Overview of the sliding door market and partitions. Designs, manufacturers, prices.

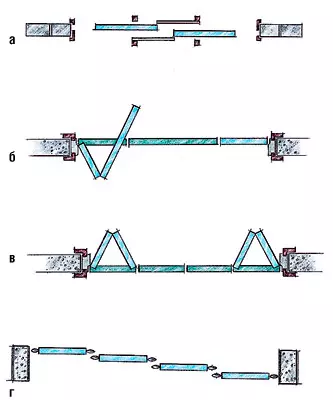

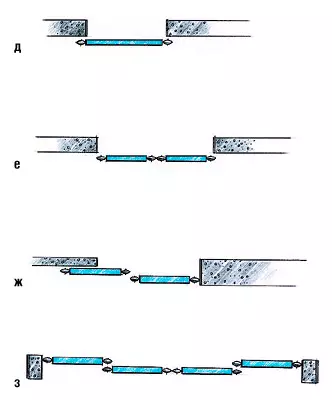

A- Two doors of the type of coupe go into common;

B-folding asymmetric door;

Foldable symmetric door;

M- four canvases are parked in the opening;

E - two sash on the wall;

Jour two sash are parked on one side of the opening;

Z- two stationary and two movable canvas

How long have you traveled in public transport? If so, we will remind that the doors occupy very little space in the subway, trams, buses, trolley buses. Lodine Similar structures were applied long before the appearance of the first car.

Sliding partitions or doors are a web or a system of sash, which close and open the opening due to linear displacement relative to its center. If this opening is equal to the size of the generally accepted door frame (90-100190-200cm), the cesspool is called the door. If it is wider and higher, stretches from the wall to the wall, from the floor to the ceiling, - partition. The main difference between the sliding structures is that the doors are closed with a doorway and can have a preliminary rack and shut down on the lock, and partitions are installed free anywhere in space. To avoid confusion, we will call the door and partitions with a sliding system. Vehicle review will be considered only hard partitions - folding or types of coupe. They are used when you need to solve two tasks: economically use the space around the doorway and overwrite the room with a popular free layout today in the kitchen, an office, living room and a dressing room.

This can be done without capital work, just using the sliding system. But it must emphasize that partitions serve more to create zones and their separation from each other than for the formation of rooms. Folds have a small thickness and will not "eat" a lot of space. When partitions are partitioned, the effect of "disappeared" walls is created, the space is visually increasing. In addition, sliding systems are stylish and modern interior decoration.

Sometimes the doors are a whole problem. Ordinary swing when opening-closures take part of the space or brave the entrance to other rooms or the corridor. In addition, they require places not filled with furniture. We are not talking about those cases when, sharply opening the door, you hit the person passing by the person. By solving all these problems, sliding designs.

Manufacturers

Finished sliding systems, ideally suitable for a particular apartment, you will most likely not find - they are made to order for a certain period (from five days to three months). Equipment, as a rule, are set only samples for which the decor and installation scheme is selected.Sliding systems are offered by two types of manufacturers. The first are known to the buyer with their cabinet furniture, wardrobes and dressing rooms. This is "Alpha", Aldo, Lumi, Mr.Doors, Kardinal, Ecalum, Stanley (Russia), Neves (France). Second-door factories that produce swing and sliding models. Unas presented products of Italian firms ASTOR Mobili, Bosca, Foa, Movi, Res, Rimadesio, Tre-P Tre-Piu, etc. and Russian Deni Design. Moreover, if the Italians send a finished product assembly within 90 days after the conclusion of the contract, the Russian companies make sliding systems here, based on an import profile and components, within 15 days. So, Mr.Doors produces doors based on Noteborn profile (Holland), Aldo collects a sash from its own parts, and the suspension mechanism takes German, from Koblenz. Finally, Kardinal makes a sliding partition from RAUMPLUS (Germany) component.

The rollers and the suspension profile and the guides for partitions based on the wooden frame are purchased by many Russian companies in Italy and Germany for the same suppliers (Pettiti Guiseppe, Koblenz, Geze), which supply the aforementioned Italian manufacturers of sliding structures. The exception is the Peter Firm "ALP", which part of the suspensions makes itself, and the part collects from the domestic aluminum profile and imported rollers. And it even sells its sets separately from the door.

Case Principle

In fact, there are two fundamental schemes of the sliding systems: on the roller reliance - flooring (the partition moves along the bottom guide) and on the roller suspension, the upper rolling (the partition moves above the floor along the upper guide). The design consists of frame flaps. A more expensive and prestigious frame is made of simple and glued lamella (made of bars) or a sheet (made of thin glued layers) of wood array. The canvas slightly easier and harder (up to 80 kg) is assembled from veneered, painted plates covered with decorative film MDF plates. Lightweight and modern frame (25-30 kg) is made from extruded aluminum alloy. Inside the frame is inserted either glass, mirror, decorative plastic, or a deaf panel (china). There are cloths from solid glass with top suspension.

Any door, even a panel, which has a veneered or painted sheet of MDF on the frame structure of coniferous rocks, not to mention the laminated chipboard door, can be suspended. And it will turn from unpacking into sliding.

Most European sliding systems are represented in wooden or aluminum performance with upper suspension. Specialists of "door" firms selling them believe that this is the only true and reliable design. Assue is a queue, most of the "furniture" companies with a large range of the wardrobe door of the compartment type, often offer customers sliding systems on a roller support, since this product is more accustomed to them. But although the furniture makers are confident in the advantage of the outdoor solution in front of the upper suspension, and the "door" in the opposite, and the other design have the right to exist. True, if each of its advantages and disadvantages have.

Roller suspension

As already mentioned, this is more popular in Italy option: the sash moves above the floor, keeping only on the top rail, which serves as a guide. There is a small gap (up to 1 cm) between the floor and partition or the door, so it is difficult for complete sound insulation of the separated premises. But they maintain a single floor covering and there is practically no noise when the sash movements.Mechanism The suspension sliding system consists of two carriages with rollers, top rail in the form of aluminum (less often steel) profile, stopper or stopper (bipper) and fasteners for frame. Caries are a cast duralumin hull (Koblenz, Germany; EKU, France) or high-strength plastics (Pettiti Guiseppe, Geze, Alpha) with two or more often four rollers installed in pairs on the same axis. For the door weighing 40-70 kg, a mechanism with two rollers (Stanley) is suitable, and for the cloth in 75-120kg is needed already 4. Winters of silent rollers are made entirely from plastics ("Alpha", Eku, Stanley), if the calculated mass of the web does not exceed 40 -50kg, and with a metal sleeve and plastic rim (Koblenz), if it is 50-80kg. The shape of the rim can be different: with the recess at Koblenz, the EKU direct at the EKU and the cone on Pettiti GuisePe. The last option is good because the rollers are self-centering, but give the doors the opportunity to swing more widely.

For smoothness, most carriages are equipped with ball or roller bearings. Large domestic and European manufacturers use similar imported mechanisms that are withstanding the load up to 120kg (240kg for Deni Design) and usually do not create problems. However, dealers or minor organizations can purchase products of other European factories or the St. Petersburg company "ALP", having different designs (there is even a pair of slip without ball bearing), operational characteristics and work resource. Therefore, it is necessary to clarify the seller, what type of mechanism you are offered and how much It fits your sash at the maximum permissible load.

The rails of most producers are made of aluminum profile of the P-shaped shape with the inner shelves, which are based on the rollers. It is characterized by high strength and rigidity. But on sale there are less rigid and noisy products made of bent sheet. Therefore, pay attention to how profile looks like. The bent product has a single thickness on all sections and rounded corners.

To stop the door, the stopper is used in the form of a clamp or rubber chipper. They are installed inside the upper guide profile. The stopper is more convenient than the bump box, but it is capable of fixing the door only in the extreme right or extreme left position. Clamp power is adjusted by screw. The door should be included in the stopper without much effort. The original foot stop offers Stanley: by pressing the pin with the side of the sash, you can stop it anywhere in the opening.

The main problem of sliding systems with upper suspension sash (backlash). After all, the canvas is suspended, and nothing prevents him from fluctuating on 5-10 cm perpendicular to the direction of movement. All firms offer certain solutions to this problem. More often free move limited by a plastic or metal flag that is installed on the floor side of the opening. The checkbox is a small corner or a rod on a flat "sole." It is part of a non-separated groove, cutting into the bottom of the door frame. When opening or closing the door slides along the flag and, thus, does not swing on the suspension. This way is bad because the movement of the sash is limited to the length of the groove and the edge of the canvas removed from the checkbox, swinging. Result The design still has a small backlash.

If the opening is wide, you can apply a multi-window system (3, 4 or more sash). The principle of action is: you pull for one sash with the top suspension, it gears and starts moving the following and so on (the number of elements can be any). In this case, the free space between the canvases does not remain. As a rule, this principle is implemented at the expense of the brackets that are under the bottom edge of the door.

According to most professionals, in general, it is almost impossible to avoid the back of the back of the top suspension, only sliding systems are won on the lower support. However, ECALUM offers a solution with upper suspension and lower plastic guides. For them, a groove in the finished parquet is done, or a ready-made wooden plank is installed with a groove at the floor finish stage. On the bottom to the door, 2 plastic flags are fixed, which are included in the guide. This design makes it possible to move the sash at any distance bounded only by the length of the lower guide.

Rail installation. Upper rail can be attached to the ceiling, wall above the opening or special frame. The main thing is that the basis is solid, able to withstand the weight of the sliding system.

At best, one or more rails are fixed to the plastered concrete slab or wall, stationary partition, erected from piece materials (such as brick, puzzle, foam concrete and slag blocks). To do this, first on the dowels or anchors is the base is a rectangular massive or disheveled bar (Aldo, Astor Mobili, Foa IT.), the chipboard panel (Mr.Doors, Ecalum) or a metal corner. Then, one or several rails are screwed to it. The base serves as a transitional element with which you can compensate for non-parallelity of the floor and ceiling, reduce vibrations and tie several paths to one coordinate system. Then the decorative panel hiding the mechanism is fixed to Brusa or Chipboard. Russian companies can collect every number of rails (3,4,5). Italians are usually limited to a three-step assembly. The exception is Bosca, offering boxes with four rails. The bases refuse only if the ceiling is perfectly aligned, and the rail profile allows you to install it on the anchors so that it will not interfere with the carriage moving.

The suspended system rail categorically cannot be attached to the drywall, this material will not hold the weight of the entire design. If there are no other installation options, specialists offer several outlets from the position:

Mounting to the slab overlap through the well-ended ceiling construction on long suspensions. The method allows to strengthen the rail at a distance of no more than 20 cm from the concrete ceiling. The installation can be carried out after repair, in the finished interior;

Make reinforcing structures under the ceiling or in the wall at the repair stage. They can be a farm or beam made of metal corner or bar. The easiest way is to make a longitudinal profile of a metal frame under plasterboard not 60, but 20cm and secure the guide to it;

Make a slot in plasterboard, attach the rail to the overlap and calculate the height of the door to the "real" ceiling. Thus, the top of the web will be hidden from the eye, and work will still have to produce during repair, to the ceiling.

European manufacturers are used for wide openings designed for two flaps, door frame. The box is inserted into the opening and the canvas hang on it. Installation is carried out on a pre-installed falsecalt with the help of the corners (used screws). All connections are closed with platbands, and caps are caps.

There are less common ways. Deni Design offers the installation of a double-circuit profile of the versus between the rigid walls. To do this, the company's assortment has a special design hidden by planets from anodized aluminum in the form of a square beam 1010cm. It can be fixed at any height from the floor, even if the distance between the walls reaches 6m. A completely exotic solution belongs to an albed Italian factory. The rail is suspended on chains similar to those who hold raster suspended ceilings, and the vertices are recorded on the walls or with vertical racks. The maximum suspension length is 5m, the height is not limited. The situation of this system, the rails are set parallel to the floor, even if the overlap is very uneven.

System with lower support

The bottom rail serves for the slotting system of the sliding system and the guide. From above, the door holds from falling the second guide. The lower support allows you to avoid swinging in principle and move the sash to the greater distance than the width of the canvas. We are the main advantage of partitions with lower support. Ancedostat is that the rails are located on the floor and several oppose it. The struts of the view of "furniture" companies, the lower rail is no worse than the top suspension. According to the opponents of such a model, you can stumble about the rails, and if they are irregularly cleaned, they are clogged with homemade dust, sand and over time are dirty, because they are constantly coming. But truly serious is only the argument associated with a violation of the integrity of the appearance of the outdoor coating. It is fair when in the separated rooms coverage the same - parquet, floorboard, tile, carpet IT.P. Anyway, the rail visually divides the side of the opening. The system is justified when the parquet is replaced by tiles, carpet parquet and on the contrary, that is, on the border between the living room and the kitchen, the bedroom and the dressing room, where the texture and color of the coating are changed.

Floor rails (tracks) are overhead and integral (cut-out). The invoices for relatively light "furniture" sash (Raumplus, NoteBorn, Stanley) are a flat metal profile with low relief (less than 10mm). They are fixed on an existing coating or a plank from chipboard using bilateral scotch (Mr.Doors) or self-tapping screws. Integral tracks for lightweight sash are more similar to a narrow metal strip, which is embedded in a floor covering or joint. "Door" integrated guides are made in the form of metal rails (one or more) inserted into a rounded wooden bar, which is made of solid wood. It is crashed into an existing coating so that only the semicircular part performs above the floor. Overhead "door" tracks consist of one of this semicircle. However, the rail does not always have in cross section the shape of the semicircular - in different manufacturers, the cross section can be different.

The door moves along the rail, as a rule, on two rollers or wheels, which are hiding in the bottom plank of the frame. Rollers just as in suspended systems are made of durable plastic (Prestige from Mr.Doors), in case of heavier partitions, with a metal sleeve (Raumplus). To eliminate the output of the sash from the path in more "advanced" systems, an anti-tiping device is used, which automatically holds the wheel on the rail (Raumplus, NoteBorn). The minimum output (in a loaded position) of the wheel is adjusted by a screw pair (RAUMPLUS) or a gearbox (NoteBorn). This allows you to align the door in height and horizontal within 1 cm.

The upper guide (traverse) of the sliding system with the bottom support does not carry almost no load. It only holds the canvas, so it is made from a thin-walled decorative P-shaped profile (Stanley, Rauplus, NoteBorn) or a metal plate (ASTOR Mobili). From the backup, the partition is protected or primitive brushes on the top edge, or two built-in carriages, including 2-3 rollers. The top rollers are also spring, the top rollers also spring up for a more dense contact and noise reduction (NoteBorn).

Artistic cloth

Externally, the sliding partition consists of a frame, inserts that fill it, and platbands-planks or panels covering connections. The price of the finished product, its operational characteristics, maintainability directly depend on these elements.Frames. Aluminum frames are practical and easy, characterized by simplicity of design and modern view. They are perceived as a thin framing. It is usually assembled on self-drawing (Raumplus, ECALUM, Stanley) and self-drawing contractors under a hex key. Only in the design of the NoteBorn housing of the rollers are the power elements that fasten the frame. In essence, any aluminum frame can be brought to the place of installation in a disassembled state. This is important if you have big flaps and a standard entrance door through which it is simply impossible to carry the collected cloth of the partition.

To give the frame of special decorativeness, most companies use a rectangular or rounded profile of different widths (3-5 cm) with captures (then do not need knobs) or without gripping. It is painted, anodized, so that different matte shades are obtained from silver to bronze (Noteborn, Raumplus), and veneer (Ecalum, Deni Design, Rimadesio, etc.). The last decision is popular among those who want to withstand the whole interior, including doors, in a single style and color. For decoration, the same veneer varieties, the same tintings and varnishes, which go to ordinary, including Italian, doors are chosen. The veneer allows you to overcome the only significant lack of doors from anodized aluminum, low-durability and maintainability of the coating in the event of scratches and other damage that even child can apply.

Wooden frames are a classic of the genre. If in your interior is a place for wooden furniture, animated veneer or made of array, "wooden" sliding systems - what you need. Imported frames are collected from glued timber (lamella or sheet) or from MDF on glue and spike-groove type connections. Russian frames are collected from the non-ceased timber (Aldo, "Alf") on the self-tapping screws and conferences, the holes under which are closed with wooden plugs. This practice allows you to collect and disassemble the frames on the spot, which is very important from the point of view of repair and transition of oversized products to the room through the door Operactions.

The main requirement of any product from the wood array is maintaining the temperature and humidity regime in the room. That is, furniture, parquet, doors are harmful too wet and too dry air, norm-40-70%. Loaded for stretching flat frame - no exception. In addition, the partition is often higher than the usual two-meter door and can separate rooms with different modes. As you know, in the heating season, when the principles of convection are valid, the humidity decreases towards the bottom upward. We have repeatedly wrote that the relative humidity in winter is capable of falling up to 20-30%, the wood is losing up to 3% of its weight. This negatively affects the shape of the door canvase, it can be a screw, unlike furniture, where the frame has a volume and hard fixes each item.

To avoid imminent consequences of dry air influence, in heated rooms, there should be alive flowers or air moisturizing devices, and in unheated or wet rooms, it is generally abandoned by wooden sliding systems.

Inserts, panels, jumpers, platbands ... But the frame is, of course, not the entire partition. Its part of it is closed with decorative inserts. They are made of glass, mirrors, MDF and chipboard, plastics. The china thickness is 4-5mm for glass and mirrors, 4-8mm for chipboard and MDF. The thicker glass, the more stronger. Mr.Doors pulls the thick sheet of 16mm MDF along the edge and inserts into a four-millimeter groove. Aldo makes glass with facet. As practice has shown, the rectangular groove does not harm the glass cut down.

Glass inserts are transparent, matte, translucent, satin (processed acid treated), stained glass, painted, with sandblasting, pattern, engraving (ALDO, ECALUM) and fusing.

The most expensive decoration for the sliding partition is artistic stained glass window. The price of the door with glass insert with a simple pattern is about $ 100 / m2. A simpler decor in the form of fusing-hot glass-cheaper. Bosco's folding recently appeared a double double-glazed door, which inserted a wooden braid. Another innovation, which was used by FOA and ECALUM, is a double double glazing with whitish fiberglass inside. This decorative material does not change with time under the action of temperature and light.

In order to secure, ordinary glass in products of many firms are covered with a special protective film. But some manufacturers offer it as a separate service, and such an important moment makes sense to find out. For example, the tempered cloth inserts only Deni Design, and in order to preserve the flawless appearance of the door on both sideways, the film is distinguishable on the surface. Kardinal offers a triplex for the PAUPLUS system. Italians hide their ways to hardening glass. As a rule, this is hardening or triplex, although it is difficult to say exactly. Nevertheless, almost all Italian products are protected.

In addition to transparent and matte protective films, there are many decorative: green, mirror, mirrored with blue, under ordinary bronze, under frosted bronze. Protective or color film is applied only to a smooth surface where there is no sandblasting pattern. Note that under simple, colored and frosted mirrors in sliding systems do not put MDF or chipboard, and simply glue the rear wall with a color film.

It is very important that the glass is inserted into the groove with a transparent flexible seal (Mr.Doors, Ecalum, Stanley) or silicone sealant (Aldo, Alpha). It increases the resistance of the insert and frame to shock loads and skews.

Plastic, veneered and laminated MDF and chipboard, MDF with tapestry or wicker, DVP- Any not very heavy slab materials can serve as a panel in a sliding design. The choice largely depends on the design concept as a whole. Popular combinations of glass inserts with wooden. They are expanded (separated) by straps, which for domestic products are added to a total price of about $ 20 each.

Overhead decorative strips on a glass or mirror canvas are often proposed - they set the rhythm of the boring monochrome surface. This successful move is applied by Noteborn and to decorate the profile itself. Together with it, multi-colored adjustments (with handles and without) are supplied, which are snapped into the frame and are easily removed, so they can be replaced in case of damage or reissue of the interior not forever.

Dimensions. The overall dimensions of the frame from any material are determined by weight and material inserts. For aluminum doors, weight is less critical than wooden. Manufacturers accurately indicate with which insertion (glass, chipboard, plastic, etc.) the maximum size of the canvase. The extending of transverse planks task simplifies.

Cashbirds in sliding, as well as the ordinary, doors can be different. For anodized aluminum partitions, they are often not put at all. Ak cost of the wooden sliding system of platbands will be added 300-600.

Brushes and compensators . Many manufacturers reduce the power of the impact between the sash when they are constructed by one rail using an end compensator, which has a kind of soft insert. The distance from the wall to the partition and between two sash is not more than 1 cm. This gap is sometimes compacted with a special brushes with a width of 0.5-1 cm, which increase the sound insulation properties of the structure.

Variants of movement of sash

Types of sliding systems differ by how "removes" the canvas and where it is installed.

Sliding System type compartment with cloth leaving wall It is organized in two ways: with a penalty and without it. For the first case, the wall is made to install the foam, which when opening the canvas drives. The cleaned door or partition is much more difficult to open, knock out when a random strike or break (if it is glass). Pencil is a wooden frame, covered with galvanized iron sheet. Inside the rail is already mounted, usually for the suspension canvase. Pencil can be installed both on one side of the opening (for a single door) and two (for bivalve). Fasten it in the opening on the mounting foam. There are options for the external trim box: a grid under the plaster and a platform with holes for plasterboard. This gives an opportunity that does not thicken the wall with an additional metal profile or one more brick (blocks), to finish directly on the box. At the edges of the opening and the box, as a rule, sealing brushes are installed and the framing (in the tone of the canvas).

Installation of the sliding system without foam is possible only in newly erected or trimmed walls. After all, the recess is formed immediately, and then access inside will be impossible, and you need to fix the suspension profile or lower rails. In addition, a specialist for installing a sliding system arrives before sealing the wall and fastens a profile to the slab overlap or wall, if it is made of bricks, aerated concrete disconnecting blocks or concrete panels.

The problem of any, with or without penalty, installation in the wall is its thickness. Thin 80 mm partitions will not allow the recess even under one door, and thick bearing reinforced concrete structures will require you to coordinate the project and high costs for diamond cutting. The only possible solution is to build plasterboard falseland, which will hide the door in the penalty (or without it). Thus, on the one hand, the profile or box is attached to an existing wall, and on the other, it is sutured with plasterboard for metal frame or penaltone. It's not necessary to close the whole wall, it is enough to close the plot where the door will move around the profile. It turns out the protrusion of 8-10 cm for one canvas with a thickness of 4.5-5 cm, given the finish.

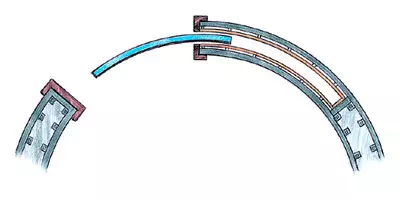

If the wall thickness and interior design allow, one box can be installed or to build a niche for two and even three doors retaining into one wall and closing one or two openings. At the same time it is necessary to take into account that they will travel to different profiles and, as a result, at different levels. There are also options for radius sliding structures: if the opening is located on a rounded wall, then the radius (rounded) door will be increasing and convenient solution.

The main advantage of the merchandise is the possibility of installing furniture near the opening, the main disadvantage of the complexity of the installation and its inability without construction work. These nuances are deprived of the next, simpler version of the sliding system.

Sliding system of type coupe with the movement of the canvas along the wall. The movable sash when opening moves from the outside along the wall away from the opening. No additional tricks are required with this type of installation. Only guide rails and decorative platbands are attached, closing, if necessary, rollers. Sodel or two sides way goes beyond the opening of the opening (depending on the number of moving flaps and whether you want them to open both right and left).

The main problem of the coupe through the wall is that in the zone of the movement of the sash there should be no obstacles to the type of convex plinth ("Europenten" with a thickness of 15mm passes), electrical products (overhead sockets, switches), lamps and finally furniture. That is, when you save the place and simplicity of the installation compared to the opening door, you can still not put anything close to the wall in the door movement zone.

Because there are radial (convex) and converging at the angle of the wall, there are partitions that can be installed along it. Radial designs on the upper suspension (they are almost twice as expensive) offer mainly Russian manufacturers of ECALUM, Aldo, Alpha and Italian company COMAS (approximately 3500 per 1m2). The angular modifications on the lower rail with the corner rack releases Raumplus, with the consecration of sash-stanley and Mr.Doors. They are not very expensive than simple sliding systems.

There are many options for the layout of mobile and stationary flaps, in the middle can be stationary, and two extreme ride along the walls. Options for doors consisting exclusively of movable sash are possible (in this case, several floor railway rails are used) moving in different directions. Most manufacturers offer component fixed sections with mobile, building the entire wall. If the ceilings height is large and the door can not reach them, the top is removed by the wall on the basis of the same frame and inserts, from which the sliding sash is made.

If the doorway is so narrow that there is not enough space for a sliding door, and the space nearby is too little so that the swing design does not interfere with (for example, did not overlap the corridor), and there is no possibility or simply do not want to break or erect the wall so that the door is retracted to Her, as an option we can offer a folding door- "book" (or "accordion").

"Harmonic". The partition that opens the opening, folding in the harmonica, differs from the designs of the piece of the coupe by what consists of several rather narrow canvases. Each of them is attached in the center of the top plank on the roller suspension to the rail. Neighboring canvases are combined into a partition with hidden loops that are not visible in the closed state. This design is good because it can overlap the opening, even if on the right and to the left there is no space for leaving the sash. Such a door remains in the opening, narrowing it in the amount of thickness of the canvas, that is, at least 8-10 cm (for double "harmonica").

Interior partitions . In order to harm some of the room, you do not need a wall that will move the canvas. The guides can be attached directly to the ceiling and the floor, and the movement of the door to limit the racks or stationary elements made on the basis of the same aluminum profile or wooden frame. Moreover, the free arrangement of the sliding system makes it possible to zonate any volumes, including room corners (for example, under the dressing room). If the interior is filled with rounded elements, a radial suspension sliding system is used. But if the interior design is based on the dominance of rectangular volumes, it is better to use an angular system from an aluminum profile, in which the doors will converge at a right angle along the floor guide.

In the dry residue

Different firms are calculated by the cost of the sliding system by different methods. Some separately evaluate the frame, separately insert. Others give the cost of a square meter of construction and a rails of rail with mechanisms. So compare prices is very difficult. Therefore, we asked the largest sellers and manufacturers to calculate one sash 90cm wide in the opening of 270 cm with an insert from the matte glass and one platband covering the mechanism. The boards, the model and color of the profile, the wood finish were not fixed. But it was implied that the minimum cost was presented from possible. It is not included in the installation, which is estimated by most organizations at 10-15% of the design cost, and delivery. Vitoga It turned out that the most cheap systems are offered by Mr.Doors, Kardinal, Stanley, after them are "ALP", LUMI, NEves, Ecalum, Aldo, and closed the chain Italian firms. Breaking price between imported and domestic structures is small. This is due to the fact that the struggle for the buyer is not at the expense of price competitive advantages, but at the expense of short delivery time, satisfying the requirements of the customer right in place, the low probability of error and delays.The lower rail is justified when: you are not confused by an anodized metal strip on the floor (the integral track is not so striking); You do not have pets, whose wool would constantly climb the guides and scored rollers (to get it from there almost impossible); The door is very heavy (extremely rare); You want the design to no case hang out.

The upper suspension is justified when: you are not confused that one of the lower corners of the sash is not fixed and hanging out (with the exception of ECALUM); A universal sliding system is required, under which the floor covering remains intact.

Aluminum frame should be preferred by wooden if you are not sure that you can provide a normal temperature for a wooden frame (20 ° C) and humidity (40-70%). The rest are only the general principles of aesthetics. We hope that the information we communicate will be useful to you.

The editorial board thanks the company "Academy of the Interior", "Alpha", "New Interior", "MBTM", "Landor-World of Doors", "Triumphal Mark", Aldo, Ecalum, Kardinal, Mr.Doors for help in preparing the material.

Table prices and specifications of sliding systems

| Firm manufacturer Systems | Motion Scheme and Manufacturer Mechanism | Maximum dimensions, widths, cm | Material carcass | Cost of design 27090cm with matte glazing * |

|---|---|---|---|---|

| "ALP" | Upper combustion "ALP" (Russia), Geze (Germany) | 210340. | Hardwood wood, glued bar, veneering | $ 650 (Alf 55, Beech) |

| Aldo. | Koblenz (Italy) | 120300. | Array of beech, oak, etc., radius partitions are possible | $ 1188. |

| Deni Design. | Top rolling (Italy) | 200600. | Anodized profile (Italy), is planned to veneer | 1100. |

| ECALUM. | Upper suspension GEZE (Germany) | 240350. | Veneered and anodized aluminum, radius and angular partitions are possible | 942 (with two straps) |

| Kardinal | Outdoor RAUPLUS (Germany) | 120330. | Laminated and anodized Aluminum Raumplus (3 species) | $ 376. |

| Lumi. | Outdoor combination from Luminator AB (Sweden) | 120290. | Anodized aluminum, Optima series | 638. |

| Suspension Juiseppe Pettiti (Italy) | 120300. | Veneered MDF, Nova Series (Norway) | 831. | |

| Mr.Doors. | Outdoor rolling | 95270. | Aluminum anodized aluminum ** Prestige, Prestige Tau | $ 386 (Prestige) $ 443 (Prestige Tau) |

| Outdoor non-NoteBorn (Holland) and Suspension EKU (France) | 140275 | Anodized Aluminum, Noteborn (Netherlands) | $ 466 (Noteborn) $ 551 (EKU) | |

| Neves. | Outdoor rolling | 100259. | Aluminum profile Duo from Neves (France) of different shades | $ 780. |

| Stanley. | Top and outdoor combustion | 120320. | Anodized Profile (Norway) | 396. |

| Astor Mobili. | Top rolling (Italy) | 120275 | Veneered glued frame of coniferous wood and MDF, there is a new model with outdoor rolling | 1182 (model Plaza, painted array) |

| Albed. | Top rolling (Italy) | 320150. | Anodized or veneered aluminum frame | 1050. |

| Bosca. | Top rolling (Italy) | 150300. | Series Exit- glued wood (maple, cherry, wenge, walnut in conilet); Exit 08-09- Oval model from the array; ENTRY-screw MDF; Light- aluminum profile | 1270 (Entry 07 model) |

| Comas. | Top rolling (Italy) | - | Glued wooden frame, radial partitions | 6000. |

| FOA. | Top rolling (Italy) | 130300. | Glued solid wood, walnut veneer, cherry, etc. | 1321 (APPIANA model) |

| Garofoli. | Top rolling (Italy) | 140280. | Glued massif solid wood | 2355 (SUPRA 5 / V model with box) |

| Gezzi Benatti. | Top rolling (Italy) | 120240. | Glued array, original designs, glass | 1000. |

| Henry Glass. | Top rolling (Italy) | 126280. | Glass canvas with an end strap or without it | 870. |

| Longhi. | Top rolling (Italy) | 158320. | With aluminum inserts - models 300,305, 306, wooden - 240, 230 | 1300 (Models 300, 240) |

| MOVI. | Top rolling (Italy) | 130300. | Anodized and veneered aluminum, all-glass cloth | 1840. |

| RES. | Top rolling (Italy) | 150320. | Anodized aluminum frame or veneer coated: wenge, mucled oak, nut or painting by customer sample | 921. |

| Rimadesio. | Top rolling (Italy) | 175314. | Veneered (wenge, choped oak, nut, cherry) and anodized aluminum | 1500 (SIPARIUM model) |

| Tre-P Tre-Piu | Top rolling (Italy) | 120300. | Anodized and veneered aluminum | 1331. |

| * - indicated averaged cost or for the model; ** - Aluminum alloy |