Features of interior partitions from plasterboard. Varieties of material, fastening methods, manufacturers.

Expanding the scale of individual housing construction, private architectural orders, author's design ... All this led to the fact that the plasterboard sheet became one of the main tools for the interior formation

Just like all ingenious

Why is the plasterboard fit so well into the gamut of finishing materials for our dwellings? First of all, thanks to the physical and hygienic properties of their main component, gypsum. This is an environmentally friendly material that does not contain toxic inclusions and having a very low pattern of radioactivity. Gypsum has a fairly good sound absorption, non-flammable, agun, and still has acidity close to the acidity of human skin.Plasterboard sheets (GLC) absorb the oversupply of moisture from the air or give it if the air is too dry, naturally by adjusting the microclimate in the residential areas. Very technologically and convenient to work. Allow the "wet" processes (for example, plastering), which means to reduce the complexity and the cost of the work produced, get rid of the construction waste and save the nerves, waiting for the end of repair. The designs of GLC are 3-4 times easier made of other building materials, simply and quickly mounted (one qualified master during the working day collects up to 60m2 drywall structures). It is hard to find a more versatile material. The set of plasterboard sheets can be facing the walls, erect interroom partitions and suspended ceilings, arrange the floor bases.

It would seem that everything is simple and clear. But as soon as you start repairing or begin to reflect on the planning and finishing of a new apartment, immediately arises a number of questions. What sheets to choose for rooms, and which are for the kitchen and bathroom? What type of drywall is more suitable for the device of curved and embossed surfaces, for the ceiling, for wall cladding? What to buy a fire-resistant or ordinary sheet? And what thickness to prefer? After all, about ten sizes are presented in the store. Let's deal with the order.

In fact, the drywall is a sheet finishing material with a so-called core of a construction gypsum reinforced with fiberglass. Sides the core is saved with a solid cardboard. Actually, from the total mass of GKL 93% falls on a gypsum core, and 6% - on the cardboard layer. The front side of the sheet plays the role of the base, fully prepared for the application of finishing coatings (plasters, wallpapers, paints, ceramic tiles, PVC-panels, etc.). The sheets themselves can be attached to the resulting base or by means of special glue, or on a metal frame.

A variety of GLC-gypsum fiber sheets, or GVL, which are not covered with cardboard. Gypsum in such sheets of reinforced with flushed cellulose waste paper and contains various technological additives, due to which the GWL acquires a higher hardness than GLC, and considerable resistance to the exposure to open flame.

On our market, drywall products are supplied mainly by two large-scale firms "Knauf Gypsum" (Russian enterprise of the German concern Knauf) and Gyproc (England). Materials are most common from domestic gypsum raw materials. In addition to the GLCs themselves, Knauf concern produces construction chemistry, tools, dry mixes, metal profiles, guaranteeing compatibility and quality of work inside the product line of the same brand. Gyproc specializes only at the production of gypsum materials, and Gyproc's plasterboard costs more (the difference in prices is 5-10%), since it comes to Russia from factories located in Finland, Poland, Sweden, Denmark and even England. GyProc sheets are attached to the frames from the metal profiles of the Russian company "Alumasvet", and for sealing seams and, if necessary, the application of the waterproofing layer, the manufacturer recommends the materials of the Rigips brand (England).

GLC for wet premises

All plasterboard sheets presented on the market can be divided into conventional (GLC) and moisture resistant (HCCV), with additives that reduce moisture absorption. UBCV Water absorption by weight is 2 times less. So, if a standard sheet is gaining 25% of moisture for a certain period of time, then moisture-resistant - only 10%. Externally GLC and G Clac easily distinguish between the color surface: conventional sheets are frozen with gray cardboard, moisture-resistant green. This is an international standard for all manufacturers. Both ordinary, and moisture-resistant sheets are produced in a special performance, with an increased resistance to the exposure to open flame (respectively, GKLO and GKLO; Gyproc manufactures fire-resistant sheet GF 15). This means that in the event of a fire of designs from these materials, one sheet (12.5 mm) thickness (12.5 mm) will be able to withstand firefire, at least 20 minutes.

It is intended to build some kind of designs from drywall, remember that the operational characteristics of GCCs depend on the humidity regime in the room. Works with drywall sheets begin only at the end of all the "wet" processes (that is, after drying the putty, plasters, etc.), when an ordinary, normal humidity regime is installed in the room, as in everyday life.

In accordance with SNIP II-3-79, normal humidity for residential premises is 60%. Standard plasterboard sheets are designed to use precisely in dry rooms with normal humidity, that is, in ordinary housing. In the kitchen and in the bathrooms, the humidity indicator can reach up to 70% (kitchen), and even up to 90% (bathroom). And although G CLEV is recommended for such wet areas, as a bathroom, a toilet or kitchen, an indispensable condition for the use of moisture-resistant sheets is the exhaust ventilation device and protection of the facial surface of the drywall, for example, waterproofing compositions, waterproof primers, paints, ceramic tiles or polychlorine coatings.

All waterproofing work is carried out before applying facing materials. Significantly facilitates the work technology from Knauf Gypsum: The company recommends applying "its" products by ensuring their compatibility among themselves. For example, to cover the walls of the bathroom, it is proposed to use moisture-resistant plasterboard G Clac and putty for the fogenfuller-hydro seams. After drying the putty on the seams, the entire surface of the G Clac is grounded with the composition of "Tifengrund", and the surfaces to which water will fall and where the moisture can be condensed, before final finish should be covered with waterproofing "Flekendicht".

Naturally, heavy plumbing equipment (sinks, mixers, shower holders, etc.) will not be able to hang without a special reliable fastening. Therefore, at the stage of assembling the framework, mortgage elements are mounted, such as metal strips. All seams between the sheets, the compounds of walls with the floor, as well as the conductive holes for pipes are sealed with sealing ribbon and waterproofing compositions. For tight facing sheets, sheets are preferable to mount on a frame of metal profiles (with a width of a shelf at least 50mm) with a pitch of 600mm racks, while the G CLEM is mounted in 2 layers on each side. It is necessary to take care of the ventilation of wet rooms by ventilating windows or channels through which the excess moisture (water vapor) will be output.

How are the designs of GLC

There are two ways of cladding walls with plasterboard sheets - frameless and frame. The frameless method provides for the attachment of sheets to relatively smooth (from reinforced concrete panels or large blocks) wall surfaces with a special glue, for example "KNAUF fogenfuller". Installation of HCL is carried out after performing the wiring of electrical and sanitary systems and the completion of all "wet" processes. Sheets are ground, and after drying the primer layer, if necessary, the holes for switches and sockets are cut on the markup. Next, a glue solution is applied to the toothed spatula on the perimeter and along the middle of the sheet, after which each sheet is raised, installed on the gaskets and pressed to the projected wall. Finally, the alignment of the finished design is carried out with the help of the rule, and control the verticality - using the construction level.For the installation of GLCs on a strongly uneven walls (from brick, sawn natural stone, small blocks, etc.), a thicker layer of gypsum glue type "KNAUF PERLFIX", applied by cells along the perimeter of the sheet in a step of about 25 cm and along the middle of the sheet with About 35 cm step. If you have to deal with very uneven surfaces, it is pre-fastened for each of the walls (also with glue) 300mm width strips performing the beacon function. In this case, the two horizontal strips are glued close to the floor and the ceiling throughout the perimeter of the room, and the vertical strips between the nimble is 600 mm.

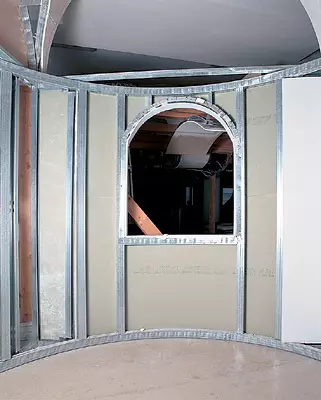

Nevertheless, the most common way to install Hlk-frame. Each manufacturer of plasterboard offers a whole system of various profiles and fastening elements (self-seed screws, dowels, etc.). The interior framework provides holes with a diameter of 30mm for wiring communications. The profiled products themselves are made by cold rolled products from galvanized steel tape with a width of 0.56-0.6mm and there are several types: guides, angular, rack, ceiling. For example, the angular perforated profiles are installed on the external corners of the designs of GLC and GWL, helping to align the angles and simultaneously protect them from mechanical damage. For fastening suspended ceilings, two-level connectors are used, suspensions with a clamp and a burden, special ceiling profiles. For the manufacture of structures with outer angles 120 or, for example, the formation of arched openings can be used special PVC profiles.

Both main suppliers of GLCs on our market - Gyproc and Knauf Gypsum - offer so-called complete systems for wall cladding, devices of mounted ceilings or interior partitions. The compartment includes everything you need (fasteners, profiles, lists themselves) with the calculation of 1m2. You can purchase any items and individually if you need to build some non-standard design. At the same time, all complete systems from Gyproc and Knavel Gypsum are designed to use standard 12.5mm thick. You can, of course, and independently develop structures from any materials, but then you will have to think through questions of strength and reliability, based on the specific situation.

All about fighting fire!

The only combustible material in plasterboard, of course, cardboard. But since there is no air between it and the inner layer, the cardboard does not burn, but only charred. The crystals of the inner layer of gypsum contain chemically bound water in an amount of approximately 17% of the mass of the sheet. In case of fire, crystals under the influence of high temperature decay, and the exempted water prevents the swollen flame. Plasterboard sheets do not allow fire to penetrate the design of them until the crystallization water evaporates completely and the sheet of the material will not begin to collapse.

All GLCs belong to the burning group of G1 (that is, according to GOST 30244-94, they are wellowing) and the igniter group B3 (according to GOST 30402- 96- Moderately flammable). If you do not want the fire to spread in a blink of an eye, it is better to choose a design that would ensure high resistance to the exposure to an open flame. This parameter is indicated in the documentation attached to each type of facing, in hours and minutes, and the professional architect will take it into account if you compose with him the possibilities of fire protection mounted in your dwelling. Thus, cladding with a single metal frame and a single-layer GLC (12.5 mm) will be able to withstand 30 minutes of open flame. A similar design, but already with two layers of GLCs weighting "under the fire" for an hour.

GVL and GVV sheets have the same fire shoes as GLK, and according to the criterion of resistance to burning, they even exceed them and as a result included in the flammability group B1. Thanks to this quality, GVL and GVVV are most often used for cladding indoors with structures on wooden or on a metal frame. Of course, it is not necessary to sow all the walls in your apartment GWL. Hypus fiber sheets have a greater density and bending strength, and besides harder than standard GLK. So, although GVL and HL-interchangeable products, it is easier to work with GLCs, because they are easier mounted.

Materials consumption standards * for facing device based on Knauf Gypsum Products

| Material, unit. Measurements | 1m2 flow consumption | price, rub. | |||||

|---|---|---|---|---|---|---|---|

| C623 (on the frame of the ceiling profile) | C625 (on a metal frame, in 1 layer) | C626 (on a metal frame, in 2 layers) | C611 (pouring on glue) | C631 (pouring on glue) | |||

| 1st layer | 2nd layer | ||||||

| Plasterboard sheet, m2 | one | 2. | one | 2. | one | - | 48,79. |

| Combined gypsum panel, m2 | - | - | - | - | - | one | 145,36. |

| Guide profile Mon 28/27, pog. M. | 0,7 | 0,7 | - | - | - | - | 11.59. |

| Guide profile Mon 75/40 (100/40), 50/40 (C626), Pog. M. | - | - | 0.7 (1,1) | 0,7 | - | - | 19-24. |

| Guide profile Mon 60/27, pog. M. | 2 (2.4) | 2. | - | - | - | - | 15.9 |

| Direct suspension (C623), pcs. | 0,7 | 0,7 | - | - | - | - | 2.97 / PC. |

| Bracket (C625, C626 with a height of more than 4 m), pcs. | - | - | 0,7 | 0,7 | - | - | - |

| Sealing tape 30 (50) 3.2, pog. M. | 0.1. | 0.1. | - | - | - | - | - |

| Sealant for partitions, packaging | 0,3. | 0,3. | 0.5 | 0.5 | - | - | - |

| Sealing tape 30 (50, 70, 100) 3.2, pog. M. | 0.75 | 0.75 | 1,2 | 1,2 | - | - | 63.73 / Roll 3 m |

| Dowel "K" 6/35, pcs. | 1,6 | 1,6 | 1,6 | 1,6 | - | - | 4.78 / PC. |

| Screwing LN 9mm (for profiles), pcs. | 1.5 (2.7) | 1.5 | 2.8 * | - | - | - | 103.35 / 1000 pcs. |

| Screw TN 25mm (for GLC), pcs. | 14 (17) | 6 (17) | 14 (17) | 6 (7) | - | - | 75.5 / 1000 pcs. |

| Screw TN 35mm (for GLC), pcs. | - | 14 (15) | - | 14 (15) | - | - | 99,72 / 1000 pcs. |

| Reinforcing tape, pog. M. | 0.75 (1,1) | 0.75 (1,1) | 0.75 (1,1) | 0.75 (1,1) | 0.75 (1,1) | 0.75 (1,1) | 49,20 / roll 10 m |

| Putty "Fugenfuller", kg | 0.3 (0.45) | 0.3 (0.75) | 0.3 (0.45) | 0.3 (0.75) | 0,3. | 0.4. | 117,36 / Bag 10 kg |

| Spacure "Uniflot", kg | 0.1. | 0.1. | 0.1. | 0.1. | 0.1. | 0.1. | 142,39 / bag 5 kg |

| Glue "Fugefuller", kg | - | - | - | - | 0.8. | 0.8. | 142,39 / bag 5 kg |

| Glue "Perlfix", kg | - | - | - | - | 3.5 | 3.5 | 182,19 / bag 30 kg |

| Bands from HCL-sheets, pog. M. | - | - | - | - | 2.6 | 2.6 | - |

| Profile angular PU 31/31 (corner protection), pog. M. | Depends on the number of angles and the height of the room | 45.65 / PC. | |||||

| Primer, L. | 0.1. | 0.1. | 0.1. | 0.1. | 0.1. | 0.1. | 1707,48 / bucket 15 kg |

| * - on 1m2 lining at the rate of 2,754m2 walls without opening, losses are not taken into account |

Thickness and Console Loads

All complete systems from Gyproc and "Knauf Gypsum" are designed to use a standard 3,5mm thick. If you want to independently develop any structures, you will have to separately think out the strength and reliability issues for each case. At the same time, note that even for ceiling compositions, the same Knauf does not use sheets with a thickness of 10mm, although many builders consider such a solution acceptable. Of course, for violation of technology, no one will repay you, but as a result you will live next to weakened, and therefore, not quite safe design. Does it satisfy you?Most of the gloss of small thickness are used for special types of work. GyProc sheets for the reconstruction of GN 6 (6mm thick) are designed to repair and modify already existing plasterboard structures. As a rule, GLC thickness is 9.5 mm from the "KNAUF Gypsum" applied to perform relief surfaces and architectural elements, for repairing already ready-made structures, as well as the lower layers of multilayer ceilings and filling out voids, openings, etc. Pesons exposed to strong Wear, for example, in the corridors, you can use particularly durable, so-called reinforced sheets of GEK 13 thickness of 12.5 mm from Gyproc. The average layer of such a sheet is made of high-density plaster reinforced with fiberglass, and the outer is made of multilayer cardboard.

By the way, for each design (complete system) it is recommended its permissible height. Let's say, from one-layer GLC you can not construct a structure with a height of 10 m- in this case, it will have insufficient flexural rigidity. The highest systems are systems from the ceiling profiles 60mm wide with mounting to the wall (permissible height - up to 10 m).

As for sound insulation, the depth of the framework is influenced by its level, the presence of separate frames (some of them is attached to the wall, part of the drywall trim), the material from which the frame (metal or wood) is made, the thickness and weight of the sheet, as well as The number of sheets in the layer. Very good sound insulation in three-layer structures, but this option will require additional costs of installing several GLC layers. You can set free-standing racking frame - without mounting to the wall (after all, it is the rigid fastening that becomes the "bridge" on which the sound waves pass through the designs). In this case, the profile system is attached only to the floor and to the overlap. Thus, you can kill two hares: to simultaneously provide and sound, and thermal insulation.

But here the facing is fixed, covered and plastered. Looking at the wall, you wonder if you can hang something on it? It is possible, but only, of course, not with the help of a nail. Here you will need a dowel, the dimensions of which are chosen depending on the thickness of the lining and weight of the cargo. For example, on the suspended ceilings from the GLC, you can accommodate only lamps weighing less than 6 kg with a special sample plastic dowels (per 1m2). Luxurious, but heavy chandelier will already have to be attached to the ceiling overlapping by anchors. As for the walls, depending on the type of GLC and its attachment, they can be placed from 2 to 50 kg on the same mounting element. In principle, the load weight of 15-40 kg per 1 m along the length of the wall with the center of gravity, removed from its side edge to a distance of up to 30 cm, can be fixed anywhere in the facing with the same dowels. Wall cabinets or shelves, weighing more than 15 kg, are attached at least at two points dowels for hollow walls. With the thickness of the casing of 12.5 mm, the permissible load on one plastic dowel (6mm diameter) for hollow walls is 20 kg, on the same but metallic - 30 kg.

And further. Do not forget: if you plan to hang on the walls heavy plumbing equipment, kitchen cabinets or cantilever bookshelves, in the places of their attachment still at the frame assembly stage you need to install metal strips, and where they will subsequently "sit" fasteners and screws.

Hypzel from plasterboard

The traditional rectangular forms of our dwellings are increasingly and more often free spaces with curved and wavy surfaces. Avteda every preservation owner wants to make his home individually and unique. Plasterboard is a building material, which is not better suitable for creating "incorrect" geometry. And, moreover, it is easily processing. From the Gl-structures, it is possible to build decorative dome, columns of different diameters, walls and partitions of any configuration (round, oval, wavy), arches and cornices of a wide variety of forms, finally, vaulted and multi-level ceilings.

In the manufacture of curved shapes, mainly used plasterboard sheets with a width of no more than 600mm. At the same time, the minimum radiation radius of a 12.5 mm thick is about 1000mm. With a decrease in the thickness of the drywall, the bending radius is also decreased, with a thickness of 9mm, the minimum radius will be equal to 500mm.

A curved sheet on a metal frame, the main elements of which most often, especially in the ceiling systems, are the ceiling profiles of 6027mm. They are also pre-rendered in accordance with the required radius of the formable surface. Curved metal profiles with any (but not less than 500mm) radius can be obtained on a special, fairly simple bending machine.

When the device of curvilinear surfaces, the template is first made by which the plasterboard leaf will be flexed. For this, first of all, the sidewalls of the template are cut out, which subsequently and provide the necessary bend radius. The radius of the template is advisable to perform slightly smaller than the radius of the formable surface. Then cut the spacers, the dimensions of which should provide the necessary width of the template, slightly smaller than that of the sheet itself. The finished shape is collected using wooden bars and screws. The ends of the sheet are fixed by clamps whose role can be played segments of a suitable rack or guide profile. To flexing the sheet, need a needle roller, which will roll the compressible side of the GLC. Consuming forms are the back side, the concave-facial. The workpiece with the "punctured" side is wetted by water until the gypsum core is completely saturated (when water is already stopped absorbed into the gypsum mass). The workpiece moistened in this way is installed on the template and gently bend in shape. After fixing the sheet in a bent position, for example, the adhesive ribbon is dried (you can not remove from the template). Similar operations are made for all other curly structural elements.

Making curvilinear elements of a small radius (100-400mm), use special, but simple equipment. This help on the back side of the plasterboard sheet (12.5 mm thick) parallel grooves of p- or V-shaped (for curvilinear surfaces) of the cross section. It does not damage the cardboard of the front side of the sheet. The distance between the groove depends on the requirements for the shape of the bending and thickness of the cutter.

The best way to avoid cracks

To do this, we must follow the technological recommendations of the manufacturer of GKK. Agree, it is unlikely that anyone will build a brick house, without having an idea what brickwork is. But the plasterboard does not seem complicated something. The simplicity of the device and installation of structures from GLC often brings those who decided to repair their own forces. Many are taken for an independent assembly, but over time, this idea turns into full collapse: the sheets are peeling from the frame, the seams are diverged. AVSE The fact is that "Cleells" probably did not know all the nuances of the installation technology, the requirements of which manufacturers are advised to follow strictly.

The success of the work and the quality of the final coating depend on many factors, even from such "little things", as a step between screws that attach sheets to the frame. What should I pay attention to?

The most important defect is cracking on the surface of the finished cladding in the area of the joints between the sheets. This case will have to redo all the work, since the interior will be hopelessly spoiled. To avoid the formation of cracks on the butt seams, all the work must be carried out with the steady humid mode and the temperature is not lower than 15C. No docking sheets on the stands of door or window openings are not allowed. And it is not surprising, because when you close the doors there is a dynamic load on the walls, and over time, the crack can appear in the place of the joints of the GLC. The direction and sequence of the installation of screws when fastening sheets is also very important. Follow the manufacturer's instructions, since the incorrect fastener creates a voltage in the sheet, which subsequently provokes the appearance of cracks. All "passing" places are susceptible to shock loads. Therefore, to protect, say, external angles do not forget to use a metal profile or a special reinforced paper.

As for adhesives, primer and leveling compositions (putty and plaster), it is possible to use only those that are recommended by the manufacturer of GLC. Only in this case is guaranteed compatibility of coatings and the quality of finished structures. Another important point is due to storage, installation and operation of structures in one humidity mode. After all, if the sheets have been influenced by high humidity for a long time, and they mounted them in a residential room, where central heating is included in the cold season, the materials will dry out and crack.

| Firm | View of sheet | Dimensions, mm. | Mass 1m2. | Types of longitudinal edges | The combustibility group and the time of the open fire resistance | Application area | Price 1m2, rub. |

|---|---|---|---|---|---|---|---|

| "Knauf Gypsum" | Normal (GLC) | 2500120012.5 | 9.3. | Straight; sophisticated | Weallor, 15 min | Used for the device of interroom partitions, suspended ceilings and inner wall cladding. Surface is suitable for any decorative finish | 50.42. |

| 250012009.5 | 7.3. | Straight; sophisticated | Weallor, 10 min | Used to perform relief surfaces and architectural elements, for repairing already ready-made structures, as well as as the lower layers of multilayer structures and filling out emptiness, openings | 50.06. | ||

| Moisture-resistant (G CLEM) | 2500120012.5 | 10.1 | Straight; sophisticated | Weallor, 15 min | Used to finish premises with high humidity | 75,1 | |

| 250012009.5 | 7,7 | Straight; sophisticated | Weallor, 10 min | Used to perform relief surfaces, for repairing already ready-made structures, as well as as the lower layers of multilayer structures and filling emptiness, open spaces in wet rooms | 62.5 | ||

| With increased fire resistance (GKLO) | 2500120012.5 | 10.2 | Straight; sophisticated | Weakly farming, 20 min | Used to finish premises with increased fire resistance requirements. Sheet core contains fibers and additives that increase the limit of fire resistance | 57,89. | |

| Hypracoloconde (GVL) | 2500120010. | 12.8. | Straight | Weaklyorny, more than 20 minutes | Used for the device of interior partitions and inner wall cladding, for lining of attic rooms. Surface is suitable for any decorative finish | 53,57 | |

| Hyproxy fiber moisture resistant (GVLV) | 2500120010. | 15,4. | Straight | Weaklyorny, more than 20 minutes | Used for the device of interroom partitions and inner lining of walls in rooms with high humidity | 66.6 | |

| Hypro-fiber moisture resistant Little-format (GVLV DIY) | 2500120010 | 13.6 | Straight | Weaklyorny, more than 20 minutes | Used for the device of national base bases, indoor decorations | 56,45. | |

| Rigips. | Hypus fuel | 240012006. | 12 | Straight | Weallor, 7.5 min | Used to create curved surfaces, walls and ceilings with a minimum bending radius 600mm | 300. |

| Gyproc. | Standard GN 13. | 2400120012.5 | nine | Straight; sophisticated | Weallor, 15 min | Used for the device of interroom partitions, suspended ceilings and inner wall cladding. Surface is suitable for any decorative finish | About 60. |

| Reinforced GEK 13. | 2600120012.5 | 11.5. | Straight; sophisticated | Weallor, 10 min | Used in structures with increased requirements for strength and resistance to shock loads | There is no data | |

| GN 6 for reconstruction | 27009006.5 | five | Sophisticated | Weallor, 7.5 min | Used to create curved surfaces, walls and ceilings with a radius of bending 20 cm, to repair old surfaces | There is no data | |

| Sheet for floor GL 15 | 240090015,4 | 15,4. | Straight | Weallor, 15 min | Used for floor base base devices | There is no data | |

| Moisture-resistant GKBI 12.5 | 2600120012.5 | nine | Straight; sophisticated | Weallor, 10 min | Used to finish premises with high humidity | About 70. | |

| Windproof GTS 9. | 27009009.5 | 7. | Straight | Weallor, 10 min | Used to finish the premises with high wind-leverability. The surface is able to pass out the moisture absorbing in building structures. Weather resistant | There is no data | |

| Fire resistant GF 15. | 2750120015,4 | 12.7 | Straight | Wem-threshold, 30 min | Used in the design of buildings with high fire resistance requirements, for lining of attic rooms | There is no data |

The editorial board thanks the Gyproc company and the KNAUF GIPS training center for help in the preparation of the material.