Varieties of chimneys to ensure the safety of a country house. Comparative cost table.

The brick chimney sometimes does not withstand the onslaught of acid condensate, formed when working with modern gas and liquid fuel boilers.

The use of a modular steel "sandwich" simplifies the design of the passage through the cool-gauge roof of the bath

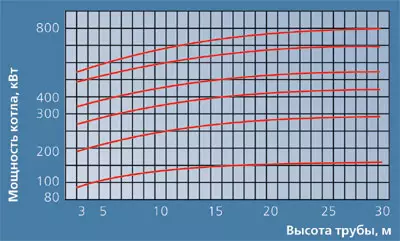

Schedule to determine the height of flue pipes for the boiler

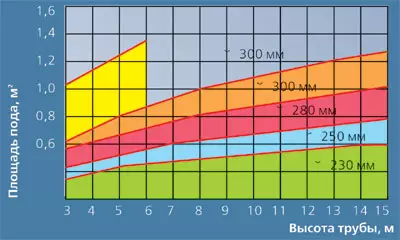

Schedule to determine the height of flue pipes for the fireplace

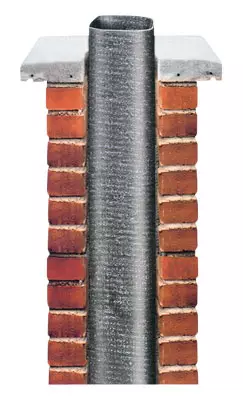

Old brick chimney can be given a new life using a polymer liner running to a temperature of 250c

Severe brick tube requires a separate foundation and is built simultaneously with walls

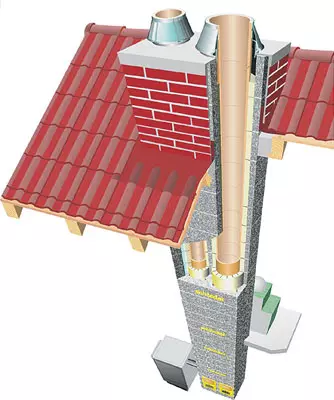

Ceramic modular chimneys are applicable for heat generators on any type of fuel. The flue gases occurs along the heat-resistant acid-resistant ceramic pipe. Modules can be two-way

A- enamel racks for smoke gases from any fuel;

Blue - for rectangular rectangular channels and pipe gaskets in cramped places

A- tap 45 single-alone;

b-pipe with silencer;

Conductive lifelcing;

Trubnaya ghomut;

Double 135 with a double-plated plug;

Erupher 90 with a plug

Chimney from the heater with an outer galvanized shell had to be changed after 4 years on other

The economizer module significantly increases the efficiency of the stove-heater, warming up the heat of the outgoing flue gases of the bathroom air

Even steel "sandwich" with a low surface temperature under fire safety conditions should defend from a wooden wall at least 200mm

With the passage of the steel two-beam chimney through the walls of combustible materials at the location of the passage around the pipe, a layer of non-combustible thermal insulator should be wrapped with a thickness of at least 100mm "pie" - heat insulator + metal sheet (ring width is not less than 130mm)

The owner of the house refused to fasten the glove tube with the help of a roof stretch. Sad result did not slow down to affect

The bum of the country construction of the nineties played with many new homeowners a dick joke: they do not even suspect that the "miner of slow motion" was laid in their dwelling. The danger is hidden in the wrong design of such a familiar element of the rural house as chimney. It is difficult to believe, but the Statistics of the Ministry of Emergency Situations of Nepium: hundreds of lives and millions of losses on the account of fire and invisions of carbon monoxide due to failures in the work of chimneys. How to avoid this?

Smoke and pipe: symbiosis problems

Hundreds of years, the chimney regularly served man. Its main task is to provide traction. True, at the same time the chimney had to constantly withstand frantic lamp of fire and smoke, but people had long learned to develop reliable, successfully operating systems. Frightened secrets' secrets seemed a guarantor of success and with the equipment of numerous, growing like mushrooms, cottages with modern boilers. But it turned out that the new technique requires other technologies in construction. This arose as if from the non-existence of the army of home-grown masters, including the livenists who undertake to put everything and everything, simply could not know. Built in the old man. It is always successful. Avteda typical consequences of a non-professional approach may be such trouble as a breakdown of thrust and unstable operation of the flue unit due to improper sections, geometry or type of chimney; Skurning the residential premises and possible carbon monoxide poisoning due to non-compliance with the norms of construction and installation, and also God! - Fire. The widespread use of brick pipes, as it turned out, is not always consistent with the peculiarities of the heating boilers. The design and material of the chimney depends primarily on the type of fuel used and the specifics of the functioning of the heating unit. But the brick chimney and is now very relevant, for example, when burning solid fuels (firewood, fireplaces and bath furnaces are coalmed with boilers). Especially since the brick is traditionally combined with the architectural appearance of any building. However, in most cases, modern heating of residential buildings provide boilers operating or on gas or liquid fuel, or combined. With their use, much more water vapors are formed (1.6 liter of water on 1m3 combusting gas) than when combustion, for example, firewood. Ito radically changes the "living conditions" of the chimney.With the normal operation of the boiler and a warm chimney, the temperature of combustion products at the chimney inlet can reach 150-200 ° C, and at the outlet of its mouth-120-170c, but here the water vapors are already carried along with smoke gases into the atmosphere. However, if for some reason the internal surfaces of the channel, the temperature of the so-called dew point dropped below, steam begins to condense and settle on the walls in the form of droplets. The temperature point of the incoming gases dew when burning gas fuel is 50-55c, liquid fuels, 45s, wood - 30- 50c, coal-25c.

In the cold season, if the chimney is badly insulated, an increased condensation of moisture occurs inside it. Sulfur, nitrogen and carbon oxides formed during fuel combustion, connecting with water vapor, form acids and mixtures of acids, which makes condensate very aggressive. This is an additional danger, this is just winter - due to the alternate freezing and thawing moisture in the upper sections (at the mouth) of the pipe. Acids are starting to actively destroy the brickwork (sometimes after 3-4 years) and first of all the seams in which leaks appear, and on the walls of oven or black drips.

Today, the construction of the chimney without taking into account the peculiarities of the work of the boiler-sign of the non-professionalism of the designer. The height and area of the smoke channel cross sections are directly dependent on the type of fuel and boiler power. There are special tables and graphs for their approval. In addition, it is necessary to take into account the various features of the action of heating units. Thus, some boilers are equipped with closed combustion chambers, during the operation of which a small overpressure is created in the chimney. So, it is necessary to ensure the tightness of the channels, otherwise the risk of fire increases.

Many patterns of boilers are equipped with automatic burners, which for regulating the water temperature act on the "Start-Heating stop-stop-stop" cycle. This mode significantly changes the physical parameters of the outgoing gases. Their density and temperature are significantly lower, and the humidity, on the contrary, is higher than that of the "traditional" combustion products formed during solid fuel combustion. Accordingly, the temperature inside the chimney changes. Following the rhythms of inclusions and turnouts of the burner, the pipe is experiencing periodic heating and cooling. The duration of such drops depends on the type of material from which the channel was made, and on the degree of thermal dehydration. Some materials are quickly heated and also quickly cooled, others, on the contrary. The faster the temperature of the pipe walls is rising, the shorter the segment of the time during which condensate can be formed.

The flue gases, departing from the most energy-saving, so-called low-temperature, and especially condensation boilers, fall into the chimney at a very low temperature - 110-130C. Because of this, there is a lot of condensate in the pipe, a whole "stream", so it is necessary to even equip the system of its neutralization and discharge into the sewer. The same, due to the increased density of smoke, in the pipe sometimes lacks the thrust, and the gases have to push with the fan (smoke). The height means that the pipe must be made gas. Therefore, low-temperature boilers are often sold with a chimney already seaman.

The first with the current furnace problems were faced by Europe and America back in the 50s of the last century. The apioner in their decision was then the American company Selkirk, which suggested its method of modernization and the rehabilitation of brick chimneys. The decision was simple and effective. It was proposed to insert the tube made of an acid-resistant steel, which is immune to the effects of condensate, was asked to insert into the chimney channel of the corresponding diameter.

Today, the production of so-called steel modular chimneys has become the global industry. They are already applied not only to upgrade existing brick pipes, but also as independent exhaust devices for the same fireplaces, furnaces and all types of heating boilers with new construction. Now these facilities are all more decisive on the roofs so familiar to our eye brick columns. Moreover, a number of manufacturers of boilers simply stipulate the need to equip their products with modern modular chimneys.

For now, the family of modular chimneys was replenished with ceramics, plastics and even glass. Vilation material depends very much on the temperature of the exhaust gases. Recall, the temperature of the smoke with incomplete combustion of solid fuel can reach up to 600c and more, liquid fuel- up to 400 ° C, and the "exhaust" of the gas boiler is still "cooler" - up to 270c.

High heating temperatures well withstand enameled and heat-resistant steel, ceramics and traditional brick. For low temperatures (up to 120 ° C), in addition to steels and ceramics, some types of plastics (polypropylene and olivineldenfluoride) and individual grades of glass are quite acceptable. Actually, on the use of the above materials and the entire current design variety of chimneys is based. But the most traditional material is brick.

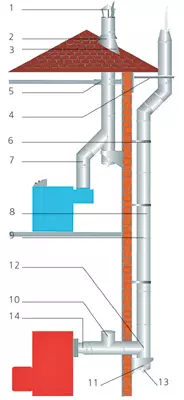

Scheme of chimney

2- apron;

3- Basis Roof;

4- console mount;

5- fastening of inter andgeted;

6- mount wall;

7 - tap;

8- pipe;

9-clamp pipe;

10- revision;

11- fastening the main one;

12-tee 90;

13-plug;

14- Adapter Cotele

The specific composition of the elements in each case varies depending on the design of the heating unit, at home and manufacturer.

Classic genre: brick chimney

The brick trumpet is a monumental thing in itself, so it requires the appropriate foundation. Its construction begins simultaneously with the house; Of course, such a structure is difficult to dismantle, it is impossible to transfer to another place, it is difficult to carry out repair work in it. The undoubted advantage of competently folded brick chimney is a long service life. After appropriate upgrades (using a modular chimney), it is also able to ensure the stable operation of gas and liquid boilers. The brick tube is constructed on the basis of strict calculations. First, the cross section of the chimney is determined. The dimensional series of brick chimney sections begins with 130130mm (for furnaces with heat transfer to 3000 kcal / h), then 130250mm (for furnaces with heat transfer to 4500 kcal / h) and further on increasing.The approximate sectional area can be determined by the power of the fuel device at the rate of about 8 cm2 per 1 kW. There is a special chart of smoke channels. For the fireplace, so that the thrust is normal, the cross section of the chimney should be at least 10% of the furnace of the inlet of the furnace. The thickness of the walls of the smoke channel is obliged to be at least 120 mm (the outer part is not less than 250mm). The inner surfaces are not plastering, but thoroughly remove excess solutions from the seams. When laying pipes, certain requirements for the composition of the solution must be observed. A limestone or lime-cement solution is used to lad out wall channels within the room, only lime-cement - for channels above the attic overlap and cement - for masonry of channels above the roof. Actually, almost all the requirements and rules for the construction of brick chimneys are given in detail in SNiP 2.04.05-91 "Heating, ventilation and air conditioning", SNIP 2.04.08-87 "Gas supply", Annex 6 ("Top of combustion products"), SNiP 3.03. 01-87 "Rules of production and acceptance of work. Stone structures. "

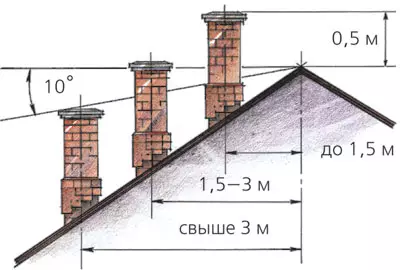

The height of flue pipes placed at a distance, which is equal to the height of a solid design, protruding over the roof, or exceeds it, should be taken:

not less than 500mm- above flat or almost flat roof;

at least 500mmm over the rod of the roof or parapet at the location of the pipe at a distance of up to 1.5 m from the skate or parapet;

not lower than the rod of the roof or parapet - at the location of the chimney at a distance of 1.5-3m from the skate or parapet;

Not lower than the line conducted from the skate down at an angle of 10 to the horizon - when the smoke tube is located from the skate at a distance of more than 3m.

Below the joining the smoke-up pipe, laid from the heating device to chimneys, the "Pocket" device should be provided with a hatch to remove soot.

The distance from the outer surface of brick flue pipes to rafters, crates and other parts of the roof of combustible and labor-burning materials should be provided in the light of at least 130 mm, from ceramic pipes without insulation - 250mm.

To upgrade the brick flue channels of complex geometry (sizgybami barrel), as well as during the construction of new chimneys, we recently applies one interesting way. We are talking about technology called Franflex (Franflex). Its essence is as follows: a flexible sleeve made in the smoke canal, made using synthetic resins and reinforced fiberglass (producer- kompozitor, Hungary). Then, at the ends, it stops, and after one end is injected with a hot steam. The resulting heating of the sleeve "inflates" and, lightening the walls, fills either the entire inner volume of the brick chimney, or part of it, if you need to reduce the section of the smoke channel. Under the action of heat resin, it hardens (polymerizes) and after 2- 4 hours it turns out a smooth, sealed inner surface of the smoke channel, not fearing corrosion and able to operate at a temperature of flue gases up to 250c. Such sleeves are produced up to 52m long and a diameter of 100-500mm. According to Fineline, such plastic turnkey cladding costs about 70 for 1 p. m with a diameter of 150mm.

Modular chimneys

Today, the expression "modular chimneys" covers a wide range of models of factory readiness, made from different materials, although initially (25 years ago) this term was only treated with steel chimney type "Sandwich". Modern designs are made from different steels, heat-resistant aluminum alloy, ceramics and plastics, as well as from a combination of these materials. Between themselves such models differ quite significantly. All varieties of modular chimneys, only the general principle of assembling pipes from individual structural elements is combined.

The important property of the modular system is the possibility of easy docking manually with the provision of reliable density of the connections. Connection of modules in different types of chimneys, of course, is different. Metallic modular elements are connected along the fuse-free or bayonet circuit, plastic - with simple mounted couplings, glass-through sealant, ceramic-sealer or cement solution.

Today's modular chimneys are a kind of "universal soldiers" capable of serving on any section of the "chimney front", since they are compatible with almost all types of heating units. Plastic and glass modular systems are used abroad so far only with low-temperature gas boilers. But for these materials, what is called "the process went", and it is undoubted that in the near future they will appear.

Traction - This is the range of air in the channel section (in the pipe), under the action of which the directional flue stream is created. With natural thrust, the driving force arises due to the difference in the density of the incoming gases and the outer air. The more this difference, the better. However, excessive traction is unprofitable, as it leads to the accelerated combustion of fuel. Solid side, to improve burning, it is customary to increase the height of the chimney, but to a reasonable limit, since the higher the pipe, the greater the resistance is the flue gases. Similar to that friction on the inner walls and the circumnetry arising when the direction of movement changes. Therefore, for example, a chimney round cross-section will be more favorable for a good thrust, rather than square, and the rectangular is the most unprofitable. By the way, an overly large cross-section of the pipe also reduces the thrust: Gaza go at low speed and have time to cool, their density increases, and the thrust falls.

Steel modular chimneys

According to the mass of application, according to the number of execution options (the number of dimensional series, the equipment, structural and assembly solutions, external design) and by the number of manufacturers, steel modular structures are far ahead of other varieties of modular chimneys.They are three species:

Single (single-mounted, single-layer), carried out either from stainless steel graded varieties of steels ("stainless steel", or from enameled unalloyed steel;

double-wall (double-circuit, insulated, with insulation between outdoor and internal circuits);

Flexible (in the form of a corrugated hose), limited nomenclature.

Metal double-wall chimneys are not quite "double-wall": structurally they are a three-layer "sandwich". The inner contour of the stainless steel corrosion-resistant, is simply stainless, less frequently galvanized steel or copper. The space between the cylinders is filled with non-combustible, non-gas or substances during heating or substances heated. More often is a basalt wool Rockwool, although other materials are used, for example, SupreSil silician cotton wool ("Elit"), basalin (Fineline, Rosinox), pearlit sand (NII km). The thickness of the thermal insulator is most often 25-30 mm, and this is enough so that the temperature on the outer shell does not exceed 80c. But there are products with a thickness of 50mm and more (up to 100mm). Single chimney is a single steel cylinder module (more often than 250, 500 and 1000 mm). In addition to directly modules that have a pipe view, the configuration includes a knee, taps, condensate collectors, support elements, clutches IT.P.

All modular chimneys have standardized internal diameter dimensions - 80, 100, 115, 120, 130, 140, 150, 160, 180, 200, 225, 250, 300, 350, 400, 450mm. Industrial chimneys may have diameters up to 1000mm. Selection of section Sets the size of the outlet of the heating boiler. Operating temperatures (depending on the steel grade and wall thicknesses) are within 400-600C. Pipes made of enameled steel are designed for boilers, fireplaces and furnaces working on solid fuel. Chimneys from "stainless steel" are good for equipping liquid-fuel and gas boilers. Single designs are used for internal installation, double-wall with a layer isolation - universal. They allow both attachments on the facade of the house and internal with the passage through the floors of the building without prejudice to the interiors. For this, manufacturers offer modules with matte, polished and mirrored surfaces. These chimneys produce such foreign firms as Raab, Schiedel, Bertrams (Germany), Jeremias (Germany-Poland), Silkirk (United Kingdom - Germany), Hild (France-Germany), Ffbofill (Spain), as well as domestic " Eliths », Fineline, Research Institute of Km, Rosinox, Inzhkomcentre," RTB-Heat Salemiervice ".

Steel chimneys possess many advantages. They are not afraid of condensate effects. Can be mounted inside existing chimneys (with modernization), as well as inside and outside the building as a separate design. We are produced in fairly wide ranges of the size of the inner diameter of the smoke channel and the thickness of the pipe material, which ensures their compatibility with all the fuel systems. Completed with a wide range of additional devices that allow you to mount turnkey chimneys. They have a small mass, do not require a special foundation, provide high installation speed, decorative. The disadvantages include low self-supporting ability and the tendency to transmit noise. Achilles heel "Stainless steel" - dislike for halogen compounds. Halogens are contained in building varnishes, glue, aerosols, so it is not recommended to burn the items in your stove containing these materials.

The most important property of stainless metal modular systems is the chemical composition of the chimney metal. Western and best Russian manufacturers apply only high-alloy stainless steel austenitic class stabilized by titanium. Such steel acid resistant and heat-resistant. This allows suppliers to give their chimneys a guarantee of 10 years. As for the "sandwiches" with an outer tube from the "galvanized", their cheapness is unlikely to compensate for the shortened life of the product (sometimes 3-5 years, if installed outside).

Flexible chimney can rather be considered a separate structural element of the class of modular chimneys. It is most often used in conjunction with other modules of both single-axis and double-wall structures- as a component of the chimney barrel in the distillation places of its axis. Sometimes these modules are used to upgrade old brick pipes. They are made by either a single-perched, taking a thin ribbon from the "stainless steel" or aluminum, or a double-wall, from the "stainless steel". The first are corrugated and more flexible than the second, but they are difficult to clean from soot. The use of aluminum pipes is limited to the temperature of 270c.

Ceramic modules

Ceramic modular systems (they are also called three-layer chimneys) are now worried about the second birth. From ordinary ceramic pipes, they transformed into comfortable insulated "cubes" of assembly blocks. The latter of different manufacturers have unequal dimensions. The center of the cube is a smoke channel-refractory ceramic tube from a chamot (thickness up to 15 mm). This is an internal circuit. The middle contour insulation of mineral wool, and the external, the outer is formed by side faces made of light concrete. Between the insulation and concrete layer are provided by emptiness (channels), providing an insulating material that warns its moisturizing and loss of basic properties. The end-to-end metal rods are laid (or places for them), permeate the entire vertical device to give the system of structural stiffness and strength. Usually, from three cubes with a hole 149-160mm, approximately 1m pipe is formed. The working temperature of ceramics is 400-600C (depending on the thickness of the material of the internal circuit). Such chimneys are used for all types of boilers and fireplaces and can pass both inside the building and outside. The circle of their suppliers is limited: Schiedel, Raab, Tone Schornstaine, Hart (all Germany) and Honka Hormi (Finland).

What are the ceramic modules remarkable? They are characterized by a high self-supporting ability, are not afraid of the effects of high temperatures and condensate, convenient and technological in the installation, have the best values of fire safety indicators and even overlap approved norms. But at the same time, they are characterized by a significant mass (from 80 kg to 1 m), which means that they require the appropriate foundation, are limited in the range of additional devices (nozzles) and require additional metal components to connect to the flue unit.

Uni ceramic modular chimneys are collected in parts:

Now "ceramics" takes a new height. For example, Schiedel offers a Keranova system to reserve old chimneys, operating both at rumus and supervising, and another UNI system, in which there are two-way modules with two-chimney holes and combined modules with channels for building ventilation mines (30 years warranty ). Since such modules are easy to position in any desired place of the room, they will noticeably simplify the construction of a new home and allow the old building without substantial costs to make an engineering. The Quadro system makes it possible to create a coaxial chimney for boilers with a closed combustion chamber and output smoke on the roof, and not on the walls, under the windows. In the chimney, the street air passes through the ring gap between the inner chamotte tube and the outer concrete sheath, heating the heat of exhaust gases, which increases the efficiency of fuel combustion. By the way, similar to the appointment of chimneys, but made of stainless steel, produces the domestic firm Rosinox under the TRIPLEKS brand, in the module of which two-wall and one-way components are constructively combined.

Punching of the hybrid variant of a two-axis steel and three-layer ceramic chimney can be adopted in which the inner circuit is made of stainless steel, and the outer concrete. Applied to modular chimneys, it is possible to argue that the advantages of such systems are clearly more than flaws.

It should be remembered that not all stainless steel are simultaneously and heat-resistant. In the building markets, stainless chimneys are offered in abundance, but they always need to clarify the brand. The resistant stainless steel classification includes brands with a large percentage of chromium, titanium and nickel, for example, such as 10x18n9t, 12x18n10t, 10x23n18. Strog it became AISI 316L, AISI 310S, in Europe, EN 1.4404, EN 1.4539, EN 1.4845.

Assembly of steel modular chimney

The pipe of the modular chimney of stainless steel can be compiled from 6-8 items of assembly modules. The main assembly element is, of course, the pipes from which the chimney barrel is assembled. The usual standard lengths are as follows: 250, 500 and 1000mm. Unbend manufacturers are allowed to carry out cutting pipes to the desired size, but most of them are not.The chimney barrel is either directly put on the outlet nozzle of the heating device (the adsadal version), or is one of it at some distance and is attached to it using an appropriate set of modules, such as tees, taps, sometimes flexible tube (wall mounting). Although the mass of the collected trunk is not very great, nevertheless, he must rely on something. For this, the support consoles, supporting nozzles and plates are used. The range of such elements is designed for each manufacturer. They are selected on the basis of the mass of the chimney, its heights and constructive features of the location. Since the modular chimney is not sufficiently self-supporting design, it must be additionally fixed to the wall guide clamps.

The partial part of the collected chimney provides for the installation of an audit elements, condensate collector, neutralizers of the assigned or collected condensate can also be used. All necessary bends of the trunk are performed using the appropriate knees or flexible pipes (combined execution). The use of a flexible tube to attach the chimney trunk to the fiber device allows you to compensate for the thermal expansion and slightly rejuvenate mechanical noise generated by vibration. To combat the latter, special silencers are also used. For a reliable docking of modules, tie clamps are used, but some models cost and without them, a bayonet compound scheme is used. In addition to the tightest clamps, the corresponding fastenings of the chimney trunk can also be needed to the wall or inside the existing brick tube, when work is carried out on the modernization of the entire smoke system. Fasteners may have different execution from different manufacturers, but in any case, their number is determined by the Supplier's recommendations. The passage through the roof requires special attention. Here are special elements with aprons made of lead, copper, galvanized or stainless steel, which are designed for different angles of the skate and are universal for any roof covering. The apron provides sealing of the Pipe Person and the possibility of thermal expansion. The gap between the pipe itself and the covering nozzle is close in a heat-resistant sealant, which guarantees reliable waterproofing of the place of the joint and the possibility of thermal expansion of the pipe in this place. There are plenty of such sealants in the market, for example, RTV from Donedeal (USA), "PentElast" from "Penta Yunion" (Russia) IDR.

Finally, the roof is "passed". A low tube (1.5-3m from the roof level) can stand independently as a self-supporting design. With a greater height, either the supporting console or ordinary stretching is used. As the final elements of the finished chimney use a conical headband, an antimal deflector and an anti-shed cap. In addition to these basic elements, various additional modules can be applied: smoke fan, silencer, reverse traction valves Maintenance of most of them is dictated by the features of the heating unit.

Modernization of classics

The process of assembling the chimney occurs somewhat more complicated when it comes to upgrading an existing brick tube. After determining the required number of assembly modules, they are started to split directly on the roof and, as they grow, lower the pipe to the trunk. At that time, a peculiar window should already be prepared in its lower part through which the "connection" of the chimney is "connected" to the flue boiler. At the same time, the support module is prepared (its option is selected depending on the design features of the location). To fix the collected modular chimney in the Mine of the Brick Pipe with the buildings and lowering, the spacer elements are used (spacer clamps). If there are knees and bends in the upgrade process, a flexible tube of the corresponding length is included, which allows you to undergo curved areas (in the field of curvature places make an opening of the smoke channel).

About very important prices

The difference in the cost of modular elements in different manufacturers can reach 25-30%. Very much, the brand and thickness of the steel used, the type of butt connections and the location of the outlet are determined here. The cost of modular chimneys from Russian manufacturers (provided that import steel) will be slightly lower than 15-20%.The price increases quite a while (up to 60%) with increasing sheet thickness and insulator thickness (up to 80%). Blooding on the surface will cost an additional 5%.

| Name of element | PC. | Russian manufacturers | Foreign manufacturers | ||||||

|---|---|---|---|---|---|---|---|---|---|

| ELITS | RTB. | Rosinox. | Fineline. | Bofill. | Jeremias. | Raab. | Schiedel | ||

| Condensate acceptor with side discharge | one | 100.0 | 25.0 | 21,4. | 36.0. | 25.0 | 69,1 | 77.0. | 83.0 |

| Tee-revision | one | 162.0 | 139,7 | 129,2 | 51.9 | 86,4. | 163,1 | 228.0 | 148.0 |

| Tee 90. | one | 150.0 | 11.6. | 119,2 | 126.5 | 130.0. | 163.0. | 307.0 | 105.0 |

| Pipe, L = 1M | 10 | 100.0 | 92,2 | 129,2 | 82.5 | 89.0 | 112.0. | 141.0 | 120.0 |

| Upper element | one | 65.0 | 40.9 | 35.8. | 32.9 | 38.5 | - | 46.0 | 38.3. |

| Console support | one | 115.0 | 76.6 | 96.9 | 56.6 | 104.0. | 59,4. | 75.0 | 72,7 |

| Clamp wall | 3. | 22.0 | 12,1 | 25.3. | 25.7 | 23,3. | 21,4. | 39.0 | 23.0 |

| Truber clamp | 13 | 5.0 | 3.5 | 6.8. | 5,4. | 2.5 | Included | 16.0 | Included |

| Value with VAT | 1723.0 | 1320.0 | 1858.0 | 1279.0 | 1386.6 | 1639.0 | 2198.0 | 1716.0 | |

| For comparison: the cost of the Ceramic UNI system (from Schiedel) - 975; Brick chimney at the rate of 70 pcs / m, with work- 780. |

Comparative table of value of a single-tube / two-pipe module at a length of a pipe 1000mm, $

| Firm | Inner diameter 130mm | Inner diameter 150mm | Inner diameter 180mm | Inner diameter 200mm |

|---|---|---|---|---|

| Selkirk. | 22.44 / 98,85. | 27.51/112,54. | 33.3 / 126.6. | 39.1 / 148,39 |

| Raab. | 35/99 | 40/113 | 47/127. | 50/149. |

| F.F.Bofill (enameled) | 18.02 / 58.6 | 20.01 / -66,11 | 25,02 / 79,64. | 27.35 / 88.65 |

| 8.0 | 9.34. | 12,01 | 20,01 | |

| BERTRAMS (enamel / aluminum) | 47/21 | - | - | - |

| Hild | - | 23/80 | 29/86. | 31/93 |

| Jeremias. | 20.04 / 76.03. | 30.41 / 87.78 | 27.65 / 100.22. | 30.41 / 111.97 |

| ELITS | 21.5 / 80. | 23.5 / 84. | 28/88.7 | 31/97,5 |

| KM | 15.8 / 38.6. | 22.1 / 49,12 | - | - / 59,65 |

| Fineline. | - | 20.6 / 61.8 | 24.7 / 74,2 | 27.5 / 82.5 |

| "Inzhkomcentre" | 15.4 / 32.6. | 16.8 / 35.4 | 18.1 / 38.8. | 19.9 / 43,2 |

| Rosinox. | 17.7 / 54.8. | 19.7 / 61.8 | 24.6 / 74,4. | 26.9 / 82.9 |

Fire safety

Fire safety smoke - a necessary condition for its operation. It begins with the right choice of the design itself and the place of its installation at a competent installation by the forces of a specialized organization that has a relevant license.

Since the working temperature of the inner contour of the pipe must withstand the temperature in 1000 ° C (soot combustion temperature) for 30 minutes, it is very important to avoid purchasing non-certified products or fake. It is clear that the chimney made from non-ferrous varieties of steel, sooner or later will lead to a fire or penetration into the premises of carbon monoxide. During the construction of the chimney, it is also necessary to comply with all the recommendations on the heat insulation of the hot surface of the pipe in possible places of contact with marked materials. It should be remembered that the same tree with long-term contact with a hot (100 ° C) surface becomes prone to self-burning. Therefore, the upper ceiling of the temperature is installed for the outer surface of the pipe, and in the case of adjustment to the combed materials, 85С. After the completion of the installation work, a fire spokesman must make sure that all fireproof norms are fully respected. After using double-wall chimneys, fire protection measures will be taken in advance even with some reinsurance, all the rules must comply with the provisions developed for brick pipes, since the chimneys of the Sandwich type in the bottom are not specified. Special attention is paid to the availability of licenses from organizations producing installation, as well as the "certification" itself of the chimney and checking the gas containers.

We hope now, our readers will agree with the statement that in the modern house (the element of which is the chimney) reliability and safety of the operation of the filling device largely depend on the competent selection of the smoke tube design and its installation.

The editors thanks Fineline, Inzhkomcentre-UDD, NII km, VivaTex-M, RTB-Heat Seloservice, "Sidel", Interma for help in the preparation of material.