The technology of building an energy efficient building on an example of the construction of a two-storey house with a total area of 256 m2

Each person going to build a country house wants this dwelling to consume as much energy as possible - it is already not suiced, and every year it will become even more expensive. We will tell about how two years ago an attempt was made to build energy efficient, that is, economical in operation, a house in the suburbs.

But if in Europe and the United States have long been from theories for the mass practices for the construction of energy-efficient houses, then in our country, in this direction only the first steps in different regions, as part of the conceived large-scale experiment, test residential buildings are erected. But only multi-unit. Ot, in order to widely implement the principles of energy saving in private construction, while even there is no speech. Nevertheless, private energy-efficient homes in our fatherland have already appeared. In the published article, we will tell about how the ABS-Stroy (Russia) company in 2008-2009. Having built such a house. But first let's figure it out with some concepts that exist in this area.

|

|

|

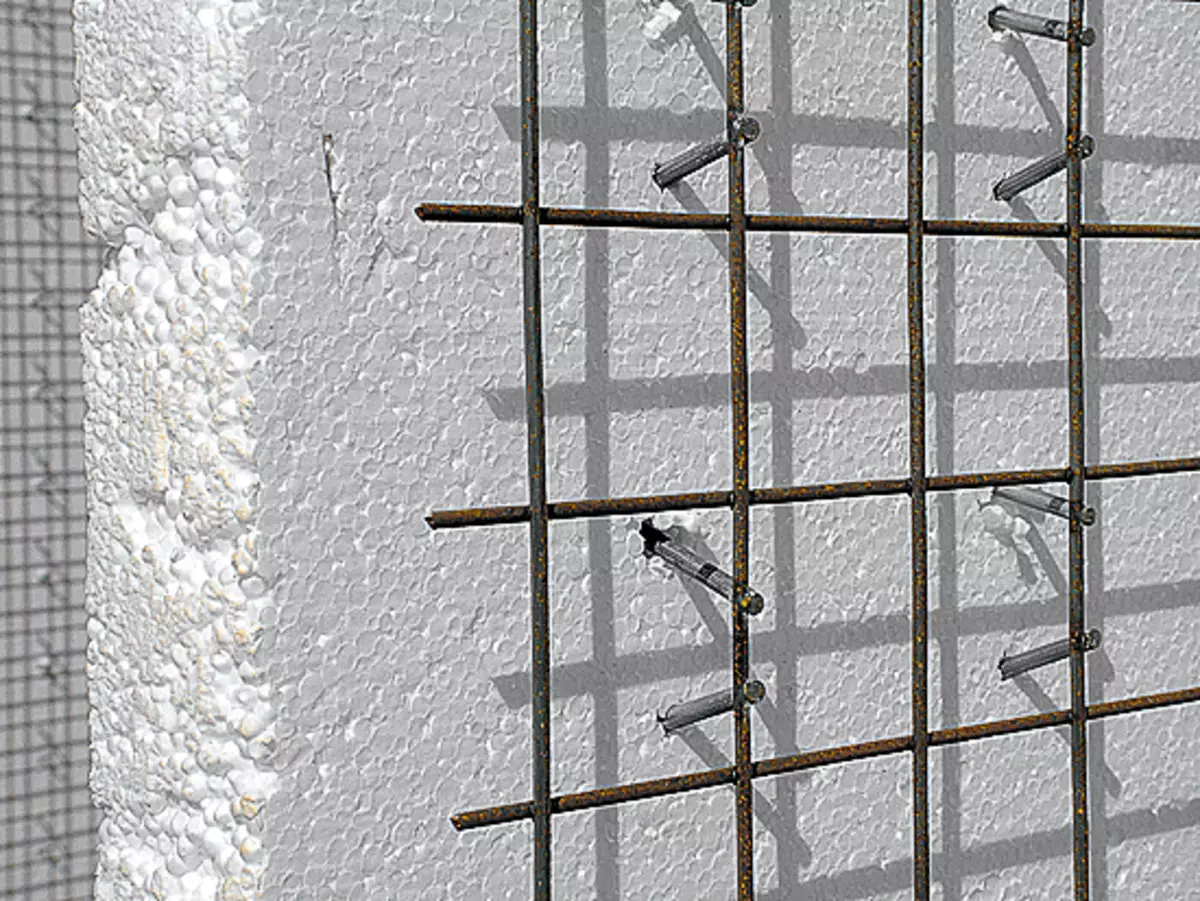

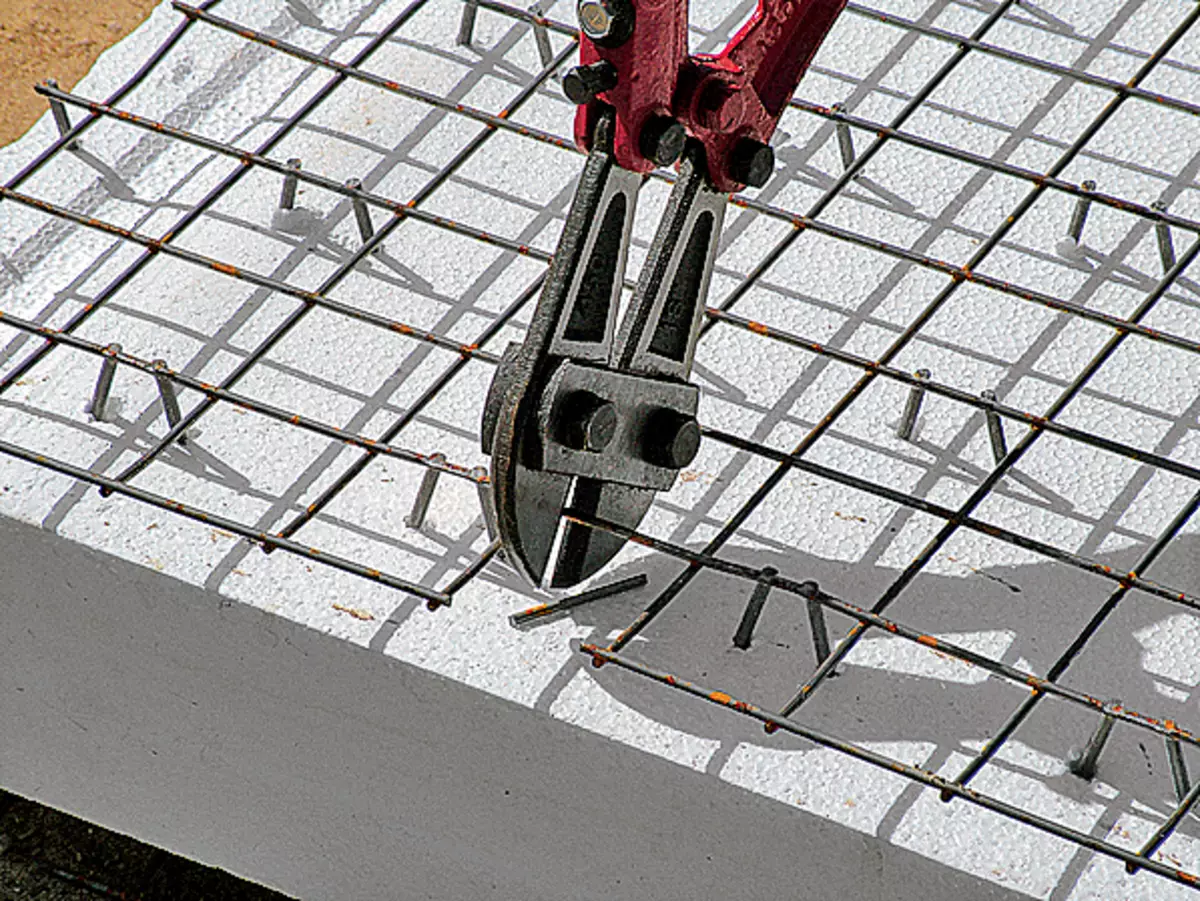

1-3. The 3D panel (1) consists of two parallel-arranged welded mesh armofamocas, interconnected by diagonal transverse rods, penetrating the corner of the polystyrene panel, which are per capita. Thanks to this design, the wall panel has high strength and elasticity. If you need to cut a design to a certain size to make the opening or a figured element of the facade, are applied as follows: First, the reinforcement mesh (2, 3) is cut through with powerful bearings or grinding on both sides, and then a conventional knife-foam core.

Bear resources

The term "energy efficient" building appeared after the energy crisis of the 70s. GHX century, when the regulations of the heat-preserves of building structures were increased by 2-3.5 times abroad. These norms were refined and more tightened, as a result of which two new terms appeared: low-power homes (DNE) and ultra-low power consumption (DOU). The annual heat consumption for the first of these (DNE) is 30-70 kW x h / m3, for the second (DUE) - 15-30 kW x h / m3.

Active home (from English. Active House) is an union of passive and smart home. Thanks to this, he not only spends little energy, but also competently disposes of the non-significant amount that consumes it. The main thing, even this minimum volume of the active building as much as possible ensures itself itself, using the energy of the sun, wind, the heat of the Earth IT.D. Active houses have already been built in a number of European countries, and in September 2010. The first such building was laid in Russia. Our magazine will definitely tell about how it will be erected.

|

|

|

|

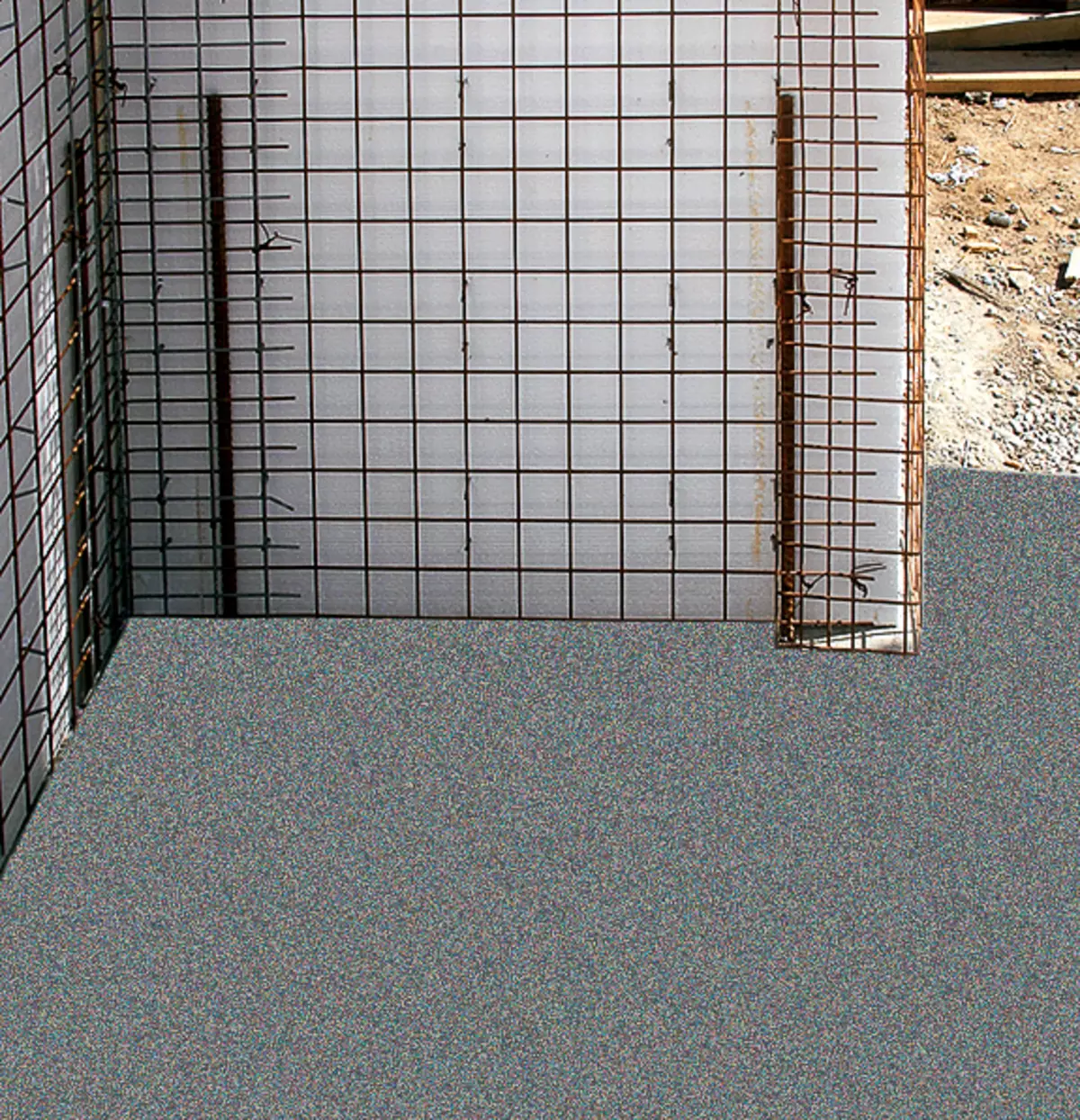

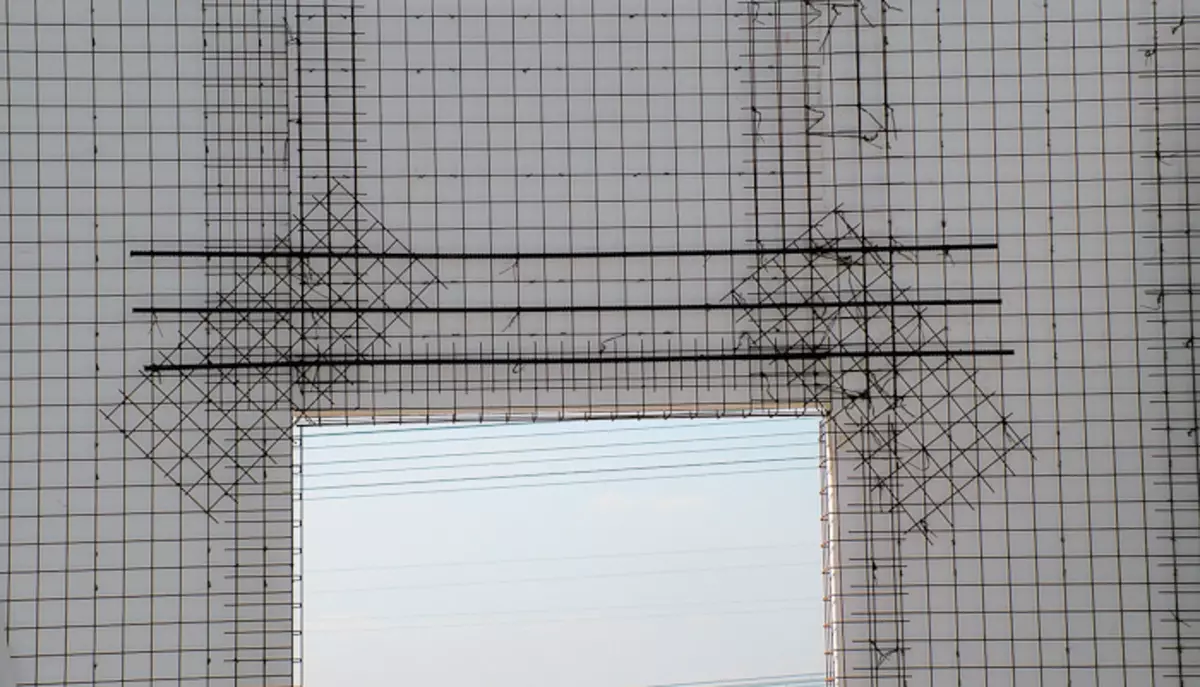

4-6. The panels with knitting wire attached to the release of reinforcement, in advance established in the foundation (4). Longitudinal joints of the panels were blocked by straight connecting grids (5). From above, the openings on both sides were reinforced by reinforcement rods, along the corners of the grid and in the perimeter-shaped grid (6).

7. Corner joints of panels both with external and from the inside, reinforced with vertical reinforcement rods, and then covered the joints bent at the right angle sections of the grid, securing them with knitting wire.

Inconale, about the concept of "Green Building" (from the English. Green Building). This is not just the name of the concept of construction and operation of energy-efficient houses, which aims to reduce the level of consumption of energy and material resources while simultaneously improving the quality of buildings and their comfort. This is a whole philosophy based on the idea of saving natural resources and even "cooperation" with the environment, which takes into account the interests of future generations (more details about Ekodoms, see "IVD", 2009, N 5; 2010, N 3).

The essence of the concept is as follows. Green House is energy efficient, economically in operation and environmental. This means that its energy consumption is at least 25% less than the usual, and in order to achieve this, during construction it is necessary to use materials that do not emit harmful substances during the period of operation of the house, nor after dismantling it. It is also desirable that they can be used again. Economic attitude towards natural resources assumes and minimizing the consumption of pure water, for which effective cleaning and secondary use (for washing, washing floors, watering plant, etc.) of rain and wastewater is organized. Green building should be built, taking into account the peculiarities of the local climate, traditions and culture of the population and in harmony with the landscape. And now, when we dealt with the terminology of energy-efficient construction, we will proceed to practice.

What was the idea?

The future owner of the house- man is quite practical. He decided that his dwelling should consume as much energy as possible, which will reduce operating costs, and over time, return most of the funds spent on the construction of the house. Perform the conceived he gathered through the use of modern construction methods.

|

|

|

8-10. When overlapping a large span over the living room, as well as in the winter garden, where they planned to use panoramic glazing, 3D-panel-based structures were reinforced by concrete columns. They were made directly in place in several ways. The columns of a small section (8, 9) made from the M300 monolithic concrete using a regular removable formwork. A figured (M-shaped) column (10) was performed from 3D panels and with subsequent strikersion was coated with concrete. Made columns together with the beams located between the 3D stoves form the spatial power frame of the house.

Specialists of the company, which he instructed the implementation of the plan, found the following solution: build walls and overlap from the so-called 3D panels, apply on their surface on both sides by the method of torturing the layer of concrete, creating the most strong, but warm construction of the building, and then insulate Walls outside foam concrete. Thermal calculations showed that a wall consisting of a 120mm polystyrene foam layer coated on both sides with concrete 50-60mm thick and additionally insulated with a foam concrete 100mm thick, will have a reduced heat transfer resistance (RO) at 4.1m2 x C / W, which overlaps Requirements Snip 23-02-2003 "Thermal protection of buildings" for the middle strip of Russia. The index of reduction of air noise will be 60dB. The owner of such calculations were quite satisfied.

Foundation

Starting a story about the foundation, we note that the construction site was located at the very end of the village, and the water was flowed onto it on the natural slope almost from all "land plots" above. Even a small rain turned this territory in real swamp. Understanding that it is impossible to build on such a plot, the customer decided to increase the ground level of approximately 1m.

The soil slept, it was crushed - it seems, it became dry. But as soon as they started to dig the first trench under the blurred point of the fruit, it was instantly filled with water. It became clear that from the basement and even from the ribbonly blunt foundation will have to refuse. However, quite quickly decided than replacing it. We dried wells to the depth below the waterproof point and, setting the reinforcement frame in them, cast piles with a diameter of 250mm. Piles tied the monolithic paintwork and covered the space between his "ribbons" sand. The concrete substrate was poured over the sand, which was laid with a layer of waterproofing, and then the plates of extruded polystyrene foam 100mm thick. They were covered with another layer of waterproofing, on top created the reinforcement frame, then cast a monolithic concrete slab with a thickness of 120mm.

|

|

|

|

|

|

|

|

|

11-15. After assembling the walls of the first floor, 3D overlap panels were laid on them. To avoid their deflection in the process of applying concrete, temporary vertical backups set (11). The panels on both sides were reinforced by the required number of reinforcement rods, which makes it possible to increase the load on the overlap (12). On the perimeter of the panels in a step of 250 mm, the reinforcement of the models were mounted and reinforced with their longitudinal reinforcement. After concreting, in these places, reinforced concrete beams of overlapping and lying on the walls of the first floor of the belt, which will become part of the volume monolithic framework. Brackets, rods and mesh reinforced 3D-panels on decorative facade protrusions (13-15).

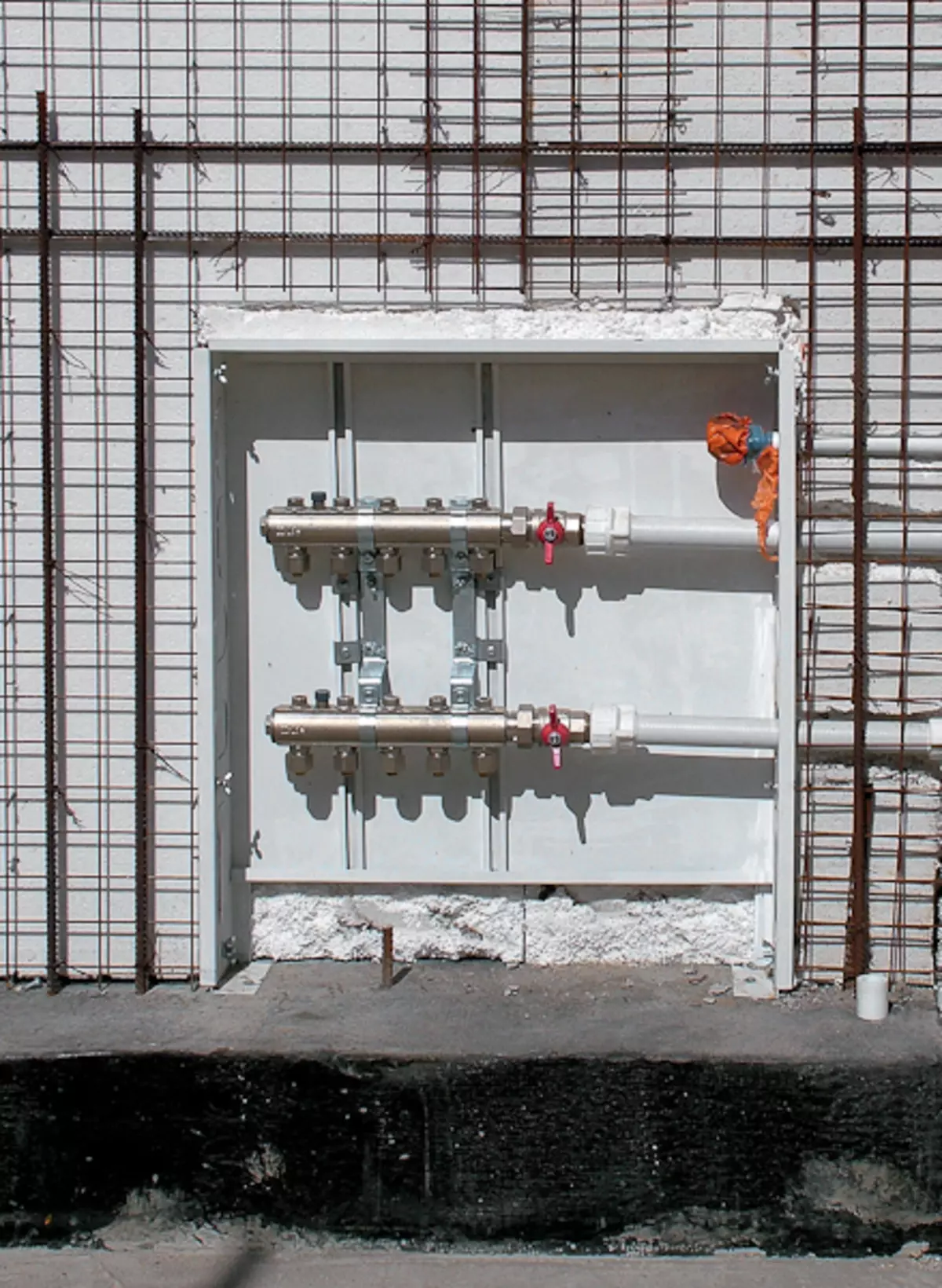

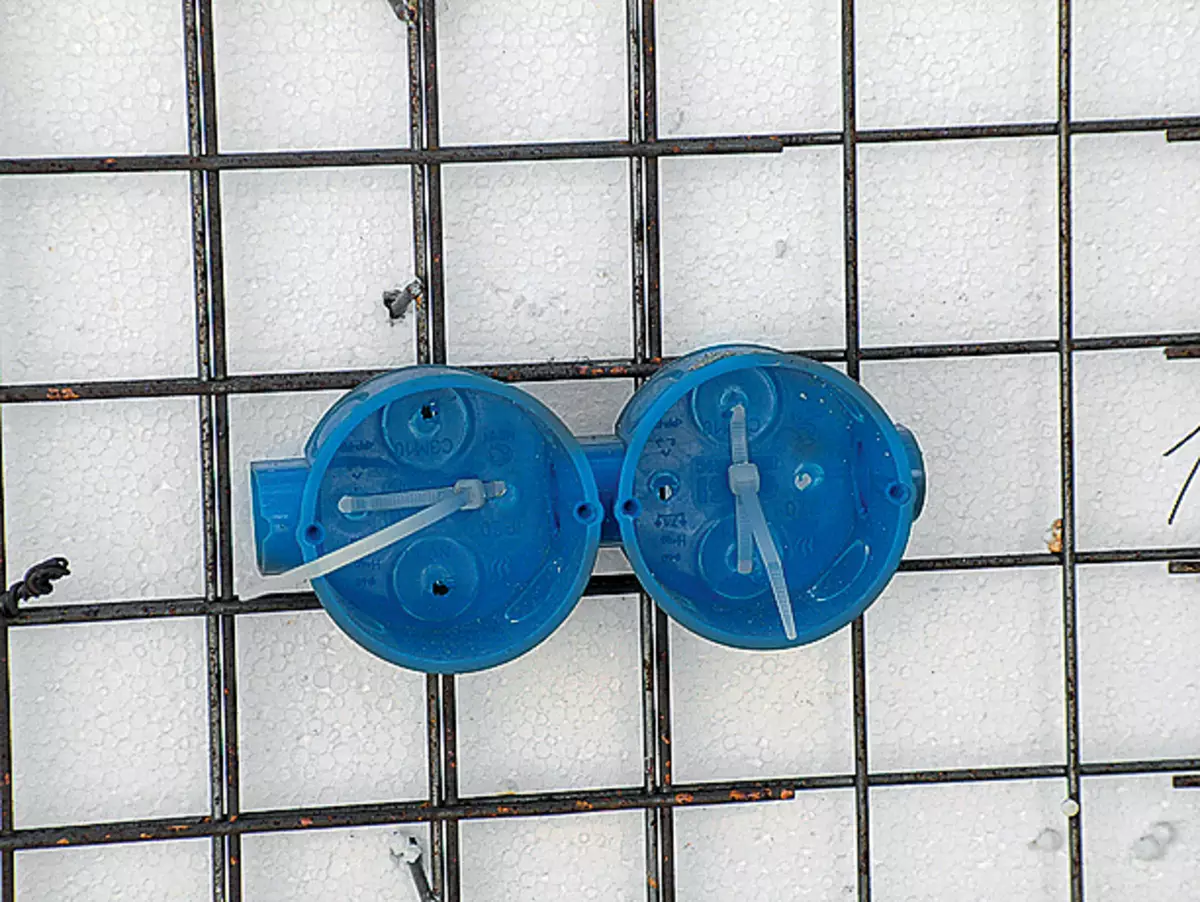

16-19. After the completion of the assembly of the walls and overlapping the first floor between the plates of polystyrene and the reinforcement grid, the pipes of hot and cold water supply and heating systems (16, 17) and electrocabels were laid (18). To do this, in polystyrene foam with a hair dryer made grooves-deepening. So that hot water in the pipes lying on the base plate has not cooled, the layer of extruded polystyrene foam (19) was influenced. Later these pipes hid a concrete screed.

The found option fits well in the conceived technology of the construction of walls. The fact is that for fastening 3D panels, reinforcement of fittings from the foundation (diameter-10mm, step-500mm) is required, and the "plates" of the walls should adjoin them with one side - internal. These issues are designed to prevent the displacement of the mounted panels both horizontally and vertically. They were created in the easiest way, setting the reinforcement rods to the still not frozen concrete of the monolithic plate.

The basis of the design of walls

The basis of the construction technology of this house is the use of 3D panels, the design of which is shown in detail in the photo. The scanned add only that the thickness of the used polystyrene plates used for the outer walls is 120 mm, for inner bearing walls and overlaps, 100mm, for partitions - 50mm. The number of divosers ranges from 100 pcs / m2 (for wall panels) up to 200 pcs / m2 (for overlap panels). The fact that the rods are welded to the grids at an angle, not only gives the design spatial rigidity, but also does not allow to shift the core.

The wards used for the bearing walls, the reinforcement grid will be from the core for 19mm, into a partition-on-16mm. The mass of the panel with a length of 3m and 1.2m wide with a plate of polystyrene foam 120mm thickness is only 27 kg. It allows you to do when installing without heavy construction equipment (for more details, see "IVD", 2009, N2).

|

|

|

|

20-21. With dry torching (20), a dry mix (sand fillers, cement, powdered additives) is loaded into a special installation hopper (21). Hence the hose with compressed air it is fed into the nozzle. Family nozzle material is mixed with water and is fond of air flow to the substrate.

22-23. Blowing about the substrate (22), the concrete mixture is significantly compacted, but the part of it (up to 25%) bounces down and falls down. The thickness of the layer applied for one cycle is 40-60mm (23). When erecting the walls of the second floor, all previously described processes are completely repeated.

Return walls from 3D panels began with one of the corners, which helped immediately give the structure stiffness. The panels were brought together and with the release of reinforcement knitting wire. The short corner was gradually attached to new panels, including those cut out in advance by openings. To create a solid mesh reinforcement frame, all the joints of the panels using a knitted wire, blocked by connecting grids, and, if necessary, reinforced reinforcement rods. Then the builders began to construct the overlap (this process is figured in detail in the photo).

"Shell" from concrete

Togotraging (from lat. Tectorium- "plaster" and concretus- "compacted") - a method of concrete work, in which the sand-concrete mixture is in layers on a concrete base under pressure of compressed air. There are two types of necrotration: dry and wet. In the first method, the immense mixture is supplied by the hose to the nozzle, where it wets it, and then it is thrown into the torque surface. When the nozzle is seconded, a predetermined solution is received.

Each method has its advantages and disadvantages. For a wet method and a compressor, less powerful, and "rebound" are needed (that is, irretrievable losses) of the material does not exceed 10%, and with the level alignment (it is carried out immediately after the opprete) there are no problems. True, the density of the concrete in the laid layer is somewhat lower than with a dry method. The same, causing concrete, it is difficult to make breaks, it can frost right in the hose.

Removable method somewhat advantages. The mixture can be supplied with long distances. In this case, the method is higher than the performance, since it is possible to apply a thicker layer of concrete in one pass. The equipment used is easy to clean (using air purging), and the period of its trouble-free operation is longer. You can work in the "Start Stop" mode. But the main - higher density and strength of concrete applied to the substrate. The lack of one, but significant: the magnitude of the "rebound" can reach 25%.

|

|

|

|

24-27. Foam concrete for insulation of walls outside was manufactured in place and poured into a removable formwork. To do this, outside the house created a frame of steel galvanized profiles 50 and 100mm (24) wide profiles (24), they were fixed on the walls with anchor screws and a bent metalloelement angle (25). In order for foam concrete, it did not flow out from the formwork created, the gaps between the wall and the profiles were filled with the mounting foam (26). Then the laminated plywood sheets were attached to the frame of the laminated plywood (27) and the gaps between them were sealant and foam. The upward zone of the formwork in the sheets was made in advance the holes in which they inserted a foam concrete with a foam concrete.

Builders preferred a dry method. However, it was not necessary to adapt from the wall of the particles in a matter of minutes from the walls in the folds of clothing, interfering. Therefore, as overalls had to use raincoats from military chemical complexes, and protective glasses replace the welder's mask. The mixture required for the oppression was made on the spot, using a small concrete mixer.

Solid insulation

Foam concrete - lightweight cellular concrete, obtained by solidification of a solution consisting of a binder (usually cement), sand, water and foam. The latter is prepared from an aqueous solution of foaming agents used in the production of detergents. Foam provides the necessary content and uniform distribution of air bubbles in concrete. Thanks to them, foam concrete advantages of stone and wood: durability, ease, good workability and ability to keep nails, screwdrivers IDR. It can be plastering, swaying with lining or other materials, paint in any color using "breathable" paints.

By varying the composition of the foam concrete, it is possible to obtain the required proportion, the predetermined strength desired by thermal conductivity. It is also possible to create products of any necessary form and volume. This allows the use of foam concrete not only as a structural material (the brand D1000-D2000), but also as a heat insulator (D400-D500 brand). The thermal conductivity in the dry state depends mainly on the density, which is indicated in the material brand.

|

|

|

28-30. So that the weather conditions do not interfere with the work on the creation of an exploited roof, the "tent" was built over it and covered with its film (28). Further, the reinforced concrete tie (29) was poured on the ceiling. When it hardened, the surface of the concrete was primed by bitumen mastic, and then laid the waterproofing (30).

Daily construction is increasingly used by a monolithic foam concrete of natural hardening filled in place. It is not surprising because it allows you to get a significant economic effect compared to the use of foam blocks. This material, taking into account work, cheaper than foam blocks. There are no costs for transportation, loading, unloading, battle, lift to floors and laying. Icho-using it, unlike other insulation, you get rid of the "cold bridges" in the seams.

The valid case was decided to apply the technology commonly used for the insulation of the monolithic foam concrete wall of the reconstructed residential buildings. To do this, the walls were first attracted to the walls of galvanized profiles, and then to non-removal laminated waterproof plywood.

Manufactured foam concrete and squeezed it to the place of fill a special mobile installation, which, together with its service specialists, "leased" from a construction company engaged in such operations. Note that the laminated plywood used in the creation of the formwork is quite expensive. Therefore, in order to save money, the walls were insulated in two stages: first on the first floor, and then, when foam concrete harden, the sheets of plywood were removed and moved to the walls of the second.

Finish at home

The outer decoration of the walls of the house is rather strict: builders simply shuffled them along the metal grid, which they fastened on the walls of the dowels. Then, according to the design project, in some places they were covered and painted, and in others, we were triggered.

|

|

|

31-33. On the waterproofing of the roof, the plates of extruded polystyrene foam and seams were treated with a sealant (31). On top of the plates, the second layer of waterproofing was laid, and then poured a concrete tie, creating a slope to the side of the drain (32). Next, the concrete was covered with waterproofing composition and put porcelain stonewares (33).

When performing these works on sections of walls, insulated foam concrete, there were no problems. Avot with decorative protrusions on the facade covered with Torcaretone, problems were: this material is very solid and so smooth that the plaster simply does not stick to it. As a result, the dowels had to use "diamond" drills and process the surface of the walls with a special primer.

Particular attention builders paid sealing and finishing the operated roof (the owner insisted on its device). In this case, both familiar and new methods and materials were used. For example, a concrete screed on which the biases of 2-3 were created to be created in the side of the roofs of the drain holes left in the roofs were treated with a two-component waterproofing composition of Terraco (Sweden) based on polyurethane. When the waterproofing layer was formed, a porcelain tile was laid on it.

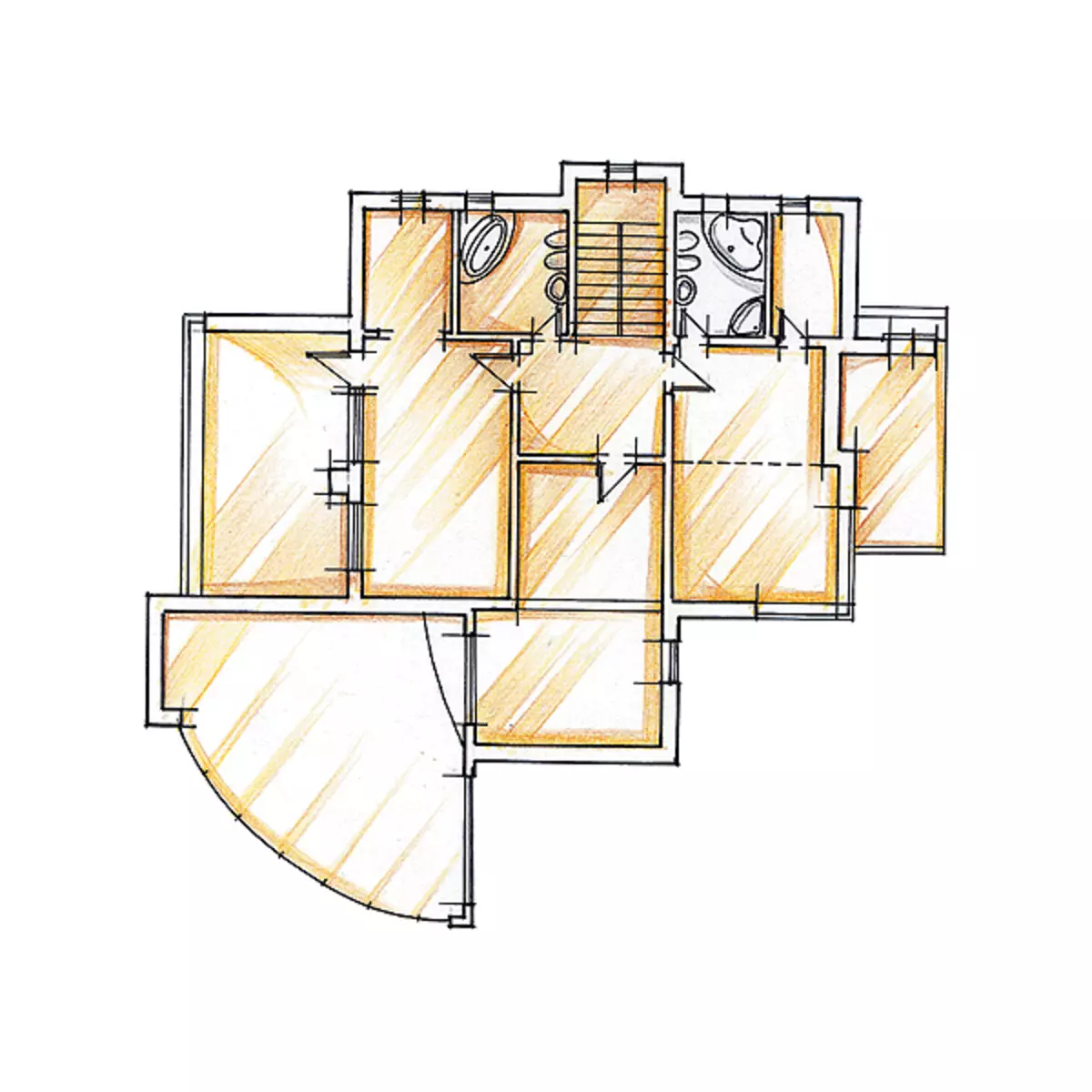

1. Tambour 3m2

2. Hallway 5,4m2

3. Wardrobe 9M2.

4. Living-dining room 67.8m2

5. Bedroom 13m2

6. Winter Garden 38,5m2

7. Bathroom 10,6m2

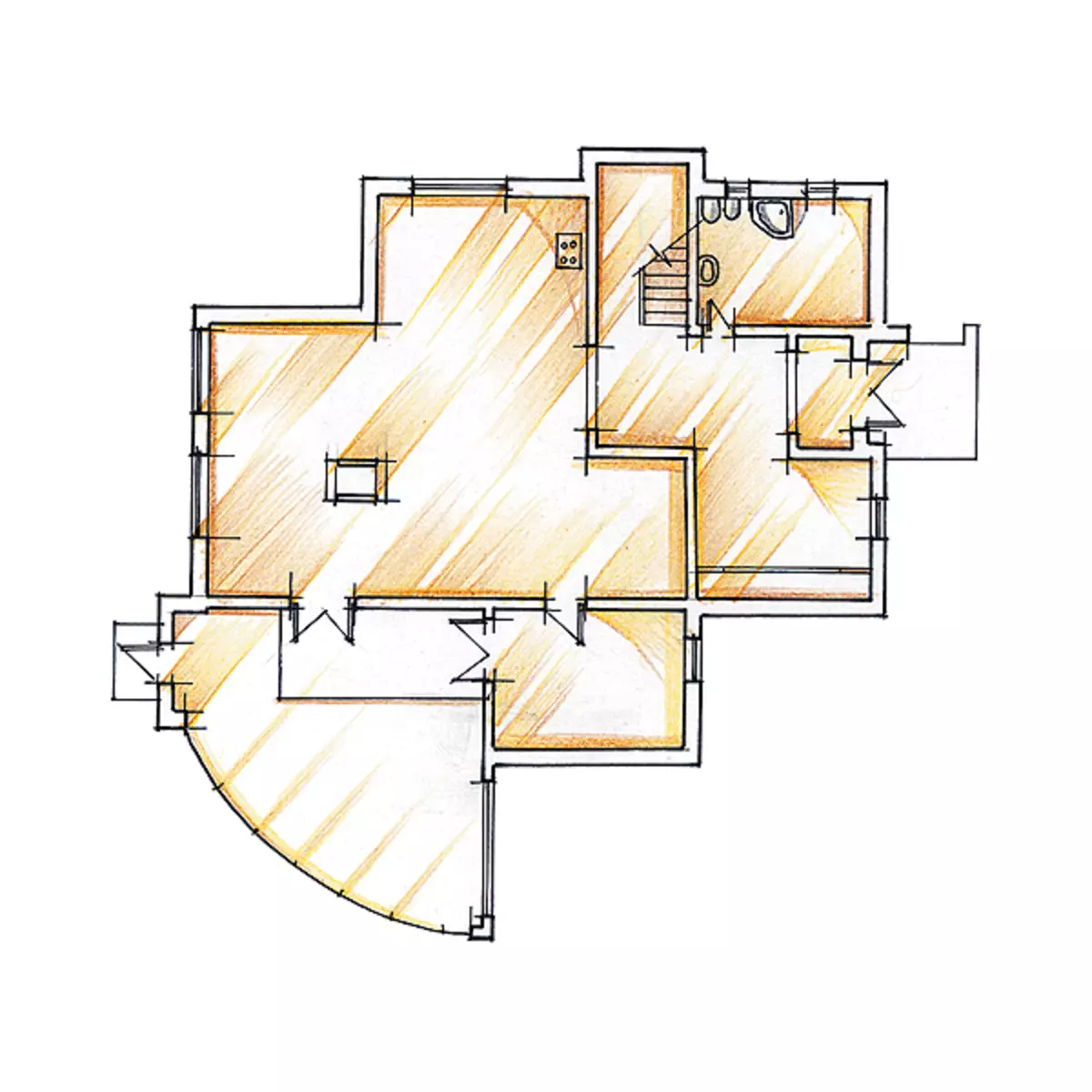

1. Hall 8.2M2

2. Cabinet 23.9M2

3. Bedroom 21,4m2

4. Bathroom 5.9M2

5. Wardrobe 4,4M2

6. Bathroom 6,6m2

7. Bedroom 19.7m2

8. Wardrobe 6,3m2

9. Balcony 19.8m2

10. Second light

Drainage pipes were laid around the house, according to which the ground moisture is discharged into a special well. There is also water with a flat roof and storm sewage, the gutter of which is laid around the perimeter of the structure. The collected moisture is used for watering the garden.

|

|

|

|

|

|

|

|

34. The only element of the house created from the usual red brick was the trumpet of the Guting Fireplace. It was erected after the construction of the house - in the ceilings under its installation, the openings were created in advance, "making" their milk formwork.

35-36. Even at the stage of the construction of walls at home, wooden bars (35) were attached to their mesh frame on both sides of the window and doorways, and the window and door frames were subsequently connected to them (36).

37. Lailed directly overlaid wiring in the owner's office hid the suspended ceiling.

38. Water warm floors in the bathrooms are one of the many elements that create a comfortable atmosphere in this house.

39-40. The metal frame of the staircase (39), which during the construction period used workers, cleared, painted, made "stone" steps (40).

41. Cupped foam concrete walls at home attached with a dowel metal grid and shtched. Then they were partially covered, primed and painted with light facade paint, and partially trimmed by cladding with a predetermined protective composition.

Avenue finishing say briefly. It was performed in accordance with the design project specifically designed by the sketches of the owners. At the same time in the interior were widely used the designs made of drywall. Floors in all rooms, apart from bedrooms, are decorated with porcelain, which greatly facilitates their cleaning.

Engineering

The house heats a gas boiler with a capacity of 40 kW. Supply-exhaust ventilation in the building is forced, and in the near future the owners plan to supplement it with an air recovery, as provided by the project. The sewage in the house is autonomous, but it allows you to purify household drains with a 98% efficiency. Consumption of chosen water coming from the well limit the lifters of the consumption of tanks, showers and mixers included in the plumbing equipment.What happened in the end?

The indicator of the resistance of the heat transfer RO for the outer walls is 4.04 m2 x os / W, for the basement overlap, 5.31m2 x / W and for warm roofing - 4.9m2 x ° C / W. What did it give? According to statistics, a house of 250m2 for the winter period is spent on heating and DHW about 6500m3 gas. In the event in the winter of 2009. It was consumed only 5180m3 gas, and for unprecedented cold winter 2010.- 5320m3. At the same time, the boiler, in addition to the house, heated also a warmed garage with an area of 125m2, in which it is installed.

|

|

|

|

42-45. A winter garden (42) became a favorite place in the home for owners. Its roof neither the designers nor the owners decided to make the entire translucent and heat loss through such a construction would be too large. Therefore, over the winter garden, we decided to create a warmed single-piece roof and the block of six attic windows (43, 44) equipped with an electric drive was mounted in it. Manages their opening and closing according to a given program installed in the premises of the Winter Garden "Weather" station. Two translucent walls here are created using three-chamber glass windows with energy-saving glasses (45).

Prior to the requirements of a passive or active building, the obtained heat maintenance indicators are still distant and RO walls of such houses should be 8-12m2 x C / W (at the current level of development of construction technologies, it provides only a frame house with walls of 500mm thick, filled with highly efficient insulation). Avot Energy Efficient Built House recognize is quite possible. IPO this criterion, he fits even into "green" standards. Avot on ecology He has not shown before them: standards exclude the use of polystyrene foam (to know about it at the beginning of construction!), Yes, and the issue of energy saving is poorly thought out. Is the same home home of the house with their contribution to the preservation of natural resources can be proud of.

The enlarged calculation of the cost * home improvement with a total area of 256m2, similar to the submitted

| Name of works | Number of | price, rub. | Cost, rub. |

|---|---|---|---|

| Foundation, Walls, Partitions, Overlap, Roofing | |||

| Soil planning, base device for foundations | set | - | 62,000 |

| The device of the pile foundation, R / w scratch | set | - | 87,000 |

| Device protective tie | 16m3 | 2187. | 35,000 |

| Insulation insulation | 150m2. | 90. | 13 500. |

| Waterproofing horizontal and lateral | 300m2. | 158. | 47 400. |

| Construction of the foundation reinforced concrete plate | 23m3 | 2770. | 63 700. |

| Construction of walls, overlap from 3D panels | 615m2. | 756. | 465,000 |

| Togcasting walls and overlaps | 1230m2. | 846. | 1,040,600 |

| Wall insulation foamineton | 41m3. | 2098. | 86,000 |

| Laying smoke pipe | set | - | 18,700 |

| Waterproofing roofing | 94m2. | 266. | 25,000 |

| Insulation roof insulation | 94m2. | 104. | 9870. |

| Facing roofing ceramiconist | 94m2. | 447. | 42,000 |

| Assembling temporary tent over the roof | 93m2. | 581. | 54,000 |

| Filling window openings | 91m2. | 516. | 47,000 |

| Front work | 407m2. | 1086. | 442,000 |

| Electrical and plumbing work | set | - | 421,000 |

| Total | 2 959 770. | ||

| Applied materials on the section | |||

| Concrete heavy | 175m3 | 3097. | 542,000 |

| Sand, Crushed, Cement, Armature | set | - | 92 000 |

| Hydrokhotloizol | 780m2. | 26. | 20 280. |

| Brick, masonry mixture | set | - | 29 000 |

| Extruded expanded polystyrene foam | 120m3 | 3100. | 372,000 |

| 3D panels | set | - | 852,000 |

| Torcaretone | 109 T. | 2844. | 310 000 |

| Sawn timber | 15m3. | 5600. | 84,000 |

| Polymer waterproofing | 94m2. | 281. | 26 400. |

| Plastering facade mixture, reinforcing mesh, facade paint | set | - | 75,000 |

| Decorative panels imitating timber | 152m2 | 605. | 92 000 |

| Window blocks, enclosing structures | set | - | 426,000 |

| Porcelain stonework, glue tiled | set | - | 189,000 |

| Plasterboard sheet, profile | set | - | 89,000 |

| A gas boiler | set | - | 272,000 |

| Plumbing and electrical equipment | set | - | 532,000 |

| Rental mechanisms and formwork | set | - | 80,000 |

| Total | 4 082 680. | ||

| * The calculation was completed without taking into account the overhead, transport and other expenses, as well as the profit of the company. |

The editorial board thanks the Council on Environmental Construction for Help in Preparation of Material.