If you need to level the significant drops of the carrying overlap or equip the screed on the base, on top of which a large number of pipes, cables and other communications are laid, the most suitable material is light cement ties.

Photo: shutterstock / fotodom.ru

The base of the floor in apartment buildings most often serve concrete slabs overlap. The layer that lines the base (or the underlying layer) to obtain the horizontal surface of the floor, is called the screed. At the same time, it performs other important functions:

- gives the floor a certain slope;

- creates a solid base for laying finish flooring;

- distributes the load on elastic heat and sound insulation materials;

- Shelters various communications;

- Increases the heat insulation of the floor.

Photo: shutterstock / fotodom.ru

The most popular screeds are obtained as a result of a mixture and subsequent solidification of a mixture consisting of a binder (usually cement), aggregates (sands of various fractions), special additives. Manufacturers of dry mixes offer different types of screeds, among them basic levels, leveling the base differentials from 5 to 80 mm; high strength, with the valve strength of the leveling layer of at least 30 MPa; Quick-hardening, with the possibility of laying the finishing floor covering after 15 hours. We will talk about light tie.

With the help of grinding cement-sand screed, small defects are eliminated, smooth irregularities and protrusions, get a smooth and smooth surface. Photo: shutterstock / fotodom.ru

A lightweight screed with high thermal insulation properties of Knauf-UBU has a small compressive strength - 1 MPa. After hardening and drying the layer over it, it is necessary to equip a solid base. It can be a dry GVL combined floor of GWL KNAUF or screed with compressiveness with a compression of at least 15 MPa, a thickness of at least 35 mm, for example, a KNAUF-tribon. And the parquet, laminate, tile are laid on them. One of the most common mistakes when working with a light tie is a subsequent device "bulk" screed without creating a separation layer. In this case, with direct contact, a stronger upper screed during solidification begins to tear a less durable bottom. So that this does not happen, on top of the light screed, be sure to lay the canvas of a special separation paper or polyethylene film and only poured high strength tie.

Denis Izhutov

Product Manager of Knauf Gypsum

Features of light tie

Light ties are most effective if necessary to align the large differences of the base - up to 30 cm, and when communications are laid on the basis of the floor - pipes, wires in protective cable channels, etc. Layer of a traditional sand-cement mixture of such an impressive thickness will require a large consumption of material, will Have a lot of mass and, accordingly, will increase the load on the supporting structures. In addition, it will take a whole eternity for drying this thick screed. Alternative options like cement-sand semi-dry ties either will also not solve the problem of consumption of material and load on overlap. Only light screeds, density and consumption of which are incomparably less than that of ordinary cement formulations, will allow to align the large differences of the base, cover the communications without providing excessive load on overlap. What makes them so easy?Light cement ties with polystyrene granules, foam glass, etc. Apply indoors with high noise insulation requirements, as well as in the "warm floor" systems to reduce heat loss through the base.

Easiness and strength

Different simulatory materials, including claymps, granulated foamworm, polystyrene granules are served by fillers for lungs. The introduction of them into the screed to one degree or another reduces the load on 1 m² of the carrier structure, increases sound insulation and reduces heat loss through the base. Please note: compressive strength in light screeds of different manufacturers differs markedly (from 1 to 15 MPa). Materials in which this indicator less than 15 MPa is used only as an intermediate leveling layer and subsequently be installed with a solid tie. Prior to that, any actions on a lightweight requires limit accuracy. Of course, you can walk on it already after 2 days after the fill. But remember that the legs of the stepladder or swaying on the chair will certainly leave dents on the surface. It is easy to distribute the load, just put on the floor of the GCL or GWL sheet and put a launcher, chairs, etc. on the screed of a strength of 15 MPa and you can more furnish the finish flooring.

Properties of lungs

- Low specific weight due to which the load on the base and supporting structures is reduced.

- Good heat and noise insulating properties due to the presence of a light filler.

- Low consumption of materials, which reduces the cost of flooring.

- The permissible layer thickness (up to 30 cm) allows you to align the base differences in one pass, increasing the performance of the work.

- High water and frost resistance, which allows maintenance of operational qualities with possible contact with water and the effects of negative temperatures.

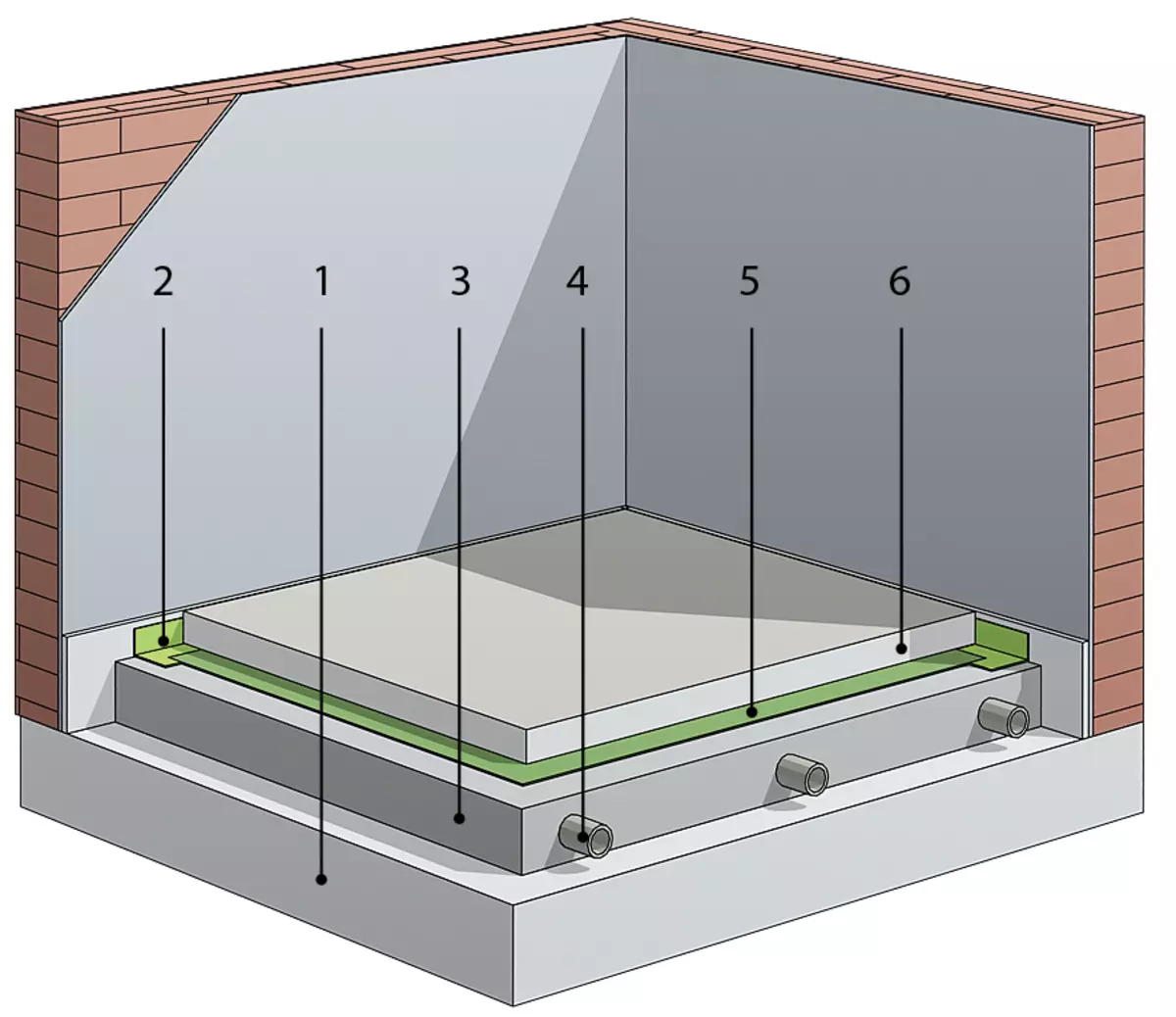

Light base arrangement scheme on dividing layer

1 - carrier base; 2 - edge ribbon; 3 - Light screed of Knauf-UBO; 4 - communications; 5 - separation paper; 6 - Knauf-tribon screed. Visualization: Igor Smirhagin / Burda Media

How to equip a light tie

What to do if you need to arrange an easy tie: buy a dry mix in the store or save and prepare the composition on the spot, having ordained masters to dilute a sand-cement mixture with granules of clay, foam glass or polystyrene? Everyone responds to this question itself, but it should be borne in mind that the leading manufacturers guarantee the behavior of the screed and the stated characteristics of the finished layer, of course, subject to the technology of work. And how to behave during operation of an independently lightweight screed, unknown. Will it be possible to achieve the required strength? What is the likelihood that the granules do not gather in one place and with pressure on it are not formed dents and emptiness? The question remains open.

Light heat and sound insulation ties are applied by beacons, which are installed at a distance of 1.5 m from each other and check in terms of level. To dissolve the screed solution, use the rule. In the case when lighthouses can reduce the thermal conductivity of the finished tie, after the frozen, they are removed, and the resulting rusts are filled with the same solution. Photo: shutterstock / fotodom.ru

In addition, modifying additives are introduced into cement mixtures, which control the shrinkage process characteristic of cement. It is extremely important in the case of thick screed, including light. Alone made of sand-cement mixtures control this process is impossible. And the greater the thickness of the layer, the greater the shrinkage.

The process of arrangement of light cement screed

The concrete and cement bases are applied to the soil of Knauf-Tifengrund and give it to dry (3 hours). The mixture of KNAUF-TSBO is nailed with clean cold water and stirred by a construction mixer to a homogeneous mass. The solution is applied by manually or plastering machine. Photo: Knauf.

After its solidification (after 1.5-2 weeks) on the surface, the lining paper is spread with an overwheltered cloths of at least 80 mm

On top of it poured a layer of a mixture of KNAUF-tribon to create a durable screed and rake

After drying, the layer laid the finish flooring

Required conditions for successful work

The end result largely depends on the compliance with the technology of work and the preliminary preparation of the foundation. Before filling light screed, it should be dry, durable, purified from dirt, dust, paints and oil spots. To increase the reliability of adhesion with the solution, it is treated with the appropriate soil. If there is a chance of a capillary moisture lift, the base is covered with a layer of waterproofing. At the surface prepared in this way, lighthouses are installed. On the perimeter of the room (on vertical surfaces) lay a deformation tape, the width of which is chosen according to the thickness of the alleged fill. The finished cement solution is applied with a layer of 20-300 mm and, as any screed, is aligned with the Rule of Lighthouses. The range of operating temperatures of air and base is 5-30 ° C. During applying and hardening, the screeds do not allow drafts, entering the floor of direct sunlight, sharp change of temperature and humidity.Light ties

Name | UBU | FC43 L starts starts | TERMOLITE. | Palafloor 307. | "Screws lightning" |

Manufacturer | Knauff | "Sedrus" | Ivsil. | Paladium. | "Students" |

Layer thickness, see | 3-30 | 3-30 | 2-30 | 2-30 | 3-30 |

Compression strength, not less than MPa | one | fifteen | 7. | 7. | fifteen |

Thermal conductivity coefficient, W / m • K | 0.1. | 0.32-0.36 | 0.1. | 0.1. | — |

Consumption, kg / m² with a layer thickness 10 mm | 7-7.5 | 12 | 5-5.5 | 4-4.5 | 10-11 |

Filler | Polystyrene foam granules | Small-phrastructive ceramzite gravel | Porous foam glass filler | Porous foam glass filler | Ceramzit |

Packaging, kg. | 25. | 25. | 12 | 12 | thirty |

price, rub. | 368. | 350. | 550. | 414. | 260. |