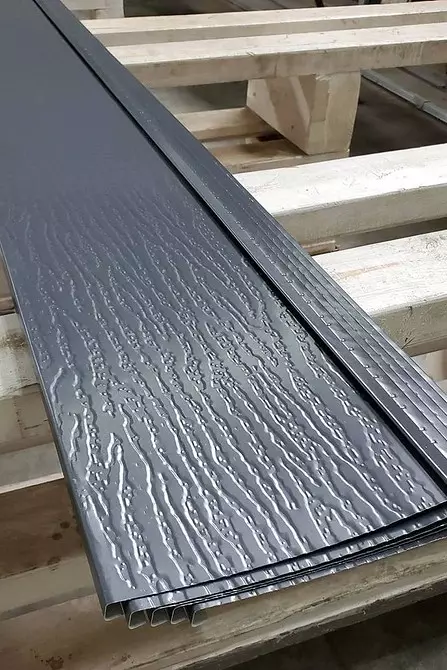

Exterior

Rakes are fixed horizontally and vertically. They are covered with a smooth layer or create texture. Similarity with various materials is achieved due to the special form of planks. For example, products imitating a natural array can be divided into four main types: shipboard, timber, block house, log. It is easy to confuse to confuse with the present, and the sheathing of the house with metal siding under the timber looks rather convincing.

What layers are the rail

- The galvanized steel strip is about 0.7 mm thick.

- Anticorrosive coating.

- Primer - it is placed on the back and face.

- Polymer decorative layer, giving a product of color. It is often applied to the drawing, imitating building materials. This layer is not always used. The photo sometimes has to see the metallic color finish.

- Matte or glossy varnish or polyester.

Which rails are included in the set

- The main coating for a smooth surface.

- The starting and finishing bar limiting it from above and below either on the sides.

- Special profiles for window and doorways, slopes and flows.

- Corner panels.

How to strip the house with your own metal siding

Tools for work

- Hacksaw and scissors for metal.

- Perforator.

- The screwdriver is either a hammer - bands are mounted on nails and self-tapping screws depending on the material of the frame.

- Construction level and plumb.

- Roulette, square, pencil.

- Protective gloves and glasses.

Preparation of the foundation

The facade is checked for carrying ability. It is necessary to calculate the mass of cladding together with the frame. To do this, multiply the surface area of the wall for a mass of 1 m2 of coating. Then we produce the same calculation for the crate. The resulting values fold. Now we know what weight should one side of the building should withstand. To understand whether it will cope with such a load, it will be necessary to help the engineering company. An engineer with special equipment will arrive at the site. He will conduct a survey and give a final conclusion.

If the installation can be carried out, the surface is carefully prepared. From it remove dirt and moisture. Work should be carried out in warm dry weather. Under the trimming should not be too humid, otherwise the material will begin to collapse, and the smell of mold will appear indoors. Condensate, dropped out of atmospheric air, will quickly evaporate through the slots in the facade, but the wall, through the soaked dampness, will have to dry under the finish longer than outdoors. In winter, it will not be able to dry the base, absorbed the autumn precipitation and the outaged. It is better to wait when he fatters and dries.

From the walls are written by falling pieces of plaster and paint, if it is well held. Mold and moss are removed. Flagpoles, holders for antennas and other metal parts removed. Cracks are expanding and removing light edges. Brick, wooden or concrete base are treated with antiseptic solution. The voids close up, and the fresh layer of material is covered with an antiseptic again. If overhaul is required, now it's time to do it while the designs are open.

Installation of crates

If the framework details are included in the kit, you will examine step-by-step instructions before installing metal siding. It may have special directions in it. There are many technical solutions, and it is impossible to consider all the features in one manual.

Start follow from marking. If decorative strips will be arranged horizontally, the elements of the crate - bars or P-shaped profiles are vertically. For vertical installation, guides are fixed horizontally. They are installed directly on the wall or connect with it using brackets. In the second case, the guides are screwed directly to M-shaped brackets, or first put a perpendicular profile. It will allow you to change the location of the details without tie them to the place where the brackets are located. The step between the guides depends on the model and its mass. On average, it is 30-60 cm. Near the windows and doors it makes it less. In the smooth areas increase.

The brackets are finished products or suspensions from the profile bent at 90 degrees. They are hanging on steel anchors. They maintain the weight of the whole design, so they should be attached to a reliable basis, which has been checking and necessary repairs.

The outdoor side of the frame is tested by level and plumb. The surface must be in the same plane. Dissakes are not allowed.

When the frame is ready, it is filled with insulation, for example, mineral wool slabs. To inside the moisture was not accumulated, they are closed with a waterproofing membrane on both sides.

How to mount metallic siding

Consider the installation of step by step. As an example, take the standard set of "shipboards".Procedure for installing details

- Starting plank.

- Corner elements located in hard-to-reach places.

- Window and doorways.

- The main coating that closes the smooth areas.

- External and internal angles to which you can easily get sick.

- Finish row.

A protective film is removed from the front side. It is needed to protect against damage during transportation and storage. The starting bar is fixed from below at a height of 3-4 mm from the soil level or from the base. The distance between nails or self-pressing is 30-40 cm. They are injected into the technological holes around the edges, moving from the center. You should leave a millimeter gap between a sheet and a hat. You can not tighten the screw tight - metal is easy to drive.

Then go to complex details. The step between screws and nails is reduced twice. In the openings, the slopes and flows are mounted. Prefabricated elements are exhibiting at the construction level. To check verticals, you can use a plumb - load on the rope.

When complex areas are ready, the main part closing the walls is fixed. If there are angular elements, rail races are between them. The bottom is screwed by self-drawing to the starting part. Step between screws - 2-3 cm.

When the lengths are not enough, special challenges use. Near the railway openings you have to be cut with scissors for metal or saw. Scrolls are made from holes under the screws. You should not use a disk saw - on the sides when heated from the rotating disk can melt the polymer layer. It is better to calculate in advance the desired length and make a short part to order. Cutting is also produced in the store when buying.

The usual rows are joined using a nickname or a special n-connector included in the kit. Without a connector, the rows are laid with an adhesive from 2.5 cm. The nest protects the inner space from the water and garbage.

The angular elements are put on top of the main coating. The basis for them is the framework. It is impossible to fix them on facing without support. The step of the self-tapping screws depends on the width of the part and its weight. If it is 50x50 cm, the distance between the screws take 50 cm. For the angles of 70x70cm, it is 40 cm.

At the final stage, the top tier is fixed. The top is snapped with a special retainer.

The described technology does not depend on the material from which the house is made. To understand whether to see the wooden house with metal siding, or decorate the construction of foam blocks, you need to explore the carrying ability of the base. There are no other restrictions.