G20 Market Overview: Properties of Material, Functional and Decorative Opportunities, Application Areas, Playing Methods.

Photo

Z. Ryutdinova

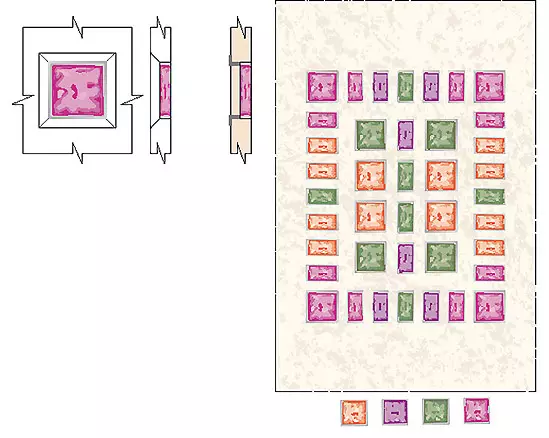

Blocks with 1, 4 or 16 cells. Seams of the same width between them and adjacent blocks create a mosaic effect

In the kitchen glass blocks - a decent alternative to ceramics

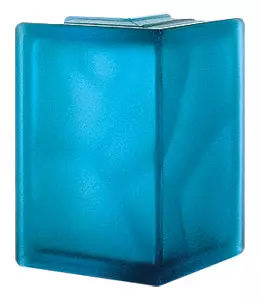

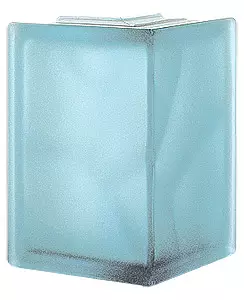

The surface of colorless or colored glass blocks can be smooth, wavy, corrugated. Such a variety allows you to get extraordinary color and light effects.

Original "Glass" walls will decorate any interior regardless of the destination of the room

The size of the walls from glass blocks inside the room should be no more than 43m

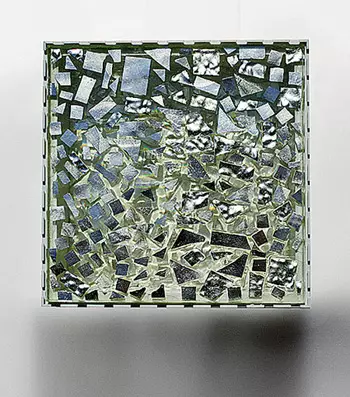

Glass artists apply sintering technology (fusing) to create decorative glass blocks that have unique expressiveness and resemble small colorful stained glass windows

Bright avant-garde glass blocks fill the paints and revive the space of the most ordinary apartments

Photo by A. Babaev

Pastel tones are appropriate in classic interiors

(A-B) placed original compositions. Relief drawing block Vitrosilicon (D) gives an interesting game of light

"Glass" floor makes space easy

The basis of the "glass" partition is square glass blocks and / or "halves". Facial and angular blocks are used to complete it.

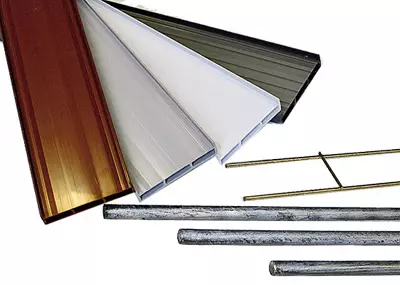

Reinforcement elements and rails of the LUX-PROF modular system

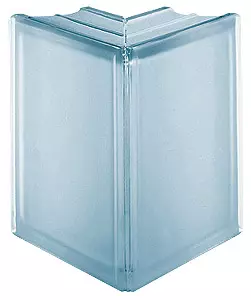

Radiped glass block (angle 45) for smooth bends of the wall

The transparent wall separates the space of the living room, but freely skips light into the input zone

Insuoleration is one of the most serious problems of many residential premises. The least natural light penetrates the input zone, corridors and halls, bathrooms ... Transparent partitions and walls from glass blocks will help correct the position. They will make visually lighter and spacious even a small apartment or house.

The glass blocks are not new: not far from the mountains of its half a century anniversary. Modern glass blocks due to the efforts of technologists and artists are distinguished by the simplicity of assembly, reliability in operation and exclusive design, which will make it possible to implement the most unusual creative ideas.

Opinion of a specialist

Over the past 5 years, the popularity of glass blocks has grown noticeably. The number of manufacturers has increased, the range of colors, a set of textures and decorative elements has become much more diverse, the line of size has expanded. The material is mainly used as partitions or their fragments, in addition to this, straight and rounded walls are erecting from it, arches, make ceilings and roofs, and outside home-diverse vaults and canopies.

However, the glass blocks have some drawbacks. First, inside such walls and partitions, various communications cannot be paved (IT sewer). Secondly, it is not easy for a "glass" wall. In addition, glass elements can not be cut to use only part of the block. An inadequance takes a glass of other sizes.

Stanislav Yakovlev,

Design Studio Design

Architectural and construction company "Dipris"

Anatomy of glass block

The glass bottle is two half-terminal cooked with each other with a glass of 6-10mm. The manufacturing process occurs at high temperatures, due to which the hermetic, partially vacuum cavity is formed inside the finished product. This design determines the unique properties of this material. For example, the sound and heat-insulating parameters "glass" partitions are not inferior to the walls of brick or foam concrete blocks of a similar thickness, sound insulation index RW = 9DB, heat transfer resistance is not less than 0.43m2k / W. The glass bar is strong enough: impact resistance is at least 0.8 J. The tensile strength is the same as the M150 brick, and is at least 15 MPa! Therefore, the walls from glass blocks are easily withstanding the ball blows, various vibrations. There are bulletproof glass blocks, which will stand, even if they throw a stone or shoot them. The material is absolutely not susceptible to significant temperature differences -40 to +50 s, and in the case of a fire prevents the spread of fire, smoke and heat radiation for 1 toh, which is not surprising, because the glass does not burn.Due to the high waterproofing properties of glass blocks, as well as their resistance to aggressive chemical media, you can separate the outer walls, which, however, should not be carriers. The load assumes the framework, and the glass blocks play the role of filler. Their end parts are slightly concave, and during the laying of the cavity is filled with adhesive mixture. The ends are often covered with white paint so that the dirty gray solution has not changed the shade of the glass block.

Indoors on the foreground are decorative quality material and simple care. The glass blocks do not absorb smells, do not accumulate dust. The cleanliness of the surface is supported using a cleaner for glass or a wet cloth moistened with any non-abrasive detergent.

Opinion of a specialist

Laying the glassloblock is a difficult matter, especially for those who do this for the first time. The surface on which the wall is erected from the hollow glass blocks should be smooth and clean. It is very important to use glue mixtures designed to work with this material. The composition includes special additives that increase the elasticity of the solution, its adhesion (adhesion) to the glass surface, as well as accelerating drying. Before preparing the solution, the dry mixture must be mixed thoroughly, since it could take the separation of its components during transportation. After adding water, the solution is stirred by a low-speed stirrer.

The outer wall of the glass blocks is fixed along the perimeter with ribs from a concrete or a cement mortar, reinforced with metal rods with anti-corrosion protection. Ribs are placed in a frame from metal profiles. At the same time, it is necessary to leave small compensation gaps that separate the glass wall from the elements of the building of the building (walls, wrappers, etc.) and will ensure the freedom of its movements when the temperature and humidity changes. The gaps are filled with moisture and frost-resistant elastic sealant.

Vyacheslav Yusupov,

Technical specialist of Krazel Rus

What is something

It would seem that the wonderful properties of glass blocks should contribute to their widespread use in the interior finish and exteriors. However, in the Russian market there are not so many companies that produce this product or are seriously engaged in its promotion. Most often, the glass blocks are one of the positions in a wide range of various finishing materials. Many and now believe that they are suitable only for non-residential premises: industrial enterprises, sports complexes and hotels. Up to the 80s. Xx in. The choice of textures and colors of glass blocks was indeed very limited. They were used to build partitions between the premises (including with high humidity), walls on the staircases. Today, along with industrial designs, a huge range of original design developments for private interiors has appeared.

Strong positions on the Russian market were taken by glass blocks of the Seves Group, which brings together several companies from different countries, including Solaris (Germany), Vetroarredo (Italy), Vitrablok (Czech Republic). Their products are highlighted in the most diverse colors, a large range of sizes and textures, the presence of all type elements. In addition, we are on sale there are glass blocks of Jinghua (China), Trend Group (Italy), Vitrosilicon (Poland), Weck (Germany). Prices for European products begin from 165 rubles. Star Glass Star Glass Blocks (Russia) are 160-260 rubles. For 1 pc. The cheapest material is the cheapest material of Grodno Glass Play Plant (Belarus): 40-60 rubles. For 1 pc.

Light and color

One of the main distinctive qualities of glass-loving lights. Explicit elements it is 75-80%; According to this indicator, they are comparable with double window glazing. The transmissibility of non-ferrous glass blocks is slightly smaller, and one-sided matte and matte-30-50%. This contributes to the creation of soft scattered lighting, leveals glare. The matte surface of the outer walls passes the light, but becomes an irresistible barrier for curious views. However, admire the surrounding landscape inhabitants of the house, alas, do not have to.

Similar effect-from transparent glass blocks with a variety of reliefs on the inside. Strips, rings, waves give unusual black and white pictures, direct the light stream at a certain angle and hide what happens behind the glass wall. But, unlike matte, they skip a lot of light and cost cheaper.

Many companies paint the glass in the mass-most often it is pastel tones. Glass blocks of bright, festive colors manufactures Vitrablok. However, the durability of the colorful layer on the surface is significantly reduced by UV rays and temperature differences, so the material is recommended to be applied not for external walls, but only indoors.

Opinion of a specialist

Often, customers underestimate the possibilities of glass blocks, but most of them do not mind, having heard the offer to use this material when interior design. A variety of textures, colors, angular and end elements allow you to realize the most incredible design ideas. At the same way, we try to leave the traditional laying of blocks as a fragment or a whole wall, acting on another technology. In front of the foam concrete, we cut the cells of the desired size and insert the glass blocks of the three to four shades, depending on the total colors of the apartment. Thus, they become interesting color fragments of the wall.

Outdoor glass blocks are rarely used. To lay the elements with a thickness of 60-80mm, it is usually possible to raise the floor level or erect the podium, and this is not like all owners of housing. If you need to lift the floor to hide communications, we give the design to the form of a specially conceived decorative solution.

Olga Kharchenko,

General Director of the Architect Bureau "Project-Group 2000"

Entertaining geometry

The most common size of glass blocks-19019080mm. Larger products-24024080, 300300100mm-used less often. With diagonal laying, square glass blocks are combined with triangular (23617280mm). Interesting decorative effects can be obtained by combining full-fledged squares and so-called "halves" (190 9080, 24011580mm). However, they are used in the construction of rounded partitions: glass blocks are installed at an angle to each other, reducing the separating seam along the inner radius and increasing the external. From the "halves" it is easier to make a glass wall or a small radius column, without spoiling the aesthetics of the surface with a grid of wide seams.

M-shaped angular glass bottle with a matte surface of the corners of glass walls are made up with a variety of corner elements. The quadrangular angular glass blocks (1909090mm) in the form of parallelepiped are used at the junction of two walls at right angles, hexagonal (190110144mm) -pod large (up to 120-130). In addition, in the range of many companies there are angular M-shaped glass blocks for building corners 60, 90 and 135. It is beautifully completed to complete the upper and side edges of the partitions will help the end elements-with beautifully decorated one or two side faces.

All perceive the glass as a fragile material, so glass blocks for the floor, according to the reviews of trading companies, are in low demand. However, they are able to withstand significant mechanical loads, and the embossed surface prevents slipping. It is not at all necessary to lay out the entire floor: the individual square or round elements with built-in luminaires will be very effective, and the flickering "points" on the stairs will protect the rise and descent. The cost of floor glass blocks Solaris-170-500rub. For 1 pc.

|

|

|

M-shaped angular glass blocks with matte surface

Solid and spot

There are several ways to lay glass blocks:

on cement-adhesive solution;

in modular cells;

In the prepared holes in the wall.

The first reminds the construction of a wall of brick or foam blocks. First prepare the base, as well as clean the surfaces with which glass blocks will come into contact. After that, carefully place the size of the future design and proceed to the process (see the photo below). It is quite laborious and takes a lot of time: non-hygroscopic glass is settled with a solution longer than a porous brick. If you put more than three rows for one reception (the block weighs more than 2kg), the lower raw seams from gravity can "go." Work should be continued only after drying the mixture. The laying of glass blocks is necessarily reinforced with metal rods (usually with a diameter of 6mm), stainless or galvanized. The reinforcement is mounted vertically and horizontally through 1-2 blocks, securely fixing in a metal frame or in the walls and plates of overlapping.

Products of Russian firms are characterized by the greatest tolerances on the size: up to 2mm (blocks of many foreign companies this parameter does not exceed 1mm). It would seem that the difference is small. But deviations in geometry become noticeable, if you put the glass blocks of different manufacturers on a smooth surface and shake. Elements with smooth faces are more stable. The more deviation, the more difficult to lay it.

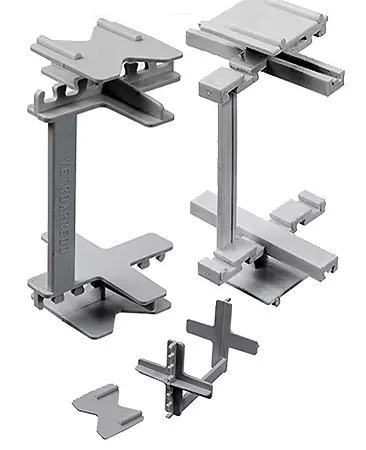

Ideal seams (2-16mm) between individual blocks are obtained using plastic mounting crosses. Moreover, the thinnest (for seams 2mm) is developed by Vetroarredo specifically for the glass blocks of the Pegasus series. When the solution is completely frozen, the outer part of the crosses is removed, and the seams are filled with a grouting mixture or colored sealants. The average cost of laying 1M2-approximately 1.5 thousand rubles.

Placement of glass blocks in special modules made of wood, MDF, lined with veneer, plastic is placed much faster. These are grilles with a cell corresponding to the size of the standard block. Most often, they are used to design fragments of walls. Modules calculated on 10, 20, 40 or more standard blocks are used individually or combine each other. The design is fixed to the floor, walls, ceiling, and then fill the cells with glass blocks, fixing them with rubber gaskets or sealant. The lattices of Italian, Polish, Chinese producers can vary in the appearance and installation of blocks. Incable, this option does not require the involvement of qualified specialists. Yes, and disassemble the design, change the drawing and collect it is not much easier to collect than to redo the cement masonry. The cost of 1m2 module - from 1.75 thousand rubles.

Glass inserts in the walls look spectacular. Extend the hole in the wall of the desired size simple. However, the wall and glassbug may not coincide in thickness. This case should be solved, from which premises the block will be slightly drowning into the wall, and in someone being with it in the same plane. If the mini-"niche" is a bathroom and kitchen, their surface is desirable to treat waterproof paint.

|

|

|

|

|

|

Kreisel Technology Masonry glass blocks on cement-adhesive solution:

The lower start line is laid out for lighthouses and level. Between the blocks, plastic crosses are installed and stainless reinforcing rods are paved;

b, the glue mixture is applied to a horizontal range and on the side;

The g- block is pressed to the beacons-cross;

D- grout for seams are applied by a special grater;

E- glass blocks are washed with a foam rubber

Window in fairy tale

Combinations of elements of different colors, textures and sizes play a considerable role in the design design of the room.

Wide scope for experiments open the elegant BRICK glass blocks (Trend Group) from transparent glass and Golden Brick with a glass mosaic tester. Elements are inserted into a special self-supporting design and fix it with glue and inserts. The "Frame + Cross" system creates inside glass blocks channels for electrical wires, so that you can illuminate separate blocks. Price - From 27.5 thousand rubles. For 1m2 design.

|

|

|

The idea of Mosaist Julio to redcoming gold between two layers of glass. Therefore, the glass blocks of the Golden BRICK collection (TrendGroup) have an effect of a textile surface. Format elements - 19819880, 1989980mm

Special color is attached to the interior of glass blocks with placed inside stained-glass miniatures made in fusing technique. Combining glass fragments of different shapes and colors, get original decors. The price of decorative elements "Stroy Market" -1.4 thousand rubles. For 1 pc.

In love, the glass blocks will help you save us from the shortage of the Sun. Evained autumn and winter days they will freely miss the desired sun rays into the house or create the illusion of their presence.

The editorial board thanks the company "Giel", "Dipris", "Kraizel Rus", the representative office of the company Trend Group, as well as the company "Stroymarket" and personally executive director I. M. Gorbach for help in preparing the material.